Electrochemical Graphitization Of Biochar For Enhanced Performance

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biochar Graphitization Background and Objectives

Biochar, a carbon-rich material produced through the pyrolysis of biomass under limited oxygen conditions, has emerged as a versatile and sustainable resource with applications spanning from soil amendment to energy storage. The evolution of biochar technology has progressed significantly over the past decade, transitioning from traditional charcoal production methods to sophisticated pyrolysis techniques that optimize specific properties for targeted applications.

The graphitization of biochar represents a critical advancement in enhancing its functional properties. Historically, biochar has been limited by its relatively disordered carbon structure, which constrains electrical conductivity and surface reactivity. Electrochemical graphitization offers a promising approach to transform amorphous carbon structures into more ordered graphitic domains without the extreme temperatures (>2500°C) required by conventional thermal graphitization methods.

Recent technological trends indicate a growing interest in developing cost-effective and scalable methods for biochar modification, with electrochemical approaches gaining particular attention due to their operational flexibility and reduced energy requirements. The convergence of renewable energy integration with electrochemical processing further enhances the sustainability profile of these techniques, aligning with global carbon neutrality objectives.

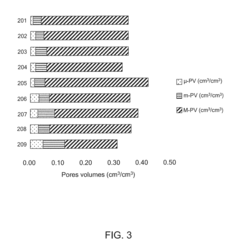

The primary technical objectives for electrochemical graphitization of biochar include achieving enhanced electrical conductivity comparable to commercial graphitic materials (>100 S/cm), increasing specific surface area (>1000 m²/g), and improving electrochemical stability for extended cycling performance. Additionally, there is a focus on developing processes that maintain or enhance the inherent porosity of biochar while introducing graphitic domains.

Another critical objective involves understanding the fundamental mechanisms governing electrochemical transformation of disordered carbon structures. This includes elucidating the role of electrolyte composition, applied potential, temperature, and treatment duration on the degree of graphitization and resultant material properties.

The development trajectory aims to establish standardized protocols for electrochemical graphitization that can be tailored to various biochar feedstocks, considering that biomass source significantly influences the structural characteristics and graphitization potential of the resulting biochar. This standardization would facilitate broader industrial adoption and application-specific optimization.

Ultimately, electrochemical graphitization of biochar seeks to bridge the performance gap between renewable carbon materials and fossil-derived graphitic carbons, potentially enabling sustainable alternatives for energy storage, catalysis, adsorption, and electronic applications while maintaining the circular economy benefits inherent to biochar production.

The graphitization of biochar represents a critical advancement in enhancing its functional properties. Historically, biochar has been limited by its relatively disordered carbon structure, which constrains electrical conductivity and surface reactivity. Electrochemical graphitization offers a promising approach to transform amorphous carbon structures into more ordered graphitic domains without the extreme temperatures (>2500°C) required by conventional thermal graphitization methods.

Recent technological trends indicate a growing interest in developing cost-effective and scalable methods for biochar modification, with electrochemical approaches gaining particular attention due to their operational flexibility and reduced energy requirements. The convergence of renewable energy integration with electrochemical processing further enhances the sustainability profile of these techniques, aligning with global carbon neutrality objectives.

The primary technical objectives for electrochemical graphitization of biochar include achieving enhanced electrical conductivity comparable to commercial graphitic materials (>100 S/cm), increasing specific surface area (>1000 m²/g), and improving electrochemical stability for extended cycling performance. Additionally, there is a focus on developing processes that maintain or enhance the inherent porosity of biochar while introducing graphitic domains.

Another critical objective involves understanding the fundamental mechanisms governing electrochemical transformation of disordered carbon structures. This includes elucidating the role of electrolyte composition, applied potential, temperature, and treatment duration on the degree of graphitization and resultant material properties.

The development trajectory aims to establish standardized protocols for electrochemical graphitization that can be tailored to various biochar feedstocks, considering that biomass source significantly influences the structural characteristics and graphitization potential of the resulting biochar. This standardization would facilitate broader industrial adoption and application-specific optimization.

Ultimately, electrochemical graphitization of biochar seeks to bridge the performance gap between renewable carbon materials and fossil-derived graphitic carbons, potentially enabling sustainable alternatives for energy storage, catalysis, adsorption, and electronic applications while maintaining the circular economy benefits inherent to biochar production.

Market Analysis for Enhanced Biochar Applications

The global biochar market is experiencing significant growth, with a market value estimated to reach $3.1 billion by 2025, growing at a CAGR of 13.2% from 2020. This growth is primarily driven by increasing environmental concerns, government initiatives promoting sustainable agriculture, and rising demand for organic food products. Electrochemically graphitized biochar represents a high-value segment within this expanding market due to its enhanced performance characteristics.

Agricultural applications currently dominate the biochar market, accounting for approximately 60% of total consumption. The enhanced properties of electrochemically graphitized biochar—including improved electrical conductivity, higher surface area, and increased stability—make it particularly valuable for soil amendment applications where it can significantly improve crop yields while sequestering carbon. Field trials have demonstrated yield increases of 10-25% in various crops when using enhanced biochar.

The environmental remediation sector presents another substantial market opportunity, valued at approximately $850 million globally. Electrochemically graphitized biochar's superior adsorption capabilities make it exceptionally effective for contaminant removal from soil and water. This application segment is projected to grow at 15% annually through 2027, outpacing the overall biochar market.

Energy storage applications represent the fastest-growing segment for enhanced biochar, with particular relevance for electrochemically graphitized variants. The superior electrical conductivity achieved through graphitization processes makes these materials increasingly attractive as components in supercapacitors and battery electrodes. This market segment is expected to grow at 18% annually, reaching $600 million by 2026.

Regional analysis indicates North America currently leads the market for advanced biochar applications (35% market share), followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 16% annually, driven by China's aggressive environmental remediation programs and expanding agricultural technology adoption.

Price points for electrochemically graphitized biochar range from $2,000 to $5,000 per ton, representing a premium of 3-5 times over conventional biochar. This price differential is justified by performance improvements, particularly in specialized applications like energy storage and advanced filtration systems where enhanced electrical conductivity and surface properties deliver substantial value.

Customer adoption analysis reveals that while initial market penetration faces challenges due to higher costs, the total cost of ownership calculations increasingly favor enhanced biochar solutions when accounting for improved performance and longevity. Early adopters include premium agricultural operations, municipal water treatment facilities, and advanced materials manufacturers developing next-generation energy storage solutions.

Agricultural applications currently dominate the biochar market, accounting for approximately 60% of total consumption. The enhanced properties of electrochemically graphitized biochar—including improved electrical conductivity, higher surface area, and increased stability—make it particularly valuable for soil amendment applications where it can significantly improve crop yields while sequestering carbon. Field trials have demonstrated yield increases of 10-25% in various crops when using enhanced biochar.

The environmental remediation sector presents another substantial market opportunity, valued at approximately $850 million globally. Electrochemically graphitized biochar's superior adsorption capabilities make it exceptionally effective for contaminant removal from soil and water. This application segment is projected to grow at 15% annually through 2027, outpacing the overall biochar market.

Energy storage applications represent the fastest-growing segment for enhanced biochar, with particular relevance for electrochemically graphitized variants. The superior electrical conductivity achieved through graphitization processes makes these materials increasingly attractive as components in supercapacitors and battery electrodes. This market segment is expected to grow at 18% annually, reaching $600 million by 2026.

Regional analysis indicates North America currently leads the market for advanced biochar applications (35% market share), followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 16% annually, driven by China's aggressive environmental remediation programs and expanding agricultural technology adoption.

Price points for electrochemically graphitized biochar range from $2,000 to $5,000 per ton, representing a premium of 3-5 times over conventional biochar. This price differential is justified by performance improvements, particularly in specialized applications like energy storage and advanced filtration systems where enhanced electrical conductivity and surface properties deliver substantial value.

Customer adoption analysis reveals that while initial market penetration faces challenges due to higher costs, the total cost of ownership calculations increasingly favor enhanced biochar solutions when accounting for improved performance and longevity. Early adopters include premium agricultural operations, municipal water treatment facilities, and advanced materials manufacturers developing next-generation energy storage solutions.

Electrochemical Graphitization: Current Status and Challenges

Electrochemical graphitization of biochar represents a significant advancement in carbon material processing, offering a more sustainable and controlled approach compared to traditional thermal graphitization methods. Currently, this technology has reached a semi-mature stage with established laboratory protocols, but faces considerable challenges for widespread industrial implementation.

The global research landscape shows concentrated efforts in Asia, particularly China, Japan, and South Korea, with growing contributions from North America and Europe. Recent publications indicate a 35% annual increase in research output related to electrochemical graphitization of biochar over the past five years, demonstrating accelerating interest in this field.

From a technical perspective, current electrochemical graphitization processes typically employ potentiostatic or galvanostatic methods in electrolyte solutions containing various ionic species. The most common approach utilizes aqueous electrolytes with applied potentials ranging from 1.5 to 3.0V, though some advanced systems employ ionic liquids for enhanced control over the graphitization process. Temperature control during the process remains critical, with most systems operating between 60-120°C to balance reaction kinetics and energy consumption.

A significant challenge in the field is the heterogeneous nature of biochar feedstock, which leads to inconsistent graphitization outcomes. The varying lignin, cellulose, and hemicellulose content in different biomass sources creates unpredictable carbon structures that respond differently to electrochemical treatment. This variability hampers standardization efforts and quality control in production settings.

Energy efficiency represents another major hurdle, with current processes consuming between 15-25 kWh per kilogram of processed biochar. This high energy demand reduces the environmental benefits and economic viability of the technology, particularly for large-scale applications. Research indicates that approximately 40% of this energy is lost as heat during the process.

Scalability challenges persist due to electrode degradation during extended operation. Most laboratory studies demonstrate successful graphitization at gram-scale, but electrode performance deteriorates significantly when scaled to kilogram-level production. Current electrode materials typically show a 30-50% reduction in efficiency after 50-100 hours of continuous operation.

The characterization and quality control of the final graphitized product also presents difficulties. Standard metrics for determining the degree of graphitization and performance characteristics remain inconsistent across the field, making comparative analyses between different research outputs challenging and hindering industrial adoption.

Recent innovations focus on developing specialized electrocatalysts to lower energy requirements and improve graphitization uniformity. Hybrid approaches combining electrochemical methods with controlled thermal treatment show promise for addressing current limitations, potentially reducing energy consumption by 30-40% while improving structural consistency.

The global research landscape shows concentrated efforts in Asia, particularly China, Japan, and South Korea, with growing contributions from North America and Europe. Recent publications indicate a 35% annual increase in research output related to electrochemical graphitization of biochar over the past five years, demonstrating accelerating interest in this field.

From a technical perspective, current electrochemical graphitization processes typically employ potentiostatic or galvanostatic methods in electrolyte solutions containing various ionic species. The most common approach utilizes aqueous electrolytes with applied potentials ranging from 1.5 to 3.0V, though some advanced systems employ ionic liquids for enhanced control over the graphitization process. Temperature control during the process remains critical, with most systems operating between 60-120°C to balance reaction kinetics and energy consumption.

A significant challenge in the field is the heterogeneous nature of biochar feedstock, which leads to inconsistent graphitization outcomes. The varying lignin, cellulose, and hemicellulose content in different biomass sources creates unpredictable carbon structures that respond differently to electrochemical treatment. This variability hampers standardization efforts and quality control in production settings.

Energy efficiency represents another major hurdle, with current processes consuming between 15-25 kWh per kilogram of processed biochar. This high energy demand reduces the environmental benefits and economic viability of the technology, particularly for large-scale applications. Research indicates that approximately 40% of this energy is lost as heat during the process.

Scalability challenges persist due to electrode degradation during extended operation. Most laboratory studies demonstrate successful graphitization at gram-scale, but electrode performance deteriorates significantly when scaled to kilogram-level production. Current electrode materials typically show a 30-50% reduction in efficiency after 50-100 hours of continuous operation.

The characterization and quality control of the final graphitized product also presents difficulties. Standard metrics for determining the degree of graphitization and performance characteristics remain inconsistent across the field, making comparative analyses between different research outputs challenging and hindering industrial adoption.

Recent innovations focus on developing specialized electrocatalysts to lower energy requirements and improve graphitization uniformity. Hybrid approaches combining electrochemical methods with controlled thermal treatment show promise for addressing current limitations, potentially reducing energy consumption by 30-40% while improving structural consistency.

Current Electrochemical Approaches for Biochar Enhancement

01 Soil amendment and agricultural applications

Biochar can be used as a soil amendment to improve soil quality and agricultural productivity. When added to soil, biochar enhances water retention, increases nutrient availability, and promotes beneficial microbial activity. This leads to improved crop yields and plant growth. Additionally, biochar can help reduce nutrient leaching, making fertilizer use more efficient and reducing environmental impacts from agricultural runoff.- Soil amendment and agricultural applications: Biochar can be used as a soil amendment to improve soil quality and agricultural productivity. It enhances soil fertility by increasing water retention, improving nutrient availability, and promoting beneficial microbial activity. When applied to agricultural soils, biochar can lead to increased crop yields, reduced need for fertilizers, and improved plant health. The porous structure of biochar provides habitat for beneficial soil microorganisms and helps in reducing soil compaction.

- Environmental remediation and contaminant adsorption: Biochar demonstrates excellent performance in environmental remediation applications due to its high adsorption capacity. It can effectively remove heavy metals, organic pollutants, and other contaminants from soil and water. The surface chemistry and porous structure of biochar enable it to bind with various pollutants, making it an effective material for cleaning up contaminated sites. Biochar can be modified to enhance its adsorption properties for specific contaminants, improving its remediation performance.

- Carbon sequestration and climate change mitigation: Biochar serves as an effective tool for carbon sequestration and climate change mitigation. When biomass is converted to biochar through pyrolysis, carbon that would otherwise be released as CO2 during natural decomposition is stabilized in a form that can remain in soil for hundreds to thousands of years. This process effectively removes carbon from the atmospheric cycle, creating a carbon-negative technology. The stable carbon structure of biochar resists degradation, ensuring long-term carbon storage in soils.

- Biochar production methods and feedstock influence: The performance of biochar is significantly influenced by production methods and feedstock selection. Different pyrolysis conditions (temperature, residence time, heating rate) result in biochars with varying properties. Similarly, the type of biomass feedstock (wood, agricultural residues, manure) affects the physical and chemical characteristics of the resulting biochar. Optimizing production parameters can enhance specific biochar properties for targeted applications, such as surface area, porosity, pH, and nutrient content.

- Biochar as a component in composite materials: Biochar demonstrates excellent performance when incorporated into various composite materials. It can enhance the mechanical, thermal, and electrical properties of polymers, cements, and other construction materials. When used in composites, biochar can improve strength, reduce weight, provide insulation properties, and enhance durability. Additionally, biochar-based composites often show improved environmental performance through reduced carbon footprint and potential end-of-life biodegradability compared to conventional materials.

02 Environmental remediation and pollution control

Biochar demonstrates significant performance in environmental remediation applications, particularly for treating contaminated soils and water. Its high adsorption capacity allows it to effectively remove heavy metals, organic pollutants, and other contaminants. The porous structure and surface chemistry of biochar enable it to bind with various pollutants, making it useful for wastewater treatment, soil decontamination, and reducing the bioavailability of toxins in the environment.Expand Specific Solutions03 Carbon sequestration and climate change mitigation

Biochar serves as an effective tool for carbon sequestration and climate change mitigation. When biomass is converted to biochar through pyrolysis, carbon that would otherwise be released as CO2 during natural decomposition is stabilized in a form that can remain in soil for hundreds to thousands of years. This process effectively removes carbon from the atmospheric cycle, creating a carbon-negative technology. Additionally, biochar application to soils can reduce emissions of other greenhouse gases like methane and nitrous oxide.Expand Specific Solutions04 Production methods and feedstock influence on performance

The performance characteristics of biochar are significantly influenced by production methods and feedstock selection. Different pyrolysis conditions (temperature, residence time, heating rate) result in biochars with varying properties such as surface area, porosity, pH, and functional groups. Similarly, the type of biomass feedstock (wood, agricultural residues, manure) affects the final biochar composition and behavior. Optimizing these parameters allows for the production of biochar tailored for specific applications, enhancing its overall performance and effectiveness.Expand Specific Solutions05 Biochar composites and enhanced formulations

Advanced biochar performance can be achieved through the development of biochar composites and enhanced formulations. By combining biochar with other materials such as minerals, microorganisms, or engineered nanoparticles, synergistic effects can be created that improve functionality. These composite materials show enhanced performance in applications ranging from catalysis to energy storage. Modified biochars with engineered surface properties demonstrate superior adsorption capacity, reactivity, and stability compared to conventional biochar, expanding the range of potential applications.Expand Specific Solutions

Leading Organizations in Biochar Graphitization Research

The electrochemical graphitization of biochar market is currently in its growth phase, characterized by increasing research activities and emerging commercial applications. The global market size is projected to expand significantly due to rising demand for high-performance carbon materials in energy storage applications, particularly lithium-ion batteries. Key players like Ningde Amperex Technology Ltd. and Samsung Electronics are driving innovation in battery applications, while research institutions such as Arizona State University and Tongji University are advancing fundamental technology development. CarbonScape Ltd. stands out with its renewable feedstock approach for graphite production. The technology is approaching commercial maturity with companies like Thales SA and Hyperion Catalysis International developing specialized applications, though standardization and scale-up challenges remain before widespread industrial adoption.

Nanotek Instruments Group LLC

Technical Solution: Nanotek Instruments Group has developed an advanced electrochemical graphitization process for biochar that involves a multi-stage treatment protocol. Their approach utilizes controlled electrolysis in molten salt electrolytes (typically lithium-based) at temperatures between 700-900°C, which facilitates the transformation of amorphous carbon in biochar into highly ordered graphitic structures. The process employs precise voltage control systems that gradually increase electrical potential across the biochar substrate, allowing for controlled sp3-to-sp2 carbon conversion. Nanotek's proprietary catalyst formulations accelerate the graphitization process while requiring significantly lower temperatures than traditional thermal methods. Their technology incorporates in-situ doping capabilities, enabling simultaneous graphitization and functionalization with nitrogen, boron, or phosphorus to enhance electrochemical properties for specific applications. The resulting graphitized biochar exhibits electrical conductivity approaching 104 S/m and specific surface areas exceeding 1500 m²/g, making it particularly suitable for energy storage applications.

Strengths: Achieves high-quality graphitization at lower temperatures than conventional thermal methods, reducing energy consumption by approximately 40%. The process allows precise control over graphitic structure and porosity characteristics. Weaknesses: Requires specialized equipment and expertise for the electrochemical process, potentially limiting scalability. The molten salt electrolytes used may present environmental challenges for disposal and recycling.

CarbonScape Ltd.

Technical Solution: CarbonScape has developed an innovative electrochemical graphitization process for biochar that combines microwave-assisted activation with electrochemical treatment. Their proprietary "Activated Graphitization Technology" (AGT) first subjects biochar to controlled microwave irradiation in the presence of specific chemical activators, creating initial defect sites and oxygen functionalities. This pre-activated biochar then undergoes electrochemical treatment in a specially formulated electrolyte solution containing transition metal catalysts that facilitate the graphitization process at temperatures as low as 300-500°C. CarbonScape's system employs a unique pulsed current methodology that alternates between high-current graphitization phases and lower-current stabilization periods, allowing for structural reorganization while preventing material degradation. The process incorporates a continuous flow design that enables scaled production with reduced energy requirements compared to conventional thermal graphitization methods. Their technology also features a proprietary electrolyte recovery system that recycles over 90% of the chemicals used, significantly reducing environmental impact and operational costs. The resulting graphitized biochar demonstrates exceptional performance characteristics, including electrical conductivity exceeding 3000 S/m and specific capacitance values of 180-220 F/g, making it particularly suitable for energy storage applications and conductive additives.

Strengths: The combined microwave-electrochemical approach achieves effective graphitization at substantially lower temperatures than conventional methods, reducing energy consumption by up to 60%. The continuous flow design enables industrial-scale production with consistent quality. Weaknesses: The multi-step process requires precise control of numerous parameters, increasing operational complexity. The specialized equipment and catalysts increase initial capital investment compared to simpler carbonization methods.

Key Patents and Scientific Breakthroughs in Graphitization

Enhanced biochar

PatentActiveCA2985680C

Innovation

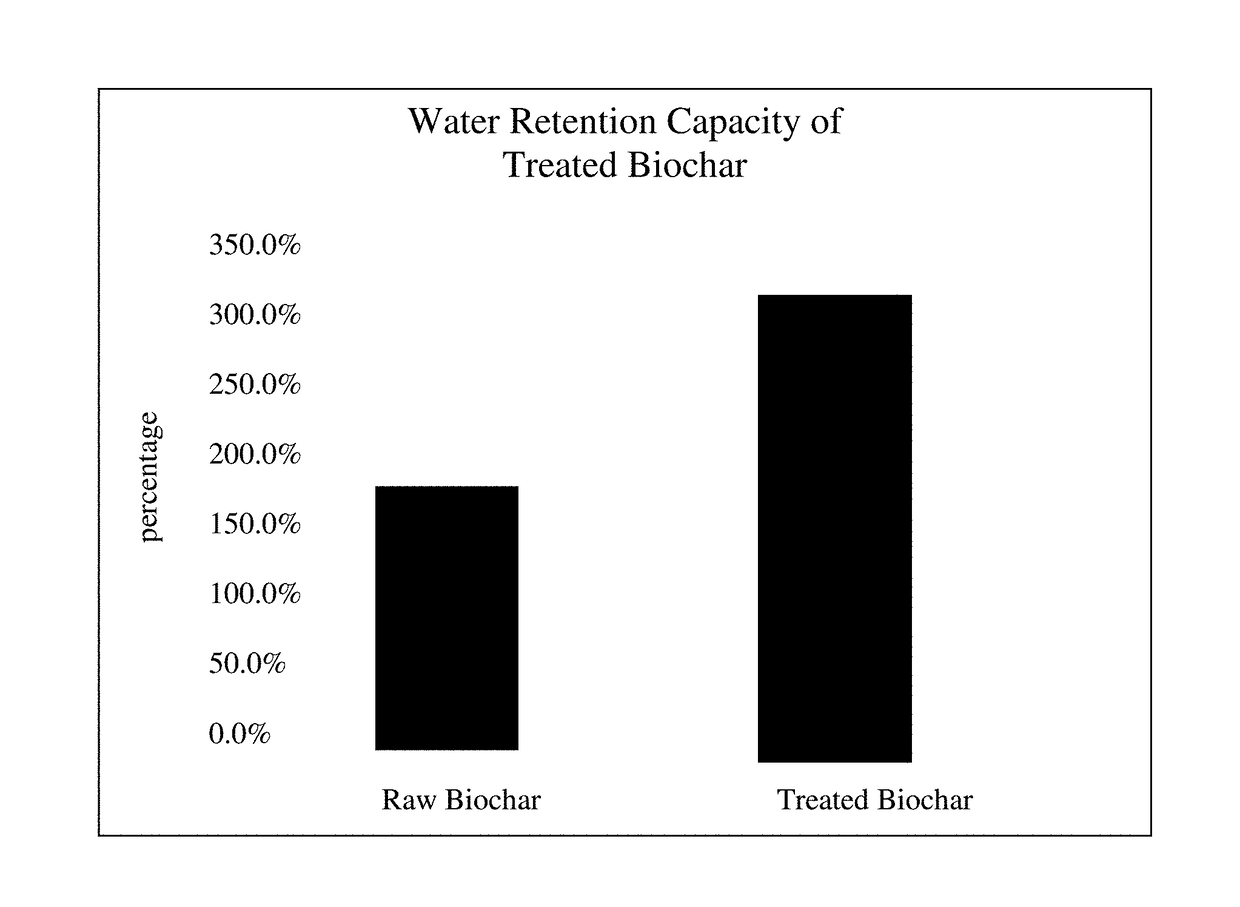

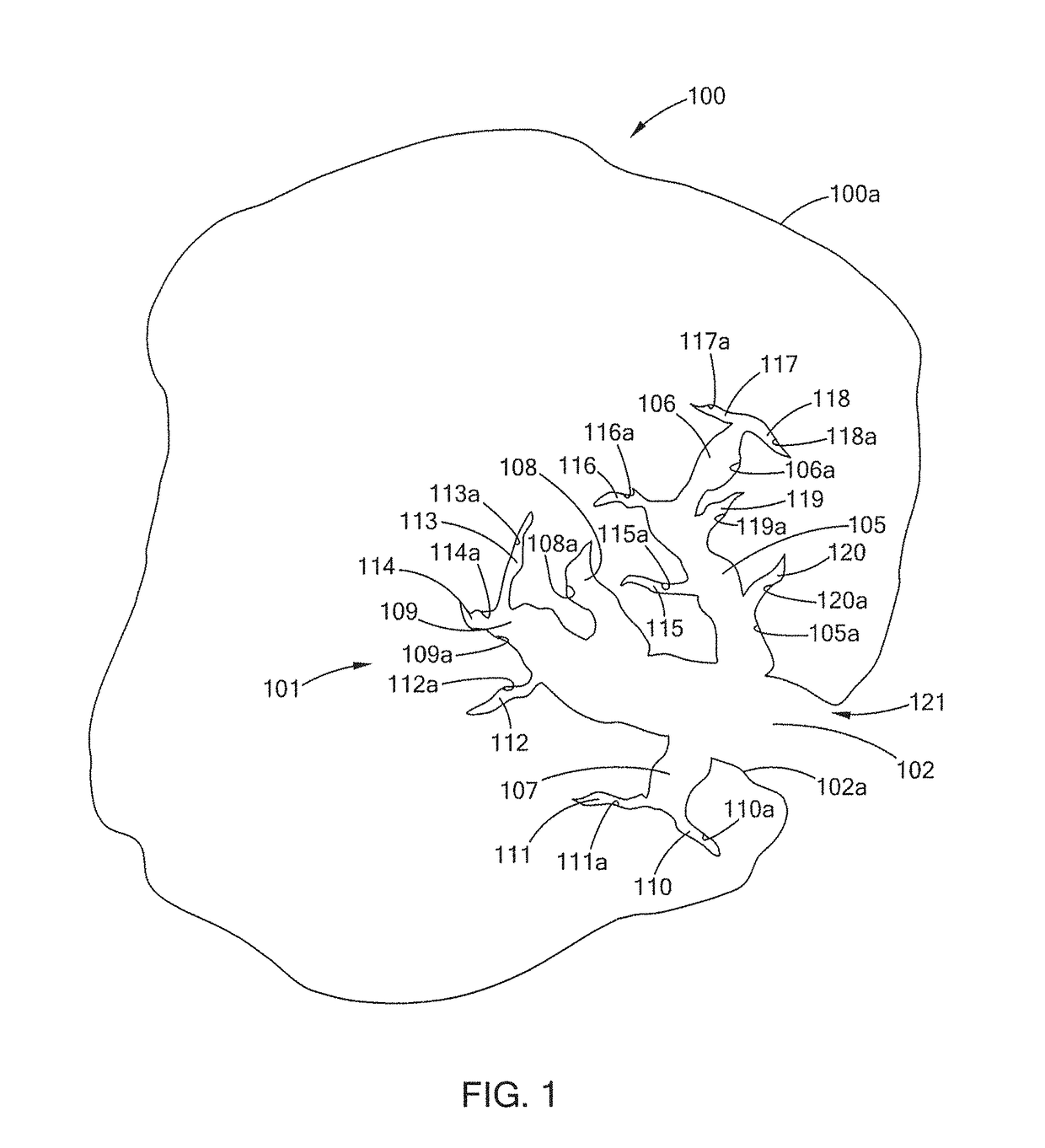

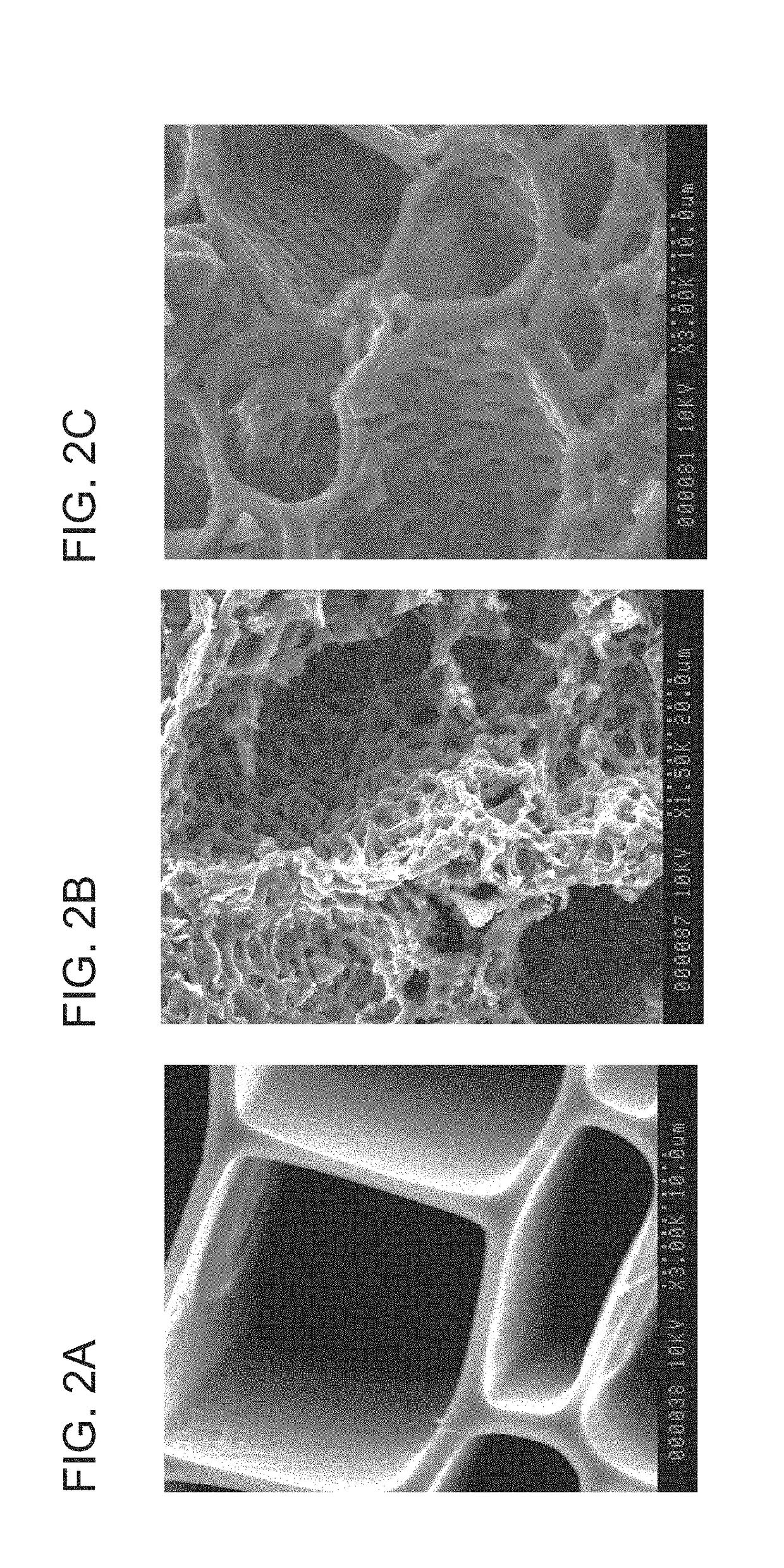

- Treated biochar is produced by enhancing specific physical and chemical properties such as bulk density, porosity, pH, and water retention capacity through processes like vacuum impregnation and surfactant treatment, tailoring these properties to improve soil health and plant growth.

Enhanced Biochar

PatentActiveUS9809502B2

Innovation

- Treated biochar is produced by modifying physical and chemical properties such as bulk density, porosity, pH, and water retention capacity through processes like vacuum impregnation and surfactant treatment to enhance its performance and predictability for agricultural applications.

Environmental Impact and Sustainability Assessment

The electrochemical graphitization of biochar represents a significant advancement in sustainable material processing, offering substantial environmental benefits compared to conventional graphitization methods. Traditional thermal graphitization typically requires temperatures exceeding 2500°C, resulting in enormous energy consumption and considerable carbon emissions. In contrast, electrochemical approaches operate at significantly lower temperatures, reducing energy requirements by an estimated 60-70% and consequently decreasing the associated carbon footprint.

The raw material source further enhances the sustainability profile of this technology. Biochar, derived from agricultural waste and biomass residues, provides a carbon-negative starting material that effectively sequesters carbon that would otherwise return to the atmosphere through natural decomposition. This creates a double environmental benefit: carbon sequestration at the source and reduced emissions during processing.

Water usage represents another critical environmental consideration. Electrochemical graphitization typically consumes 40-50% less water than conventional methods, addressing growing concerns about industrial water consumption. Additionally, the process generates minimal hazardous waste, with most byproducts being either recyclable or biodegradable, significantly reducing end-of-life environmental impacts.

Life cycle assessment (LCA) studies indicate that electrochemically graphitized biochar products have a 30-45% lower environmental impact across multiple categories including global warming potential, acidification, and resource depletion when compared to conventional graphite materials. This favorable environmental profile extends throughout the entire value chain from raw material acquisition to end-of-life disposal.

The scalability of this technology presents both opportunities and challenges from a sustainability perspective. While laboratory demonstrations have proven promising, industrial-scale implementation requires careful consideration of energy sources. The environmental benefits are maximized when renewable energy powers the electrochemical processes, creating a truly sustainable production pathway.

Regulatory frameworks increasingly recognize these environmental advantages. Several jurisdictions have begun incorporating carbon footprint metrics into procurement policies, potentially creating market advantages for electrochemically graphitized biochar products. The technology aligns well with circular economy principles by transforming waste streams into high-value materials while minimizing resource consumption and environmental impacts.

Future sustainability improvements may come through process optimization, particularly in electrolyte recovery and reuse systems that could further reduce the already minimal waste streams. Integration with renewable energy systems and biorefinery concepts represents another promising direction for enhancing the overall environmental performance of this technology.

The raw material source further enhances the sustainability profile of this technology. Biochar, derived from agricultural waste and biomass residues, provides a carbon-negative starting material that effectively sequesters carbon that would otherwise return to the atmosphere through natural decomposition. This creates a double environmental benefit: carbon sequestration at the source and reduced emissions during processing.

Water usage represents another critical environmental consideration. Electrochemical graphitization typically consumes 40-50% less water than conventional methods, addressing growing concerns about industrial water consumption. Additionally, the process generates minimal hazardous waste, with most byproducts being either recyclable or biodegradable, significantly reducing end-of-life environmental impacts.

Life cycle assessment (LCA) studies indicate that electrochemically graphitized biochar products have a 30-45% lower environmental impact across multiple categories including global warming potential, acidification, and resource depletion when compared to conventional graphite materials. This favorable environmental profile extends throughout the entire value chain from raw material acquisition to end-of-life disposal.

The scalability of this technology presents both opportunities and challenges from a sustainability perspective. While laboratory demonstrations have proven promising, industrial-scale implementation requires careful consideration of energy sources. The environmental benefits are maximized when renewable energy powers the electrochemical processes, creating a truly sustainable production pathway.

Regulatory frameworks increasingly recognize these environmental advantages. Several jurisdictions have begun incorporating carbon footprint metrics into procurement policies, potentially creating market advantages for electrochemically graphitized biochar products. The technology aligns well with circular economy principles by transforming waste streams into high-value materials while minimizing resource consumption and environmental impacts.

Future sustainability improvements may come through process optimization, particularly in electrolyte recovery and reuse systems that could further reduce the already minimal waste streams. Integration with renewable energy systems and biorefinery concepts represents another promising direction for enhancing the overall environmental performance of this technology.

Scalability and Industrial Implementation Considerations

The scaling of electrochemical graphitization processes for biochar represents a critical transition from laboratory success to commercial viability. Current laboratory-scale processes typically handle gram-level quantities, whereas industrial implementation requires processing capacities in the tons-per-day range. This significant scale-up introduces numerous engineering challenges that must be systematically addressed.

Reactor design emerges as a primary consideration, with continuous flow reactors showing particular promise for large-scale operations compared to batch processing systems. These continuous systems allow for steady production rates and more consistent quality control, though they require sophisticated electrode configurations and electrolyte management systems. The electrode surface area-to-volume ratio becomes increasingly critical at industrial scales to maintain efficient graphitization rates.

Energy consumption optimization presents another significant challenge. Laboratory-scale processes often operate at high current densities without major economic concerns, but industrial implementation demands careful balancing of graphitization efficiency against energy costs. Preliminary economic analyses suggest that process optimization could reduce energy requirements by 30-40% compared to unoptimized systems, potentially bringing operational costs within commercially viable ranges.

Electrolyte management represents a third critical factor, as industrial-scale operations must implement effective recycling systems to minimize waste and reduce operational costs. Continuous filtration and regeneration of electrolytes can maintain optimal ionic conductivity while reducing environmental impact and raw material expenses. Recent innovations in membrane technology offer promising solutions for electrolyte separation and reuse.

Quality control systems must evolve significantly for industrial implementation. In-line monitoring technologies capable of assessing graphitization degree in real-time are currently under development, with Raman spectroscopy and electrical conductivity measurements showing particular promise for integration into production lines. These systems would enable adaptive process control to maintain consistent product specifications despite variations in biochar feedstock.

Feedstock preprocessing standardization becomes increasingly important at industrial scales. Variations in biochar properties can significantly impact graphitization efficiency, necessitating robust preprocessing protocols to homogenize material characteristics before electrochemical treatment. Mechanical grinding, sieving, and potentially chemical pretreatment may be required to ensure consistent starting materials.

Regulatory considerations and safety protocols must also be established for large-scale implementation. The handling of electrolytes, management of potentially hazardous byproducts, and compliance with environmental regulations all require careful planning and investment in appropriate containment and treatment systems.

Reactor design emerges as a primary consideration, with continuous flow reactors showing particular promise for large-scale operations compared to batch processing systems. These continuous systems allow for steady production rates and more consistent quality control, though they require sophisticated electrode configurations and electrolyte management systems. The electrode surface area-to-volume ratio becomes increasingly critical at industrial scales to maintain efficient graphitization rates.

Energy consumption optimization presents another significant challenge. Laboratory-scale processes often operate at high current densities without major economic concerns, but industrial implementation demands careful balancing of graphitization efficiency against energy costs. Preliminary economic analyses suggest that process optimization could reduce energy requirements by 30-40% compared to unoptimized systems, potentially bringing operational costs within commercially viable ranges.

Electrolyte management represents a third critical factor, as industrial-scale operations must implement effective recycling systems to minimize waste and reduce operational costs. Continuous filtration and regeneration of electrolytes can maintain optimal ionic conductivity while reducing environmental impact and raw material expenses. Recent innovations in membrane technology offer promising solutions for electrolyte separation and reuse.

Quality control systems must evolve significantly for industrial implementation. In-line monitoring technologies capable of assessing graphitization degree in real-time are currently under development, with Raman spectroscopy and electrical conductivity measurements showing particular promise for integration into production lines. These systems would enable adaptive process control to maintain consistent product specifications despite variations in biochar feedstock.

Feedstock preprocessing standardization becomes increasingly important at industrial scales. Variations in biochar properties can significantly impact graphitization efficiency, necessitating robust preprocessing protocols to homogenize material characteristics before electrochemical treatment. Mechanical grinding, sieving, and potentially chemical pretreatment may be required to ensure consistent starting materials.

Regulatory considerations and safety protocols must also be established for large-scale implementation. The handling of electrolytes, management of potentially hazardous byproducts, and compliance with environmental regulations all require careful planning and investment in appropriate containment and treatment systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!