Electrode Coating Techniques For High-Biochar Content Slurries

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biochar Electrode Coating Background and Objectives

Biochar, a carbon-rich material produced through pyrolysis of biomass, has emerged as a promising sustainable electrode material for energy storage applications. The evolution of biochar utilization in electrochemical systems can be traced back to early research on carbon-based electrodes in the 1990s, with significant acceleration in the past decade due to increasing focus on renewable energy solutions and circular economy principles.

The technical trajectory of biochar electrode development has progressed from basic carbonaceous material applications to sophisticated engineered electrodes with tailored properties. Initially, biochar was primarily considered as an economic alternative to activated carbon, but recent research has revealed its unique advantages including hierarchical porosity, heteroatom doping potential, and sustainable production pathways.

Current technical trends indicate a growing interest in high-biochar content electrodes to maximize sustainability benefits while maintaining or enhancing electrochemical performance. This represents a paradigm shift from traditional approaches where biochar was used as a minor additive rather than a primary component in electrode formulations.

The primary technical objective of developing advanced coating techniques for high-biochar content slurries is to overcome the inherent challenges associated with biochar's physical and chemical properties. These include variable particle morphology, hydrophobicity, poor dispersion stability, and limited electrical conductivity compared to synthetic carbon materials.

Specifically, this research aims to establish reproducible and scalable methods for preparing homogeneous electrode slurries with biochar content exceeding 70% by weight, while maintaining adequate rheological properties for conventional coating processes. The target applications encompass supercapacitors, lithium-ion batteries, and emerging energy storage technologies where sustainable materials can provide competitive advantages.

Secondary objectives include optimizing binder interactions with biochar surfaces, enhancing the electrical connectivity between biochar particles, and developing pre-treatment methods to standardize biochar properties across different feedstocks and production conditions. These improvements are essential for transitioning biochar electrodes from laboratory curiosities to commercially viable products.

The long-term technical vision encompasses the development of fully bio-derived electrode systems where biochar serves as the primary active material, complemented by bio-based binders and environmentally benign processing methods. This aligns with global sustainability goals and the increasing regulatory pressure to reduce the environmental footprint of energy storage technologies throughout their lifecycle.

The technical trajectory of biochar electrode development has progressed from basic carbonaceous material applications to sophisticated engineered electrodes with tailored properties. Initially, biochar was primarily considered as an economic alternative to activated carbon, but recent research has revealed its unique advantages including hierarchical porosity, heteroatom doping potential, and sustainable production pathways.

Current technical trends indicate a growing interest in high-biochar content electrodes to maximize sustainability benefits while maintaining or enhancing electrochemical performance. This represents a paradigm shift from traditional approaches where biochar was used as a minor additive rather than a primary component in electrode formulations.

The primary technical objective of developing advanced coating techniques for high-biochar content slurries is to overcome the inherent challenges associated with biochar's physical and chemical properties. These include variable particle morphology, hydrophobicity, poor dispersion stability, and limited electrical conductivity compared to synthetic carbon materials.

Specifically, this research aims to establish reproducible and scalable methods for preparing homogeneous electrode slurries with biochar content exceeding 70% by weight, while maintaining adequate rheological properties for conventional coating processes. The target applications encompass supercapacitors, lithium-ion batteries, and emerging energy storage technologies where sustainable materials can provide competitive advantages.

Secondary objectives include optimizing binder interactions with biochar surfaces, enhancing the electrical connectivity between biochar particles, and developing pre-treatment methods to standardize biochar properties across different feedstocks and production conditions. These improvements are essential for transitioning biochar electrodes from laboratory curiosities to commercially viable products.

The long-term technical vision encompasses the development of fully bio-derived electrode systems where biochar serves as the primary active material, complemented by bio-based binders and environmentally benign processing methods. This aligns with global sustainability goals and the increasing regulatory pressure to reduce the environmental footprint of energy storage technologies throughout their lifecycle.

Market Analysis for Biochar-Based Electrodes

The global market for biochar-based electrodes is experiencing significant growth, driven by increasing demand for sustainable energy storage solutions and environmental remediation technologies. Current market valuations indicate that biochar-based electrode applications reached approximately 320 million USD in 2022, with projections suggesting a compound annual growth rate of 14.7% through 2028. This growth trajectory is primarily fueled by expanding applications in supercapacitors, batteries, and environmental sensing technologies.

Energy storage represents the largest market segment for biochar-based electrodes, accounting for roughly 45% of total market share. Within this segment, supercapacitors are emerging as the fastest-growing application due to biochar's high surface area, electrical conductivity, and cost-effectiveness compared to traditional activated carbon materials. The renewable energy sector's expansion has created substantial demand for efficient energy storage solutions, positioning biochar-based electrodes as an attractive alternative to conventional materials.

Environmental remediation applications constitute the second-largest market segment at approximately 30% market share. Biochar-based electrodes are increasingly utilized in electrochemical water treatment systems, soil remediation technologies, and environmental monitoring devices. Their ability to adsorb contaminants while facilitating electrochemical reactions makes them particularly valuable for addressing complex environmental challenges.

Regionally, North America and Europe currently dominate the market with combined market share exceeding 60%. This dominance stems from stringent environmental regulations, substantial research funding, and growing adoption of renewable energy technologies. However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years, driven by rapid industrialization, increasing environmental concerns, and government initiatives promoting sustainable technologies.

Key customer segments include energy storage manufacturers, environmental technology companies, research institutions, and government agencies focused on sustainability initiatives. The industrial sector represents approximately 35% of end-users, followed by the research and development sector at 25%, and environmental services at 20%.

Market challenges include scaling production processes for consistent electrode quality, optimizing biochar properties for specific applications, and competing with established carbon materials. Despite these challenges, the growing emphasis on circular economy principles and carbon sequestration benefits provides biochar-based electrodes with significant competitive advantages in sustainability-focused markets.

Consumer trends indicate increasing preference for environmentally responsible technologies with reduced carbon footprints, creating favorable market conditions for biochar-derived products. This shift in consumer behavior, coupled with tightening environmental regulations worldwide, suggests continued market expansion for biochar-based electrode technologies across multiple industry sectors.

Energy storage represents the largest market segment for biochar-based electrodes, accounting for roughly 45% of total market share. Within this segment, supercapacitors are emerging as the fastest-growing application due to biochar's high surface area, electrical conductivity, and cost-effectiveness compared to traditional activated carbon materials. The renewable energy sector's expansion has created substantial demand for efficient energy storage solutions, positioning biochar-based electrodes as an attractive alternative to conventional materials.

Environmental remediation applications constitute the second-largest market segment at approximately 30% market share. Biochar-based electrodes are increasingly utilized in electrochemical water treatment systems, soil remediation technologies, and environmental monitoring devices. Their ability to adsorb contaminants while facilitating electrochemical reactions makes them particularly valuable for addressing complex environmental challenges.

Regionally, North America and Europe currently dominate the market with combined market share exceeding 60%. This dominance stems from stringent environmental regulations, substantial research funding, and growing adoption of renewable energy technologies. However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years, driven by rapid industrialization, increasing environmental concerns, and government initiatives promoting sustainable technologies.

Key customer segments include energy storage manufacturers, environmental technology companies, research institutions, and government agencies focused on sustainability initiatives. The industrial sector represents approximately 35% of end-users, followed by the research and development sector at 25%, and environmental services at 20%.

Market challenges include scaling production processes for consistent electrode quality, optimizing biochar properties for specific applications, and competing with established carbon materials. Despite these challenges, the growing emphasis on circular economy principles and carbon sequestration benefits provides biochar-based electrodes with significant competitive advantages in sustainability-focused markets.

Consumer trends indicate increasing preference for environmentally responsible technologies with reduced carbon footprints, creating favorable market conditions for biochar-derived products. This shift in consumer behavior, coupled with tightening environmental regulations worldwide, suggests continued market expansion for biochar-based electrode technologies across multiple industry sectors.

Technical Challenges in High-Biochar Slurry Processing

The processing of high-biochar content slurries for electrode coating presents significant technical challenges that must be addressed to achieve optimal performance. The primary obstacle lies in the rheological properties of these slurries, which exhibit non-Newtonian behavior characterized by high viscosity and yield stress. This behavior becomes increasingly problematic as biochar content increases, creating difficulties in achieving uniform dispersion and preventing agglomeration of particles.

Particle size distribution represents another critical challenge, as biochar typically contains a wide range of particle sizes and irregular morphologies. These characteristics can lead to inconsistent coating thickness, poor adhesion to current collectors, and potential cracking during drying processes. The heterogeneous nature of biochar, with varying degrees of porosity and surface functionality depending on feedstock and pyrolysis conditions, further complicates slurry formulation.

Surface chemistry interactions between biochar particles and binder materials present additional complexities. The hydrophobic nature of many biochar varieties can result in poor wetting and inadequate binding, necessitating careful selection of compatible binders and dispersants. Furthermore, the high surface area of biochar particles tends to absorb significant amounts of solvent and binder, requiring precise formulation adjustments to maintain proper rheological properties.

Scalability issues emerge when transitioning from laboratory-scale to industrial production. Conventional coating equipment designed for traditional electrode materials often struggles with high-biochar content slurries due to their unique flow properties. Specialized mixing and coating equipment may be necessary, potentially increasing production costs and complexity.

Stability concerns also plague high-biochar slurries, as they tend to exhibit sedimentation and phase separation during storage. This necessitates either immediate use after preparation or the development of effective stabilization strategies to maintain homogeneity over time.

The drying and curing processes for high-biochar electrodes require careful optimization to prevent cracking, delamination, or uneven shrinkage. The porous nature of biochar can trap solvents, leading to longer drying times or defects in the final electrode structure if drying parameters are not properly controlled.

Environmental and safety considerations must also be addressed, as fine biochar particles can pose respiratory hazards during handling and processing. Additionally, depending on the solvent system used, VOC emissions during drying may require mitigation strategies to comply with environmental regulations.

Addressing these technical challenges requires interdisciplinary approaches combining expertise in materials science, colloid chemistry, and process engineering to develop innovative solutions for effective electrode manufacturing with high-biochar content slurries.

Particle size distribution represents another critical challenge, as biochar typically contains a wide range of particle sizes and irregular morphologies. These characteristics can lead to inconsistent coating thickness, poor adhesion to current collectors, and potential cracking during drying processes. The heterogeneous nature of biochar, with varying degrees of porosity and surface functionality depending on feedstock and pyrolysis conditions, further complicates slurry formulation.

Surface chemistry interactions between biochar particles and binder materials present additional complexities. The hydrophobic nature of many biochar varieties can result in poor wetting and inadequate binding, necessitating careful selection of compatible binders and dispersants. Furthermore, the high surface area of biochar particles tends to absorb significant amounts of solvent and binder, requiring precise formulation adjustments to maintain proper rheological properties.

Scalability issues emerge when transitioning from laboratory-scale to industrial production. Conventional coating equipment designed for traditional electrode materials often struggles with high-biochar content slurries due to their unique flow properties. Specialized mixing and coating equipment may be necessary, potentially increasing production costs and complexity.

Stability concerns also plague high-biochar slurries, as they tend to exhibit sedimentation and phase separation during storage. This necessitates either immediate use after preparation or the development of effective stabilization strategies to maintain homogeneity over time.

The drying and curing processes for high-biochar electrodes require careful optimization to prevent cracking, delamination, or uneven shrinkage. The porous nature of biochar can trap solvents, leading to longer drying times or defects in the final electrode structure if drying parameters are not properly controlled.

Environmental and safety considerations must also be addressed, as fine biochar particles can pose respiratory hazards during handling and processing. Additionally, depending on the solvent system used, VOC emissions during drying may require mitigation strategies to comply with environmental regulations.

Addressing these technical challenges requires interdisciplinary approaches combining expertise in materials science, colloid chemistry, and process engineering to develop innovative solutions for effective electrode manufacturing with high-biochar content slurries.

Current Slurry Formulation and Coating Methods

01 Electrochemical deposition techniques

Electrochemical deposition is a widely used technique for electrode coating that involves the use of electrical current to reduce metal ions in a solution onto a conductive substrate. This process allows for precise control of coating thickness and composition, resulting in high-quality electrode coatings. Various parameters such as current density, electrolyte composition, and deposition time can be optimized to enhance coating quality and adhesion to the substrate.- Physical vapor deposition techniques for electrode coatings: Physical vapor deposition (PVD) techniques such as sputtering and evaporation are used to create high-quality electrode coatings with precise thickness control. These methods involve depositing thin films of conductive materials onto electrode substrates under vacuum conditions. PVD techniques allow for excellent adhesion, uniformity, and purity of the coating, which are critical factors for electrode performance and durability.

- Chemical vapor deposition methods for enhanced coating quality: Chemical vapor deposition (CVD) methods involve chemical reactions of gaseous reactants on or near the substrate surface to form a solid coating. These techniques produce highly conformal electrode coatings with excellent adhesion and can be used to deposit a wide range of materials including metals, ceramics, and composites. Modified CVD processes such as plasma-enhanced CVD offer improved control over coating microstructure and properties, resulting in higher quality electrode coatings with better electrical performance.

- Solution-based coating techniques for electrodes: Solution-based coating methods including sol-gel processing, dip coating, spin coating, and spray coating provide cost-effective approaches for electrode coating. These techniques involve applying liquid precursors that transform into solid coatings through chemical reactions or solvent evaporation. They allow for precise control of coating composition and thickness, and can be used to create functional electrode coatings with tailored properties. The quality of these coatings can be optimized by controlling solution chemistry, deposition parameters, and post-deposition treatments.

- Quality assessment and control methods for electrode coatings: Various techniques are employed to assess and control the quality of electrode coatings, including surface analysis methods, electrochemical testing, and mechanical property evaluation. These methods help to identify defects, measure thickness uniformity, evaluate adhesion strength, and assess electrical performance. Real-time monitoring during the coating process allows for immediate adjustments to process parameters, ensuring consistent coating quality. Post-production quality control procedures help to identify and eliminate defective electrodes before they reach end-use applications.

- Advanced electrode coating materials and composites: Novel materials and composite formulations are being developed to enhance electrode coating performance and quality. These include nanostructured materials, conductive polymers, ceramic-metal composites, and carbon-based materials such as graphene. These advanced materials offer improved electrical conductivity, mechanical stability, and electrochemical performance. Multi-layer and gradient coatings combine different materials to achieve synergistic properties that cannot be obtained with single-material coatings, resulting in electrodes with superior performance characteristics.

02 Physical vapor deposition methods

Physical vapor deposition (PVD) techniques, including sputtering and thermal evaporation, are employed for creating high-quality electrode coatings. These methods involve the vaporization of coating materials in a vacuum environment and their subsequent condensation onto the substrate surface. PVD techniques offer excellent control over coating thickness and uniformity, resulting in dense, pure coatings with superior adhesion properties and electrical conductivity for electrode applications.Expand Specific Solutions03 Chemical vapor deposition processes

Chemical vapor deposition (CVD) processes involve the reaction of gaseous precursors on a heated substrate surface to form a solid coating. This technique allows for the creation of highly uniform and conformal electrode coatings, even on complex geometries. By carefully controlling reaction parameters such as temperature, pressure, and gas flow rates, high-quality coatings with excellent adhesion and desired electrical properties can be achieved for various electrode applications.Expand Specific Solutions04 Sol-gel coating techniques

Sol-gel coating techniques involve the transformation of a solution (sol) into a gel-like network that can be applied to electrode surfaces. This method allows for precise control of coating composition at the molecular level and can be used to create porous or dense coatings depending on processing conditions. Sol-gel techniques are particularly valuable for creating functional electrode coatings with tailored properties such as specific catalytic activity, controlled porosity, and enhanced durability for electrochemical applications.Expand Specific Solutions05 Quality assessment and control methods

Various methods are employed to assess and control the quality of electrode coatings, including surface analysis techniques, electrochemical testing, and mechanical property evaluation. These methods help ensure coating uniformity, adhesion strength, and functional performance. Advanced characterization techniques such as scanning electron microscopy, X-ray diffraction, and impedance spectroscopy are used to analyze coating morphology, structure, and electrochemical behavior. Process monitoring and statistical quality control approaches are implemented to maintain consistent coating quality across production batches.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The electrode coating techniques for high-biochar content slurries market is in an early growth phase, with increasing interest driven by sustainable battery manufacturing demands. The global market size is expanding as battery manufacturers seek eco-friendly alternatives for electrode materials. Technologically, the field remains moderately mature with significant innovation potential. Leading players like LG Energy Solution, SK On, and Northvolt are advancing commercial applications, while established battery manufacturers including Panasonic Energy and A123 Systems are investing in R&D. Companies like VINATECH and Shanghai Aowei Technology are developing specialized coating techniques for biochar integration. The competitive landscape features both battery giants and specialized materials companies like Guangdong Fenghua Advanced Technology, indicating a diversifying market with opportunities for technical differentiation.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed advanced electrode coating techniques specifically designed for high-biochar content slurries in lithium-ion battery production. Their proprietary "Bio-Slurry Coating System" incorporates a multi-stage mixing process that effectively disperses biochar particles within the electrode slurry while maintaining optimal viscosity for coating applications. The technology employs specialized binders and dispersants that create strong adhesion between biochar particles and active materials, preventing agglomeration during the coating process. Their system includes precision-controlled doctor blade coating with real-time viscosity monitoring that automatically adjusts coating parameters to accommodate the unique rheological properties of biochar-rich slurries. Additionally, they've implemented a gradual drying protocol that prevents cracking in high-biochar content electrodes by controlling moisture evaporation rates across the electrode surface.

Strengths: Superior dispersion of biochar particles resulting in uniform electrode surfaces; adaptive coating parameters that respond to viscosity changes in real-time; excellent adhesion between biochar and active materials. Weaknesses: Higher processing costs compared to conventional coating methods; requires specialized equipment that may limit manufacturing flexibility; longer processing times needed for optimal biochar integration.

GM Global Technology Operations LLC

Technical Solution: GM Global Technology Operations has developed the "EcoCote" electrode manufacturing system specifically for high-biochar content slurries used in next-generation energy storage devices. Their approach begins with a proprietary biochar pre-processing technique that optimizes particle morphology and surface chemistry for electrode applications. The EcoCote system employs a sequential mixing protocol that incorporates biochar in multiple stages while applying controlled acoustic energy to break up agglomerates without compromising the carbon structure. GM's technology features specialized water-based binder systems that create strong interfacial adhesion with biochar particles while maintaining environmentally friendly processing. Their coating equipment incorporates precision-controlled comma bar applicators with dynamic gap adjustment capabilities that respond to the unique rheological properties of biochar-rich slurries. Additionally, GM has developed an adaptive drying system that continuously monitors moisture content across the electrode and adjusts drying parameters in real-time to prevent defect formation. The EcoCote process also includes a specialized calendering step with variable pressure zones designed to optimize the microstructure of biochar-enhanced electrodes.

Strengths: Environmentally friendly water-based processing compatible with high biochar content; excellent coating uniformity and adhesion; optimized microstructure for enhanced electrochemical performance. Weaknesses: Slower processing speeds compared to conventional electrode manufacturing; requires tight control of ambient conditions during processing; higher complexity in quality control monitoring.

Key Patents in Biochar Electrode Coating

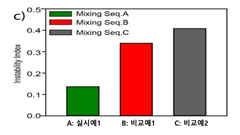

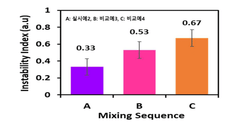

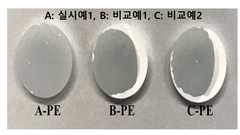

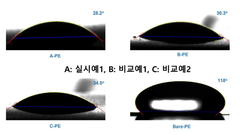

Manufacturing Method of Coating slurry and Electrode slurry according to mixing sequence for high-performance battery component materials

PatentPendingKR1020240001058A

Innovation

- A method for manufacturing coating and electrode material slurries involving sequential addition of surfactants, inorganic particles, and binders in specific ratios and solvents to enhance dispersion stability and wettability, using SiO2, AlOOH, and other inorganic particles, and binders like polyvinylidene fluoride, polyacrylic acid, and conductive materials like graphite to stabilize silicon electrodes.

Method for preparation of secondary battery electrode slurry

PatentPendingEP4576233A1

Innovation

- A method involving the use of an extruder to simultaneously knead and convey raw materials, including an electrode active material, conductive agent, and thickener, with controlled solvent addition to achieve a high solid content and manageable viscosity, allowing for continuous slurry preparation.

Sustainability Impact Assessment

The implementation of high-biochar content slurries in electrode coating techniques presents significant sustainability advantages across environmental, economic, and social dimensions. From an environmental perspective, biochar utilization represents a carbon-negative approach, as it effectively sequesters carbon that would otherwise be released into the atmosphere through natural decomposition or incineration of biomass. When incorporated into electrodes, biochar derived from agricultural waste or forestry residues creates a circular economy pathway that reduces waste while providing functional materials for energy storage applications.

The greenhouse gas emission reductions associated with biochar-based electrodes are substantial when compared to conventional carbon materials. Life cycle assessments indicate potential carbon dioxide equivalent reductions of 2-5 tons per ton of biochar utilized, depending on feedstock source and processing methods. Additionally, the production process for biochar-enhanced electrodes typically requires lower temperatures than traditional carbon material synthesis, resulting in reduced energy consumption during manufacturing.

Water conservation represents another critical sustainability benefit. Traditional electrode slurry preparation often involves environmentally problematic solvents, whereas biochar-based formulations can be optimized for aqueous processing, reducing both toxic emissions and water contamination risks. Field studies demonstrate up to 40% reduction in hazardous waste generation when implementing biochar-based electrode coating techniques.

From an economic sustainability perspective, the utilization of agricultural and forestry waste streams as biochar feedstock creates new value chains for previously underutilized resources. This approach can generate supplemental income for agricultural communities while simultaneously reducing waste management costs. The localization potential of biochar production further enhances economic sustainability by reducing transportation emissions and creating regional manufacturing opportunities.

Social sustainability benefits include improved working conditions through reduced exposure to toxic solvents during electrode manufacturing. The development of biochar supply chains also creates opportunities for skill development in rural communities, particularly in regions with abundant biomass resources. Implementation of these technologies can support just transition initiatives in communities previously dependent on fossil fuel extraction or processing.

Long-term sustainability impacts extend to resource conservation, as biochar-based electrodes reduce dependence on mineral-based carbons that require energy-intensive mining operations. The renewable nature of biomass feedstocks ensures supply chain resilience against resource depletion concerns that affect conventional battery materials. When integrated into comprehensive sustainability frameworks, high-biochar content electrode technologies align with multiple United Nations Sustainable Development Goals, particularly those related to climate action, responsible consumption, and sustainable industrialization.

The greenhouse gas emission reductions associated with biochar-based electrodes are substantial when compared to conventional carbon materials. Life cycle assessments indicate potential carbon dioxide equivalent reductions of 2-5 tons per ton of biochar utilized, depending on feedstock source and processing methods. Additionally, the production process for biochar-enhanced electrodes typically requires lower temperatures than traditional carbon material synthesis, resulting in reduced energy consumption during manufacturing.

Water conservation represents another critical sustainability benefit. Traditional electrode slurry preparation often involves environmentally problematic solvents, whereas biochar-based formulations can be optimized for aqueous processing, reducing both toxic emissions and water contamination risks. Field studies demonstrate up to 40% reduction in hazardous waste generation when implementing biochar-based electrode coating techniques.

From an economic sustainability perspective, the utilization of agricultural and forestry waste streams as biochar feedstock creates new value chains for previously underutilized resources. This approach can generate supplemental income for agricultural communities while simultaneously reducing waste management costs. The localization potential of biochar production further enhances economic sustainability by reducing transportation emissions and creating regional manufacturing opportunities.

Social sustainability benefits include improved working conditions through reduced exposure to toxic solvents during electrode manufacturing. The development of biochar supply chains also creates opportunities for skill development in rural communities, particularly in regions with abundant biomass resources. Implementation of these technologies can support just transition initiatives in communities previously dependent on fossil fuel extraction or processing.

Long-term sustainability impacts extend to resource conservation, as biochar-based electrodes reduce dependence on mineral-based carbons that require energy-intensive mining operations. The renewable nature of biomass feedstocks ensures supply chain resilience against resource depletion concerns that affect conventional battery materials. When integrated into comprehensive sustainability frameworks, high-biochar content electrode technologies align with multiple United Nations Sustainable Development Goals, particularly those related to climate action, responsible consumption, and sustainable industrialization.

Scale-up Considerations for Industrial Implementation

Transitioning from laboratory-scale electrode coating processes to industrial production presents significant challenges for high-biochar content slurries. The unique rheological properties of biochar-laden slurries, characterized by their thixotropic behavior and tendency to agglomerate, necessitate specialized equipment modifications and process adaptations. Industrial implementation requires careful consideration of mixing systems capable of maintaining homogeneity across large volumes, with high-shear mixers and ultrasonic dispersion technologies showing promise for preventing biochar sedimentation during scale-up operations.

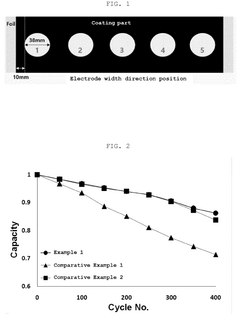

Coating uniformity becomes increasingly critical at industrial scales, where even minor variations can lead to substantial performance inconsistencies across production batches. Continuous coating processes, rather than batch operations, offer advantages for maintaining consistent quality parameters. Advanced process monitoring systems incorporating real-time viscosity measurements and optical inspection technologies enable manufacturers to detect deviations promptly and implement corrective actions before significant material waste occurs.

Energy consumption represents another crucial consideration, as the higher viscosity of biochar slurries typically demands greater power input for processing. Engineering solutions such as optimized pump designs and energy-efficient mixing technologies can mitigate these increased energy requirements. Additionally, heat management systems must be implemented to dissipate the thermal energy generated during high-volume mixing operations, preventing premature slurry degradation or solvent evaporation that could alter coating characteristics.

Material handling logistics present unique challenges for industrial biochar electrode production. The hygroscopic nature of biochar necessitates controlled environmental conditions throughout the supply chain and manufacturing process. Automated feeding systems designed specifically for high-particulate materials can ensure consistent material delivery while minimizing worker exposure to airborne particles. Closed-loop solvent recovery systems become economically viable at industrial scales, reducing environmental impact and operational costs.

Quality control protocols must evolve beyond laboratory testing methods to accommodate high-throughput production. Inline characterization techniques, including laser diffraction particle size analysis and electrical impedance measurements, can provide real-time feedback on critical quality parameters. Statistical process control methodologies tailored to biochar electrode manufacturing enable systematic identification of process drift before specification limits are exceeded, maintaining consistent product performance across production volumes.

Cost considerations ultimately determine commercial viability, with initial capital expenditure for specialized equipment balanced against operational efficiencies gained through scale. Modular production systems offer advantages for phased implementation, allowing manufacturers to validate process parameters at intermediate scales before committing to full industrial capacity. Strategic partnerships with equipment manufacturers experienced in handling challenging slurry compositions can accelerate technology transfer from laboratory to production environments.

Coating uniformity becomes increasingly critical at industrial scales, where even minor variations can lead to substantial performance inconsistencies across production batches. Continuous coating processes, rather than batch operations, offer advantages for maintaining consistent quality parameters. Advanced process monitoring systems incorporating real-time viscosity measurements and optical inspection technologies enable manufacturers to detect deviations promptly and implement corrective actions before significant material waste occurs.

Energy consumption represents another crucial consideration, as the higher viscosity of biochar slurries typically demands greater power input for processing. Engineering solutions such as optimized pump designs and energy-efficient mixing technologies can mitigate these increased energy requirements. Additionally, heat management systems must be implemented to dissipate the thermal energy generated during high-volume mixing operations, preventing premature slurry degradation or solvent evaporation that could alter coating characteristics.

Material handling logistics present unique challenges for industrial biochar electrode production. The hygroscopic nature of biochar necessitates controlled environmental conditions throughout the supply chain and manufacturing process. Automated feeding systems designed specifically for high-particulate materials can ensure consistent material delivery while minimizing worker exposure to airborne particles. Closed-loop solvent recovery systems become economically viable at industrial scales, reducing environmental impact and operational costs.

Quality control protocols must evolve beyond laboratory testing methods to accommodate high-throughput production. Inline characterization techniques, including laser diffraction particle size analysis and electrical impedance measurements, can provide real-time feedback on critical quality parameters. Statistical process control methodologies tailored to biochar electrode manufacturing enable systematic identification of process drift before specification limits are exceeded, maintaining consistent product performance across production volumes.

Cost considerations ultimately determine commercial viability, with initial capital expenditure for specialized equipment balanced against operational efficiencies gained through scale. Modular production systems offer advantages for phased implementation, allowing manufacturers to validate process parameters at intermediate scales before committing to full industrial capacity. Strategic partnerships with equipment manufacturers experienced in handling challenging slurry compositions can accelerate technology transfer from laboratory to production environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!