Sustainable Supply Chains For Industrial Biochar Sourcing

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biochar Technology Evolution and Sustainability Goals

Biochar technology has evolved significantly over the past decades, transitioning from traditional charcoal production methods to sophisticated pyrolysis systems designed specifically for biochar production. The earliest forms of biochar can be traced back to ancient Amazonian practices of creating "Terra Preta" or black earth, where charcoal was deliberately incorporated into soils to enhance fertility. Modern biochar technology emerged in the early 2000s when researchers began to recognize its potential for carbon sequestration and soil amendment.

The evolution of biochar production technology has seen three distinct phases. The first phase (2000-2010) focused on basic pyrolysis systems with limited control over production parameters. The second phase (2010-2018) introduced more sophisticated reactor designs with improved temperature control, residence time management, and feedstock flexibility. The current phase (2018-present) emphasizes integrated systems that optimize both biochar quality and energy recovery while minimizing environmental impacts.

Technological advancements have significantly improved biochar production efficiency. Modern systems can achieve carbon conversion efficiencies of 30-50%, compared to 10-20% in traditional methods. Additionally, contemporary technologies can precisely control biochar properties such as surface area, pore structure, and functional groups, allowing for customization based on specific applications. These improvements have expanded biochar's utility beyond agriculture to include water filtration, building materials, and industrial applications.

Sustainability goals in biochar development have evolved in parallel with technological advancements. Initially, the focus was primarily on carbon sequestration potential. However, the sustainability framework has expanded to include broader environmental, social, and economic considerations. Current sustainability goals encompass reducing greenhouse gas emissions throughout the entire supply chain, minimizing water usage, preventing soil degradation, and ensuring equitable access to biochar technology for diverse communities.

The industry has established several certification standards to ensure biochar quality and sustainability. The International Biochar Initiative (IBI) Biochar Standards and the European Biochar Certificate (EBC) provide frameworks for assessing biochar quality and production sustainability. These standards evaluate factors such as carbon stability, contaminant levels, production efficiency, and feedstock sustainability. Future technological development aims to achieve carbon-negative production systems that sequester more carbon than they emit throughout the entire lifecycle.

Looking forward, biochar technology evolution is trending toward decentralized, modular production systems that can be deployed close to feedstock sources, reducing transportation emissions and costs. Integration with renewable energy systems and waste management infrastructure represents another significant trend, creating synergistic systems that maximize resource efficiency and minimize environmental impact. These technological trajectories align with broader sustainability goals of circular economy principles and climate change mitigation strategies.

The evolution of biochar production technology has seen three distinct phases. The first phase (2000-2010) focused on basic pyrolysis systems with limited control over production parameters. The second phase (2010-2018) introduced more sophisticated reactor designs with improved temperature control, residence time management, and feedstock flexibility. The current phase (2018-present) emphasizes integrated systems that optimize both biochar quality and energy recovery while minimizing environmental impacts.

Technological advancements have significantly improved biochar production efficiency. Modern systems can achieve carbon conversion efficiencies of 30-50%, compared to 10-20% in traditional methods. Additionally, contemporary technologies can precisely control biochar properties such as surface area, pore structure, and functional groups, allowing for customization based on specific applications. These improvements have expanded biochar's utility beyond agriculture to include water filtration, building materials, and industrial applications.

Sustainability goals in biochar development have evolved in parallel with technological advancements. Initially, the focus was primarily on carbon sequestration potential. However, the sustainability framework has expanded to include broader environmental, social, and economic considerations. Current sustainability goals encompass reducing greenhouse gas emissions throughout the entire supply chain, minimizing water usage, preventing soil degradation, and ensuring equitable access to biochar technology for diverse communities.

The industry has established several certification standards to ensure biochar quality and sustainability. The International Biochar Initiative (IBI) Biochar Standards and the European Biochar Certificate (EBC) provide frameworks for assessing biochar quality and production sustainability. These standards evaluate factors such as carbon stability, contaminant levels, production efficiency, and feedstock sustainability. Future technological development aims to achieve carbon-negative production systems that sequester more carbon than they emit throughout the entire lifecycle.

Looking forward, biochar technology evolution is trending toward decentralized, modular production systems that can be deployed close to feedstock sources, reducing transportation emissions and costs. Integration with renewable energy systems and waste management infrastructure represents another significant trend, creating synergistic systems that maximize resource efficiency and minimize environmental impact. These technological trajectories align with broader sustainability goals of circular economy principles and climate change mitigation strategies.

Market Analysis for Industrial Biochar Applications

The global biochar market is experiencing significant growth, valued at approximately $1.5 billion in 2022 and projected to reach $3.1 billion by 2027, representing a compound annual growth rate (CAGR) of 14.8%. This growth is primarily driven by increasing awareness of sustainable agricultural practices and the rising demand for carbon sequestration solutions to combat climate change.

Industrial applications of biochar extend beyond traditional agricultural uses, creating diverse market opportunities. The soil amendment sector remains dominant, accounting for roughly 60% of current biochar consumption, as biochar improves soil fertility, water retention, and crop yields while reducing fertilizer requirements. This application is particularly valuable in regions with degraded soils or facing water scarcity challenges.

Carbon sequestration represents the fastest-growing application segment, with annual growth rates exceeding 20%. As organizations worldwide commit to carbon neutrality goals, biochar's ability to store carbon for centuries makes it an attractive option for carbon offset programs and environmental compliance strategies. Several carbon credit markets now recognize biochar as a legitimate carbon removal technology.

Water filtration applications are gaining traction in both municipal and industrial settings, where biochar serves as a cost-effective alternative to activated carbon for removing contaminants. The wastewater treatment segment is expected to grow at 16% annually through 2027, driven by stricter environmental regulations and increasing industrial pollution concerns.

Emerging applications in construction materials, particularly as an additive in concrete and asphalt, show promising growth potential. Initial studies indicate that biochar-enhanced building materials offer improved insulation properties and reduced carbon footprints. Though currently representing less than 5% of the market, this segment could expand significantly as green building standards become more widespread.

Regionally, North America and Europe lead in biochar adoption, collectively accounting for approximately 65% of global market value. However, the Asia-Pacific region is expected to witness the highest growth rate (17.5% CAGR) due to increasing agricultural intensification and environmental regulations in countries like China and India.

Key market challenges include price volatility of raw materials, inconsistent product quality standards, and underdeveloped supply chain infrastructure. The average production cost ranges from $300-800 per ton, with significant variations based on feedstock type, production method, and scale of operation. Establishing reliable, sustainable supply chains remains critical for market expansion and price stabilization.

Industrial applications of biochar extend beyond traditional agricultural uses, creating diverse market opportunities. The soil amendment sector remains dominant, accounting for roughly 60% of current biochar consumption, as biochar improves soil fertility, water retention, and crop yields while reducing fertilizer requirements. This application is particularly valuable in regions with degraded soils or facing water scarcity challenges.

Carbon sequestration represents the fastest-growing application segment, with annual growth rates exceeding 20%. As organizations worldwide commit to carbon neutrality goals, biochar's ability to store carbon for centuries makes it an attractive option for carbon offset programs and environmental compliance strategies. Several carbon credit markets now recognize biochar as a legitimate carbon removal technology.

Water filtration applications are gaining traction in both municipal and industrial settings, where biochar serves as a cost-effective alternative to activated carbon for removing contaminants. The wastewater treatment segment is expected to grow at 16% annually through 2027, driven by stricter environmental regulations and increasing industrial pollution concerns.

Emerging applications in construction materials, particularly as an additive in concrete and asphalt, show promising growth potential. Initial studies indicate that biochar-enhanced building materials offer improved insulation properties and reduced carbon footprints. Though currently representing less than 5% of the market, this segment could expand significantly as green building standards become more widespread.

Regionally, North America and Europe lead in biochar adoption, collectively accounting for approximately 65% of global market value. However, the Asia-Pacific region is expected to witness the highest growth rate (17.5% CAGR) due to increasing agricultural intensification and environmental regulations in countries like China and India.

Key market challenges include price volatility of raw materials, inconsistent product quality standards, and underdeveloped supply chain infrastructure. The average production cost ranges from $300-800 per ton, with significant variations based on feedstock type, production method, and scale of operation. Establishing reliable, sustainable supply chains remains critical for market expansion and price stabilization.

Global Biochar Production Challenges and Constraints

The global biochar production landscape faces significant challenges that impede the development of sustainable supply chains. Currently, production capacity remains fragmented and insufficient to meet growing industrial demand. Most biochar production facilities operate at small to medium scales, with limited output ranging from 50 to 500 tons annually, creating a substantial gap between supply capabilities and industrial requirements that often exceed thousands of tons per year.

Raw material sourcing presents another critical constraint. While biochar can theoretically be produced from various biomass feedstocks, the quality and characteristics of the resulting biochar vary significantly depending on the source material. Agricultural residues, forestry waste, and dedicated energy crops each present their own availability challenges, seasonal fluctuations, and competing uses that complicate consistent procurement strategies.

Technical barriers further restrict production scaling. The pyrolysis process requires precise temperature control (typically 350-700°C) and oxygen-limited environments that demand specialized equipment and expertise. Many existing production facilities utilize batch processing methods rather than continuous production systems, resulting in inefficiencies and quality inconsistencies that hinder industrial adoption. The energy requirements for pyrolysis also create sustainability paradoxes when fossil fuels power biochar production.

Regulatory frameworks present a complex patchwork globally. The absence of standardized certification systems and quality parameters creates market uncertainty. In regions like the European Union, biochar must meet European Biochar Certificate (EBC) standards, while North America follows International Biochar Initiative (IBI) guidelines. This regulatory fragmentation increases compliance costs and complicates cross-border supply chains.

Economic viability remains challenging due to high production costs. Current production methods result in biochar prices ranging from $500 to $2,500 per ton, significantly higher than competing materials in many industrial applications. The capital expenditure for establishing industrial-scale production facilities (>5,000 tons annually) typically exceeds $2-5 million, creating substantial barriers to entry and limiting production expansion.

Logistical constraints further complicate supply chain development. Biochar's low density (typically 0.3-0.5 g/cm³) results in high transportation costs relative to value. Additionally, dust management, moisture control, and potential spontaneous combustion risks during storage and transport require specialized handling protocols that add complexity and cost to distribution networks.

These multifaceted challenges necessitate integrated approaches to overcome production constraints and establish viable industrial biochar supply chains that can meet growing demand across agricultural, environmental remediation, and carbon sequestration applications.

Raw material sourcing presents another critical constraint. While biochar can theoretically be produced from various biomass feedstocks, the quality and characteristics of the resulting biochar vary significantly depending on the source material. Agricultural residues, forestry waste, and dedicated energy crops each present their own availability challenges, seasonal fluctuations, and competing uses that complicate consistent procurement strategies.

Technical barriers further restrict production scaling. The pyrolysis process requires precise temperature control (typically 350-700°C) and oxygen-limited environments that demand specialized equipment and expertise. Many existing production facilities utilize batch processing methods rather than continuous production systems, resulting in inefficiencies and quality inconsistencies that hinder industrial adoption. The energy requirements for pyrolysis also create sustainability paradoxes when fossil fuels power biochar production.

Regulatory frameworks present a complex patchwork globally. The absence of standardized certification systems and quality parameters creates market uncertainty. In regions like the European Union, biochar must meet European Biochar Certificate (EBC) standards, while North America follows International Biochar Initiative (IBI) guidelines. This regulatory fragmentation increases compliance costs and complicates cross-border supply chains.

Economic viability remains challenging due to high production costs. Current production methods result in biochar prices ranging from $500 to $2,500 per ton, significantly higher than competing materials in many industrial applications. The capital expenditure for establishing industrial-scale production facilities (>5,000 tons annually) typically exceeds $2-5 million, creating substantial barriers to entry and limiting production expansion.

Logistical constraints further complicate supply chain development. Biochar's low density (typically 0.3-0.5 g/cm³) results in high transportation costs relative to value. Additionally, dust management, moisture control, and potential spontaneous combustion risks during storage and transport require specialized handling protocols that add complexity and cost to distribution networks.

These multifaceted challenges necessitate integrated approaches to overcome production constraints and establish viable industrial biochar supply chains that can meet growing demand across agricultural, environmental remediation, and carbon sequestration applications.

Current Sustainable Sourcing Solutions for Biochar

01 Biochar production methods for sustainability

Various sustainable methods for producing biochar have been developed, focusing on efficient conversion of biomass waste into valuable carbon-rich material. These methods include pyrolysis processes that minimize energy consumption and maximize carbon sequestration. Advanced techniques ensure the production process itself remains environmentally friendly while creating a product that contributes to carbon negativity and waste reduction.- Biochar production methods for sustainable applications: Various methods for producing biochar in a sustainable manner have been developed. These methods focus on optimizing pyrolysis conditions, feedstock selection, and processing techniques to create biochar with specific properties suitable for environmental applications. Sustainable production methods aim to minimize energy consumption and emissions while maximizing carbon sequestration potential, contributing to overall environmental sustainability.

- Soil enhancement and agricultural applications: Biochar can significantly improve soil quality and agricultural productivity through various mechanisms. When incorporated into soil, biochar enhances water retention, nutrient availability, and microbial activity. It also helps in reducing soil acidity and improving soil structure. These properties make biochar an effective and sustainable solution for agricultural applications, particularly in degraded soils, contributing to food security and sustainable farming practices.

- Carbon sequestration and climate change mitigation: Biochar serves as an effective tool for carbon sequestration and climate change mitigation. By converting biomass into stable carbon forms that resist decomposition, biochar can store carbon in soil for hundreds to thousands of years. This process effectively removes carbon dioxide from the atmosphere, helping to offset greenhouse gas emissions. The long-term stability of biochar carbon makes it a promising strategy for addressing climate change through negative emissions technologies.

- Waste management and circular economy integration: Biochar production offers sustainable waste management solutions by converting various organic waste streams into valuable resources. Agricultural residues, forestry waste, and even municipal solid waste can be transformed into biochar, reducing landfill burden and preventing methane emissions from decomposition. This approach supports circular economy principles by closing resource loops and creating value from waste materials, while simultaneously addressing environmental challenges.

- Environmental remediation applications: Biochar has proven effective for environmental remediation of contaminated soils and water. Its high surface area, porosity, and functional groups enable it to adsorb and immobilize various pollutants including heavy metals, organic contaminants, and excess nutrients. Biochar-based remediation technologies offer sustainable alternatives to conventional methods, as they are often less energy-intensive, utilize waste materials, and provide additional benefits such as improved soil health and carbon sequestration.

02 Soil enhancement and agricultural applications

Biochar applications in agriculture focus on improving soil quality and sustainability. When incorporated into soil, biochar enhances water retention, nutrient availability, and microbial activity. This leads to increased crop yields while reducing the need for chemical fertilizers. The long-term stability of biochar in soil also contributes to carbon sequestration, making agricultural practices more environmentally sustainable.Expand Specific Solutions03 Carbon sequestration and climate change mitigation

Biochar serves as an effective tool for carbon sequestration and climate change mitigation. By converting biomass that would otherwise decompose and release carbon dioxide into stable biochar, carbon can be locked away for hundreds to thousands of years. Systems for measuring, reporting, and verifying carbon sequestration through biochar application have been developed to quantify climate benefits and potentially generate carbon credits.Expand Specific Solutions04 Waste management and circular economy integration

Biochar production offers sustainable waste management solutions by converting various organic waste streams into valuable resources. This approach supports circular economy principles by transforming agricultural residues, forestry waste, and even municipal solid waste into biochar. The process reduces landfill volumes, prevents methane emissions from decomposing waste, and creates a product with multiple beneficial applications.Expand Specific Solutions05 Water treatment and environmental remediation

Biochar has proven effective for environmental remediation and water treatment applications. Its high surface area and adsorptive properties make it suitable for removing contaminants from water, including heavy metals, organic pollutants, and excess nutrients. Sustainable water filtration systems incorporating biochar provide cost-effective solutions for clean water access while utilizing a renewable, carbon-negative material.Expand Specific Solutions

Key Industrial Biochar Producers and Suppliers

The sustainable biochar supply chain market is currently in an early growth phase, characterized by increasing industrial adoption and research momentum. The global biochar market, valued at approximately $1.5 billion, is projected to expand significantly due to rising carbon sequestration demands and agricultural applications. While technical feasibility has been established, scalable industrial supply chains remain underdeveloped. Academic institutions like Kunming University of Science & Technology, University of Florida, and Ghent University are driving fundamental research, while commercial players such as Carbon Gold, Aries Clean Technologies, and Air Burners are developing practical implementation solutions. The competitive landscape features a mix of specialized biochar producers, agricultural technology companies, and research institutions working to overcome production scale, standardization, and distribution challenges.

Air Burners, Inc.

Technical Solution: Air Burners has developed the BioCharger system, a mobile biochar production technology specifically designed for sustainable forestry and agricultural waste management. Their approach utilizes a modified air curtain burner that creates a controlled, oxygen-limited environment for converting woody biomass into high-quality biochar. The system can be deployed directly at biomass collection sites, eliminating transportation costs and emissions associated with centralized production facilities. The BioCharger technology can process up to 20 tons of woody debris daily, producing approximately 2-3 tons of biochar with carbon content exceeding 80%. Their mobile units incorporate automated temperature control systems that maintain optimal pyrolysis conditions between 500-700°C, ensuring consistent biochar quality regardless of deployment location. Air Burners has implemented a comprehensive logistics management system that optimizes deployment scheduling based on biomass availability and biochar demand, creating efficient regional supply networks that minimize environmental impact while maximizing production capacity.

Strengths: Mobile production eliminates transportation emissions and costs; on-site processing creates immediate value from waste materials; flexibility to serve multiple industries and locations with the same equipment. Weaknesses: Smaller production scale compared to fixed facilities; quality consistency challenges across different deployment environments; limited ability to capture and utilize thermal energy compared to stationary systems.

Aries Clean Technologies LLC

Technical Solution: Aries Clean Technologies has developed a patented gasification technology specifically designed for sustainable biochar production from various biomass feedstocks. Their Fluidized Bed Gasification system converts agricultural waste, wood residues, and other organic materials into biochar while simultaneously generating renewable energy. The process operates at temperatures between 700-900°C in an oxygen-limited environment, which optimizes biochar quality and carbon sequestration potential. Their industrial-scale facilities can process up to 64 tons of feedstock daily, with biochar yields of approximately 10-15% by weight. Aries has implemented a blockchain-based tracking system to verify the carbon negative footprint of their biochar, enabling carbon credit generation and ensuring supply chain transparency. Their facilities are strategically located near biomass sources to minimize transportation emissions and create regional circular economies.

Strengths: Integrated energy production alongside biochar creation maximizes economic viability; modular design allows for scalable implementation based on regional biomass availability; comprehensive carbon accounting system enhances marketability. Weaknesses: Higher capital costs compared to simpler pyrolysis systems; requires consistent feedstock quality for optimal operation; energy co-production focus may sometimes compromise optimal biochar characteristics for certain applications.

Innovative Biochar Production Patents and Research

Method, design and development of pyrolysis reactor for biochar production from agricultural residues

PatentActiveIN201811009557A

Innovation

- Development of low-cost, simple, and self-sustaining pyrolysis reactors made from locally available materials like bricks, sand, and clay, which convert agricultural residues into biochar with high yield, using controlled oxygen environments and red-hot charcoal ignition, allowing for easy construction and operation by unskilled farmers.

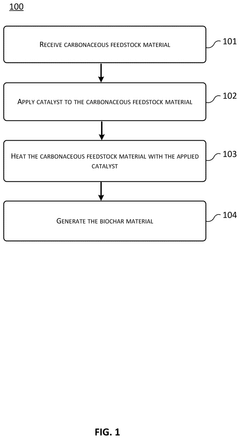

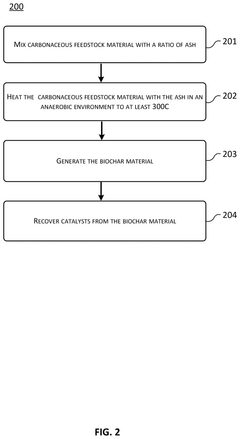

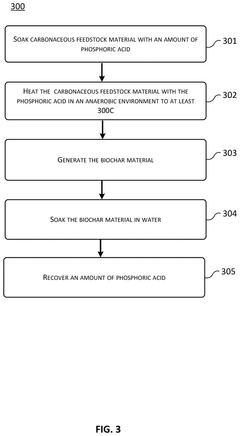

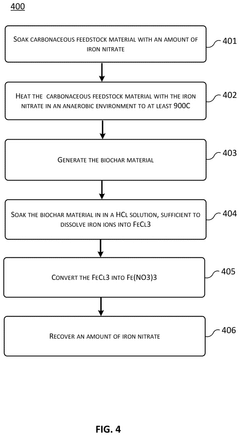

Catalytic conversion of carbonaceous feedstock material into a biochar product

PatentActiveUS20240318082A1

Innovation

- The use of catalysts such as phosphoric acid, iron, and recovered biomass ash to direct the decomposition pathways of carbonaceous feedstock materials during pyrolysis, enhancing biochar yield and stability, and incorporating mineral ash to alter biochar properties and improve agronomic benefits.

Carbon Credit Opportunities in Biochar Supply Chains

The integration of biochar production into carbon credit markets represents a significant economic opportunity for sustainable supply chains. Biochar's carbon sequestration properties make it an ideal candidate for carbon offset projects, with each ton of biochar potentially sequestering 2.5-3 tons of CO2 equivalent when applied to soil. This carbon negativity creates substantial value in voluntary carbon markets where credits currently trade between $5-$50 per ton of CO2 equivalent, depending on project quality and verification standards.

Several established carbon credit methodologies now recognize biochar, including the European Biochar Certificate (EBC), Verra's Verified Carbon Standard (VCS), and the American Carbon Registry (ACR). These frameworks provide the necessary verification infrastructure to monetize the climate benefits of biochar production and application. The process typically involves baseline establishment, monitoring, reporting, and third-party verification to ensure carbon sequestration claims are legitimate and permanent.

For industrial biochar sourcing operations, integrating carbon credit generation requires careful supply chain documentation. This includes tracking feedstock origin, production parameters, transportation emissions, and final application methods. Advanced traceability systems utilizing blockchain or digital ledger technologies can enhance transparency and reduce verification costs, making smaller-scale operations more economically viable within carbon markets.

The economic returns from carbon credits can significantly improve the financial viability of biochar supply chains. Analysis indicates that carbon credit revenue can offset 30-60% of production costs in well-designed systems, effectively subsidizing biochar production and making it more competitive with conventional alternatives. This economic incentive helps overcome the initial cost barriers that have historically limited biochar adoption.

Emerging trends in carbon markets further enhance these opportunities. Premium pricing for carbon removal credits with high co-benefits (such as soil health improvement and waste management) creates additional value streams. Corporate buyers increasingly seek high-quality offsets with verified environmental and social benefits beyond carbon sequestration, positioning biochar projects favorably in this evolving marketplace.

Policy developments are also supportive, with initiatives like the EU Carbon Farming Initiative and the US Growing Climate Solutions Act creating frameworks that could accelerate biochar carbon credit adoption. These policies aim to simplify participation for agricultural producers and industrial partners in carbon markets, potentially expanding the economic viability of biochar supply chains across diverse geographic and operational contexts.

Several established carbon credit methodologies now recognize biochar, including the European Biochar Certificate (EBC), Verra's Verified Carbon Standard (VCS), and the American Carbon Registry (ACR). These frameworks provide the necessary verification infrastructure to monetize the climate benefits of biochar production and application. The process typically involves baseline establishment, monitoring, reporting, and third-party verification to ensure carbon sequestration claims are legitimate and permanent.

For industrial biochar sourcing operations, integrating carbon credit generation requires careful supply chain documentation. This includes tracking feedstock origin, production parameters, transportation emissions, and final application methods. Advanced traceability systems utilizing blockchain or digital ledger technologies can enhance transparency and reduce verification costs, making smaller-scale operations more economically viable within carbon markets.

The economic returns from carbon credits can significantly improve the financial viability of biochar supply chains. Analysis indicates that carbon credit revenue can offset 30-60% of production costs in well-designed systems, effectively subsidizing biochar production and making it more competitive with conventional alternatives. This economic incentive helps overcome the initial cost barriers that have historically limited biochar adoption.

Emerging trends in carbon markets further enhance these opportunities. Premium pricing for carbon removal credits with high co-benefits (such as soil health improvement and waste management) creates additional value streams. Corporate buyers increasingly seek high-quality offsets with verified environmental and social benefits beyond carbon sequestration, positioning biochar projects favorably in this evolving marketplace.

Policy developments are also supportive, with initiatives like the EU Carbon Farming Initiative and the US Growing Climate Solutions Act creating frameworks that could accelerate biochar carbon credit adoption. These policies aim to simplify participation for agricultural producers and industrial partners in carbon markets, potentially expanding the economic viability of biochar supply chains across diverse geographic and operational contexts.

Regulatory Framework for Biochar Production and Trade

The regulatory landscape for biochar production and trade is complex and evolving, with significant variations across different regions and countries. In the European Union, biochar production falls under several regulatory frameworks, including the EU Fertilising Products Regulation (FPR) 2019/1009, which now includes biochar as a Component Material Category (CMC). This regulation establishes quality standards, safety requirements, and conformity assessment procedures for biochar products entering the European market.

In the United States, biochar regulation is less centralized, with oversight divided between the Environmental Protection Agency (EPA), the Department of Agriculture (USDA), and state-level environmental agencies. The EPA regulates biochar production facilities under air emission standards, while the USDA has established voluntary certification programs for biochar as a soil amendment through its National Organic Program.

Asia-Pacific countries demonstrate varying regulatory approaches. Japan has integrated biochar into its carbon reduction strategy with specific quality standards for agricultural applications. China has recently implemented national standards for biochar production and application as part of its carbon neutrality goals, focusing on feedstock requirements and production parameters.

Certification systems play a crucial role in standardizing biochar quality across international markets. The European Biochar Certificate (EBC) and the International Biochar Initiative (IBI) Biochar Certification Program have emerged as leading voluntary certification schemes, establishing parameters for carbon content, contaminant limits, and production sustainability. These certification systems facilitate international trade by providing recognized quality benchmarks.

Carbon credit frameworks increasingly incorporate biochar production. The Verified Carbon Standard (VCS) and Gold Standard have developed methodologies for quantifying and verifying carbon sequestration through biochar application, creating additional revenue streams for producers through carbon markets. This integration with carbon finance mechanisms is accelerating investment in sustainable biochar supply chains.

Emerging regulatory trends include the development of end-of-waste criteria specific to biochar, which would clarify when biochar ceases to be classified as waste and becomes a product. Additionally, life cycle assessment (LCA) requirements are being incorporated into regulatory frameworks to ensure comprehensive environmental impact evaluation of biochar production systems. These developments aim to address sustainability concerns while facilitating market growth.

Transportation and storage regulations present additional compliance challenges for biochar supply chains. Classification of biochar under dangerous goods regulations varies by jurisdiction, with some regions requiring special handling procedures due to potential combustibility concerns. Harmonization efforts are underway to standardize these requirements and reduce trade barriers while maintaining safety standards.

In the United States, biochar regulation is less centralized, with oversight divided between the Environmental Protection Agency (EPA), the Department of Agriculture (USDA), and state-level environmental agencies. The EPA regulates biochar production facilities under air emission standards, while the USDA has established voluntary certification programs for biochar as a soil amendment through its National Organic Program.

Asia-Pacific countries demonstrate varying regulatory approaches. Japan has integrated biochar into its carbon reduction strategy with specific quality standards for agricultural applications. China has recently implemented national standards for biochar production and application as part of its carbon neutrality goals, focusing on feedstock requirements and production parameters.

Certification systems play a crucial role in standardizing biochar quality across international markets. The European Biochar Certificate (EBC) and the International Biochar Initiative (IBI) Biochar Certification Program have emerged as leading voluntary certification schemes, establishing parameters for carbon content, contaminant limits, and production sustainability. These certification systems facilitate international trade by providing recognized quality benchmarks.

Carbon credit frameworks increasingly incorporate biochar production. The Verified Carbon Standard (VCS) and Gold Standard have developed methodologies for quantifying and verifying carbon sequestration through biochar application, creating additional revenue streams for producers through carbon markets. This integration with carbon finance mechanisms is accelerating investment in sustainable biochar supply chains.

Emerging regulatory trends include the development of end-of-waste criteria specific to biochar, which would clarify when biochar ceases to be classified as waste and becomes a product. Additionally, life cycle assessment (LCA) requirements are being incorporated into regulatory frameworks to ensure comprehensive environmental impact evaluation of biochar production systems. These developments aim to address sustainability concerns while facilitating market growth.

Transportation and storage regulations present additional compliance challenges for biochar supply chains. Classification of biochar under dangerous goods regulations varies by jurisdiction, with some regions requiring special handling procedures due to potential combustibility concerns. Harmonization efforts are underway to standardize these requirements and reduce trade barriers while maintaining safety standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!