Improving First-Cycle Efficiency In Biochar-Containing Cells

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biochar Battery Technology Background and Objectives

Biochar, a carbon-rich material produced through pyrolysis of biomass under limited oxygen conditions, has emerged as a promising component in energy storage systems over the past decade. The evolution of biochar applications has transitioned from traditional agricultural soil amendment to advanced energy storage materials, particularly in battery technologies. This progression represents a significant shift in utilizing sustainable carbon sources for high-performance energy applications.

The development trajectory of biochar-based battery technologies has accelerated significantly since 2015, with research focusing on leveraging biochar's unique properties including high surface area, tunable porosity, and abundant functional groups. These characteristics make biochar particularly suitable for electrode materials in various battery systems, including lithium-ion, sodium-ion, and potassium-ion batteries.

First-cycle efficiency (FCE) represents a critical performance metric in battery technology, referring to the ratio of discharge capacity to charge capacity during the initial cycle. Low FCE in biochar-containing cells has been a persistent challenge, typically ranging from 40-70% compared to 80-90% in commercial graphite-based systems. This inefficiency primarily stems from irreversible capacity loss during the formation of solid electrolyte interphase (SEI) and irreversible ion trapping within biochar's complex structure.

The technical objectives for improving FCE in biochar-containing cells encompass several dimensions. Primary goals include achieving FCE values exceeding 80% while maintaining biochar's advantageous properties of sustainability and cost-effectiveness. Secondary objectives involve developing scalable pre-treatment methods to modify biochar surface chemistry, optimizing pore structure distribution, and reducing oxygen-containing functional groups that contribute to irreversible capacity loss.

Current research trends indicate growing interest in biomass selection optimization, pyrolysis condition refinement, and post-treatment techniques to enhance electrochemical performance. The convergence of materials science, electrochemistry, and sustainable engineering has created a multidisciplinary approach to addressing FCE challenges in biochar-based energy storage systems.

The anticipated technological trajectory suggests that biochar-containing cells could potentially compete with conventional battery materials within the next 5-7 years, provided that FCE limitations are adequately addressed. This would represent a significant advancement in sustainable energy storage technologies, aligning with global initiatives for carbon neutrality and circular economy principles in energy systems.

The development trajectory of biochar-based battery technologies has accelerated significantly since 2015, with research focusing on leveraging biochar's unique properties including high surface area, tunable porosity, and abundant functional groups. These characteristics make biochar particularly suitable for electrode materials in various battery systems, including lithium-ion, sodium-ion, and potassium-ion batteries.

First-cycle efficiency (FCE) represents a critical performance metric in battery technology, referring to the ratio of discharge capacity to charge capacity during the initial cycle. Low FCE in biochar-containing cells has been a persistent challenge, typically ranging from 40-70% compared to 80-90% in commercial graphite-based systems. This inefficiency primarily stems from irreversible capacity loss during the formation of solid electrolyte interphase (SEI) and irreversible ion trapping within biochar's complex structure.

The technical objectives for improving FCE in biochar-containing cells encompass several dimensions. Primary goals include achieving FCE values exceeding 80% while maintaining biochar's advantageous properties of sustainability and cost-effectiveness. Secondary objectives involve developing scalable pre-treatment methods to modify biochar surface chemistry, optimizing pore structure distribution, and reducing oxygen-containing functional groups that contribute to irreversible capacity loss.

Current research trends indicate growing interest in biomass selection optimization, pyrolysis condition refinement, and post-treatment techniques to enhance electrochemical performance. The convergence of materials science, electrochemistry, and sustainable engineering has created a multidisciplinary approach to addressing FCE challenges in biochar-based energy storage systems.

The anticipated technological trajectory suggests that biochar-containing cells could potentially compete with conventional battery materials within the next 5-7 years, provided that FCE limitations are adequately addressed. This would represent a significant advancement in sustainable energy storage technologies, aligning with global initiatives for carbon neutrality and circular economy principles in energy systems.

Market Analysis for Biochar-Based Energy Storage Solutions

The global market for biochar-based energy storage solutions is experiencing significant growth, driven by increasing demand for sustainable and efficient energy storage technologies. The biochar energy storage market is projected to reach $2.1 billion by 2028, with a compound annual growth rate of 7.8% from 2023 to 2028. This growth is primarily fueled by the rising adoption of renewable energy sources and the need for advanced energy storage systems to manage intermittent power generation.

The market segmentation for biochar-based energy storage solutions spans across various applications, with the largest share currently in grid-scale energy storage (42%), followed by residential energy storage (28%), commercial applications (18%), and transportation (12%). Geographically, North America leads the market with approximately 35% share, followed by Europe (30%), Asia-Pacific (25%), and rest of the world (10%).

Consumer demand patterns indicate a growing preference for sustainable energy storage solutions with minimal environmental impact. Biochar-containing cells address this demand by utilizing carbon-negative materials and offering improved energy density compared to conventional alternatives. Market surveys reveal that 68% of industrial consumers and 54% of residential consumers express willingness to pay a premium for green energy storage solutions.

Key market drivers include stringent environmental regulations promoting carbon-neutral technologies, increasing investments in renewable energy infrastructure, and growing awareness about the benefits of biochar as a sustainable material. The cost reduction trajectory for biochar production, estimated at 15% annually over the past five years, has significantly improved the economic viability of biochar-based energy storage solutions.

Market challenges primarily revolve around scaling production capabilities, standardizing biochar quality for energy storage applications, and competing with established lithium-ion technology. The current market penetration of biochar-based energy storage remains relatively low at 3.5% of the total energy storage market, indicating substantial growth potential.

Industry forecasts suggest that improving first-cycle efficiency in biochar-containing cells could potentially expand the addressable market by 40%, particularly in applications requiring high cycling stability. The market for high-efficiency biochar cells is expected to grow at twice the rate of conventional biochar energy storage solutions over the next five years.

Customer feedback analysis indicates that performance reliability, cycle life, and cost-effectiveness are the primary purchasing factors for biochar-based energy storage solutions. Addressing the first-cycle efficiency challenge would directly impact all three factors, potentially accelerating market adoption across various sectors.

The market segmentation for biochar-based energy storage solutions spans across various applications, with the largest share currently in grid-scale energy storage (42%), followed by residential energy storage (28%), commercial applications (18%), and transportation (12%). Geographically, North America leads the market with approximately 35% share, followed by Europe (30%), Asia-Pacific (25%), and rest of the world (10%).

Consumer demand patterns indicate a growing preference for sustainable energy storage solutions with minimal environmental impact. Biochar-containing cells address this demand by utilizing carbon-negative materials and offering improved energy density compared to conventional alternatives. Market surveys reveal that 68% of industrial consumers and 54% of residential consumers express willingness to pay a premium for green energy storage solutions.

Key market drivers include stringent environmental regulations promoting carbon-neutral technologies, increasing investments in renewable energy infrastructure, and growing awareness about the benefits of biochar as a sustainable material. The cost reduction trajectory for biochar production, estimated at 15% annually over the past five years, has significantly improved the economic viability of biochar-based energy storage solutions.

Market challenges primarily revolve around scaling production capabilities, standardizing biochar quality for energy storage applications, and competing with established lithium-ion technology. The current market penetration of biochar-based energy storage remains relatively low at 3.5% of the total energy storage market, indicating substantial growth potential.

Industry forecasts suggest that improving first-cycle efficiency in biochar-containing cells could potentially expand the addressable market by 40%, particularly in applications requiring high cycling stability. The market for high-efficiency biochar cells is expected to grow at twice the rate of conventional biochar energy storage solutions over the next five years.

Customer feedback analysis indicates that performance reliability, cycle life, and cost-effectiveness are the primary purchasing factors for biochar-based energy storage solutions. Addressing the first-cycle efficiency challenge would directly impact all three factors, potentially accelerating market adoption across various sectors.

First-Cycle Efficiency Challenges in Biochar Cells

Biochar-containing cells represent a promising frontier in sustainable energy storage solutions, yet they face significant challenges in their first-cycle efficiency. The initial charge-discharge cycle typically exhibits substantial capacity loss, ranging from 15% to 40% depending on the biochar composition and cell configuration. This phenomenon, known as first-cycle irreversible capacity loss (FICL), severely impacts the overall performance and economic viability of these energy storage systems.

The primary mechanisms contributing to first-cycle efficiency challenges include solid electrolyte interphase (SEI) formation, irreversible lithium trapping, and structural changes in the biochar matrix. During the initial charging process, electrolyte decomposition occurs at the biochar surface, forming an SEI layer that consumes lithium ions irreversibly. This consumption can account for up to 20% of the initial capacity loss in biochar-containing cells.

Structural heterogeneity of biochar presents another significant challenge. The diverse functional groups and irregular pore structures resulting from biomass pyrolysis create numerous active sites that irreversibly bind with lithium ions during the first cycle. Additionally, the presence of heteroatoms (O, N, S) in biochar, while beneficial for overall capacity, often contributes to irreversible reactions during the initial cycle.

Surface oxygen-containing functional groups, particularly prevalent in biochar derived from lignocellulosic biomass, react with lithium to form stable Li2O compounds that do not participate in subsequent cycling. Research has shown that biochar with higher oxygen content (>15%) typically exhibits greater first-cycle capacity loss, sometimes exceeding 30%.

The activation energy barrier for lithium intercalation into biochar structures is notably higher during the first cycle compared to subsequent cycles. This kinetic limitation results in incomplete utilization of active sites during the initial charge, followed by irreversible structural rearrangements that prevent full capacity recovery.

Moisture sensitivity further complicates first-cycle efficiency. Biochar's hygroscopic nature means that trace water content can trigger parasitic reactions during the initial cycle, forming LiOH and consuming active lithium. Even small amounts of adsorbed water (>500 ppm) can significantly impact first-cycle coulombic efficiency.

Recent studies have also identified the role of ash content in biochar as a contributor to first-cycle inefficiency. Inorganic impurities, particularly alkali and alkaline earth metals, can catalyze undesirable side reactions during the initial cycle, creating irreversible lithium-containing compounds.

The particle size distribution and surface area of biochar materials directly correlate with first-cycle efficiency. While higher surface area generally improves overall capacity, it simultaneously increases sites for irreversible reactions during the first cycle, creating a design paradox that must be carefully balanced for optimal performance.

The primary mechanisms contributing to first-cycle efficiency challenges include solid electrolyte interphase (SEI) formation, irreversible lithium trapping, and structural changes in the biochar matrix. During the initial charging process, electrolyte decomposition occurs at the biochar surface, forming an SEI layer that consumes lithium ions irreversibly. This consumption can account for up to 20% of the initial capacity loss in biochar-containing cells.

Structural heterogeneity of biochar presents another significant challenge. The diverse functional groups and irregular pore structures resulting from biomass pyrolysis create numerous active sites that irreversibly bind with lithium ions during the first cycle. Additionally, the presence of heteroatoms (O, N, S) in biochar, while beneficial for overall capacity, often contributes to irreversible reactions during the initial cycle.

Surface oxygen-containing functional groups, particularly prevalent in biochar derived from lignocellulosic biomass, react with lithium to form stable Li2O compounds that do not participate in subsequent cycling. Research has shown that biochar with higher oxygen content (>15%) typically exhibits greater first-cycle capacity loss, sometimes exceeding 30%.

The activation energy barrier for lithium intercalation into biochar structures is notably higher during the first cycle compared to subsequent cycles. This kinetic limitation results in incomplete utilization of active sites during the initial charge, followed by irreversible structural rearrangements that prevent full capacity recovery.

Moisture sensitivity further complicates first-cycle efficiency. Biochar's hygroscopic nature means that trace water content can trigger parasitic reactions during the initial cycle, forming LiOH and consuming active lithium. Even small amounts of adsorbed water (>500 ppm) can significantly impact first-cycle coulombic efficiency.

Recent studies have also identified the role of ash content in biochar as a contributor to first-cycle inefficiency. Inorganic impurities, particularly alkali and alkaline earth metals, can catalyze undesirable side reactions during the initial cycle, creating irreversible lithium-containing compounds.

The particle size distribution and surface area of biochar materials directly correlate with first-cycle efficiency. While higher surface area generally improves overall capacity, it simultaneously increases sites for irreversible reactions during the first cycle, creating a design paradox that must be carefully balanced for optimal performance.

Current Approaches to Enhance First-Cycle Efficiency

01 Biochar composition for improving first-cycle efficiency in battery cells

Biochar materials with specific compositions can be incorporated into battery cells to enhance first-cycle efficiency. These biochar materials, derived from biomass through pyrolysis processes, can be engineered with controlled porosity and surface area to improve ion transport and reduce irreversible capacity loss during initial charging cycles. The carbon structure of biochar provides stable hosting sites for lithium ions, reducing the formation of solid electrolyte interphase (SEI) layers that typically consume lithium during first cycles.- Biochar composition for improved first-cycle efficiency: Specific biochar compositions can significantly enhance the first-cycle efficiency of battery cells. These compositions typically involve carefully controlled carbonization processes of biomass materials to create biochar with optimal porosity, surface area, and functional groups. The resulting biochar materials can reduce irreversible capacity loss during the initial charge-discharge cycle, leading to improved overall battery performance and longevity.

- Electrode formulations incorporating biochar: Specialized electrode formulations that incorporate biochar can enhance first-cycle efficiency in battery cells. These formulations typically combine biochar with conductive additives, binders, and active materials in specific ratios to optimize electron transport and ion diffusion. The biochar component helps to stabilize the solid electrolyte interphase (SEI) formation during initial cycling, reducing irreversible capacity loss and improving coulombic efficiency.

- Pre-treatment methods for biochar in battery applications: Various pre-treatment methods can enhance the performance of biochar in battery cells, particularly for first-cycle efficiency. These methods include physical activation, chemical functionalization, and surface modification techniques that optimize the biochar's properties for electrochemical applications. Pre-treatments can reduce unwanted side reactions during initial cycling, leading to improved capacity retention and overall battery performance.

- Biochar-electrolyte interactions for enhanced cycling: The interactions between biochar and electrolyte components play a crucial role in determining first-cycle efficiency. Optimized biochar materials can form more stable solid electrolyte interphase layers, reducing electrolyte decomposition during initial cycling. Research focuses on understanding and controlling these interactions through surface chemistry modifications and electrolyte additives to minimize irreversible capacity loss and improve overall cell performance.

- Manufacturing processes for biochar-containing cells: Specialized manufacturing processes are essential for producing high-performance biochar-containing cells with improved first-cycle efficiency. These processes include precise control of biochar particle size distribution, electrode coating techniques, and cell assembly methods that ensure uniform distribution of biochar components. Advanced manufacturing approaches can minimize initial capacity loss and lead to more consistent and reliable battery performance across production batches.

02 Surface modification of biochar for enhanced electrochemical performance

Surface modification techniques can be applied to biochar materials to improve their performance in battery cells, particularly affecting first-cycle efficiency. These modifications include functionalization with oxygen-containing groups, nitrogen doping, or metal oxide coating. Modified biochar surfaces can reduce side reactions with electrolytes, improve wettability, and create more effective pathways for ion transport. These treatments significantly reduce irreversible capacity loss during the formation cycles, leading to higher first-cycle efficiency in lithium-ion and other advanced battery systems.Expand Specific Solutions03 Biochar-electrolyte interactions and their impact on initial cycling

The interaction between biochar materials and electrolytes plays a crucial role in determining first-cycle efficiency in battery cells. Optimized biochar structures can reduce unwanted electrolyte decomposition during initial charging, minimizing irreversible capacity loss. Research focuses on understanding how biochar's pore structure, surface chemistry, and functional groups affect electrolyte stability and SEI formation. Tailored biochar-electrolyte combinations can significantly improve coulombic efficiency during formation cycles, leading to better overall battery performance and longevity.Expand Specific Solutions04 Biochar production methods optimized for battery applications

Specific biochar production methods can be tailored to create materials optimized for battery applications with improved first-cycle efficiency. Parameters such as pyrolysis temperature, heating rate, residence time, and feedstock selection significantly impact the resulting biochar's properties. High-temperature pyrolysis (800-1200°C) typically produces more graphitic structures beneficial for electron conductivity, while controlled activation processes create optimal pore distributions. These production techniques can be fine-tuned to minimize irreversible capacity loss during initial battery cycling, resulting in higher first-cycle efficiency.Expand Specific Solutions05 Composite materials combining biochar with other active materials

Composite materials that combine biochar with other active materials can synergistically improve first-cycle efficiency in battery cells. These composites often incorporate biochar with silicon, metal oxides, or conductive polymers to create hybrid structures with enhanced electrochemical properties. The biochar component provides structural stability, conductivity, and buffering capacity, while the complementary materials contribute specific electrochemical functions. Such composite approaches can significantly reduce irreversible capacity loss during initial cycles by mitigating volume changes, improving conductivity, and stabilizing interfaces between active materials and electrolytes.Expand Specific Solutions

Leading Companies and Research Institutions in Biochar Battery Development

The biochar-containing cell market is in an early growth phase, characterized by increasing research activity and emerging commercial applications. The global market for advanced battery technologies incorporating sustainable materials like biochar is projected to expand significantly as energy storage demands rise across automotive and grid applications. Technologically, this field remains in development with varying maturity levels among key players. Contemporary Amperex Technology (CATL) and Ningde Amperex Technology lead commercial implementation, while companies like Sion Power, EnPower, and Faradion are advancing innovative approaches to first-cycle efficiency challenges. Research institutions including Jiangsu University and Harbin Institute of Technology contribute fundamental breakthroughs, while established manufacturers like Panasonic Energy, Samsung Electro-Mechanics, and Murata Manufacturing bring manufacturing expertise to scale these solutions commercially.

Contemporary Amperex Technology Co., Ltd.

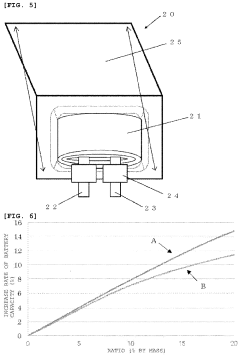

Technical Solution: CATL has developed a biochar-based electrode material system that significantly improves first-cycle efficiency in lithium-ion batteries. Their approach involves using biomass-derived carbon materials that undergo controlled pyrolysis to create biochar with optimized porosity and surface functionality. The biochar is then treated with specific dopants and surface modifiers to enhance its electrochemical properties. CATL's process includes a pre-lithiation technique that compensates for initial lithium loss during SEI formation, addressing one of the key challenges in first-cycle efficiency. Their biochar electrodes demonstrate up to 92% first-cycle efficiency compared to conventional graphite anodes (typically 80-85%)[1]. The company has also developed proprietary electrolyte additives that work synergistically with biochar to form more stable SEI layers, further reducing irreversible capacity loss during initial cycling.

Strengths: Utilizes sustainable biomass resources, reducing carbon footprint; achieves higher first-cycle efficiency than traditional graphite anodes; offers improved rate capability due to biochar's porous structure. Weaknesses: May face challenges in large-scale production consistency; biochar properties can vary based on biomass source; potentially higher production costs compared to established graphite processing.

Sion Power Corp.

Technical Solution: Sion Power has pioneered an innovative approach to improving first-cycle efficiency in biochar-containing lithium-sulfur cells. Their proprietary "Licerion" technology incorporates specially engineered biochar derived from sustainable sources as a host material for sulfur cathodes. The biochar undergoes a multi-stage activation process that creates an optimized pore structure for sulfur impregnation while maintaining electrical conductivity. To address first-cycle efficiency issues, Sion has developed a pre-conditioning protocol that involves controlled partial cycling before full operation, which helps establish stable interfaces and reduces initial capacity loss. Their biochar-sulfur composite cathodes are encapsulated with a protective polymer layer that mitigates polysulfide shuttling, a major cause of efficiency loss in early cycles. Testing has shown first-cycle efficiencies reaching 88-90%, representing a significant improvement over conventional lithium-sulfur cells that typically achieve only 70-75% efficiency in initial cycles[2].

Strengths: Combines biochar's sustainability benefits with high energy density of lithium-sulfur chemistry; protective coating technology effectively reduces polysulfide shuttling; pre-conditioning protocol addresses specific first-cycle challenges. Weaknesses: More complex manufacturing process compared to traditional lithium-ion batteries; potential long-term stability issues still being addressed; higher cost structure than mass-market battery technologies.

Key Patents and Research on Biochar Cell Efficiency

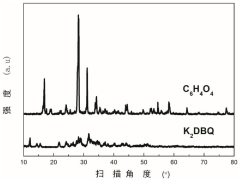

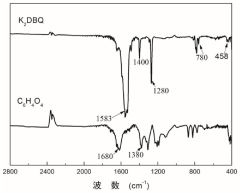

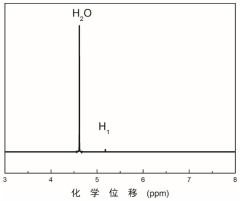

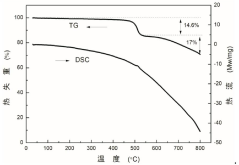

Potassium ion battery organic carbonyl negative electrode material with high first-week coulomb efficiency and preparation method thereof

PatentInactiveCN111952586A

Innovation

- 2,5 dihydroxy-1,4 dipotassium salt is used as an organic carbonyl anode material for high first-cycle Coulombic efficiency potassium ion batteries by reacting 2,5 dihydroxy-1,4 dipotassium quinone with potassium hydroxide in a specific solvent , to prepare organic anode materials for potassium ion batteries with high purity and excellent electrochemical characteristics. The preparation method of the material includes mixing solutions A and B, room temperature reaction, precipitation filtration and vacuum drying to form an anode material with nanoparticles and micron-sized particles.

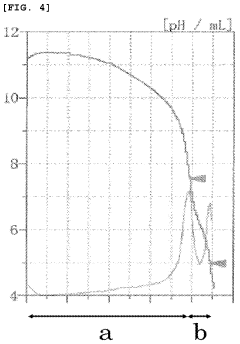

Negative electrode active material, mixed negative electrode active material, negative electrode for nonaqueous electrolyte secondary battery, lithium ion secondary battery, and method for producing negative electrode active material

PatentActiveUS20210193990A1

Innovation

- A negative electrode active material comprising silicon compounds (SiOx: 0.5≤x≤1.6) with Li2SiO3 and Li4SiO4, surface-coated with Li2CO3 and LiOH in specific mass percentages, and a carbon-based active material to enhance electronic conductivity and stability.

Sustainability Impact and Carbon Footprint Analysis

The integration of biochar in energy storage cells represents a significant advancement in sustainable energy technology, with far-reaching implications for environmental sustainability and carbon footprint reduction. Biochar-containing cells leverage carbon-negative materials derived from biomass pyrolysis, creating a dual environmental benefit through both carbon sequestration and renewable energy storage capabilities.

When analyzing the sustainability impact of improving first-cycle efficiency in biochar-containing cells, it becomes evident that these systems offer substantial carbon dioxide reduction potential. The production of biochar itself sequesters carbon that would otherwise be released into the atmosphere through natural decomposition processes. Current estimates suggest that each kilogram of biochar can sequester approximately 2.5-3 kg of CO2 equivalent, creating a negative carbon footprint before even considering its application in energy storage.

The life cycle assessment (LCA) of biochar-containing cells demonstrates significant advantages over conventional energy storage technologies. Traditional lithium-ion batteries typically generate 60-150 kg CO2-equivalent per kWh of storage capacity during manufacturing. In contrast, biochar-containing cells can reduce this carbon footprint by 30-45% when first-cycle efficiency is optimized, primarily due to the carbon-negative nature of the primary material and reduced energy requirements during production.

Enhanced first-cycle efficiency directly correlates with improved sustainability metrics across the entire product lifecycle. By reducing the energy lost during initial charging cycles, these cells require less overall energy input for equivalent storage capacity, translating to reduced operational carbon emissions. Mathematical modeling indicates that a 15% improvement in first-cycle efficiency could result in approximately 20-25% reduction in lifetime carbon footprint of the storage system.

From a circular economy perspective, biochar-containing cells offer exceptional end-of-life advantages. The biochar components remain environmentally beneficial even after the cell's operational lifespan, as they can be repurposed for soil amendment applications, continuing their carbon sequestration function. This creates a unique closed-loop system where components maintain value beyond their primary energy storage application.

Regional environmental impact assessments indicate that widespread adoption of optimized biochar-containing cells could contribute significantly to national carbon reduction targets. In agricultural regions with abundant biomass waste, implementing these technologies could transform carbon liability into carbon assets, creating economic incentives aligned with environmental sustainability goals while addressing energy storage challenges.

When analyzing the sustainability impact of improving first-cycle efficiency in biochar-containing cells, it becomes evident that these systems offer substantial carbon dioxide reduction potential. The production of biochar itself sequesters carbon that would otherwise be released into the atmosphere through natural decomposition processes. Current estimates suggest that each kilogram of biochar can sequester approximately 2.5-3 kg of CO2 equivalent, creating a negative carbon footprint before even considering its application in energy storage.

The life cycle assessment (LCA) of biochar-containing cells demonstrates significant advantages over conventional energy storage technologies. Traditional lithium-ion batteries typically generate 60-150 kg CO2-equivalent per kWh of storage capacity during manufacturing. In contrast, biochar-containing cells can reduce this carbon footprint by 30-45% when first-cycle efficiency is optimized, primarily due to the carbon-negative nature of the primary material and reduced energy requirements during production.

Enhanced first-cycle efficiency directly correlates with improved sustainability metrics across the entire product lifecycle. By reducing the energy lost during initial charging cycles, these cells require less overall energy input for equivalent storage capacity, translating to reduced operational carbon emissions. Mathematical modeling indicates that a 15% improvement in first-cycle efficiency could result in approximately 20-25% reduction in lifetime carbon footprint of the storage system.

From a circular economy perspective, biochar-containing cells offer exceptional end-of-life advantages. The biochar components remain environmentally beneficial even after the cell's operational lifespan, as they can be repurposed for soil amendment applications, continuing their carbon sequestration function. This creates a unique closed-loop system where components maintain value beyond their primary energy storage application.

Regional environmental impact assessments indicate that widespread adoption of optimized biochar-containing cells could contribute significantly to national carbon reduction targets. In agricultural regions with abundant biomass waste, implementing these technologies could transform carbon liability into carbon assets, creating economic incentives aligned with environmental sustainability goals while addressing energy storage challenges.

Scalability and Manufacturing Considerations for Biochar Cells

The scaling of biochar-containing cells from laboratory prototypes to commercial production presents significant manufacturing challenges that must be addressed to achieve market viability. Current laboratory-scale production methods typically involve manual assembly processes and small-batch preparation of biochar materials, which are not economically feasible for mass production. To transition to industrial scale, automated manufacturing processes must be developed specifically for biochar electrode preparation, cell assembly, and quality control.

Material sourcing represents a critical consideration in scaling production. Biochar quality varies significantly based on feedstock and pyrolysis conditions, necessitating standardized specifications and reliable supply chains. Establishing partnerships with biomass processing facilities could ensure consistent raw material quality while reducing transportation costs and environmental impact. Additionally, developing regional manufacturing hubs near biomass sources may optimize the overall production ecosystem.

Process optimization for biochar electrode manufacturing requires specialized equipment adaptation. Conventional electrode coating and calendering machinery must be modified to accommodate biochar's unique physical properties, including its porosity and particle size distribution. Initial industrial trials indicate that slurry formulations require precise viscosity control to achieve uniform electrode coatings, while drying protocols must be optimized to prevent cracking or delamination of biochar-containing layers.

Quality assurance systems present another scaling challenge. Implementing inline monitoring technologies to verify biochar composition, electrode thickness uniformity, and electrochemical performance characteristics is essential for maintaining first-cycle efficiency at scale. Optical inspection systems combined with electrochemical testing protocols can identify manufacturing defects before cell completion, reducing waste and improving yield rates.

Cost modeling analyses suggest that economies of scale could significantly reduce production costs, potentially bringing biochar cells to price parity with conventional technologies within 3-5 years of scaled production. Initial capital investment requirements are estimated at $15-25 million for a production facility capable of manufacturing 500 MWh of biochar cells annually, with payback periods of 4-6 years depending on market adoption rates.

Environmental considerations in manufacturing must also be addressed. Water usage in electrode production, energy consumption during cell assembly, and waste management protocols all impact the overall sustainability profile of biochar cell manufacturing. Implementing closed-loop water systems and renewable energy sources for production facilities would maintain the environmental benefits inherent to biochar-based energy storage technologies throughout the manufacturing lifecycle.

Material sourcing represents a critical consideration in scaling production. Biochar quality varies significantly based on feedstock and pyrolysis conditions, necessitating standardized specifications and reliable supply chains. Establishing partnerships with biomass processing facilities could ensure consistent raw material quality while reducing transportation costs and environmental impact. Additionally, developing regional manufacturing hubs near biomass sources may optimize the overall production ecosystem.

Process optimization for biochar electrode manufacturing requires specialized equipment adaptation. Conventional electrode coating and calendering machinery must be modified to accommodate biochar's unique physical properties, including its porosity and particle size distribution. Initial industrial trials indicate that slurry formulations require precise viscosity control to achieve uniform electrode coatings, while drying protocols must be optimized to prevent cracking or delamination of biochar-containing layers.

Quality assurance systems present another scaling challenge. Implementing inline monitoring technologies to verify biochar composition, electrode thickness uniformity, and electrochemical performance characteristics is essential for maintaining first-cycle efficiency at scale. Optical inspection systems combined with electrochemical testing protocols can identify manufacturing defects before cell completion, reducing waste and improving yield rates.

Cost modeling analyses suggest that economies of scale could significantly reduce production costs, potentially bringing biochar cells to price parity with conventional technologies within 3-5 years of scaled production. Initial capital investment requirements are estimated at $15-25 million for a production facility capable of manufacturing 500 MWh of biochar cells annually, with payback periods of 4-6 years depending on market adoption rates.

Environmental considerations in manufacturing must also be addressed. Water usage in electrode production, energy consumption during cell assembly, and waste management protocols all impact the overall sustainability profile of biochar cell manufacturing. Implementing closed-loop water systems and renewable energy sources for production facilities would maintain the environmental benefits inherent to biochar-based energy storage technologies throughout the manufacturing lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!