Binderless Electrodes Using Highly Conductive Biochar Structures

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biochar Electrode Technology Background and Objectives

Biochar, a carbon-rich material produced through the pyrolysis of biomass under limited oxygen conditions, has emerged as a promising sustainable material for various applications. The evolution of biochar technology can be traced back to ancient agricultural practices, but its modern scientific exploration began in the late 20th century with the discovery of Terra Preta soils in the Amazon Basin, which contained high amounts of charcoal and exhibited exceptional fertility.

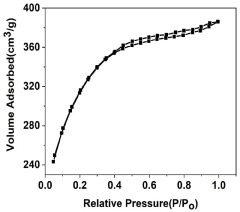

In recent years, biochar research has expanded beyond agricultural applications into energy storage and conversion systems. The inherent properties of biochar—high surface area, tunable porosity, electrical conductivity, and chemical stability—have positioned it as an attractive candidate for electrode materials in energy storage devices such as supercapacitors, batteries, and fuel cells.

Traditional electrode manufacturing processes typically require binders to maintain structural integrity, which often compromises electrical conductivity and adds complexity to production. The concept of binderless electrodes using highly conductive biochar structures represents a significant technological advancement that aims to overcome these limitations by eliminating the need for binders while maintaining or enhancing electrode performance.

The technical evolution trend in this field is moving toward precise control of biochar properties through advanced pyrolysis techniques, feedstock selection, and post-treatment methods. Researchers are increasingly focusing on tailoring biochar's physical and chemical characteristics to optimize its electrical conductivity, which is crucial for electrode applications.

The primary technical objectives in developing binderless biochar electrodes include: achieving high electrical conductivity comparable to conventional carbon materials; creating self-supporting structures with mechanical stability; developing scalable and cost-effective production methods; and ensuring environmental sustainability throughout the material lifecycle.

Another important goal is to understand the fundamental structure-property relationships in biochar materials, particularly how processing conditions affect the graphitization degree, pore structure, and surface functionality, which in turn influence the electrochemical performance of the resulting electrodes.

The integration of biochar electrodes into commercial energy storage devices represents a convergence of renewable material science and clean energy technology, aligning with global sustainability goals. This technology has the potential to reduce the environmental footprint of energy storage systems while potentially improving their performance and reducing costs.

As research progresses, the field is expected to move toward multifunctional biochar electrodes that not only store or convert energy efficiently but also offer additional benefits such as self-healing capabilities, flexibility for wearable electronics, or integration with biological systems for bioelectronic applications.

In recent years, biochar research has expanded beyond agricultural applications into energy storage and conversion systems. The inherent properties of biochar—high surface area, tunable porosity, electrical conductivity, and chemical stability—have positioned it as an attractive candidate for electrode materials in energy storage devices such as supercapacitors, batteries, and fuel cells.

Traditional electrode manufacturing processes typically require binders to maintain structural integrity, which often compromises electrical conductivity and adds complexity to production. The concept of binderless electrodes using highly conductive biochar structures represents a significant technological advancement that aims to overcome these limitations by eliminating the need for binders while maintaining or enhancing electrode performance.

The technical evolution trend in this field is moving toward precise control of biochar properties through advanced pyrolysis techniques, feedstock selection, and post-treatment methods. Researchers are increasingly focusing on tailoring biochar's physical and chemical characteristics to optimize its electrical conductivity, which is crucial for electrode applications.

The primary technical objectives in developing binderless biochar electrodes include: achieving high electrical conductivity comparable to conventional carbon materials; creating self-supporting structures with mechanical stability; developing scalable and cost-effective production methods; and ensuring environmental sustainability throughout the material lifecycle.

Another important goal is to understand the fundamental structure-property relationships in biochar materials, particularly how processing conditions affect the graphitization degree, pore structure, and surface functionality, which in turn influence the electrochemical performance of the resulting electrodes.

The integration of biochar electrodes into commercial energy storage devices represents a convergence of renewable material science and clean energy technology, aligning with global sustainability goals. This technology has the potential to reduce the environmental footprint of energy storage systems while potentially improving their performance and reducing costs.

As research progresses, the field is expected to move toward multifunctional biochar electrodes that not only store or convert energy efficiently but also offer additional benefits such as self-healing capabilities, flexibility for wearable electronics, or integration with biological systems for bioelectronic applications.

Market Analysis for Binderless Electrode Applications

The global market for binderless electrodes using highly conductive biochar structures is experiencing significant growth, driven by increasing demand for sustainable energy storage solutions. The market size for advanced electrode materials was valued at approximately $5.6 billion in 2022 and is projected to reach $12.3 billion by 2030, with binderless biochar electrodes representing an emerging segment with substantial growth potential.

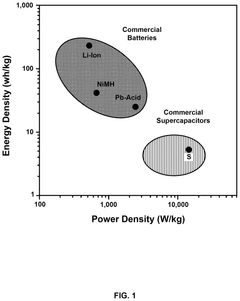

Energy storage applications currently dominate the market landscape, with supercapacitors and lithium-ion batteries being the primary beneficiaries of binderless biochar electrode technology. The supercapacitor market specifically is growing at a CAGR of 21.8% and is expected to reach $16.95 billion by 2027, creating substantial opportunities for advanced electrode materials.

Geographically, Asia-Pacific leads the market with over 45% share, driven by extensive manufacturing capabilities in China, South Korea, and Japan. North America follows with approximately 30% market share, bolstered by significant research investments and growing adoption of renewable energy technologies. Europe accounts for about 20% of the market, with particularly strong growth in Germany and Scandinavian countries due to aggressive climate policies.

By application segment, electronics represents the largest current market at 38%, followed by automotive applications at 27%, renewable energy storage at 22%, and industrial applications at 13%. The automotive sector is experiencing the fastest growth rate as electric vehicle production accelerates globally, creating increased demand for high-performance, sustainable electrode materials.

Key market drivers include stringent environmental regulations promoting sustainable materials, increasing demand for high-performance energy storage solutions, and growing research funding for green technologies. The cost advantage of biochar-based materials, derived from waste biomass, provides a compelling economic incentive as raw material costs for traditional electrode materials continue to rise.

Market challenges include scaling production processes to industrial levels, ensuring consistent quality across batches, and competing with established electrode technologies. Additionally, lack of standardization in biochar production and characterization presents barriers to widespread commercial adoption.

Consumer electronics manufacturers are increasingly seeking sustainable components, creating a rapidly expanding niche market for binderless biochar electrodes in portable devices. This segment is expected to grow at 24.3% annually through 2028, outpacing the broader market.

Energy storage applications currently dominate the market landscape, with supercapacitors and lithium-ion batteries being the primary beneficiaries of binderless biochar electrode technology. The supercapacitor market specifically is growing at a CAGR of 21.8% and is expected to reach $16.95 billion by 2027, creating substantial opportunities for advanced electrode materials.

Geographically, Asia-Pacific leads the market with over 45% share, driven by extensive manufacturing capabilities in China, South Korea, and Japan. North America follows with approximately 30% market share, bolstered by significant research investments and growing adoption of renewable energy technologies. Europe accounts for about 20% of the market, with particularly strong growth in Germany and Scandinavian countries due to aggressive climate policies.

By application segment, electronics represents the largest current market at 38%, followed by automotive applications at 27%, renewable energy storage at 22%, and industrial applications at 13%. The automotive sector is experiencing the fastest growth rate as electric vehicle production accelerates globally, creating increased demand for high-performance, sustainable electrode materials.

Key market drivers include stringent environmental regulations promoting sustainable materials, increasing demand for high-performance energy storage solutions, and growing research funding for green technologies. The cost advantage of biochar-based materials, derived from waste biomass, provides a compelling economic incentive as raw material costs for traditional electrode materials continue to rise.

Market challenges include scaling production processes to industrial levels, ensuring consistent quality across batches, and competing with established electrode technologies. Additionally, lack of standardization in biochar production and characterization presents barriers to widespread commercial adoption.

Consumer electronics manufacturers are increasingly seeking sustainable components, creating a rapidly expanding niche market for binderless biochar electrodes in portable devices. This segment is expected to grow at 24.3% annually through 2028, outpacing the broader market.

Current Challenges in Conductive Biochar Development

Despite significant advancements in biochar-based electrode development, several critical challenges persist in creating highly conductive binderless biochar structures. The primary obstacle remains achieving consistently high electrical conductivity across different biochar batches. Current production methods yield biochar with conductivity values ranging from 10-200 S/m, whereas commercial applications typically require minimum conductivity of 500 S/m. This variability stems from inconsistent carbonization processes and feedstock heterogeneity.

Temperature control during pyrolysis presents another significant challenge. Research indicates that optimal electrical properties develop at temperatures between 700-900°C, but maintaining precise temperature profiles throughout large biochar samples remains difficult with current technology. Temperature gradients within production vessels lead to inconsistent graphitization and consequently variable conductivity across the final product.

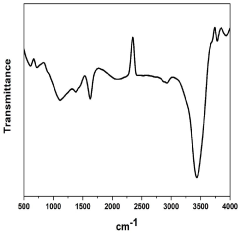

Surface functionality control represents a third major hurdle. While certain oxygen-containing functional groups can enhance specific electrochemical properties, they often reduce overall electrical conductivity. Researchers struggle to develop methods that selectively maintain beneficial functional groups while eliminating those that impede electron transfer. Current chemical and thermal activation techniques lack the precision needed for this selective functionalization.

Scalability issues further complicate commercial viability. Laboratory-scale production methods that yield highly conductive biochar often fail to translate to industrial scales. The complex relationship between reactor design, heat transfer dynamics, and resulting biochar properties creates significant engineering challenges when scaling up production volumes from grams to kilograms or tons.

Mechanical stability presents another persistent challenge. Binderless electrodes must maintain structural integrity during operation, but highly conductive biochar often exhibits brittleness and poor mechanical properties. Without traditional polymer binders, these electrodes can experience significant degradation during cycling, particularly in applications involving volume changes or mechanical stress.

Reproducibility remains problematic across the field. Published studies frequently report exceptional conductivity values but fail to provide sufficiently detailed methodologies to enable replication. This knowledge gap hinders systematic improvement and standardization of production techniques.

Finally, characterization methods for conductive biochar lack standardization. Different measurement techniques and sample preparation methods yield varying conductivity values for identical materials, making cross-study comparisons difficult and slowing collective progress in the field. Establishing standardized testing protocols represents a crucial step toward addressing this challenge.

Temperature control during pyrolysis presents another significant challenge. Research indicates that optimal electrical properties develop at temperatures between 700-900°C, but maintaining precise temperature profiles throughout large biochar samples remains difficult with current technology. Temperature gradients within production vessels lead to inconsistent graphitization and consequently variable conductivity across the final product.

Surface functionality control represents a third major hurdle. While certain oxygen-containing functional groups can enhance specific electrochemical properties, they often reduce overall electrical conductivity. Researchers struggle to develop methods that selectively maintain beneficial functional groups while eliminating those that impede electron transfer. Current chemical and thermal activation techniques lack the precision needed for this selective functionalization.

Scalability issues further complicate commercial viability. Laboratory-scale production methods that yield highly conductive biochar often fail to translate to industrial scales. The complex relationship between reactor design, heat transfer dynamics, and resulting biochar properties creates significant engineering challenges when scaling up production volumes from grams to kilograms or tons.

Mechanical stability presents another persistent challenge. Binderless electrodes must maintain structural integrity during operation, but highly conductive biochar often exhibits brittleness and poor mechanical properties. Without traditional polymer binders, these electrodes can experience significant degradation during cycling, particularly in applications involving volume changes or mechanical stress.

Reproducibility remains problematic across the field. Published studies frequently report exceptional conductivity values but fail to provide sufficiently detailed methodologies to enable replication. This knowledge gap hinders systematic improvement and standardization of production techniques.

Finally, characterization methods for conductive biochar lack standardization. Different measurement techniques and sample preparation methods yield varying conductivity values for identical materials, making cross-study comparisons difficult and slowing collective progress in the field. Establishing standardized testing protocols represents a crucial step toward addressing this challenge.

Current Binderless Electrode Manufacturing Approaches

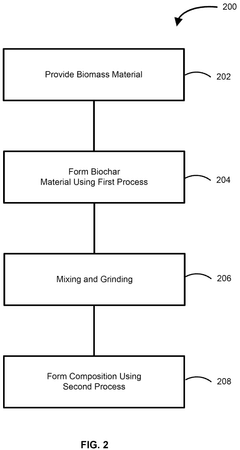

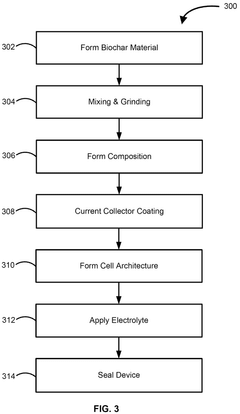

01 Biochar-based binderless electrodes with enhanced conductivity

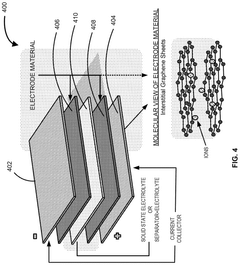

Biochar structures can be used to create binderless electrodes with enhanced electrical conductivity. These electrodes are manufactured by processing biomass-derived carbon materials at specific temperatures to optimize their conductive properties. The absence of binders improves electron transfer and increases the effective surface area, resulting in superior electrochemical performance compared to conventional electrodes.- Biochar-based binderless electrodes with enhanced conductivity: Biochar structures can be used to create binderless electrodes with enhanced electrical conductivity. The inherent porous structure and carbon content of biochar provide natural conductive pathways, eliminating the need for traditional binders. These electrodes demonstrate improved electron transfer capabilities and reduced internal resistance, making them suitable for various electrochemical applications. The conductivity can be further enhanced through activation processes that increase surface area and pore development.

- Pyrolysis conditions for optimizing biochar conductivity: The electrical conductivity of binderless biochar electrodes can be significantly influenced by pyrolysis conditions. Parameters such as temperature, heating rate, and residence time during the carbonization process affect the graphitization degree and structural ordering of the resulting biochar. Higher pyrolysis temperatures typically yield biochar with improved conductivity due to increased aromaticity and reduced functional groups. Controlled pyrolysis conditions can produce biochar with tailored conductive properties suitable for specific electrode applications.

- Surface modification techniques for biochar conductivity enhancement: Various surface modification techniques can be employed to enhance the conductivity of binderless biochar electrodes. These include chemical activation with agents like KOH or H3PO4, acid/base treatments, and doping with heteroatoms such as nitrogen or phosphorus. Surface functionalization can create additional electron pathways, reduce contact resistance, and improve the overall electrochemical performance. Modified biochar structures exhibit higher conductivity and improved stability in electrochemical systems without requiring conventional binders.

- Composite biochar structures for advanced electrode applications: Composite structures combining biochar with other conductive materials can create high-performance binderless electrodes. Incorporating materials such as graphene, carbon nanotubes, or conductive polymers into biochar matrices enhances electron transfer and creates synergistic effects. These composite structures maintain the binderless advantage while significantly improving conductivity and electrochemical performance. The hierarchical pore structure of such composites facilitates ion transport and increases the accessible surface area for electrochemical reactions.

- Applications of binderless biochar electrodes in energy storage devices: Binderless biochar electrodes with enhanced conductivity find applications in various energy storage devices such as supercapacitors, batteries, and fuel cells. The absence of binders increases the active material content and improves the electrode-electrolyte interface, resulting in higher energy and power densities. These electrodes demonstrate excellent cycling stability and rate capability due to their robust structure and efficient electron transport pathways. The sustainable nature of biochar-based electrodes also offers environmental advantages over conventional electrode materials.

02 Surface modification techniques for biochar conductivity enhancement

Various surface modification techniques can be applied to biochar structures to enhance their electrical conductivity for binderless electrode applications. These include chemical activation, physical activation, and doping with heteroatoms. Such modifications create more conductive pathways within the biochar structure, optimize pore distribution, and introduce functional groups that facilitate electron transfer.Expand Specific Solutions03 Pyrolysis conditions affecting biochar electrode conductivity

The pyrolysis conditions used during biochar production significantly impact the conductivity of resulting binderless electrodes. Parameters such as temperature, heating rate, residence time, and atmosphere (inert or reducing) determine the graphitization degree, pore structure, and conductive properties of the biochar. Optimized pyrolysis conditions can produce biochar with higher carbon content and more ordered structures that exhibit enhanced electrical conductivity.Expand Specific Solutions04 Biomass source selection for conductive biochar electrodes

The selection of biomass feedstock significantly influences the conductivity of binderless biochar electrodes. Different biomass sources contain varying amounts of carbon, minerals, and other elements that affect the final electrode properties. Lignocellulosic materials with high carbon content and low ash typically yield biochar with better conductivity. Specific agricultural wastes, wood residues, and specialized biomass can be selected to optimize the conductive properties of the resulting biochar electrodes.Expand Specific Solutions05 Composite biochar structures for enhanced electrode performance

Composite biochar structures can be developed by incorporating other conductive materials to enhance the performance of binderless electrodes. These composites may include combinations of biochar with graphene, carbon nanotubes, conductive polymers, or metal nanoparticles. The resulting hybrid materials exhibit synergistic effects that improve electrical conductivity, mechanical stability, and electrochemical performance while maintaining the binderless nature of the electrode structure.Expand Specific Solutions

Leading Organizations in Conductive Biochar Research

Binderless electrodes using highly conductive biochar structures represent an emerging technology at the intersection of renewable energy and advanced materials. The market is in its early growth phase, with increasing interest driven by sustainability demands and energy storage needs. Key players include established corporations like Toray Industries and Medtronic, alongside innovative startups such as Florrent, Inc. and Cambrian Innovation. Academic institutions, particularly University of Wollongong and Washington University in St. Louis, are contributing significant research advancements. The technology is approaching commercial viability, with companies like Biotectix and CATL (Ningde Amperex) exploring applications in medical devices and energy storage. The global market shows promising growth potential as industries seek more sustainable electrode materials with reduced environmental impact.

University of Wollongong

Technical Solution: University of Wollongong has pioneered innovative approaches to binderless electrodes using highly conductive biochar structures. Their research team has developed a process that converts biomass waste into high-performance carbon electrodes through controlled pyrolysis at temperatures between 700-900°C, followed by activation processes that enhance surface area and conductivity. Their proprietary technique creates self-supporting biochar structures with conductivity exceeding 200 S/cm without requiring traditional polymer binders. The university has demonstrated these electrodes in supercapacitors achieving energy densities of 8-12 Wh/kg while maintaining power densities above 5 kW/kg. Their biochar electrodes feature hierarchical pore structures that facilitate rapid ion transport while maintaining mechanical integrity during charge-discharge cycles.

Strengths: Exceptional sustainability credentials using waste biomass feedstocks; superior cycle stability (>10,000 cycles with <5% capacity loss); elimination of PVDF and other fluorinated binders reduces environmental impact. Weaknesses: Scale-up challenges for industrial production; variability in performance depending on biomass source; lower volumetric energy density compared to some conventional electrode materials.

Sichuan University

Technical Solution: Sichuan University has developed an advanced approach to binderless biochar electrodes through their proprietary "self-activation" technique. Their method involves a one-step pyrolysis process of biomass precursors (primarily agricultural wastes like rice husks and corn stalks) under precisely controlled conditions with catalytic additives that simultaneously create porous structures and enhance conductivity. The resulting biochar exhibits electrical conductivity of 150-180 S/cm with specific surface areas reaching 1200-1500 m²/g. Their electrodes demonstrate exceptional electrochemical performance with capacitance retention of over 95% after 5,000 cycles. The university has also pioneered composite biochar structures incorporating nitrogen and phosphorus dopants that further enhance electron transfer capabilities while maintaining mechanical integrity without traditional binders.

Strengths: Cost-effective single-step production process; excellent utilization of regional agricultural waste streams; superior rate capability for high-power applications. Weaknesses: Limited mechanical strength under extreme conditions; challenges in achieving uniform quality across large production batches; potential for metal contaminants from catalytic additives.

Key Patents in Highly Conductive Biochar Structures

Biomass-based method and composition

PatentActiveUS12110456B2

Innovation

- The development of biomass-based electrode compositions formed using biochar and activation compounds like fungi and silicaceous materials, which are pyrolyzed to create high-surface-area carbon without the need for additional binders, enhancing energy and power density while being environmentally friendly.

Functionalized biochar composition and method for preparation thereof

PatentPendingIN202111036876A

Innovation

- A functionalized biochar composition is developed by chemically activating desmostachya leaves extract with zinc chloride and copper oxide, creating a porous material with improved wettability and structural strength, which is then carbonized to produce a high-surface-area electrode material.

Sustainability Impact of Biochar Electrode Technologies

The adoption of biochar electrode technologies represents a significant advancement in sustainable energy storage systems, offering substantial environmental benefits across multiple dimensions. The production of biochar from biomass waste materials creates a circular economy pathway that diverts agricultural and forestry residues from landfills or incineration, reducing waste management burdens and associated greenhouse gas emissions.

When compared to conventional electrode materials, biochar-based electrodes demonstrate a markedly lower carbon footprint. Life cycle assessments indicate that biochar electrode production can reduce carbon emissions by 40-60% compared to traditional carbon-based electrodes, primarily due to the carbon sequestration properties inherent in the biochar production process. This carbon negativity potential positions biochar electrodes as a climate change mitigation technology.

Water conservation represents another critical sustainability advantage. Traditional electrode manufacturing processes typically require substantial water usage for processing and purification. In contrast, biochar electrode production, particularly binderless approaches, can reduce water consumption by up to 70%, addressing growing concerns about industrial water usage in regions facing water scarcity.

The elimination of synthetic binders in binderless biochar electrodes further enhances their environmental profile by removing petroleum-derived polymers from the production chain. This reduces dependence on fossil resources and eliminates potential toxic emissions associated with binder decomposition during electrode recycling or disposal phases.

From a resource efficiency perspective, biochar electrodes leverage locally available biomass feedstocks, reducing transportation emissions and supporting regional economic development. The diversity of potential feedstocks—ranging from agricultural residues to food processing wastes—provides flexibility and resilience in supply chains while creating value from materials previously considered waste.

End-of-life considerations also favor biochar electrode technologies. Unlike conventional electrodes that may contain heavy metals or toxic components requiring specialized disposal, biochar electrodes can potentially be recycled into soil amendments after their useful life in energy storage applications, completing a truly circular material journey.

Economic analyses suggest that as production scales increase, biochar electrode technologies could achieve cost parity with conventional alternatives while delivering superior sustainability metrics. This economic viability, coupled with environmental benefits, positions biochar electrodes as a promising technology for meeting the growing demand for sustainable energy storage solutions in a carbon-constrained future.

When compared to conventional electrode materials, biochar-based electrodes demonstrate a markedly lower carbon footprint. Life cycle assessments indicate that biochar electrode production can reduce carbon emissions by 40-60% compared to traditional carbon-based electrodes, primarily due to the carbon sequestration properties inherent in the biochar production process. This carbon negativity potential positions biochar electrodes as a climate change mitigation technology.

Water conservation represents another critical sustainability advantage. Traditional electrode manufacturing processes typically require substantial water usage for processing and purification. In contrast, biochar electrode production, particularly binderless approaches, can reduce water consumption by up to 70%, addressing growing concerns about industrial water usage in regions facing water scarcity.

The elimination of synthetic binders in binderless biochar electrodes further enhances their environmental profile by removing petroleum-derived polymers from the production chain. This reduces dependence on fossil resources and eliminates potential toxic emissions associated with binder decomposition during electrode recycling or disposal phases.

From a resource efficiency perspective, biochar electrodes leverage locally available biomass feedstocks, reducing transportation emissions and supporting regional economic development. The diversity of potential feedstocks—ranging from agricultural residues to food processing wastes—provides flexibility and resilience in supply chains while creating value from materials previously considered waste.

End-of-life considerations also favor biochar electrode technologies. Unlike conventional electrodes that may contain heavy metals or toxic components requiring specialized disposal, biochar electrodes can potentially be recycled into soil amendments after their useful life in energy storage applications, completing a truly circular material journey.

Economic analyses suggest that as production scales increase, biochar electrode technologies could achieve cost parity with conventional alternatives while delivering superior sustainability metrics. This economic viability, coupled with environmental benefits, positions biochar electrodes as a promising technology for meeting the growing demand for sustainable energy storage solutions in a carbon-constrained future.

Scalability and Cost Analysis of Binderless Biochar Electrodes

The scalability of binderless biochar electrodes represents a critical factor in their potential for widespread commercial adoption. Current production methods primarily operate at laboratory scale, with batch sizes typically ranging from 5-50 grams. Scaling to industrial levels presents several engineering challenges, particularly in maintaining consistent material properties across larger production volumes. Continuous flow pyrolysis systems show promise for scaling production, with theoretical throughput capacities of 100-500 kg/day, though these systems require significant capital investment ranging from $500,000 to $2 million for initial setup.

Cost analysis reveals that raw material sourcing constitutes 15-30% of total production expenses, with biomass feedstock costs varying significantly ($50-200/ton) depending on source and quality. The energy-intensive pyrolysis process accounts for 30-45% of production costs, requiring temperatures between 600-900°C maintained for 1-3 hours. Current production costs for high-quality binderless biochar electrodes range from $80-150/kg at laboratory scale, significantly higher than conventional carbon electrodes ($20-40/kg).

Economic modeling suggests that scaling production could reduce costs by 40-60% through economies of scale, with the break-even point occurring at approximately 500-1000 kg monthly production. The elimination of binders provides a 15-25% cost advantage by removing both material costs and processing steps associated with binder application and curing.

Environmental cost-benefit analysis demonstrates additional economic advantages through carbon sequestration benefits, with each kilogram of biochar potentially sequestering 2.5-3 kg of CO₂ equivalent. This could translate to carbon credits valued at $5-15 per kilogram of electrode material, depending on carbon market pricing.

Market entry strategies should focus initially on high-value niche applications where performance benefits justify premium pricing, such as specialized energy storage systems and environmental remediation technologies. As production scales and costs decrease, broader market penetration becomes economically viable, particularly in grid-scale energy storage applications where cost sensitivity is high.

The technology readiness level (TRL) for binderless biochar electrodes currently stands at 4-5, indicating validation in laboratory and limited field environments. Advancement to TRL 7-9 requires demonstration of cost-effective scaling strategies and long-term performance validation in real-world applications, estimated to require 2-3 years of focused development with appropriate investment.

Cost analysis reveals that raw material sourcing constitutes 15-30% of total production expenses, with biomass feedstock costs varying significantly ($50-200/ton) depending on source and quality. The energy-intensive pyrolysis process accounts for 30-45% of production costs, requiring temperatures between 600-900°C maintained for 1-3 hours. Current production costs for high-quality binderless biochar electrodes range from $80-150/kg at laboratory scale, significantly higher than conventional carbon electrodes ($20-40/kg).

Economic modeling suggests that scaling production could reduce costs by 40-60% through economies of scale, with the break-even point occurring at approximately 500-1000 kg monthly production. The elimination of binders provides a 15-25% cost advantage by removing both material costs and processing steps associated with binder application and curing.

Environmental cost-benefit analysis demonstrates additional economic advantages through carbon sequestration benefits, with each kilogram of biochar potentially sequestering 2.5-3 kg of CO₂ equivalent. This could translate to carbon credits valued at $5-15 per kilogram of electrode material, depending on carbon market pricing.

Market entry strategies should focus initially on high-value niche applications where performance benefits justify premium pricing, such as specialized energy storage systems and environmental remediation technologies. As production scales and costs decrease, broader market penetration becomes economically viable, particularly in grid-scale energy storage applications where cost sensitivity is high.

The technology readiness level (TRL) for binderless biochar electrodes currently stands at 4-5, indicating validation in laboratory and limited field environments. Advancement to TRL 7-9 requires demonstration of cost-effective scaling strategies and long-term performance validation in real-world applications, estimated to require 2-3 years of focused development with appropriate investment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!