Biochar Activation Kinetics And Process Control

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biochar Activation Fundamentals and Research Objectives

Biochar activation represents a critical process in transforming raw carbonaceous materials into highly effective adsorbents with enhanced surface area and functional properties. The evolution of biochar activation techniques has progressed significantly over the past decades, transitioning from traditional physical activation methods to more sophisticated chemical and hybrid approaches. This technological progression has been driven by the increasing demand for specialized carbon materials in environmental remediation, energy storage, and agricultural applications.

The fundamental mechanisms underlying biochar activation involve the selective removal of carbon atoms and the creation of porous structures through controlled oxidation processes. Physical activation typically employs steam, CO2, or air at elevated temperatures (700-1000°C), while chemical activation utilizes reagents such as KOH, H3PO4, or ZnCl2 at relatively lower temperatures (400-700°C). The kinetics of these processes are governed by complex interactions between the precursor material properties, activation agents, temperature profiles, and residence times.

Recent technological trends indicate a growing interest in microwave-assisted activation, hydrothermal carbonization followed by activation, and plasma-enhanced activation techniques. These emerging methods offer potential advantages in terms of energy efficiency, process control precision, and the ability to tailor specific surface properties. The integration of real-time monitoring systems and advanced process control algorithms represents another significant development trajectory in this field.

The primary research objectives in biochar activation kinetics focus on establishing comprehensive mathematical models that accurately describe the reaction pathways and transformation mechanisms. These models aim to predict the development of porosity, surface area, and functional group formation as functions of process parameters. Additionally, research efforts are directed toward understanding the influence of feedstock characteristics on activation behavior, as biomass composition significantly impacts the resulting activated biochar properties.

Process control optimization represents another critical research objective, with emphasis on developing adaptive control strategies that can respond to variations in feedstock properties and process conditions. The implementation of machine learning algorithms for predictive modeling and process optimization has shown promising results in laboratory-scale studies, though industrial-scale validation remains a challenge.

The ultimate goal of current research endeavors is to establish standardized protocols for biochar activation that enable precise engineering of carbon materials with tailored properties for specific applications. This includes developing activation processes that selectively enhance certain characteristics (e.g., microporosity for gas adsorption, mesoporosity for liquid-phase applications, or specific surface functionalities for contaminant binding) while minimizing energy consumption and environmental impact.

The fundamental mechanisms underlying biochar activation involve the selective removal of carbon atoms and the creation of porous structures through controlled oxidation processes. Physical activation typically employs steam, CO2, or air at elevated temperatures (700-1000°C), while chemical activation utilizes reagents such as KOH, H3PO4, or ZnCl2 at relatively lower temperatures (400-700°C). The kinetics of these processes are governed by complex interactions between the precursor material properties, activation agents, temperature profiles, and residence times.

Recent technological trends indicate a growing interest in microwave-assisted activation, hydrothermal carbonization followed by activation, and plasma-enhanced activation techniques. These emerging methods offer potential advantages in terms of energy efficiency, process control precision, and the ability to tailor specific surface properties. The integration of real-time monitoring systems and advanced process control algorithms represents another significant development trajectory in this field.

The primary research objectives in biochar activation kinetics focus on establishing comprehensive mathematical models that accurately describe the reaction pathways and transformation mechanisms. These models aim to predict the development of porosity, surface area, and functional group formation as functions of process parameters. Additionally, research efforts are directed toward understanding the influence of feedstock characteristics on activation behavior, as biomass composition significantly impacts the resulting activated biochar properties.

Process control optimization represents another critical research objective, with emphasis on developing adaptive control strategies that can respond to variations in feedstock properties and process conditions. The implementation of machine learning algorithms for predictive modeling and process optimization has shown promising results in laboratory-scale studies, though industrial-scale validation remains a challenge.

The ultimate goal of current research endeavors is to establish standardized protocols for biochar activation that enable precise engineering of carbon materials with tailored properties for specific applications. This includes developing activation processes that selectively enhance certain characteristics (e.g., microporosity for gas adsorption, mesoporosity for liquid-phase applications, or specific surface functionalities for contaminant binding) while minimizing energy consumption and environmental impact.

Market Analysis for Activated Biochar Applications

The global activated biochar market is experiencing significant growth, driven by increasing environmental concerns and the push for sustainable solutions across various industries. Currently valued at approximately 2.1 billion USD in 2023, the market is projected to reach 3.5 billion USD by 2028, representing a compound annual growth rate (CAGR) of 10.8%. This growth trajectory is supported by expanding applications across multiple sectors including agriculture, water treatment, air purification, and energy storage.

Agriculture remains the dominant application segment, accounting for roughly 40% of the total market share. The demand for activated biochar in this sector is primarily driven by its soil amendment properties, which improve crop yields while sequestering carbon. The water treatment segment follows closely, representing about 30% of the market, with increasing adoption in municipal water treatment facilities and industrial wastewater management systems.

Geographically, North America and Europe currently lead the market, collectively accounting for approximately 60% of global consumption. However, the Asia-Pacific region is emerging as the fastest-growing market with a CAGR of 12.5%, fueled by rapid industrialization, increasing environmental regulations, and growing agricultural activities in countries like China, India, and Japan.

The market is characterized by a fragmented competitive landscape with a mix of large multinational corporations and specialized regional players. Key market participants include Carbon Gold Ltd., Biochar Supreme, Pacific Biochar, and Cool Planet Energy Systems, who are actively investing in research and development to enhance activation processes and expand application possibilities.

Consumer trends indicate a growing preference for sustainably produced activated biochar, with certification programs like the International Biochar Initiative (IBI) certification gaining importance. Price sensitivity varies significantly across application segments, with agricultural applications being more price-sensitive compared to specialized industrial applications.

Regulatory support is increasingly favorable, with carbon credit mechanisms and environmental policies in many countries incentivizing biochar production and utilization. The European Union's carbon farming initiative and similar programs in North America are creating additional market drivers through carbon offset opportunities.

Future market growth is expected to be driven by technological advancements in activation processes that enhance specific properties for targeted applications, as well as the development of novel applications in emerging fields such as electronics, construction materials, and pharmaceutical industries.

Agriculture remains the dominant application segment, accounting for roughly 40% of the total market share. The demand for activated biochar in this sector is primarily driven by its soil amendment properties, which improve crop yields while sequestering carbon. The water treatment segment follows closely, representing about 30% of the market, with increasing adoption in municipal water treatment facilities and industrial wastewater management systems.

Geographically, North America and Europe currently lead the market, collectively accounting for approximately 60% of global consumption. However, the Asia-Pacific region is emerging as the fastest-growing market with a CAGR of 12.5%, fueled by rapid industrialization, increasing environmental regulations, and growing agricultural activities in countries like China, India, and Japan.

The market is characterized by a fragmented competitive landscape with a mix of large multinational corporations and specialized regional players. Key market participants include Carbon Gold Ltd., Biochar Supreme, Pacific Biochar, and Cool Planet Energy Systems, who are actively investing in research and development to enhance activation processes and expand application possibilities.

Consumer trends indicate a growing preference for sustainably produced activated biochar, with certification programs like the International Biochar Initiative (IBI) certification gaining importance. Price sensitivity varies significantly across application segments, with agricultural applications being more price-sensitive compared to specialized industrial applications.

Regulatory support is increasingly favorable, with carbon credit mechanisms and environmental policies in many countries incentivizing biochar production and utilization. The European Union's carbon farming initiative and similar programs in North America are creating additional market drivers through carbon offset opportunities.

Future market growth is expected to be driven by technological advancements in activation processes that enhance specific properties for targeted applications, as well as the development of novel applications in emerging fields such as electronics, construction materials, and pharmaceutical industries.

Technical Barriers and Global Development Status

Despite significant advancements in biochar activation technologies, several technical barriers continue to impede optimal process control and kinetics understanding. The primary challenge remains the complex heterogeneity of biomass feedstocks, which creates unpredictable activation behaviors and inconsistent product quality. This variability significantly complicates the development of standardized activation protocols and reliable kinetic models.

Temperature control during activation represents another critical barrier, particularly in large-scale operations where maintaining uniform thermal conditions throughout the reactor becomes increasingly difficult. Temperature gradients within activation vessels lead to inconsistent product characteristics and reduced efficiency. Current monitoring technologies often fail to provide real-time, spatially resolved temperature data needed for precise process control.

The energy intensity of traditional activation methods presents both economic and environmental challenges. Physical activation typically requires temperatures exceeding 800°C maintained for extended periods, while chemical activation processes utilize corrosive reagents that necessitate specialized equipment and create waste management issues. These factors significantly impact the sustainability and commercial viability of biochar activation.

Globally, research efforts addressing these challenges show distinct regional focuses. North American institutions primarily concentrate on developing advanced in-situ monitoring technologies and process automation systems. The European research community emphasizes sustainable activation methods with reduced environmental footprints, including microwave-assisted and solar-thermal activation approaches. Meanwhile, Asian research groups, particularly in China and South Korea, lead in scaling up traditional activation technologies and optimizing chemical activation processes.

Recent technological breakthroughs include the development of continuous-flow activation systems in Germany that reduce energy consumption by 30% compared to batch processes. Japanese researchers have pioneered non-thermal plasma activation methods that operate at near-ambient temperatures. Australian innovations in microwave-assisted activation demonstrate significant reductions in processing time while maintaining product quality.

The commercial landscape remains fragmented, with most industrial-scale activation processes still relying on modified conventional technologies. However, the emergence of specialized equipment manufacturers in Europe and North America is gradually improving technology transfer from research institutions to industrial applications. Regulatory frameworks regarding activated biochar production vary significantly across regions, creating additional challenges for global technology standardization and market development.

Temperature control during activation represents another critical barrier, particularly in large-scale operations where maintaining uniform thermal conditions throughout the reactor becomes increasingly difficult. Temperature gradients within activation vessels lead to inconsistent product characteristics and reduced efficiency. Current monitoring technologies often fail to provide real-time, spatially resolved temperature data needed for precise process control.

The energy intensity of traditional activation methods presents both economic and environmental challenges. Physical activation typically requires temperatures exceeding 800°C maintained for extended periods, while chemical activation processes utilize corrosive reagents that necessitate specialized equipment and create waste management issues. These factors significantly impact the sustainability and commercial viability of biochar activation.

Globally, research efforts addressing these challenges show distinct regional focuses. North American institutions primarily concentrate on developing advanced in-situ monitoring technologies and process automation systems. The European research community emphasizes sustainable activation methods with reduced environmental footprints, including microwave-assisted and solar-thermal activation approaches. Meanwhile, Asian research groups, particularly in China and South Korea, lead in scaling up traditional activation technologies and optimizing chemical activation processes.

Recent technological breakthroughs include the development of continuous-flow activation systems in Germany that reduce energy consumption by 30% compared to batch processes. Japanese researchers have pioneered non-thermal plasma activation methods that operate at near-ambient temperatures. Australian innovations in microwave-assisted activation demonstrate significant reductions in processing time while maintaining product quality.

The commercial landscape remains fragmented, with most industrial-scale activation processes still relying on modified conventional technologies. However, the emergence of specialized equipment manufacturers in Europe and North America is gradually improving technology transfer from research institutions to industrial applications. Regulatory frameworks regarding activated biochar production vary significantly across regions, creating additional challenges for global technology standardization and market development.

Current Activation Methodologies and Parameters

01 Physical activation methods for biochar

Physical activation methods involve treating biochar with gases at high temperatures to enhance its porosity and surface area. Common methods include steam activation, CO2 activation, and thermal treatment. These processes follow specific kinetic models that describe the rate of pore development and surface modification. The activation temperature, residence time, and gas flow rate are critical parameters that influence the kinetics of the activation process and the resulting properties of the activated biochar.- Physical activation methods for biochar: Physical activation methods involve treating biochar with gases at high temperatures to enhance its porosity and surface area. Common methods include steam activation, CO2 activation, and thermal treatment under controlled atmospheres. These processes follow specific kinetic models that describe the rate of pore development and surface modification. The activation temperature, residence time, and gas flow rate are critical parameters that influence the kinetics of the activation process and the resulting properties of the activated biochar.

- Chemical activation processes and kinetics: Chemical activation of biochar involves treatment with chemical agents such as KOH, H3PO4, ZnCl2, or other alkaline/acidic compounds. The kinetics of chemical activation are influenced by the concentration of the activating agent, reaction temperature, and contact time. These processes typically follow different reaction mechanisms compared to physical activation, often resulting in more developed pore structures at lower temperatures. The chemical activation kinetics can be modeled using various mathematical approaches to predict the development of surface functionality and porosity.

- Microwave-assisted activation kinetics: Microwave-assisted activation represents an emerging technique for biochar activation with distinct kinetic advantages. This method provides rapid and volumetric heating, resulting in unique activation kinetics characterized by shorter activation times and more uniform pore development. The dielectric properties of biochar and activating agents play crucial roles in determining the efficiency and rate of the activation process. Microwave activation often follows different kinetic models compared to conventional heating methods, with potential energy savings and enhanced control over the activation process.

- Modeling and optimization of activation kinetics: Various mathematical models are employed to describe and predict the kinetics of biochar activation processes. These include pseudo-first-order, pseudo-second-order, intraparticle diffusion, and Elovich models. Advanced computational techniques such as artificial neural networks and response surface methodology are used to optimize activation parameters based on kinetic data. Understanding the activation kinetics enables the prediction of optimal process conditions to achieve desired properties such as specific surface area, pore volume distribution, and surface functionality in the activated biochar.

- Influence of feedstock properties on activation kinetics: The properties of the original biomass feedstock significantly influence the activation kinetics of biochar. Factors such as lignin content, cellulose/hemicellulose ratio, ash content, and elemental composition affect how the biochar responds to activation treatments. Different biomass sources exhibit varying activation kinetics, requiring adjustments to activation parameters to achieve optimal results. The pyrolysis conditions used to produce the initial biochar also play a crucial role in determining subsequent activation behavior and kinetics, as they establish the initial carbon structure that undergoes activation.

02 Chemical activation processes and kinetics

Chemical activation of biochar involves treatment with chemical agents such as KOH, H3PO4, ZnCl2, or other alkaline/acidic compounds. The kinetics of chemical activation are influenced by the concentration of the activating agent, reaction temperature, and contact time. These processes typically follow different reaction mechanisms compared to physical activation, often resulting in more developed microporous structures. The chemical activation kinetics can be modeled using various mathematical approaches to predict the development of surface functional groups and porosity.Expand Specific Solutions03 Microwave-assisted activation kinetics

Microwave-assisted activation represents an innovative approach for biochar activation with distinct kinetic advantages. This method provides rapid and uniform heating, resulting in faster activation rates compared to conventional heating methods. The kinetics of microwave activation are characterized by reduced activation energy requirements and accelerated reaction rates. The process parameters, including microwave power, exposure time, and the presence of microwave absorbers, significantly influence the activation kinetics and the resulting biochar properties.Expand Specific Solutions04 Modeling and optimization of activation kinetics

Various mathematical models are employed to describe and predict biochar activation kinetics, including pseudo-first-order, pseudo-second-order, and diffusion models. These models help in understanding the rate-limiting steps and mechanisms involved in the activation process. Advanced computational techniques, such as artificial neural networks and response surface methodology, are used to optimize the activation parameters based on kinetic data. The modeling approaches enable the prediction of optimal activation conditions to achieve desired biochar properties for specific applications.Expand Specific Solutions05 Influence of feedstock characteristics on activation kinetics

The properties of the original biomass feedstock significantly impact the activation kinetics of biochar. Factors such as lignin content, cellulose structure, ash content, and particle size affect the reactivity and activation behavior. Different biomass sources exhibit varying activation kinetics under similar conditions, leading to activated biochars with distinct properties. Understanding these relationships is crucial for developing tailored activation protocols for specific feedstocks to achieve desired functional properties in the final activated biochar product.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Biochar activation kinetics and process control technology is currently in a growth phase, with the market expanding due to increasing environmental concerns and sustainable agriculture demands. The global biochar market is projected to reach significant scale as applications diversify across agricultural, environmental remediation, and carbon sequestration sectors. From a technological maturity perspective, research institutions like Tsinghua University, Southeast University, and Huazhong University of Science & Technology are leading academic advancements, while specialized companies such as Carbon Gold Ltd., Full Circle Biochar, and Carbon Technology Holdings LLC are commercializing innovations. Larger industrial players including Cummins, Inc. are exploring biochar applications for emissions reduction, indicating growing cross-sector interest. The competitive landscape shows a blend of academic research leadership and emerging commercial applications, with significant potential for process optimization innovations.

Carbon Gold Ltd.

Technical Solution: Carbon Gold has developed a proprietary biochar activation process that focuses on enhancing the functional properties of biochar through controlled temperature pyrolysis and post-treatment activation. Their technology employs a two-stage activation process: initial pyrolysis at 400-600°C in oxygen-limited conditions, followed by steam activation at elevated temperatures (700-900°C) to develop microporous structures. The company has implemented real-time monitoring systems using infrared spectroscopy to track the chemical transformations during activation, allowing for precise control of residence time and temperature profiles. Their process incorporates biological inoculants during the cooling phase to enhance the biochar's microbial properties and nutrient retention capabilities. Carbon Gold's approach emphasizes the production of biochar with specific agricultural applications, focusing on optimizing cation exchange capacity and water retention properties through carefully controlled activation kinetics.

Strengths: Precise control over functional properties for agricultural applications; integration of biological enhancement during production. Weaknesses: Energy-intensive activation process; limited scalability for industrial-scale production; relatively high production costs compared to conventional soil amendments.

Accelergy Corp.

Technical Solution: Accelergy Corporation has developed an advanced catalytic biochar activation technology that significantly enhances the kinetics of the activation process. Their approach utilizes proprietary metal-organic catalyst formulations that reduce activation energy requirements while promoting uniform pore development. The process employs a fluidized bed reactor system with precise temperature zoning (350-850°C) that allows for controlled exposure of biochar to activation agents. Accelergy's technology incorporates real-time monitoring of activation progress through electrical conductivity measurements of the biochar, enabling dynamic adjustment of process parameters. Their system features a patented gas recirculation mechanism that optimizes the concentration of activation agents (CO2, steam, or chemical activators) throughout the process, ensuring uniform activation across the biochar particles. The company has implemented a sophisticated process control system that utilizes predictive modeling to anticipate reaction kinetics based on feedstock characteristics, allowing for automated adjustment of residence time, temperature profiles, and activating agent concentrations to achieve targeted biochar properties.

Strengths: Accelerated activation kinetics through catalytic enhancement; precise control over pore size distribution; reduced energy consumption compared to conventional activation methods. Weaknesses: Higher complexity in process control; potential catalyst recovery challenges; increased production costs due to catalyst requirements.

Key Patents and Scientific Breakthroughs

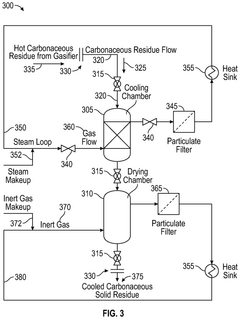

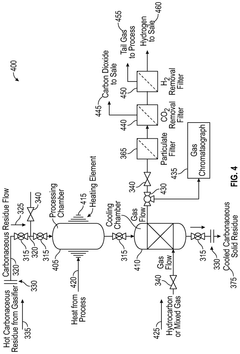

Methods and systems for producing an enhanced surface area biochar product

PatentActiveUS12187616B2

Innovation

- A processing vessel with multiple independently temperature-controlled chambers and counter-flow steam injection is used to adjust biochar temperature, cool it with injected steam, and recover volatiles through dehydration, enhancing the activation level and surface area of the biochar.

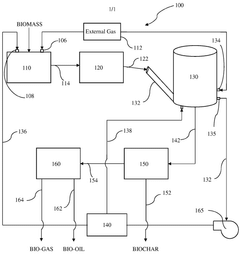

Improved process for the production of biochar

PatentWO2024168168A1

Innovation

- A continuous external source of gas is used to supplement the heat generated by the pyrolysis process, allowing for more precise control over temperature and heating rate, reducing the risk of fires or explosions, and increasing the yield of biochar and other pyrolysis products.

Environmental Impact and Sustainability Assessment

The environmental impact of biochar activation processes extends far beyond the immediate production benefits. Life cycle assessments reveal that properly activated biochar can sequester carbon for centuries, with potential carbon negative footprints when integrated into comprehensive waste management systems. Studies indicate that one ton of biochar can sequester approximately 2.5-3 tons of CO2 equivalent, making it a powerful tool for climate change mitigation.

Water quality improvements represent another significant environmental benefit. Activated biochar's enhanced porosity and surface functionality enable it to adsorb agricultural runoff contaminants, reducing nitrogen and phosphorus leaching by 30-60% in field trials. This characteristic positions biochar as a valuable component in watershed protection strategies and helps mitigate eutrophication in aquatic ecosystems.

The sustainability profile of biochar activation processes varies considerably depending on energy sources and activation methods. Chemical activation using KOH or H3PO4 presents higher environmental burdens through chemical waste generation and processing emissions. Conversely, physical activation with steam or CO2 typically demonstrates lower environmental impacts, particularly when utilizing renewable energy sources or waste heat recovery systems from adjacent industrial processes.

Resource efficiency metrics indicate that biochar activation can transform agricultural and forestry waste streams into value-added products, creating circular economy opportunities. The process diverts biomass from landfills where it would otherwise generate methane, a potent greenhouse gas with 28 times the warming potential of CO2. This waste-to-resource conversion pathway significantly enhances the sustainability credentials of biochar activation.

Land remediation capabilities further enhance the environmental profile of activated biochar. Field applications have demonstrated its effectiveness in immobilizing heavy metals in contaminated soils, reducing bioavailability by 40-90% depending on metal species and biochar properties. This remediation potential offers sustainable alternatives to more invasive and disruptive soil treatment methods.

Energy consumption during activation remains a critical sustainability concern. Physical activation processes typically require temperatures between 700-900°C, consuming 3-5 GJ per ton of activated biochar produced. Implementing heat recovery systems and optimizing activation kinetics can reduce this energy demand by 20-30%, significantly improving the overall environmental footprint of the process.

Biodiversity impacts should also be considered in sustainability assessments. When applied to soils, activated biochar has been shown to enhance microbial diversity and activity, potentially increasing soil ecosystem resilience. However, production facilities must carefully manage emissions to prevent localized air quality degradation that could negatively impact surrounding ecosystems.

Water quality improvements represent another significant environmental benefit. Activated biochar's enhanced porosity and surface functionality enable it to adsorb agricultural runoff contaminants, reducing nitrogen and phosphorus leaching by 30-60% in field trials. This characteristic positions biochar as a valuable component in watershed protection strategies and helps mitigate eutrophication in aquatic ecosystems.

The sustainability profile of biochar activation processes varies considerably depending on energy sources and activation methods. Chemical activation using KOH or H3PO4 presents higher environmental burdens through chemical waste generation and processing emissions. Conversely, physical activation with steam or CO2 typically demonstrates lower environmental impacts, particularly when utilizing renewable energy sources or waste heat recovery systems from adjacent industrial processes.

Resource efficiency metrics indicate that biochar activation can transform agricultural and forestry waste streams into value-added products, creating circular economy opportunities. The process diverts biomass from landfills where it would otherwise generate methane, a potent greenhouse gas with 28 times the warming potential of CO2. This waste-to-resource conversion pathway significantly enhances the sustainability credentials of biochar activation.

Land remediation capabilities further enhance the environmental profile of activated biochar. Field applications have demonstrated its effectiveness in immobilizing heavy metals in contaminated soils, reducing bioavailability by 40-90% depending on metal species and biochar properties. This remediation potential offers sustainable alternatives to more invasive and disruptive soil treatment methods.

Energy consumption during activation remains a critical sustainability concern. Physical activation processes typically require temperatures between 700-900°C, consuming 3-5 GJ per ton of activated biochar produced. Implementing heat recovery systems and optimizing activation kinetics can reduce this energy demand by 20-30%, significantly improving the overall environmental footprint of the process.

Biodiversity impacts should also be considered in sustainability assessments. When applied to soils, activated biochar has been shown to enhance microbial diversity and activity, potentially increasing soil ecosystem resilience. However, production facilities must carefully manage emissions to prevent localized air quality degradation that could negatively impact surrounding ecosystems.

Scalability and Industrial Implementation Challenges

The scaling of biochar activation processes from laboratory to industrial scale presents significant engineering and economic challenges. Current laboratory-scale activation processes typically operate with batch sizes of 100g-5kg, while commercial implementation requires throughput of several tons per day. This scale disparity creates numerous technical hurdles that must be addressed before widespread industrial adoption can occur.

Temperature uniformity represents a primary challenge in scaled-up activation systems. Laboratory reactors can maintain precise temperature control (±5°C) throughout small samples, whereas industrial-scale reactors often develop temperature gradients exceeding 50°C across the activation chamber. These gradients lead to inconsistent activation levels and product quality variability, necessitating advanced heat distribution systems and reactor designs that ensure uniform thermal profiles.

Gas flow dynamics change dramatically at industrial scales, affecting activation kinetics. The residence time distribution of activating gases (steam, CO2, or chemical activating agents) becomes more heterogeneous in large reactors, resulting in uneven activation. Engineering solutions such as fluidized bed reactors or rotary kilns can improve gas-solid contact efficiency, but these systems introduce additional complexity and capital costs to the activation process.

Energy efficiency considerations become paramount at industrial scale. The energy requirements for heating large volumes of biochar to activation temperatures (700-900°C) are substantial. Heat recovery systems and process integration are essential for economic viability, with potential for 30-40% energy savings through strategic heat exchange networks and combustion of process by-products.

Feedstock variability presents another significant challenge. While laboratory studies typically use homogeneous, carefully prepared feedstocks, industrial implementation must accommodate heterogeneous biomass sources with varying moisture content, particle size, and composition. This variability necessitates robust process control systems capable of real-time adjustments to activation parameters based on feedstock characteristics.

Capital investment requirements for industrial-scale biochar activation facilities are substantial, with estimated costs of $5-15 million for facilities processing 10,000-50,000 tons annually. The economic viability depends heavily on achieving consistent product quality that commands premium pricing in specialized applications such as water treatment, soil remediation, or advanced material production.

Regulatory compliance and environmental considerations add further complexity to industrial implementation. Emissions control systems must be designed to manage volatile organic compounds, particulates, and potential contaminants released during the activation process, with requirements varying significantly across different jurisdictions.

Temperature uniformity represents a primary challenge in scaled-up activation systems. Laboratory reactors can maintain precise temperature control (±5°C) throughout small samples, whereas industrial-scale reactors often develop temperature gradients exceeding 50°C across the activation chamber. These gradients lead to inconsistent activation levels and product quality variability, necessitating advanced heat distribution systems and reactor designs that ensure uniform thermal profiles.

Gas flow dynamics change dramatically at industrial scales, affecting activation kinetics. The residence time distribution of activating gases (steam, CO2, or chemical activating agents) becomes more heterogeneous in large reactors, resulting in uneven activation. Engineering solutions such as fluidized bed reactors or rotary kilns can improve gas-solid contact efficiency, but these systems introduce additional complexity and capital costs to the activation process.

Energy efficiency considerations become paramount at industrial scale. The energy requirements for heating large volumes of biochar to activation temperatures (700-900°C) are substantial. Heat recovery systems and process integration are essential for economic viability, with potential for 30-40% energy savings through strategic heat exchange networks and combustion of process by-products.

Feedstock variability presents another significant challenge. While laboratory studies typically use homogeneous, carefully prepared feedstocks, industrial implementation must accommodate heterogeneous biomass sources with varying moisture content, particle size, and composition. This variability necessitates robust process control systems capable of real-time adjustments to activation parameters based on feedstock characteristics.

Capital investment requirements for industrial-scale biochar activation facilities are substantial, with estimated costs of $5-15 million for facilities processing 10,000-50,000 tons annually. The economic viability depends heavily on achieving consistent product quality that commands premium pricing in specialized applications such as water treatment, soil remediation, or advanced material production.

Regulatory compliance and environmental considerations add further complexity to industrial implementation. Emissions control systems must be designed to manage volatile organic compounds, particulates, and potential contaminants released during the activation process, with requirements varying significantly across different jurisdictions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!