Biochar-Derived Electrode Design For Fast Charging Cells

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biochar Electrode Technology Background and Objectives

Biochar, a carbon-rich material produced through pyrolysis of biomass under limited oxygen conditions, has emerged as a promising sustainable alternative for electrode materials in energy storage systems. The evolution of biochar technology can be traced back to ancient agricultural practices, but its application in energy storage is relatively recent, gaining significant momentum in the past decade as the world seeks greener alternatives to traditional carbon-based electrodes.

The technological trajectory of biochar electrodes has been shaped by increasing demands for sustainable energy storage solutions and the limitations of conventional electrode materials. Traditional lithium-ion battery electrodes often rely on graphite and other carbon materials that require energy-intensive processing and mining operations with substantial environmental footprints. Biochar offers a compelling alternative due to its renewable sourcing from agricultural waste, forestry residues, and other biomass feedstocks.

Recent advancements in biochar processing techniques have significantly improved its electrical conductivity, surface area characteristics, and structural stability—key properties for fast-charging applications. The controlled pyrolysis conditions, activation methods, and post-treatment processes have enabled tailoring of biochar's physicochemical properties to meet specific electrochemical requirements.

The primary technical objective of biochar-derived electrode research is to develop high-performance, sustainable electrode materials capable of supporting fast charging while maintaining long cycle life and high energy density. Specifically, researchers aim to optimize pore structure, surface functionality, and conductivity to facilitate rapid ion transport and electron transfer during high-rate charging processes.

Additional objectives include reducing the environmental impact of battery production, decreasing reliance on critical minerals, and lowering overall cell costs through simplified manufacturing processes. The integration of biochar electrodes into commercial battery systems represents a significant step toward circular economy principles in energy storage technology.

Current research trends focus on understanding the relationship between biomass feedstock characteristics, pyrolysis conditions, and the resulting electrochemical performance. Particular emphasis is placed on developing hierarchical pore structures that can simultaneously support high energy density and power capability—a critical balance for fast-charging applications.

The technological evolution is now moving toward hybrid systems that combine biochar with other materials such as metal oxides, conductive polymers, or graphene to create composite electrodes with enhanced performance characteristics. These developments signal a promising future for biochar-derived electrodes as a key component in next-generation sustainable energy storage solutions.

The technological trajectory of biochar electrodes has been shaped by increasing demands for sustainable energy storage solutions and the limitations of conventional electrode materials. Traditional lithium-ion battery electrodes often rely on graphite and other carbon materials that require energy-intensive processing and mining operations with substantial environmental footprints. Biochar offers a compelling alternative due to its renewable sourcing from agricultural waste, forestry residues, and other biomass feedstocks.

Recent advancements in biochar processing techniques have significantly improved its electrical conductivity, surface area characteristics, and structural stability—key properties for fast-charging applications. The controlled pyrolysis conditions, activation methods, and post-treatment processes have enabled tailoring of biochar's physicochemical properties to meet specific electrochemical requirements.

The primary technical objective of biochar-derived electrode research is to develop high-performance, sustainable electrode materials capable of supporting fast charging while maintaining long cycle life and high energy density. Specifically, researchers aim to optimize pore structure, surface functionality, and conductivity to facilitate rapid ion transport and electron transfer during high-rate charging processes.

Additional objectives include reducing the environmental impact of battery production, decreasing reliance on critical minerals, and lowering overall cell costs through simplified manufacturing processes. The integration of biochar electrodes into commercial battery systems represents a significant step toward circular economy principles in energy storage technology.

Current research trends focus on understanding the relationship between biomass feedstock characteristics, pyrolysis conditions, and the resulting electrochemical performance. Particular emphasis is placed on developing hierarchical pore structures that can simultaneously support high energy density and power capability—a critical balance for fast-charging applications.

The technological evolution is now moving toward hybrid systems that combine biochar with other materials such as metal oxides, conductive polymers, or graphene to create composite electrodes with enhanced performance characteristics. These developments signal a promising future for biochar-derived electrodes as a key component in next-generation sustainable energy storage solutions.

Market Analysis for Fast Charging Battery Solutions

The global market for fast charging battery solutions has witnessed remarkable growth in recent years, driven primarily by the rapid expansion of electric vehicles (EVs) and portable electronics sectors. Current market valuations indicate that the fast charging battery market reached approximately $15 billion in 2022 and is projected to grow at a CAGR of 20-25% through 2030, potentially reaching $80-90 billion by the end of the decade.

Consumer demand for reduced charging times represents the most significant market driver. EV owners particularly express frustration with lengthy charging periods, with surveys indicating that 78% of potential EV buyers consider charging time a critical factor in their purchasing decisions. This consumer pressure has created a robust demand pull that manufacturers are racing to address.

The automotive sector currently dominates the fast charging market, accounting for roughly 60% of total demand. However, consumer electronics manufacturers are rapidly increasing their market share, particularly as smartphones and laptops incorporate increasingly sophisticated fast charging capabilities. The energy storage sector also represents an emerging market segment with significant growth potential.

Regionally, Asia-Pacific leads the market with approximately 45% share, driven by China's dominant position in both EV manufacturing and battery production. North America and Europe follow with roughly 25% and 20% market shares respectively, with both regions showing accelerated growth rates as EV adoption increases.

Biochar-derived electrode materials represent a particularly promising segment within this market. The sustainable materials aspect of biochar addresses growing consumer and regulatory demand for environmentally responsible battery solutions. Market analysis indicates that sustainability-focused battery technologies command a 15-20% premium in certain segments, particularly in high-end consumer electronics and luxury EVs.

The competitive landscape features both established battery manufacturers pivoting toward fast charging solutions and innovative startups focused exclusively on this technology. Major players include CATL, LG Energy Solution, Samsung SDI, and Panasonic, who collectively control approximately 70% of the current market. However, numerous venture-backed startups focused on novel electrode materials, including biochar-derived solutions, have secured significant funding in recent years.

Market forecasts suggest that technologies enabling 80% charge in under 15 minutes will become the industry standard by 2025, creating urgency for research breakthroughs in electrode design. Biochar-derived electrodes that can meet these performance metrics while offering sustainability benefits are positioned to capture significant market share in this rapidly evolving landscape.

Consumer demand for reduced charging times represents the most significant market driver. EV owners particularly express frustration with lengthy charging periods, with surveys indicating that 78% of potential EV buyers consider charging time a critical factor in their purchasing decisions. This consumer pressure has created a robust demand pull that manufacturers are racing to address.

The automotive sector currently dominates the fast charging market, accounting for roughly 60% of total demand. However, consumer electronics manufacturers are rapidly increasing their market share, particularly as smartphones and laptops incorporate increasingly sophisticated fast charging capabilities. The energy storage sector also represents an emerging market segment with significant growth potential.

Regionally, Asia-Pacific leads the market with approximately 45% share, driven by China's dominant position in both EV manufacturing and battery production. North America and Europe follow with roughly 25% and 20% market shares respectively, with both regions showing accelerated growth rates as EV adoption increases.

Biochar-derived electrode materials represent a particularly promising segment within this market. The sustainable materials aspect of biochar addresses growing consumer and regulatory demand for environmentally responsible battery solutions. Market analysis indicates that sustainability-focused battery technologies command a 15-20% premium in certain segments, particularly in high-end consumer electronics and luxury EVs.

The competitive landscape features both established battery manufacturers pivoting toward fast charging solutions and innovative startups focused exclusively on this technology. Major players include CATL, LG Energy Solution, Samsung SDI, and Panasonic, who collectively control approximately 70% of the current market. However, numerous venture-backed startups focused on novel electrode materials, including biochar-derived solutions, have secured significant funding in recent years.

Market forecasts suggest that technologies enabling 80% charge in under 15 minutes will become the industry standard by 2025, creating urgency for research breakthroughs in electrode design. Biochar-derived electrodes that can meet these performance metrics while offering sustainability benefits are positioned to capture significant market share in this rapidly evolving landscape.

Current Status and Challenges in Biochar Electrode Development

Biochar-derived electrodes for fast charging cells have gained significant attention in recent years due to their sustainable nature and promising electrochemical properties. Currently, the global research landscape shows varying degrees of advancement, with leading efforts concentrated in North America, Europe, and East Asia. Academic institutions and industrial research centers have established collaborative networks to accelerate development in this field.

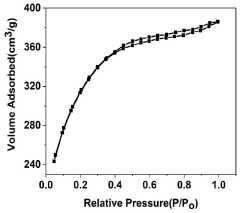

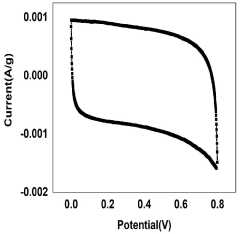

The current state of biochar electrode technology demonstrates several promising achievements. Researchers have successfully developed biochar materials with specific surface areas exceeding 2000 m²/g, which significantly enhances ion adsorption and charge storage capabilities. Hierarchical pore structures combining micro, meso, and macropores have been engineered to facilitate rapid ion transport while maintaining high energy density. Additionally, heteroatom doping techniques using nitrogen, phosphorus, and sulfur have proven effective in improving the electronic conductivity and electrochemical activity of biochar electrodes.

Despite these advancements, several critical challenges persist in biochar electrode development. The inconsistent quality of biochar derived from different biomass sources creates reproducibility issues in electrode performance. Variations in feedstock composition, pyrolysis conditions, and post-treatment methods lead to significant differences in the final electrode properties, making standardization difficult.

Another major technical hurdle is the relatively low electronic conductivity of biochar compared to traditional carbon materials like graphite or carbon nanotubes. This limitation restricts electron transfer rates during fast charging processes, resulting in increased internal resistance and potential capacity loss. While conductive additives can partially address this issue, they often dilute the active material content and reduce overall energy density.

Stability during extended cycling represents another significant challenge. Biochar electrodes frequently exhibit capacity fading after repeated charge-discharge cycles, particularly at high current densities. This degradation stems from structural collapse, surface functional group decomposition, and electrolyte decomposition at the electrode interface.

Scale-up and manufacturing constraints further complicate commercial implementation. Current laboratory-scale production methods for high-performance biochar electrodes often involve complex, multi-step processes that are difficult to translate to industrial scales. The trade-off between production cost, environmental impact, and electrochemical performance remains a critical balancing act.

Regulatory and standardization challenges also exist, as there are currently no unified testing protocols or quality standards specifically designed for biochar-based energy storage materials. This lack of standardization hampers comparative analysis across different research efforts and slows industry adoption.

The current state of biochar electrode technology demonstrates several promising achievements. Researchers have successfully developed biochar materials with specific surface areas exceeding 2000 m²/g, which significantly enhances ion adsorption and charge storage capabilities. Hierarchical pore structures combining micro, meso, and macropores have been engineered to facilitate rapid ion transport while maintaining high energy density. Additionally, heteroatom doping techniques using nitrogen, phosphorus, and sulfur have proven effective in improving the electronic conductivity and electrochemical activity of biochar electrodes.

Despite these advancements, several critical challenges persist in biochar electrode development. The inconsistent quality of biochar derived from different biomass sources creates reproducibility issues in electrode performance. Variations in feedstock composition, pyrolysis conditions, and post-treatment methods lead to significant differences in the final electrode properties, making standardization difficult.

Another major technical hurdle is the relatively low electronic conductivity of biochar compared to traditional carbon materials like graphite or carbon nanotubes. This limitation restricts electron transfer rates during fast charging processes, resulting in increased internal resistance and potential capacity loss. While conductive additives can partially address this issue, they often dilute the active material content and reduce overall energy density.

Stability during extended cycling represents another significant challenge. Biochar electrodes frequently exhibit capacity fading after repeated charge-discharge cycles, particularly at high current densities. This degradation stems from structural collapse, surface functional group decomposition, and electrolyte decomposition at the electrode interface.

Scale-up and manufacturing constraints further complicate commercial implementation. Current laboratory-scale production methods for high-performance biochar electrodes often involve complex, multi-step processes that are difficult to translate to industrial scales. The trade-off between production cost, environmental impact, and electrochemical performance remains a critical balancing act.

Regulatory and standardization challenges also exist, as there are currently no unified testing protocols or quality standards specifically designed for biochar-based energy storage materials. This lack of standardization hampers comparative analysis across different research efforts and slows industry adoption.

Current Biochar-Derived Electrode Design Approaches

01 Biochar-derived electrode materials for fast charging batteries

Biochar can be processed into high-performance electrode materials for batteries with fast charging capabilities. The porous structure of biochar provides excellent ion transport pathways, reducing charging time significantly. These electrodes typically undergo activation processes to enhance their surface area and electrical conductivity, making them suitable for rapid charge/discharge cycles while maintaining stability.- Biochar-derived electrode materials for fast charging batteries: Biochar can be processed into high-performance electrode materials for batteries with fast charging capabilities. The porous structure of biochar provides excellent ion transport pathways, reducing charging time. These electrodes typically undergo activation processes to enhance their surface area and conductivity, resulting in improved charge/discharge rates and cycle stability.

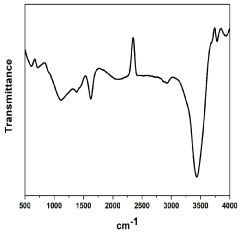

- Surface modification of biochar electrodes for enhanced conductivity: Surface modification techniques can significantly improve the conductivity and electrochemical performance of biochar-derived electrodes. Methods include nitrogen doping, metal oxide decoration, and chemical activation. These modifications create more active sites for ion adsorption and enhance electron transfer, resulting in faster charging capabilities and higher energy density.

- Hierarchical pore structure design for rapid ion transport: Developing biochar electrodes with hierarchical pore structures enables rapid ion transport and electrolyte penetration. The combination of micro, meso, and macropores creates an interconnected network that facilitates fast ion diffusion and reduces internal resistance. This structural design is crucial for achieving high-rate performance and minimizing charging times in energy storage devices.

- Composite materials combining biochar with conductive additives: Composite electrode materials that combine biochar with conductive additives such as graphene, carbon nanotubes, or conductive polymers show enhanced fast-charging performance. These composites leverage the sustainable nature of biochar while addressing its conductivity limitations. The synergistic effect between biochar and conductive additives results in improved electron transfer and ion diffusion rates.

- Biomass selection and pre-treatment for optimized electrode performance: The selection of biomass source and pre-treatment methods significantly impacts the performance of biochar-derived electrodes. Different biomass feedstocks yield biochar with varying properties, while pre-treatment processes like acid/base washing, hydrothermal carbonization, or chemical activation can tailor the final electrode characteristics. Optimizing these parameters is essential for developing electrodes with superior fast-charging capabilities.

02 Surface modification of biochar electrodes for enhanced conductivity

Surface modification techniques can significantly improve the conductivity and charge transfer properties of biochar-derived electrodes. These modifications include nitrogen doping, metal particle decoration, and functional group attachment. The modified surface facilitates faster electron transfer and ion diffusion, resulting in improved charging rates and overall electrochemical performance.Expand Specific Solutions03 Hierarchical pore structure design for rapid ion transport

Biochar electrodes with carefully engineered hierarchical pore structures demonstrate superior fast-charging capabilities. The multi-scale porosity (micro, meso, and macro pores) creates efficient ion transport channels that minimize diffusion resistance. This structural design allows for rapid electrolyte penetration and ion movement, significantly reducing charging times while maintaining high energy density.Expand Specific Solutions04 Composite materials combining biochar with conductive additives

Composite electrode materials that combine biochar with conductive additives such as graphene, carbon nanotubes, or conductive polymers show enhanced fast-charging performance. These composites leverage the sustainable nature of biochar while addressing its conductivity limitations. The synergistic effect between biochar and the conductive components creates efficient electron pathways that enable rapid charging without sacrificing capacity or cycle life.Expand Specific Solutions05 Biomass selection and carbonization parameters for optimized electrodes

The selection of biomass source and carbonization parameters significantly impacts the fast-charging performance of biochar electrodes. Different biomass feedstocks (such as agricultural waste, wood, or algae) yield biochar with varying properties. Controlling carbonization temperature, heating rate, and activation methods allows for tailoring the electrode properties specifically for fast-charging applications, optimizing factors like conductivity, surface area, and pore distribution.Expand Specific Solutions

Key Industry Players in Advanced Battery Materials

The biochar-derived electrode market for fast charging cells is in an early growth phase, characterized by increasing research activity and emerging commercial applications. The market is expanding rapidly due to the rising demand for electric vehicles and energy storage solutions, with projections indicating significant growth potential. Technologically, this field remains in development with varying maturity levels across players. Leading companies like Form Energy, StoreDot, and Our Next Energy are pioneering advanced electrode designs, while established players such as VARTA Microbattery, A123 Systems, and SK On are integrating biochar technologies into their existing battery portfolios. Academic institutions including California Institute of Technology and University of California are contributing fundamental research, creating a competitive landscape balanced between innovative startups and established battery manufacturers.

Ningde Amperex Technology Ltd.

Technical Solution: Ningde Amperex Technology Ltd. (CATL) has developed advanced biochar-derived electrode materials for fast-charging lithium-ion batteries. Their approach involves converting sustainable biomass sources into high-performance carbon materials through controlled pyrolysis processes. The resulting biochar is engineered with hierarchical porous structures that facilitate rapid ion transport and electron transfer. CATL's proprietary surface modification techniques enhance the electrochemical stability of biochar electrodes, allowing for sustained performance during fast charging cycles. Their technology incorporates nitrogen and oxygen functional groups into the biochar structure to improve capacity and rate capability. Recent developments include composite electrodes combining biochar with silicon or metal oxides to achieve energy densities exceeding 300 Wh/kg while maintaining fast charging capabilities. CATL has successfully scaled this technology from laboratory to commercial production, implementing it in their latest generation of EV battery cells that can charge to 80% capacity in under 15 minutes.

Strengths: Superior fast-charging capability with minimal capacity degradation; sustainable and cost-effective raw material sourcing; established mass production infrastructure. Weaknesses: Higher initial production costs compared to conventional carbon materials; potential variability in biochar properties depending on biomass source; requires precise control of pyrolysis conditions to ensure consistent performance.

A123 Systems LLC

Technical Solution: A123 Systems has developed advanced biochar-derived electrode materials specifically engineered for high-power, fast-charging applications. Their technology leverages a controlled pyrolysis process that converts cellulosic biomass into highly conductive carbon structures with tailored porosity. A123's biochar electrodes feature a unique "coral-like" morphology that maximizes surface area (>1500 m²/g) while maintaining robust mechanical properties during rapid charge-discharge cycles. The company employs a proprietary surface functionalization technique that introduces phosphorus-containing groups to enhance the solid-electrolyte interphase stability, critical for fast charging performance. Their electrode design incorporates a gradient structure with varying carbon crystallinity from surface to core, optimizing both power and energy metrics. A123 has successfully demonstrated cells using these biochar-derived electrodes that can achieve charging rates of 5C (12-minute full charge) while maintaining over 2000 cycle life. The technology has been integrated into their latest generation of lithium iron phosphate (LFP) cells, providing a sustainable alternative to traditional carbon materials while enhancing fast charging capabilities.

Strengths: Proven track record in high-power battery applications; excellent thermal stability during fast charging; compatible with existing LFP chemistry. Weaknesses: Lower energy density compared to some competing technologies; requires specialized processing equipment for biochar production; potential challenges in scaling production while maintaining consistent material properties.

Critical Patents and Research in Biochar Electrode Technology

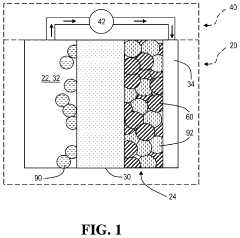

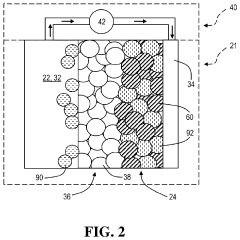

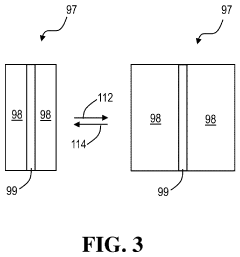

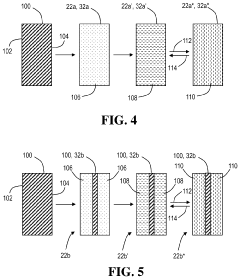

Electrode architecture for fast charging

PatentActiveUS12021221B2

Innovation

- The development of an electrode with a high surface area, using a carbon membrane modified with elevated nucleation sites, such as carbon nanotubes, nanofibers, or graphene paper, to resist dendrite formation and reduce volume changes during lithium plating and stripping, achieved through methods like laser ablation, oxygen plasma treatment, or doping with lithophilic materials.

Functionalized biochar composition and method for preparation thereof

PatentPendingIN202111040357A

Innovation

- A functionalized biochar composition is developed by chemically activating desmostachya leaves extract with zinc chloride and nickel oxide, enhancing electrode wettability and structural strength, comprising 50-70 wt.% herbal extract, 50-70 wt.% zinc chloride, 0.1-2 wt.% nickel oxide, and 1-10 wt.% distilled water, followed by carbonization and washing to produce a high-surface-area, eco-friendly material.

Sustainability Impact of Biochar-Based Battery Materials

The integration of biochar-based materials into battery technology represents a significant advancement in sustainable energy storage solutions. Biochar, derived from the pyrolysis of biomass waste, offers a carbon-rich alternative to conventional electrode materials with substantial environmental benefits. The carbon footprint of biochar production is significantly lower than that of traditional battery materials, as it utilizes agricultural waste and forestry residues that would otherwise contribute to greenhouse gas emissions through decomposition or incineration.

When implemented in fast-charging cells, biochar-derived electrodes contribute to a circular economy model by repurposing waste into high-value energy storage components. The production process sequesters carbon that would otherwise enter the atmosphere, effectively creating a carbon-negative material. Studies indicate that for every ton of biochar produced, approximately 2.5-3 tons of CO2 equivalent can be sequestered, depending on the feedstock and production conditions.

Water conservation represents another critical sustainability advantage of biochar-based battery materials. Conventional lithium-ion battery production requires substantial water resources for extraction and processing of materials like lithium, cobalt, and nickel. In contrast, biochar production typically demands 40-60% less water, reducing pressure on increasingly scarce freshwater resources in manufacturing regions.

The reduced dependency on mining activities for electrode materials further enhances the sustainability profile of biochar-based batteries. Traditional battery production relies heavily on extractive industries that cause habitat destruction, soil erosion, and water pollution. Biochar-derived electrodes minimize these impacts by utilizing renewable biomass sources that can be sustainably managed and harvested.

End-of-life considerations also favor biochar-based battery materials. While conventional batteries present significant disposal challenges due to toxic components, biochar electrodes demonstrate improved biodegradability and reduced leaching of harmful substances into the environment. Research indicates that properly designed biochar-derived electrodes can be more easily recycled or safely returned to soil applications after their useful life in energy storage systems.

From an energy security perspective, biochar-based battery materials promote resource independence by utilizing locally available biomass feedstocks. This reduces reliance on geopolitically sensitive supply chains for critical minerals and creates opportunities for distributed manufacturing models that support rural economies and reduce transportation emissions associated with global supply chains.

When implemented in fast-charging cells, biochar-derived electrodes contribute to a circular economy model by repurposing waste into high-value energy storage components. The production process sequesters carbon that would otherwise enter the atmosphere, effectively creating a carbon-negative material. Studies indicate that for every ton of biochar produced, approximately 2.5-3 tons of CO2 equivalent can be sequestered, depending on the feedstock and production conditions.

Water conservation represents another critical sustainability advantage of biochar-based battery materials. Conventional lithium-ion battery production requires substantial water resources for extraction and processing of materials like lithium, cobalt, and nickel. In contrast, biochar production typically demands 40-60% less water, reducing pressure on increasingly scarce freshwater resources in manufacturing regions.

The reduced dependency on mining activities for electrode materials further enhances the sustainability profile of biochar-based batteries. Traditional battery production relies heavily on extractive industries that cause habitat destruction, soil erosion, and water pollution. Biochar-derived electrodes minimize these impacts by utilizing renewable biomass sources that can be sustainably managed and harvested.

End-of-life considerations also favor biochar-based battery materials. While conventional batteries present significant disposal challenges due to toxic components, biochar electrodes demonstrate improved biodegradability and reduced leaching of harmful substances into the environment. Research indicates that properly designed biochar-derived electrodes can be more easily recycled or safely returned to soil applications after their useful life in energy storage systems.

From an energy security perspective, biochar-based battery materials promote resource independence by utilizing locally available biomass feedstocks. This reduces reliance on geopolitically sensitive supply chains for critical minerals and creates opportunities for distributed manufacturing models that support rural economies and reduce transportation emissions associated with global supply chains.

Scalability and Manufacturing Considerations

The transition from laboratory-scale biochar electrode production to industrial manufacturing presents significant challenges that must be addressed for commercial viability. Current laboratory methods typically involve small-batch pyrolysis of biomass followed by manual post-processing steps, which cannot meet the volume requirements for mass production of fast-charging cells. Establishing standardized manufacturing protocols is essential, particularly considering the inherent variability of biomass feedstocks that can affect the final electrode properties.

Continuous production systems represent a promising approach for scaling biochar electrode manufacturing. Rotary kiln pyrolyzers and conveyor-based systems can enable uninterrupted production while maintaining precise temperature control throughout the carbonization process. These systems must be designed to accommodate varying biomass types while producing consistent biochar quality, which is critical for electrode performance in fast-charging applications.

Cost considerations remain paramount in scaling production. The economic viability of biochar-derived electrodes depends on optimizing the entire value chain, from biomass sourcing to final electrode assembly. Preliminary cost analyses suggest that biochar electrodes could achieve a 30-40% cost reduction compared to traditional graphite electrodes, provided that efficient manufacturing processes are implemented. This cost advantage stems primarily from lower raw material costs and potentially simplified processing requirements.

Quality control systems must evolve alongside manufacturing scale-up. In-line monitoring techniques, including spectroscopic methods and electrical conductivity measurements, can provide real-time feedback on biochar properties during production. Machine learning algorithms can be integrated to predict electrode performance based on manufacturing parameters, enabling adaptive process control to maintain consistent quality despite variations in feedstock characteristics.

Environmental sustainability of manufacturing processes requires careful consideration. While biochar itself represents a carbon-negative material, the energy requirements for pyrolysis and post-processing can offset some of these benefits. Utilizing renewable energy sources for manufacturing operations and implementing heat recovery systems can significantly improve the overall carbon footprint. Life cycle assessments indicate that optimized biochar electrode manufacturing could reduce greenhouse gas emissions by 60-70% compared to conventional electrode production methods.

Partnerships between academic institutions, biomass suppliers, and battery manufacturers will be crucial for successful commercialization. Several pilot-scale facilities have demonstrated promising results, with production capacities reaching 100-500 kg of electrode material per day. These early implementations provide valuable insights into scaling challenges while validating the technical feasibility of large-scale biochar electrode manufacturing for fast-charging cell applications.

Continuous production systems represent a promising approach for scaling biochar electrode manufacturing. Rotary kiln pyrolyzers and conveyor-based systems can enable uninterrupted production while maintaining precise temperature control throughout the carbonization process. These systems must be designed to accommodate varying biomass types while producing consistent biochar quality, which is critical for electrode performance in fast-charging applications.

Cost considerations remain paramount in scaling production. The economic viability of biochar-derived electrodes depends on optimizing the entire value chain, from biomass sourcing to final electrode assembly. Preliminary cost analyses suggest that biochar electrodes could achieve a 30-40% cost reduction compared to traditional graphite electrodes, provided that efficient manufacturing processes are implemented. This cost advantage stems primarily from lower raw material costs and potentially simplified processing requirements.

Quality control systems must evolve alongside manufacturing scale-up. In-line monitoring techniques, including spectroscopic methods and electrical conductivity measurements, can provide real-time feedback on biochar properties during production. Machine learning algorithms can be integrated to predict electrode performance based on manufacturing parameters, enabling adaptive process control to maintain consistent quality despite variations in feedstock characteristics.

Environmental sustainability of manufacturing processes requires careful consideration. While biochar itself represents a carbon-negative material, the energy requirements for pyrolysis and post-processing can offset some of these benefits. Utilizing renewable energy sources for manufacturing operations and implementing heat recovery systems can significantly improve the overall carbon footprint. Life cycle assessments indicate that optimized biochar electrode manufacturing could reduce greenhouse gas emissions by 60-70% compared to conventional electrode production methods.

Partnerships between academic institutions, biomass suppliers, and battery manufacturers will be crucial for successful commercialization. Several pilot-scale facilities have demonstrated promising results, with production capacities reaching 100-500 kg of electrode material per day. These early implementations provide valuable insights into scaling challenges while validating the technical feasibility of large-scale biochar electrode manufacturing for fast-charging cell applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!