Electrochemical Benefits Of Hybrid Biochar/Carbon Black Mixes

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrochemical Hybrid Materials Background and Objectives

The field of electrochemical energy storage and conversion has witnessed significant advancements over the past decades, driven by the increasing global demand for sustainable energy solutions. Within this domain, hybrid materials combining biochar and carbon black have emerged as promising candidates for various electrochemical applications, including supercapacitors, batteries, and fuel cells. This technological evolution represents a convergence of traditional carbon-based materials science with sustainable biomass utilization strategies.

Biochar, derived from the pyrolysis of biomass under oxygen-limited conditions, has gained attention due to its renewable nature, cost-effectiveness, and customizable properties. Historically, carbon black has been the industry standard for electrochemical applications owing to its excellent conductivity and well-established manufacturing processes. The hybridization of these materials represents a strategic approach to leverage the complementary properties of both components while mitigating their individual limitations.

The technological trajectory of hybrid biochar/carbon black materials has been shaped by advancements in pyrolysis techniques, surface modification methods, and composite fabrication processes. Early research focused primarily on substituting expensive carbon materials with biochar, while recent developments have shifted toward purposeful engineering of synergistic hybrid structures with enhanced electrochemical performance.

Current research objectives in this field center on optimizing the electrochemical benefits of these hybrid materials through precise control of their composition, structure, and interface properties. Key technical goals include enhancing electrical conductivity, increasing specific surface area, improving ion transport kinetics, and ensuring long-term electrochemical stability under various operating conditions.

The development of these hybrid materials aligns with broader technological trends toward sustainable and circular economy principles in materials science. By utilizing biomass waste streams for biochar production and combining them with industrial carbon black, researchers aim to create value-added materials with reduced environmental footprint and competitive electrochemical performance.

Looking forward, the technical objectives for hybrid biochar/carbon black materials include achieving conductivity values comparable to pure carbon black systems while maintaining the cost advantages and sustainability benefits of biochar. Additionally, researchers are working toward standardizing characterization methods and establishing clear structure-property relationships to enable predictive design of these hybrid materials for specific electrochemical applications.

Biochar, derived from the pyrolysis of biomass under oxygen-limited conditions, has gained attention due to its renewable nature, cost-effectiveness, and customizable properties. Historically, carbon black has been the industry standard for electrochemical applications owing to its excellent conductivity and well-established manufacturing processes. The hybridization of these materials represents a strategic approach to leverage the complementary properties of both components while mitigating their individual limitations.

The technological trajectory of hybrid biochar/carbon black materials has been shaped by advancements in pyrolysis techniques, surface modification methods, and composite fabrication processes. Early research focused primarily on substituting expensive carbon materials with biochar, while recent developments have shifted toward purposeful engineering of synergistic hybrid structures with enhanced electrochemical performance.

Current research objectives in this field center on optimizing the electrochemical benefits of these hybrid materials through precise control of their composition, structure, and interface properties. Key technical goals include enhancing electrical conductivity, increasing specific surface area, improving ion transport kinetics, and ensuring long-term electrochemical stability under various operating conditions.

The development of these hybrid materials aligns with broader technological trends toward sustainable and circular economy principles in materials science. By utilizing biomass waste streams for biochar production and combining them with industrial carbon black, researchers aim to create value-added materials with reduced environmental footprint and competitive electrochemical performance.

Looking forward, the technical objectives for hybrid biochar/carbon black materials include achieving conductivity values comparable to pure carbon black systems while maintaining the cost advantages and sustainability benefits of biochar. Additionally, researchers are working toward standardizing characterization methods and establishing clear structure-property relationships to enable predictive design of these hybrid materials for specific electrochemical applications.

Market Applications for Biochar/Carbon Black Composites

The biochar/carbon black composite market is experiencing significant growth across multiple sectors due to the unique electrochemical properties these hybrid materials offer. In energy storage applications, these composites are revolutionizing supercapacitor and battery technologies. The enhanced conductivity and surface area provided by the carbon black component, combined with the sustainable and cost-effective nature of biochar, creates materials that deliver superior energy density and cycling stability compared to traditional carbon materials.

The environmental remediation sector represents another substantial market opportunity. These composites demonstrate exceptional adsorption capabilities for heavy metals and organic pollutants in wastewater treatment systems. The global water treatment chemicals market, which these materials can penetrate, continues to expand as industrial discharge regulations tighten worldwide and clean water scarcity becomes more prevalent.

Agricultural applications constitute a growing market segment where biochar/carbon black composites serve dual purposes. They function as soil amendments that improve fertility while simultaneously sequestering carbon. The slow-release properties of nutrients bound to these composites create value-added fertilizer products that reduce nutrient leaching and improve crop yields.

In the catalyst support market, these hybrid materials are gaining traction as platforms for metal catalysts in industrial chemical processes. Their tunable surface chemistry and porosity allow for customized catalyst designs that enhance reaction efficiency and selectivity, potentially reducing energy requirements in chemical manufacturing.

Concrete and construction materials represent an emerging application with significant volume potential. Incorporating biochar/carbon black composites into concrete can improve mechanical properties while reducing the carbon footprint of construction projects. This aligns with the growing demand for sustainable building materials in green construction initiatives.

The electronics industry is exploring these composites for electromagnetic interference (EMI) shielding applications. The electrical conductivity of carbon black combined with the lightweight nature of biochar creates materials that can protect sensitive electronic components while adding minimal weight to devices.

Medical applications are also emerging, particularly in drug delivery systems and biosensors. The biocompatibility of certain biochar formulations, combined with the electrical properties of carbon black, creates platforms for controlled release mechanisms and electrochemical sensing devices that can monitor biological markers.

The environmental remediation sector represents another substantial market opportunity. These composites demonstrate exceptional adsorption capabilities for heavy metals and organic pollutants in wastewater treatment systems. The global water treatment chemicals market, which these materials can penetrate, continues to expand as industrial discharge regulations tighten worldwide and clean water scarcity becomes more prevalent.

Agricultural applications constitute a growing market segment where biochar/carbon black composites serve dual purposes. They function as soil amendments that improve fertility while simultaneously sequestering carbon. The slow-release properties of nutrients bound to these composites create value-added fertilizer products that reduce nutrient leaching and improve crop yields.

In the catalyst support market, these hybrid materials are gaining traction as platforms for metal catalysts in industrial chemical processes. Their tunable surface chemistry and porosity allow for customized catalyst designs that enhance reaction efficiency and selectivity, potentially reducing energy requirements in chemical manufacturing.

Concrete and construction materials represent an emerging application with significant volume potential. Incorporating biochar/carbon black composites into concrete can improve mechanical properties while reducing the carbon footprint of construction projects. This aligns with the growing demand for sustainable building materials in green construction initiatives.

The electronics industry is exploring these composites for electromagnetic interference (EMI) shielding applications. The electrical conductivity of carbon black combined with the lightweight nature of biochar creates materials that can protect sensitive electronic components while adding minimal weight to devices.

Medical applications are also emerging, particularly in drug delivery systems and biosensors. The biocompatibility of certain biochar formulations, combined with the electrical properties of carbon black, creates platforms for controlled release mechanisms and electrochemical sensing devices that can monitor biological markers.

Technical Challenges in Hybrid Carbon Material Development

Despite significant advancements in hybrid biochar/carbon black materials, several technical challenges persist that impede their widespread application and commercialization. The primary challenge lies in achieving consistent quality and reproducibility in biochar production. The heterogeneous nature of biomass feedstocks results in variable physical and chemical properties of the resulting biochar, making standardization difficult for industrial applications. This variability directly impacts the electrochemical performance of hybrid materials, creating obstacles for quality control in manufacturing processes.

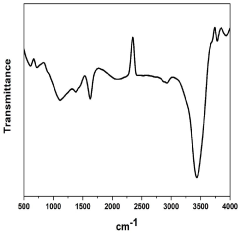

Surface chemistry optimization presents another significant hurdle. The complex interplay between biochar's functional groups and carbon black's properties requires precise engineering to maximize electrochemical benefits. Current techniques for surface modification often involve harsh chemical treatments that can compromise the structural integrity of biochar or introduce undesirable contaminants, affecting the overall performance of the hybrid material.

Scalability remains a persistent challenge in transitioning from laboratory success to industrial implementation. Many promising biochar/carbon black hybrid formulations demonstrate excellent performance in small-scale experiments but face significant engineering challenges when scaled up. The economic viability of large-scale production processes, particularly those involving specialized activation or functionalization steps, often becomes questionable when considering market competitiveness.

Porosity control and engineering represent another technical barrier. The ideal pore size distribution for specific electrochemical applications requires sophisticated processing techniques that are difficult to implement consistently. While carbon black offers relatively uniform properties, biochar's pore structure varies significantly based on feedstock and pyrolysis conditions, making it challenging to achieve targeted porosity profiles in hybrid materials.

Stability and durability issues also plague hybrid carbon materials, particularly in demanding electrochemical environments. Degradation mechanisms, including surface oxidation, structural collapse during cycling, and leaching of functional groups, can significantly reduce the operational lifespan of these materials. The development of stabilization strategies that preserve electrochemical performance without compromising other beneficial properties remains an active research area.

Integration challenges with existing manufacturing processes further complicate commercial adoption. Many industries have established carbon black handling systems that may not be compatible with biochar's physical properties. The development of processing techniques that allow seamless incorporation of hybrid materials into existing production lines without significant capital investment is crucial for market penetration.

Environmental and safety concerns associated with fine carbon particle handling and potential dust explosivity risks must also be addressed through appropriate engineering controls and safety protocols, adding another layer of complexity to the development process.

Surface chemistry optimization presents another significant hurdle. The complex interplay between biochar's functional groups and carbon black's properties requires precise engineering to maximize electrochemical benefits. Current techniques for surface modification often involve harsh chemical treatments that can compromise the structural integrity of biochar or introduce undesirable contaminants, affecting the overall performance of the hybrid material.

Scalability remains a persistent challenge in transitioning from laboratory success to industrial implementation. Many promising biochar/carbon black hybrid formulations demonstrate excellent performance in small-scale experiments but face significant engineering challenges when scaled up. The economic viability of large-scale production processes, particularly those involving specialized activation or functionalization steps, often becomes questionable when considering market competitiveness.

Porosity control and engineering represent another technical barrier. The ideal pore size distribution for specific electrochemical applications requires sophisticated processing techniques that are difficult to implement consistently. While carbon black offers relatively uniform properties, biochar's pore structure varies significantly based on feedstock and pyrolysis conditions, making it challenging to achieve targeted porosity profiles in hybrid materials.

Stability and durability issues also plague hybrid carbon materials, particularly in demanding electrochemical environments. Degradation mechanisms, including surface oxidation, structural collapse during cycling, and leaching of functional groups, can significantly reduce the operational lifespan of these materials. The development of stabilization strategies that preserve electrochemical performance without compromising other beneficial properties remains an active research area.

Integration challenges with existing manufacturing processes further complicate commercial adoption. Many industries have established carbon black handling systems that may not be compatible with biochar's physical properties. The development of processing techniques that allow seamless incorporation of hybrid materials into existing production lines without significant capital investment is crucial for market penetration.

Environmental and safety concerns associated with fine carbon particle handling and potential dust explosivity risks must also be addressed through appropriate engineering controls and safety protocols, adding another layer of complexity to the development process.

Current Synthesis Methods for Biochar/Carbon Black Hybrids

01 Enhanced electrochemical performance in energy storage devices

Hybrid biochar/carbon black mixtures demonstrate superior electrochemical performance in energy storage applications such as batteries and supercapacitors. The combination leverages biochar's high surface area and carbon black's excellent conductivity, resulting in improved charge-discharge efficiency, higher energy density, and better cycling stability. These hybrid materials show enhanced electron transfer rates and reduced internal resistance compared to single-component electrodes.- Enhanced electrochemical performance in energy storage devices: Hybrid biochar/carbon black mixtures demonstrate superior electrochemical performance in energy storage applications such as batteries and supercapacitors. The synergistic effect between biochar's high surface area and carbon black's excellent conductivity leads to improved charge storage capacity, faster charge/discharge rates, and enhanced cycling stability. These hybrid materials offer a sustainable alternative to traditional carbon materials while maintaining or exceeding performance metrics.

- Improved conductivity and electron transfer properties: The combination of biochar with carbon black creates a hybrid material with optimized electrical conductivity. Carbon black provides excellent electron pathways throughout the material, while biochar contributes additional conductive networks and active sites. This synergistic effect enhances electron transfer kinetics, reduces internal resistance, and improves overall electrochemical efficiency in various applications including sensors, electrodes, and conductive composites.

- Sustainable production and environmental benefits: Hybrid biochar/carbon black materials offer significant environmental advantages through sustainable production methods. Biochar derived from waste biomass reduces carbon footprint while carbon black provides performance enhancement. These hybrid materials enable partial replacement of petroleum-based carbons with renewable alternatives, contributing to circular economy principles while maintaining functional properties. The production process can be optimized to reduce energy consumption and environmental impact.

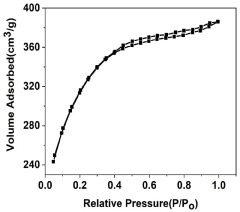

- Tailored porosity and surface area characteristics: The combination of biochar and carbon black allows for precise engineering of porosity and surface area characteristics. Biochar contributes hierarchical pore structures while carbon black fills gaps and creates additional interfaces. This tailored porosity enhances electrolyte accessibility, ion diffusion, and surface interactions. The hybrid materials can be optimized for specific applications by controlling the ratio of components and processing conditions to achieve desired pore size distributions and surface functionalities.

- Enhanced catalytic activity and electrode performance: Hybrid biochar/carbon black materials exhibit improved catalytic activity and electrode performance in electrochemical systems. The combination provides abundant active sites, optimized surface chemistry, and enhanced interaction with metal catalysts or functional groups. These materials demonstrate superior performance in fuel cells, electrocatalysis, and electrochemical sensors. The synergistic effect between components leads to lower overpotentials, improved reaction kinetics, and greater durability in harsh electrochemical environments.

02 Sustainable electrode materials for electrochemical applications

Biochar derived from biomass waste combined with carbon black creates environmentally sustainable electrode materials for various electrochemical applications. These hybrid materials reduce dependence on fossil-based carbon sources while maintaining or improving performance. The renewable nature of biochar, coupled with carbon black's established properties, offers a green alternative for electrochemical systems with reduced carbon footprint and lower production costs.Expand Specific Solutions03 Improved conductivity and surface area characteristics

Hybrid biochar/carbon black materials exhibit synergistic effects that enhance both electrical conductivity and effective surface area. Carbon black contributes excellent electron transport properties while biochar provides high porosity and surface functionality. This combination creates materials with optimized pore structure, increased active sites for electrochemical reactions, and improved electrolyte accessibility, resulting in enhanced performance for applications requiring both high conductivity and large surface area.Expand Specific Solutions04 Tailored surface chemistry and functionalization

The surface chemistry of hybrid biochar/carbon black materials can be tailored through various functionalization methods to enhance specific electrochemical properties. These modifications include oxygen-containing functional groups, nitrogen doping, and metal oxide incorporation. Such treatments improve wettability, ion adsorption capacity, and catalytic activity, leading to better performance in applications like fuel cells, sensors, and electrocatalysis. The ability to customize surface properties allows optimization for specific electrochemical reactions.Expand Specific Solutions05 Cost-effective manufacturing processes for hybrid carbon materials

Innovative manufacturing processes enable cost-effective production of hybrid biochar/carbon black materials with controlled properties. These methods include co-pyrolysis of biomass with carbon black precursors, mechanical mixing followed by thermal treatment, and solution-based processing techniques. Such approaches allow precise control over composition, morphology, and particle size distribution while maintaining scalability for industrial applications. The resulting materials offer an economical alternative to more expensive carbon materials while delivering comparable or superior electrochemical performance.Expand Specific Solutions

Leading Companies and Research Institutions in Carbon Materials

The electrochemical benefits of hybrid biochar/carbon black mixes represent an emerging field at the intersection of renewable energy and advanced materials. This market is in its early growth phase, with increasing applications in energy storage, catalysis, and environmental remediation. Key players include established chemical companies like Cabot Corp., which brings expertise in specialty carbons and performance materials, and Robert Bosch GmbH, leveraging these materials for mobility solutions. Academic institutions such as Sichuan University and Arizona State University are driving fundamental research, while energy companies like TotalEnergies and Shell are exploring applications in sustainable energy systems. The technology is advancing from laboratory research to commercial applications, with companies like PrairieChar developing proprietary micro-carbon technologies that demonstrate the growing commercial viability of these hybrid materials.

Cabot Corp.

Technical Solution: Cabot Corporation has developed advanced hybrid biochar/carbon black composites for electrochemical applications, focusing on enhanced energy storage systems. Their proprietary process combines specially engineered carbon black with biochar derived from sustainable biomass feedstocks. The resulting hybrid material exhibits synergistic effects where carbon black provides high electrical conductivity and surface area (typically 1000-1500 m²/g), while biochar contributes functional surface groups and sustainable carbon content. Cabot's technology involves precise control of pyrolysis conditions to optimize biochar properties, followed by proprietary surface treatments to enhance compatibility with carbon black. Their hybrid materials demonstrate up to 30% improved capacitance in supercapacitor applications and enhanced cycling stability in battery electrodes compared to conventional carbon materials. The company has also developed specialized formulations for different electrochemical applications, including tailored pore size distributions and surface functionalities.

Strengths: Industry-leading expertise in carbon black manufacturing; established global supply chain; advanced material characterization capabilities; proprietary surface modification technologies. Weaknesses: Higher production costs compared to conventional carbon materials; variability in biochar properties depending on feedstock source; scaling challenges for specialized high-performance formulations.

Sichuan University

Technical Solution: Sichuan University has developed innovative hybrid biochar/carbon black materials for electrochemical applications through their advanced materials research program. Their approach focuses on creating synergistic carbon composites that leverage the complementary properties of both materials. The university's research team has pioneered a "controlled co-pyrolysis" technique that enables simultaneous conversion of biomass and carbon black precursors under precisely controlled conditions. This process creates intimate mixing at the molecular level, resulting in hybrid materials with unique structural and electrochemical properties. Their materials feature hierarchical pore structures with optimized micro/meso/macropore distributions that facilitate rapid ion transport while maintaining high surface area (typically 800-1200 m²/g). Sichuan University researchers have demonstrated that their hybrid materials exhibit enhanced electrochemical performance in various applications, including up to 35% improvement in specific capacitance for supercapacitor electrodes and significantly improved cycling stability in lithium-ion battery anodes. Their research has also shown that the hybrid materials demonstrate superior electrocatalytic activity for oxygen reduction reactions, with performance metrics approaching those of precious metal catalysts but at significantly lower cost. The university has developed several specialized formulations optimized for different electrochemical applications, including versions with engineered surface functionality through controlled heteroatom doping.

Strengths: Cutting-edge research capabilities; innovative synthesis approaches; comprehensive material characterization facilities; strong publication record in high-impact journals. Weaknesses: Limited industrial-scale production capabilities; focus primarily on fundamental research rather than commercial applications; potential challenges in technology transfer and scale-up.

Key Electrochemical Performance Enhancements of Hybrid Systems

Functionalized biochar composition and method for preparation thereof

PatentPendingIN202111036876A

Innovation

- A functionalized biochar composition is developed by chemically activating desmostachya leaves extract with zinc chloride and copper oxide, creating a porous material with improved wettability and structural strength, which is then carbonized to produce a high-surface-area electrode material.

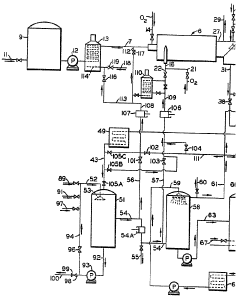

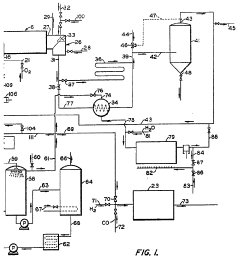

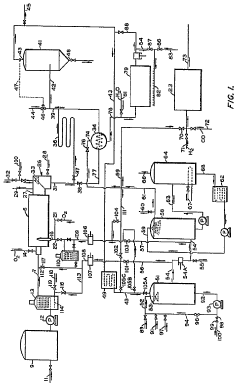

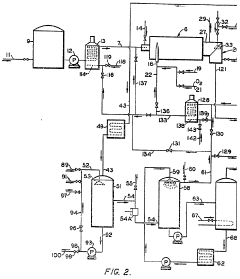

Improvements in or relating to a process an apparatus for making carbon black and treating effluent gases therefrom and for making hydrogen-containing synthesis gas

PatentInactiveGB719221A

Innovation

- A process and apparatus that comprehensively treat effluent gases to recover carbon black, utilizing a water slurry to remove and recycle it, enhancing thermal efficiency and producing superior carbon black, which can be used to create a carbon black aqueous slurry for latex mixing, thereby addressing the inefficiencies and pollution issues.

Environmental Sustainability and Circular Economy Implications

The integration of biochar and carbon black in hybrid mixes represents a significant advancement in sustainable materials science with profound implications for environmental sustainability and circular economy principles. These hybrid materials leverage waste biomass conversion into value-added products, creating a closed-loop system that reduces dependence on virgin carbon materials while simultaneously addressing waste management challenges.

The environmental benefits begin at the production stage, where biochar synthesis through pyrolysis of agricultural residues, forestry waste, and other biomass sources effectively sequesters carbon that would otherwise be released through natural decomposition or incineration. When combined with carbon black in electrochemical applications, these hybrid materials extend product lifecycles while reducing the carbon footprint compared to traditional carbon-based materials.

Water purification systems utilizing these hybrid materials demonstrate exceptional sustainability credentials. The adsorptive properties of biochar/carbon black composites enable the removal of heavy metals and organic pollutants from wastewater streams, providing an environmentally responsible alternative to conventional treatment methods that often rely on energy-intensive processes or hazardous chemicals.

From a circular economy perspective, these hybrid materials exemplify the principles of resource efficiency and waste valorization. Agricultural and forestry sectors benefit from new revenue streams through the conversion of what was previously considered waste into high-value carbon materials. This transformation creates economic incentives for sustainable land management practices and reduces the environmental burden of waste disposal.

The scalability of biochar production from locally available biomass resources promotes decentralized manufacturing models that align with circular economy frameworks. Regional production reduces transportation emissions associated with material distribution while creating local employment opportunities in green technology sectors.

Energy storage applications of these hybrid materials further enhance their sustainability profile. By improving the performance and longevity of energy storage devices, biochar/carbon black composites contribute to the broader transition toward renewable energy systems. The enhanced cycle stability and capacity retention observed in these hybrid materials translate to fewer replacement cycles and reduced material consumption over time.

Regulatory frameworks increasingly recognize the environmental benefits of these materials, with carbon credits and sustainability certifications becoming available for technologies that incorporate biochar-based components. This policy support strengthens the economic case for adoption while accelerating the transition toward more sustainable industrial practices across multiple sectors.

The environmental benefits begin at the production stage, where biochar synthesis through pyrolysis of agricultural residues, forestry waste, and other biomass sources effectively sequesters carbon that would otherwise be released through natural decomposition or incineration. When combined with carbon black in electrochemical applications, these hybrid materials extend product lifecycles while reducing the carbon footprint compared to traditional carbon-based materials.

Water purification systems utilizing these hybrid materials demonstrate exceptional sustainability credentials. The adsorptive properties of biochar/carbon black composites enable the removal of heavy metals and organic pollutants from wastewater streams, providing an environmentally responsible alternative to conventional treatment methods that often rely on energy-intensive processes or hazardous chemicals.

From a circular economy perspective, these hybrid materials exemplify the principles of resource efficiency and waste valorization. Agricultural and forestry sectors benefit from new revenue streams through the conversion of what was previously considered waste into high-value carbon materials. This transformation creates economic incentives for sustainable land management practices and reduces the environmental burden of waste disposal.

The scalability of biochar production from locally available biomass resources promotes decentralized manufacturing models that align with circular economy frameworks. Regional production reduces transportation emissions associated with material distribution while creating local employment opportunities in green technology sectors.

Energy storage applications of these hybrid materials further enhance their sustainability profile. By improving the performance and longevity of energy storage devices, biochar/carbon black composites contribute to the broader transition toward renewable energy systems. The enhanced cycle stability and capacity retention observed in these hybrid materials translate to fewer replacement cycles and reduced material consumption over time.

Regulatory frameworks increasingly recognize the environmental benefits of these materials, with carbon credits and sustainability certifications becoming available for technologies that incorporate biochar-based components. This policy support strengthens the economic case for adoption while accelerating the transition toward more sustainable industrial practices across multiple sectors.

Scalability and Cost Analysis of Hybrid Carbon Production

The scalability of hybrid biochar/carbon black production represents a critical factor in determining the commercial viability of these electrochemically beneficial materials. Current production methods vary significantly in terms of scale potential, with pyrolysis systems ranging from small batch processors handling kilograms per day to industrial-scale continuous systems capable of processing several tons daily. The transition from laboratory to commercial scale presents several engineering challenges, particularly in maintaining consistent quality and electrochemical properties across larger production volumes.

Cost analysis reveals that biochar production expenses typically range from $500-2,000 per ton, depending on feedstock selection, processing technology, and energy requirements. Carbon black, conversely, commands higher production costs of $1,200-3,500 per ton due to its more energy-intensive manufacturing process and petroleum-based feedstock requirements. The economic advantage of hybrid systems emerges from the potential to leverage lower-cost biomass feedstocks while maintaining performance characteristics comparable to pure carbon black.

Feedstock availability represents another crucial scalability factor. While carbon black relies on limited petroleum resources, biochar can utilize diverse biomass sources including agricultural waste, forestry residues, and dedicated energy crops. This feedstock flexibility enhances supply chain resilience but introduces variability in the final product characteristics that must be carefully managed through standardized processing protocols.

Energy consumption during production significantly impacts both cost structures and environmental footprints. Traditional carbon black manufacturing requires approximately 30-50 GJ per ton, while biochar production typically consumes 10-25 GJ per ton. Hybrid approaches that optimize the ratio between components can potentially reduce overall energy requirements by 15-30%, improving both economic and environmental sustainability metrics.

Infrastructure requirements for scaled production present additional considerations. Carbon black facilities typically require substantial capital investment ($50-150 million for plants producing 50,000+ tons annually) and sophisticated emissions control systems. Biochar production facilities can be deployed at smaller scales with lower capital requirements ($5-20 million for comparable output), potentially enabling distributed production models closer to biomass sources.

Market adoption barriers must also be addressed for successful scaling. These include customer perception issues regarding performance consistency, regulatory uncertainties surrounding novel carbon materials, and competition from established carbon black supply chains. Strategic partnerships with end-users in electrochemical applications can accelerate adoption through collaborative development and validation processes.

Cost analysis reveals that biochar production expenses typically range from $500-2,000 per ton, depending on feedstock selection, processing technology, and energy requirements. Carbon black, conversely, commands higher production costs of $1,200-3,500 per ton due to its more energy-intensive manufacturing process and petroleum-based feedstock requirements. The economic advantage of hybrid systems emerges from the potential to leverage lower-cost biomass feedstocks while maintaining performance characteristics comparable to pure carbon black.

Feedstock availability represents another crucial scalability factor. While carbon black relies on limited petroleum resources, biochar can utilize diverse biomass sources including agricultural waste, forestry residues, and dedicated energy crops. This feedstock flexibility enhances supply chain resilience but introduces variability in the final product characteristics that must be carefully managed through standardized processing protocols.

Energy consumption during production significantly impacts both cost structures and environmental footprints. Traditional carbon black manufacturing requires approximately 30-50 GJ per ton, while biochar production typically consumes 10-25 GJ per ton. Hybrid approaches that optimize the ratio between components can potentially reduce overall energy requirements by 15-30%, improving both economic and environmental sustainability metrics.

Infrastructure requirements for scaled production present additional considerations. Carbon black facilities typically require substantial capital investment ($50-150 million for plants producing 50,000+ tons annually) and sophisticated emissions control systems. Biochar production facilities can be deployed at smaller scales with lower capital requirements ($5-20 million for comparable output), potentially enabling distributed production models closer to biomass sources.

Market adoption barriers must also be addressed for successful scaling. These include customer perception issues regarding performance consistency, regulatory uncertainties surrounding novel carbon materials, and competition from established carbon black supply chains. Strategic partnerships with end-users in electrochemical applications can accelerate adoption through collaborative development and validation processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!