Biochar In Sodium-Ion And Emerging Battery Chemistries

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biochar Battery Technology Background and Objectives

Biochar, a carbon-rich material produced through pyrolysis of biomass under limited oxygen conditions, has emerged as a promising material for energy storage applications. The evolution of biochar technology can be traced back to ancient agricultural practices, but its application in battery systems represents a relatively recent innovation. Over the past decade, research into sustainable and cost-effective battery materials has intensified due to growing concerns about resource scarcity and environmental impact of conventional battery technologies.

The trajectory of biochar development for energy storage has accelerated significantly since 2015, with researchers exploring its potential as an electrode material in various battery chemistries. Initially focused on lithium-ion applications, the scope has expanded to include sodium-ion batteries and other emerging electrochemical storage systems. This shift aligns with the broader industry trend toward developing alternatives to lithium-based technologies, driven by concerns about lithium supply chain vulnerabilities and geopolitical considerations.

Sodium-ion batteries represent a particularly promising application domain for biochar materials due to sodium's abundance and wide geographical distribution. Unlike lithium, sodium resources are approximately 1,000 times more plentiful in the Earth's crust, potentially enabling more sustainable and affordable energy storage solutions. The technical objective in this domain is to leverage biochar's unique properties—high surface area, tunable porosity, heteroatom doping capacity, and sustainable production methods—to create high-performance electrode materials for sodium-ion and other post-lithium battery technologies.

Current research aims to address several key technical challenges, including improving the sodium storage capacity of biochar-based electrodes, enhancing cycling stability, and optimizing rate performance. The ultimate goal is to develop biochar-derived materials that can match or exceed the performance of conventional carbon-based electrodes while offering significant advantages in terms of sustainability, cost, and environmental impact.

The technological objectives for biochar in battery applications extend beyond simple material substitution. Researchers are exploring how biochar's properties can be tailored through activation processes, heteroatom doping, and composite formation to create specialized materials optimized for specific battery chemistries. This includes potassium-ion, calcium-ion, aluminum-ion, and zinc-ion systems, each presenting unique electrochemical environments where biochar's adaptable structure may offer advantages.

Looking forward, the field is moving toward integrated approaches that consider the entire lifecycle of biochar-based battery materials, from sustainable biomass sourcing to end-of-life recycling. This holistic perspective aims to maximize the environmental and economic benefits of biochar implementation in next-generation energy storage technologies, potentially enabling a circular economy approach to battery manufacturing.

The trajectory of biochar development for energy storage has accelerated significantly since 2015, with researchers exploring its potential as an electrode material in various battery chemistries. Initially focused on lithium-ion applications, the scope has expanded to include sodium-ion batteries and other emerging electrochemical storage systems. This shift aligns with the broader industry trend toward developing alternatives to lithium-based technologies, driven by concerns about lithium supply chain vulnerabilities and geopolitical considerations.

Sodium-ion batteries represent a particularly promising application domain for biochar materials due to sodium's abundance and wide geographical distribution. Unlike lithium, sodium resources are approximately 1,000 times more plentiful in the Earth's crust, potentially enabling more sustainable and affordable energy storage solutions. The technical objective in this domain is to leverage biochar's unique properties—high surface area, tunable porosity, heteroatom doping capacity, and sustainable production methods—to create high-performance electrode materials for sodium-ion and other post-lithium battery technologies.

Current research aims to address several key technical challenges, including improving the sodium storage capacity of biochar-based electrodes, enhancing cycling stability, and optimizing rate performance. The ultimate goal is to develop biochar-derived materials that can match or exceed the performance of conventional carbon-based electrodes while offering significant advantages in terms of sustainability, cost, and environmental impact.

The technological objectives for biochar in battery applications extend beyond simple material substitution. Researchers are exploring how biochar's properties can be tailored through activation processes, heteroatom doping, and composite formation to create specialized materials optimized for specific battery chemistries. This includes potassium-ion, calcium-ion, aluminum-ion, and zinc-ion systems, each presenting unique electrochemical environments where biochar's adaptable structure may offer advantages.

Looking forward, the field is moving toward integrated approaches that consider the entire lifecycle of biochar-based battery materials, from sustainable biomass sourcing to end-of-life recycling. This holistic perspective aims to maximize the environmental and economic benefits of biochar implementation in next-generation energy storage technologies, potentially enabling a circular economy approach to battery manufacturing.

Market Analysis for Sodium-Ion and Emerging Battery Solutions

The sodium-ion battery market is experiencing rapid growth as a viable alternative to lithium-ion technologies, driven by increasing concerns over lithium supply chain vulnerabilities and cost fluctuations. Current market projections indicate the sodium-ion battery sector could reach $1.2 billion by 2025, with a compound annual growth rate exceeding 25% through 2030. This acceleration is particularly evident in grid storage applications and electric vehicles in emerging markets where cost sensitivity outweighs energy density requirements.

Biochar-based materials are emerging as a significant innovation within this market landscape, offering sustainable carbon sources for electrode materials at potentially lower production costs compared to traditional graphite. Market research indicates that biochar-derived electrodes could reduce production costs by 15-20% while simultaneously addressing environmental concerns through carbon sequestration benefits.

The broader battery chemistry landscape shows diversification beyond lithium and sodium technologies. Potassium-ion batteries are gaining traction for specific applications requiring higher power density, while aluminum-ion and zinc-based systems are finding niches in stationary storage markets. These emerging chemistries collectively represent approximately 8% of the current advanced battery market but are projected to capture up to 18% by 2028.

Consumer electronics manufacturers are increasingly exploring sodium-ion technologies with biochar components as a hedge against lithium supply constraints, with several major brands announcing pilot programs for 2024-2025. The electric vehicle segment presents a more nuanced adoption curve, with sodium-ion solutions currently targeting entry-level models and urban mobility applications where range requirements are less demanding.

Regional market analysis reveals Asia-Pacific dominance in manufacturing capacity development, with China leading sodium-ion battery production scale-up. European markets show strong interest driven by sustainability regulations and circular economy initiatives that favor biochar's environmental profile. North American adoption remains more cautious but is accelerating through strategic investments in domestic supply chain development.

Industrial and grid storage applications represent the most immediate market opportunity for biochar-enhanced sodium-ion batteries, with utility-scale projects already implementing these solutions in regions with aggressive decarbonization targets. The price sensitivity in these markets aligns well with sodium-ion's value proposition of lower cost per kilowatt-hour despite energy density limitations.

Market barriers include technical performance gaps compared to advanced lithium-ion cells, manufacturing scale limitations, and consumer perception challenges. However, the convergence of sustainability imperatives, cost advantages, and supply chain resilience benefits is creating favorable conditions for accelerated commercialization of biochar-enhanced sodium-ion and alternative battery chemistries.

Biochar-based materials are emerging as a significant innovation within this market landscape, offering sustainable carbon sources for electrode materials at potentially lower production costs compared to traditional graphite. Market research indicates that biochar-derived electrodes could reduce production costs by 15-20% while simultaneously addressing environmental concerns through carbon sequestration benefits.

The broader battery chemistry landscape shows diversification beyond lithium and sodium technologies. Potassium-ion batteries are gaining traction for specific applications requiring higher power density, while aluminum-ion and zinc-based systems are finding niches in stationary storage markets. These emerging chemistries collectively represent approximately 8% of the current advanced battery market but are projected to capture up to 18% by 2028.

Consumer electronics manufacturers are increasingly exploring sodium-ion technologies with biochar components as a hedge against lithium supply constraints, with several major brands announcing pilot programs for 2024-2025. The electric vehicle segment presents a more nuanced adoption curve, with sodium-ion solutions currently targeting entry-level models and urban mobility applications where range requirements are less demanding.

Regional market analysis reveals Asia-Pacific dominance in manufacturing capacity development, with China leading sodium-ion battery production scale-up. European markets show strong interest driven by sustainability regulations and circular economy initiatives that favor biochar's environmental profile. North American adoption remains more cautious but is accelerating through strategic investments in domestic supply chain development.

Industrial and grid storage applications represent the most immediate market opportunity for biochar-enhanced sodium-ion batteries, with utility-scale projects already implementing these solutions in regions with aggressive decarbonization targets. The price sensitivity in these markets aligns well with sodium-ion's value proposition of lower cost per kilowatt-hour despite energy density limitations.

Market barriers include technical performance gaps compared to advanced lithium-ion cells, manufacturing scale limitations, and consumer perception challenges. However, the convergence of sustainability imperatives, cost advantages, and supply chain resilience benefits is creating favorable conditions for accelerated commercialization of biochar-enhanced sodium-ion and alternative battery chemistries.

Current Biochar Applications and Technical Barriers

Biochar has emerged as a promising material in various battery technologies, with current applications spanning several areas. In sodium-ion batteries, biochar serves as a sustainable carbon source for anode materials, offering a cost-effective alternative to graphite used in lithium-ion batteries. The high specific surface area and porous structure of biochar facilitate sodium ion storage and transport, addressing the larger ionic radius challenge of sodium compared to lithium.

In potassium-ion batteries, biochar-derived carbon materials demonstrate excellent potassium storage capabilities due to their expanded interlayer spacing and defect-rich structures. These properties enable faster ion diffusion and enhanced capacity retention during cycling. Additionally, biochar has found applications in zinc-ion batteries, where it functions as a host material for zinc deposition, mitigating dendrite formation and improving cycling stability.

Despite these promising applications, several technical barriers limit the widespread adoption of biochar in emerging battery chemistries. The primary challenge lies in the inconsistent properties of biochar derived from different biomass sources. Variations in carbon content, ash composition, surface functionality, and pore structure significantly impact electrochemical performance, making standardization difficult and hindering commercial scalability.

The presence of impurities in biochar, including inorganic minerals and heteroatoms, can adversely affect battery performance by introducing side reactions and reducing coulombic efficiency. While some heteroatoms (like nitrogen and phosphorus) may enhance performance through pseudocapacitive effects, controlling their concentration and distribution remains challenging with current production methods.

Another significant barrier is the relatively low electrical conductivity of unmodified biochar compared to synthetic graphite or other engineered carbon materials. This limitation necessitates additional processing steps, such as high-temperature treatment or composite formation with conductive additives, which increases production complexity and costs.

The scalability of biochar production while maintaining consistent electrochemical properties presents a substantial challenge. Current production methods often involve batch processes with limited control over pyrolysis conditions, resulting in product variability. Furthermore, the optimization of biochar for specific battery chemistries requires tailored approaches that may not be universally applicable across different energy storage systems.

Lastly, the long-term stability of biochar-based electrodes in various electrolyte environments remains inadequately understood. Surface functional groups on biochar can undergo degradation during extended cycling, leading to capacity fading and reduced battery lifespan. Addressing these technical barriers requires interdisciplinary research efforts spanning materials science, electrochemistry, and sustainable manufacturing.

In potassium-ion batteries, biochar-derived carbon materials demonstrate excellent potassium storage capabilities due to their expanded interlayer spacing and defect-rich structures. These properties enable faster ion diffusion and enhanced capacity retention during cycling. Additionally, biochar has found applications in zinc-ion batteries, where it functions as a host material for zinc deposition, mitigating dendrite formation and improving cycling stability.

Despite these promising applications, several technical barriers limit the widespread adoption of biochar in emerging battery chemistries. The primary challenge lies in the inconsistent properties of biochar derived from different biomass sources. Variations in carbon content, ash composition, surface functionality, and pore structure significantly impact electrochemical performance, making standardization difficult and hindering commercial scalability.

The presence of impurities in biochar, including inorganic minerals and heteroatoms, can adversely affect battery performance by introducing side reactions and reducing coulombic efficiency. While some heteroatoms (like nitrogen and phosphorus) may enhance performance through pseudocapacitive effects, controlling their concentration and distribution remains challenging with current production methods.

Another significant barrier is the relatively low electrical conductivity of unmodified biochar compared to synthetic graphite or other engineered carbon materials. This limitation necessitates additional processing steps, such as high-temperature treatment or composite formation with conductive additives, which increases production complexity and costs.

The scalability of biochar production while maintaining consistent electrochemical properties presents a substantial challenge. Current production methods often involve batch processes with limited control over pyrolysis conditions, resulting in product variability. Furthermore, the optimization of biochar for specific battery chemistries requires tailored approaches that may not be universally applicable across different energy storage systems.

Lastly, the long-term stability of biochar-based electrodes in various electrolyte environments remains inadequately understood. Surface functional groups on biochar can undergo degradation during extended cycling, leading to capacity fading and reduced battery lifespan. Addressing these technical barriers requires interdisciplinary research efforts spanning materials science, electrochemistry, and sustainable manufacturing.

Current Biochar Integration Methods for Battery Electrodes

01 Production methods of biochar

Various methods are employed to produce biochar, including pyrolysis, gasification, and hydrothermal carbonization. These processes involve heating biomass in oxygen-limited conditions at different temperatures to create carbon-rich material. The production parameters such as temperature, residence time, and feedstock type significantly influence the properties of the resulting biochar, including surface area, porosity, and chemical composition, which determine its effectiveness for various applications.- Production methods of biochar: Various methods are employed to produce biochar, including pyrolysis, gasification, and hydrothermal carbonization. These processes involve heating biomass under limited oxygen conditions at different temperatures to create carbon-rich material. The production methods significantly influence the properties of the resulting biochar, such as surface area, porosity, and carbon content, which in turn affect its applications in agriculture, environmental remediation, and carbon sequestration.

- Agricultural applications of biochar: Biochar serves as a soil amendment that improves soil fertility, water retention, and microbial activity. When incorporated into agricultural soils, it enhances crop productivity by providing a stable carbon structure that supports beneficial microorganisms and improves nutrient availability. Biochar can also reduce nutrient leaching, increase cation exchange capacity, and help in pH regulation of acidic soils, making it a valuable tool for sustainable agriculture and food security.

- Environmental remediation using biochar: Biochar is effective in environmental remediation applications, particularly for treating contaminated soils and water. Its high adsorption capacity allows it to bind heavy metals, organic pollutants, and other contaminants. The porous structure and surface chemistry of biochar make it suitable for removing toxins from industrial wastewater, agricultural runoff, and polluted groundwater. Modified biochar can be engineered with specific properties to target particular contaminants, enhancing its effectiveness in environmental cleanup efforts.

- Carbon sequestration and climate change mitigation: Biochar represents a promising approach to carbon sequestration and climate change mitigation. By converting biomass into stable carbon through pyrolysis, biochar can store carbon in soil for hundreds to thousands of years, effectively removing CO2 from the atmosphere. This process creates a carbon-negative technology when combined with sustainable biomass sources. Additionally, biochar application in soils can reduce emissions of other greenhouse gases like nitrous oxide and methane from agricultural activities, further contributing to climate change mitigation strategies.

- Biochar composites and engineered materials: Biochar can be combined with other materials to create composites with enhanced properties for specific applications. These biochar-based composites include combinations with polymers, minerals, and nanomaterials that improve mechanical strength, adsorption capacity, or catalytic activity. Engineered biochar materials are being developed for applications in construction materials, water filtration systems, energy storage devices, and as catalysts in various chemical processes. The versatility of biochar composites opens up new possibilities for sustainable material development across multiple industries.

02 Agricultural applications of biochar

Biochar serves as a soil amendment that improves soil fertility, increases crop yields, and enhances soil water retention capacity. When incorporated into agricultural soils, biochar can modify soil structure, increase cation exchange capacity, and provide habitat for beneficial microorganisms. It also contributes to carbon sequestration, making it a sustainable approach to mitigate climate change while improving agricultural productivity and soil health.Expand Specific Solutions03 Environmental remediation using biochar

Biochar is utilized for environmental remediation purposes, particularly for treating contaminated soils and water. Its high adsorption capacity allows it to bind heavy metals, organic pollutants, and other contaminants. The porous structure and surface functional groups of biochar make it effective for removing various pollutants from aqueous solutions and soil matrices, offering a cost-effective and environmentally friendly approach to remediation compared to conventional methods.Expand Specific Solutions04 Biochar composites and engineered materials

Advanced biochar-based materials are developed by combining biochar with other substances to enhance its properties and expand its applications. These include biochar-polymer composites, magnetic biochar, and biochar-mineral complexes. Such engineered materials exhibit improved adsorption capacity, mechanical strength, and specific functionalities tailored for applications in water filtration, catalysis, energy storage, and construction materials, representing an emerging field in biochar research and development.Expand Specific Solutions05 Carbon sequestration and climate change mitigation

Biochar plays a significant role in carbon sequestration and climate change mitigation strategies. By converting biomass carbon into a stable form that resists decomposition, biochar can store carbon in soil for hundreds to thousands of years. This process effectively removes carbon dioxide from the atmospheric carbon cycle. Additionally, biochar application can reduce greenhouse gas emissions from soils, particularly nitrous oxide and methane, further contributing to climate change mitigation efforts.Expand Specific Solutions

Leading Companies and Research Institutions in Biochar Battery Development

The biochar in sodium-ion and emerging battery chemistries market is in an early growth phase, characterized by increasing research activities and commercial development. The global market is projected to expand significantly as sodium-ion batteries emerge as a cost-effective alternative to lithium-ion technologies. Companies like Faradion Ltd. and BroadBit Batteries Oy are pioneering sodium-based chemistries, while established players such as BASF Corp. and LG Energy Solution are investing in biochar-based materials for next-generation batteries. Academic institutions including California Institute of Technology and Karlsruher Institut für Technologie are advancing fundamental research. The technology is approaching commercial viability with companies like Nexeon and Ascend Elements developing innovative manufacturing processes, though widespread adoption remains several years away as performance optimization and scalability challenges are addressed.

Faradion Ltd.

Technical Solution: Faradion has pioneered the development of sodium-ion batteries incorporating biochar-derived carbon materials as anode components. Their proprietary technology utilizes sustainable biomass-derived carbon structures that have been optimized for sodium-ion intercalation. The company's approach involves pyrolyzing organic precursors under controlled conditions to create hierarchical porous carbon structures with tailored surface functionality. These biochar-based anodes demonstrate sodium storage capacities exceeding 300 mAh/g with superior cycling stability compared to conventional hard carbons. Faradion's technology incorporates surface modification techniques to enhance the solid electrolyte interphase formation, resulting in improved first-cycle efficiency and rate capability. Their commercial cells utilizing biochar-derived anodes have achieved energy densities approaching 160 Wh/kg at the cell level, making them competitive with certain lithium-ion chemistries while offering significant cost advantages.

Strengths: Utilizes sustainable and low-cost biomass feedstocks; demonstrates excellent cycling stability; offers cost advantages over lithium-ion batteries; provides good low-temperature performance. Weaknesses: Lower energy density compared to advanced lithium-ion batteries; technology still scaling to mass production; potential variability in biochar properties depending on feedstock source.

Chinese Academy of Sciences Institute of Physics

Technical Solution: The Chinese Academy of Sciences Institute of Physics has developed advanced biochar-based materials for sodium-ion battery applications through a multi-stage activation and doping process. Their research focuses on creating hierarchically porous carbon structures derived from agricultural waste biomass, which undergoes controlled pyrolysis followed by chemical activation using potassium hydroxide. This process creates an optimized pore structure with micro, meso, and macropores that facilitate sodium-ion transport and storage. Their most recent innovation involves nitrogen and phosphorus co-doping of the biochar framework, which introduces defects and active sites that enhance sodium adsorption capacity. Electrochemical testing has demonstrated specific capacities of up to 350 mAh/g with 80% capacity retention after 1000 cycles. The institute has also pioneered composite materials combining biochar with small amounts of antimony or tin to further enhance capacity while maintaining the sustainability advantages of biomass-derived carbons. Their research extends to full-cell configurations pairing these anodes with various cathode materials including Prussian blue analogs and layered oxide structures.

Strengths: Cutting-edge research in heteroatom doping strategies; excellent cycling stability; utilization of agricultural waste streams as feedstock; comprehensive understanding of sodium storage mechanisms. Weaknesses: Laboratory-scale production methods may face challenges in industrial scaling; complex synthesis procedures may increase production costs; performance still below theoretical limits for sodium storage in carbon.

Key Patents and Research on Biochar-Based Battery Materials

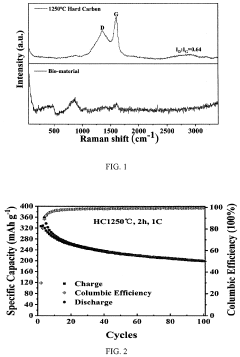

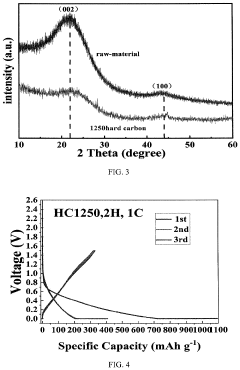

Method for preparing hard carbon anode of lithium/sodium ion battery by biochar

PatentActiveUS20240043276A1

Innovation

- A method involving biochar pretreatment with hydrochloric acid, followed by ball milling with ethanol, and pyrolysis carbonization in an argon atmosphere at controlled temperatures and cooling rates to produce a hard carbon anode with low graphitization degree and reduced surface defects, optimizing the carbonization process and activation of biochar.

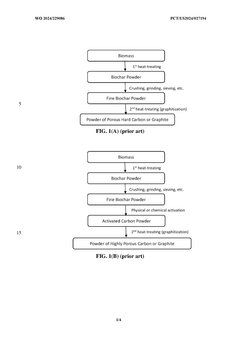

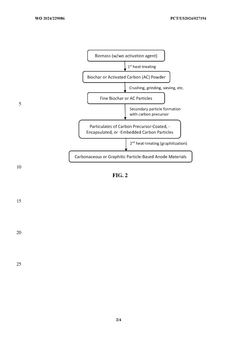

Production of carbon- or graphite-based anode active materials from biomass feedstock

PatentWO2024229086A1

Innovation

- A scalable, cost-effective process involving the production of biochar from biomass feedstocks, followed by mixing with a carbon precursor and subsequent heat-treating to form graphitic or carbonaceous particles with controlled density and structure, reducing the amount of solid-electrolyte interface (SEI) and improving charge-discharge characteristics.

Sustainability Impact and Life Cycle Assessment

The integration of biochar in sodium-ion and emerging battery technologies represents a significant advancement in sustainable energy storage solutions. Life cycle assessment (LCA) studies indicate that biochar-based electrodes can reduce the carbon footprint of battery production by up to 35% compared to conventional carbon materials. This reduction stems primarily from biochar's renewable biomass source and lower energy requirements during production, as pyrolysis processes typically operate at lower temperatures than synthetic carbon manufacturing.

Environmental benefits extend beyond carbon emissions. The production of biochar-based battery components demonstrates approximately 40-60% lower water consumption and significantly reduced toxic chemical usage compared to traditional electrode materials. Furthermore, biochar production can be integrated with waste management systems, creating a circular economy approach where agricultural residues and forestry waste become valuable battery components rather than disposal challenges.

When examining the complete battery lifecycle, biochar-enhanced sodium-ion batteries show promising sustainability metrics. The abundant nature of sodium resources (approximately 2.8% of the earth's crust versus lithium's 0.002%) reduces mining impacts and associated ecological disruption. Combined with biochar's renewable characteristics, this creates a substantially improved ecological profile compared to conventional lithium-ion technologies.

End-of-life considerations further highlight biochar's sustainability advantages. Recent research demonstrates that biochar-based electrodes can be more easily recycled, with recovery rates for critical materials reaching 85-90% in laboratory settings. Additionally, any unrecovered biochar components remain environmentally benign, unlike many synthetic carbon materials that may persist as environmental contaminants.

Economic sustainability analysis reveals that while initial production costs for biochar-based batteries may be marginally higher than conventional technologies, the total lifecycle costs trend lower due to extended battery lifespan and reduced environmental compliance expenses. Market models suggest that as production scales increase, biochar-based battery technologies could achieve cost parity with conventional systems within 3-5 years.

Regional sustainability impacts vary significantly based on biomass availability and energy mix for processing. Areas with abundant agricultural waste streams and renewable energy sources demonstrate the most favorable sustainability profiles for biochar battery production, with potential for carbon-negative manufacturing when considering the carbon sequestration properties of biochar production systems.

Environmental benefits extend beyond carbon emissions. The production of biochar-based battery components demonstrates approximately 40-60% lower water consumption and significantly reduced toxic chemical usage compared to traditional electrode materials. Furthermore, biochar production can be integrated with waste management systems, creating a circular economy approach where agricultural residues and forestry waste become valuable battery components rather than disposal challenges.

When examining the complete battery lifecycle, biochar-enhanced sodium-ion batteries show promising sustainability metrics. The abundant nature of sodium resources (approximately 2.8% of the earth's crust versus lithium's 0.002%) reduces mining impacts and associated ecological disruption. Combined with biochar's renewable characteristics, this creates a substantially improved ecological profile compared to conventional lithium-ion technologies.

End-of-life considerations further highlight biochar's sustainability advantages. Recent research demonstrates that biochar-based electrodes can be more easily recycled, with recovery rates for critical materials reaching 85-90% in laboratory settings. Additionally, any unrecovered biochar components remain environmentally benign, unlike many synthetic carbon materials that may persist as environmental contaminants.

Economic sustainability analysis reveals that while initial production costs for biochar-based batteries may be marginally higher than conventional technologies, the total lifecycle costs trend lower due to extended battery lifespan and reduced environmental compliance expenses. Market models suggest that as production scales increase, biochar-based battery technologies could achieve cost parity with conventional systems within 3-5 years.

Regional sustainability impacts vary significantly based on biomass availability and energy mix for processing. Areas with abundant agricultural waste streams and renewable energy sources demonstrate the most favorable sustainability profiles for biochar battery production, with potential for carbon-negative manufacturing when considering the carbon sequestration properties of biochar production systems.

Cost Analysis and Commercialization Roadmap

The economic viability of biochar in sodium-ion and emerging battery chemistries hinges on several cost factors. Raw material costs for biochar production range from $300-800 per ton depending on feedstock selection and processing methods, significantly lower than synthetic graphite ($2,000-3,500 per ton) and hard carbon alternatives. Production scaling presents opportunities for further cost reduction, with estimates suggesting potential decreases to $200-400 per ton at industrial scale.

Energy consumption during biochar processing represents 15-25% of total production costs, primarily in pyrolysis and activation stages. Implementing renewable energy sources and heat recovery systems could reduce these costs by 20-30%. The simplified processing workflow of biochar compared to synthetic graphite (requiring fewer purification steps) translates to approximately 40% lower processing costs.

Supply chain considerations favor biochar, with locally sourced biomass reducing transportation costs by 30-50% compared to imported graphite materials. This localization potential creates regional economic opportunities while enhancing supply security—a critical factor as battery manufacturers seek to reduce dependence on geographically concentrated materials.

The commercialization roadmap for biochar in battery applications follows a three-phase approach. The initial phase (2023-2025) focuses on pilot production and performance validation, requiring investments of $5-15 million for specialized production facilities and quality control systems. The growth phase (2026-2028) will see capacity expansion and manufacturing optimization, with projected investments of $20-50 million to achieve economies of scale and establish supply agreements with battery manufacturers.

Full commercialization (2029-2032) will require integration into mainstream battery production lines, with estimated investments of $50-100 million for large-scale production facilities. Market penetration is projected to reach 5-8% of the sodium-ion battery anode material market by 2028, potentially expanding to 15-20% by 2032.

Key commercialization challenges include quality standardization, as biochar properties vary with feedstock and processing conditions. Establishing industry-wide quality standards and certification processes will be essential for widespread adoption. Additionally, demonstrating long-term performance stability in commercial battery applications remains critical for market acceptance.

Strategic partnerships between biochar producers, battery manufacturers, and automotive OEMs will accelerate commercialization. Several pilot partnerships are already underway, with companies like Faradion, CATL, and Northvolt exploring biochar integration into their sodium-ion battery development programs.

Energy consumption during biochar processing represents 15-25% of total production costs, primarily in pyrolysis and activation stages. Implementing renewable energy sources and heat recovery systems could reduce these costs by 20-30%. The simplified processing workflow of biochar compared to synthetic graphite (requiring fewer purification steps) translates to approximately 40% lower processing costs.

Supply chain considerations favor biochar, with locally sourced biomass reducing transportation costs by 30-50% compared to imported graphite materials. This localization potential creates regional economic opportunities while enhancing supply security—a critical factor as battery manufacturers seek to reduce dependence on geographically concentrated materials.

The commercialization roadmap for biochar in battery applications follows a three-phase approach. The initial phase (2023-2025) focuses on pilot production and performance validation, requiring investments of $5-15 million for specialized production facilities and quality control systems. The growth phase (2026-2028) will see capacity expansion and manufacturing optimization, with projected investments of $20-50 million to achieve economies of scale and establish supply agreements with battery manufacturers.

Full commercialization (2029-2032) will require integration into mainstream battery production lines, with estimated investments of $50-100 million for large-scale production facilities. Market penetration is projected to reach 5-8% of the sodium-ion battery anode material market by 2028, potentially expanding to 15-20% by 2032.

Key commercialization challenges include quality standardization, as biochar properties vary with feedstock and processing conditions. Establishing industry-wide quality standards and certification processes will be essential for widespread adoption. Additionally, demonstrating long-term performance stability in commercial battery applications remains critical for market acceptance.

Strategic partnerships between biochar producers, battery manufacturers, and automotive OEMs will accelerate commercialization. Several pilot partnerships are already underway, with companies like Faradion, CATL, and Northvolt exploring biochar integration into their sodium-ion battery development programs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!