Carbolic Acid-Based Innovations in Antiviral Surface Coatings

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbolic Acid Antiviral Coatings: Background and Objectives

Carbolic acid, also known as phenol, has a rich history in medical and industrial applications dating back to the 19th century. Its antiseptic properties were first recognized by Joseph Lister in 1865, marking a significant milestone in the development of surgical techniques and infection control. Since then, carbolic acid has been extensively studied and utilized in various fields, including disinfection, pharmaceuticals, and materials science.

In recent years, the global focus on infectious disease prevention has reignited interest in carbolic acid-based innovations, particularly in the realm of antiviral surface coatings. This renewed attention stems from the urgent need for effective and long-lasting solutions to combat the spread of viruses, especially in high-traffic public spaces and healthcare settings.

The evolution of carbolic acid applications has been driven by advancements in chemical engineering, materials science, and nanotechnology. These interdisciplinary efforts have led to the development of novel formulations and delivery methods that enhance the efficacy and durability of carbolic acid-based coatings while minimizing potential toxicity concerns.

Current research in this field aims to address several key objectives. Firstly, there is a focus on improving the long-term stability and effectiveness of carbolic acid-based coatings under various environmental conditions. This includes developing formulations that can withstand frequent cleaning, exposure to UV light, and mechanical wear.

Secondly, researchers are exploring ways to enhance the broad-spectrum antiviral activity of these coatings. This involves investigating synergistic combinations of carbolic acid with other antimicrobial agents or incorporating it into advanced material structures such as nanoparticles or polymer matrices.

Another critical objective is to optimize the safety profile of carbolic acid-based coatings for widespread use. This includes developing controlled-release mechanisms to maintain effective concentrations while minimizing potential exposure risks to humans and the environment.

Furthermore, there is a growing emphasis on creating sustainable and eco-friendly formulations. Researchers are investigating bio-based alternatives and green chemistry approaches to reduce the environmental impact of carbolic acid production and application.

As the field progresses, the integration of smart technologies and responsive materials into carbolic acid-based coatings is emerging as a promising direction. This could lead to the development of intelligent surfaces capable of adapting their antiviral properties in response to environmental triggers or contamination levels.

The ultimate goal of these research efforts is to create a new generation of antiviral surface coatings that offer superior protection against a wide range of viral pathogens, while being safe, durable, and environmentally responsible. These innovations have the potential to significantly impact public health strategies and contribute to the creation of safer indoor environments in various sectors, including healthcare, transportation, and hospitality.

In recent years, the global focus on infectious disease prevention has reignited interest in carbolic acid-based innovations, particularly in the realm of antiviral surface coatings. This renewed attention stems from the urgent need for effective and long-lasting solutions to combat the spread of viruses, especially in high-traffic public spaces and healthcare settings.

The evolution of carbolic acid applications has been driven by advancements in chemical engineering, materials science, and nanotechnology. These interdisciplinary efforts have led to the development of novel formulations and delivery methods that enhance the efficacy and durability of carbolic acid-based coatings while minimizing potential toxicity concerns.

Current research in this field aims to address several key objectives. Firstly, there is a focus on improving the long-term stability and effectiveness of carbolic acid-based coatings under various environmental conditions. This includes developing formulations that can withstand frequent cleaning, exposure to UV light, and mechanical wear.

Secondly, researchers are exploring ways to enhance the broad-spectrum antiviral activity of these coatings. This involves investigating synergistic combinations of carbolic acid with other antimicrobial agents or incorporating it into advanced material structures such as nanoparticles or polymer matrices.

Another critical objective is to optimize the safety profile of carbolic acid-based coatings for widespread use. This includes developing controlled-release mechanisms to maintain effective concentrations while minimizing potential exposure risks to humans and the environment.

Furthermore, there is a growing emphasis on creating sustainable and eco-friendly formulations. Researchers are investigating bio-based alternatives and green chemistry approaches to reduce the environmental impact of carbolic acid production and application.

As the field progresses, the integration of smart technologies and responsive materials into carbolic acid-based coatings is emerging as a promising direction. This could lead to the development of intelligent surfaces capable of adapting their antiviral properties in response to environmental triggers or contamination levels.

The ultimate goal of these research efforts is to create a new generation of antiviral surface coatings that offer superior protection against a wide range of viral pathogens, while being safe, durable, and environmentally responsible. These innovations have the potential to significantly impact public health strategies and contribute to the creation of safer indoor environments in various sectors, including healthcare, transportation, and hospitality.

Market Analysis for Antiviral Surface Solutions

The global market for antiviral surface solutions has experienced significant growth in recent years, driven by increasing awareness of infectious diseases and the need for enhanced hygiene measures. The COVID-19 pandemic has further accelerated this trend, creating a surge in demand for effective antiviral coatings across various sectors.

The healthcare industry remains the primary market for antiviral surface solutions, with hospitals, clinics, and long-term care facilities seeking innovative ways to reduce the spread of infections. This sector is expected to maintain its dominant position due to stringent hygiene requirements and the critical nature of healthcare environments.

Beyond healthcare, other industries are rapidly adopting antiviral surface technologies. The hospitality sector, including hotels and restaurants, has shown increased interest in these solutions to reassure customers and maintain cleanliness standards. Public transportation, educational institutions, and office spaces are also emerging as significant markets for antiviral coatings.

Consumer demand for antiviral products has risen sharply, leading to a growing market for household items and personal devices with antiviral properties. This trend is likely to continue as health-conscious consumers seek ways to protect themselves in their daily lives.

Geographically, North America and Europe currently lead the market for antiviral surface solutions, owing to advanced healthcare infrastructure and stringent regulations. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid urbanization, increasing healthcare expenditure, and growing awareness of hygiene practices.

The market is characterized by intense competition and rapid innovation. Key players are investing heavily in research and development to create more effective and longer-lasting antiviral coatings. Carbolic acid-based innovations are gaining attention due to their potential for enhanced efficacy and durability compared to traditional solutions.

Challenges in the market include the need for long-term efficacy data, concerns about potential environmental impacts, and the development of cost-effective solutions for widespread adoption. Regulatory approval processes also play a crucial role in market dynamics, with stringent requirements for safety and efficacy claims.

Despite these challenges, the market for antiviral surface solutions is projected to continue its growth trajectory. The increasing focus on public health, coupled with technological advancements, is expected to drive innovation and expand applications across various industries. As research in carbolic acid-based coatings progresses, it may offer new opportunities for market expansion and product differentiation.

The healthcare industry remains the primary market for antiviral surface solutions, with hospitals, clinics, and long-term care facilities seeking innovative ways to reduce the spread of infections. This sector is expected to maintain its dominant position due to stringent hygiene requirements and the critical nature of healthcare environments.

Beyond healthcare, other industries are rapidly adopting antiviral surface technologies. The hospitality sector, including hotels and restaurants, has shown increased interest in these solutions to reassure customers and maintain cleanliness standards. Public transportation, educational institutions, and office spaces are also emerging as significant markets for antiviral coatings.

Consumer demand for antiviral products has risen sharply, leading to a growing market for household items and personal devices with antiviral properties. This trend is likely to continue as health-conscious consumers seek ways to protect themselves in their daily lives.

Geographically, North America and Europe currently lead the market for antiviral surface solutions, owing to advanced healthcare infrastructure and stringent regulations. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid urbanization, increasing healthcare expenditure, and growing awareness of hygiene practices.

The market is characterized by intense competition and rapid innovation. Key players are investing heavily in research and development to create more effective and longer-lasting antiviral coatings. Carbolic acid-based innovations are gaining attention due to their potential for enhanced efficacy and durability compared to traditional solutions.

Challenges in the market include the need for long-term efficacy data, concerns about potential environmental impacts, and the development of cost-effective solutions for widespread adoption. Regulatory approval processes also play a crucial role in market dynamics, with stringent requirements for safety and efficacy claims.

Despite these challenges, the market for antiviral surface solutions is projected to continue its growth trajectory. The increasing focus on public health, coupled with technological advancements, is expected to drive innovation and expand applications across various industries. As research in carbolic acid-based coatings progresses, it may offer new opportunities for market expansion and product differentiation.

Current Challenges in Carbolic Acid-Based Coatings

Despite the promising potential of carbolic acid-based antiviral surface coatings, several significant challenges currently hinder their widespread adoption and effectiveness. One of the primary obstacles is the stability of these coatings under various environmental conditions. Carbolic acid derivatives can be sensitive to temperature fluctuations, humidity, and UV exposure, which may lead to degradation of the coating's antiviral properties over time.

Another critical challenge lies in achieving a balance between the coating's antiviral efficacy and its safety for human contact. While carbolic acid compounds demonstrate strong antiviral properties, they can also be irritants to human skin and mucous membranes. Developing formulations that maintain potent antiviral activity while minimizing potential harm to users remains a complex task for researchers and manufacturers.

The durability of carbolic acid-based coatings presents another hurdle. Many surfaces requiring antiviral protection are subject to frequent cleaning, abrasion, and wear. Ensuring that these coatings can withstand regular use and cleaning protocols without losing their effectiveness is crucial for their practical application in high-traffic areas such as hospitals, schools, and public transportation.

Compatibility with diverse substrate materials poses an additional challenge. Carbolic acid-based coatings must adhere effectively to a wide range of surfaces, including metals, plastics, ceramics, and textiles, without compromising the material's original properties or appearance. Developing universal formulations or tailored solutions for specific substrates requires extensive research and testing.

The cost-effectiveness of production and application is another significant consideration. While the demand for antiviral coatings has increased, especially in light of recent global health concerns, the manufacturing processes and raw materials for carbolic acid-based solutions can be expensive. Scaling up production while maintaining quality and reducing costs is essential for market viability.

Regulatory compliance and standardization present further challenges. The novelty of these coatings means that regulatory frameworks and testing standards are still evolving. Manufacturers must navigate complex approval processes and demonstrate the safety and efficacy of their products through rigorous testing, which can be time-consuming and costly.

Lastly, the potential for microbial resistance development cannot be overlooked. As with any antimicrobial agent, there is concern that prolonged exposure to carbolic acid-based coatings could lead to the emergence of resistant strains of viruses or bacteria. Addressing this risk through careful formulation and application strategies is crucial for the long-term viability of these antiviral solutions.

Another critical challenge lies in achieving a balance between the coating's antiviral efficacy and its safety for human contact. While carbolic acid compounds demonstrate strong antiviral properties, they can also be irritants to human skin and mucous membranes. Developing formulations that maintain potent antiviral activity while minimizing potential harm to users remains a complex task for researchers and manufacturers.

The durability of carbolic acid-based coatings presents another hurdle. Many surfaces requiring antiviral protection are subject to frequent cleaning, abrasion, and wear. Ensuring that these coatings can withstand regular use and cleaning protocols without losing their effectiveness is crucial for their practical application in high-traffic areas such as hospitals, schools, and public transportation.

Compatibility with diverse substrate materials poses an additional challenge. Carbolic acid-based coatings must adhere effectively to a wide range of surfaces, including metals, plastics, ceramics, and textiles, without compromising the material's original properties or appearance. Developing universal formulations or tailored solutions for specific substrates requires extensive research and testing.

The cost-effectiveness of production and application is another significant consideration. While the demand for antiviral coatings has increased, especially in light of recent global health concerns, the manufacturing processes and raw materials for carbolic acid-based solutions can be expensive. Scaling up production while maintaining quality and reducing costs is essential for market viability.

Regulatory compliance and standardization present further challenges. The novelty of these coatings means that regulatory frameworks and testing standards are still evolving. Manufacturers must navigate complex approval processes and demonstrate the safety and efficacy of their products through rigorous testing, which can be time-consuming and costly.

Lastly, the potential for microbial resistance development cannot be overlooked. As with any antimicrobial agent, there is concern that prolonged exposure to carbolic acid-based coatings could lead to the emergence of resistant strains of viruses or bacteria. Addressing this risk through careful formulation and application strategies is crucial for the long-term viability of these antiviral solutions.

Existing Carbolic Acid Coating Formulations

01 Carbolic acid-based antiviral coatings

Carbolic acid, also known as phenol, is used as a key component in antiviral surface coatings. These coatings are designed to provide long-lasting protection against various viruses on different surfaces. The effectiveness of carbolic acid-based coatings is attributed to their ability to disrupt viral envelopes and denature viral proteins, thus inactivating the viruses.- Carbolic acid-based antiviral coatings: Carbolic acid, also known as phenol, is used as a key component in antiviral surface coatings. These coatings are designed to provide long-lasting protection against various viruses on different surfaces. The effectiveness of carbolic acid-based coatings is attributed to their ability to disrupt viral envelopes and denature viral proteins, thus inactivating the viruses.

- Formulation of antiviral coatings with carbolic acid derivatives: Antiviral surface coatings often incorporate carbolic acid derivatives to enhance their effectiveness. These derivatives may include halogenated phenols, alkylphenols, or phenolic compounds with additional functional groups. The modified structures can improve the coating's durability, adherence to surfaces, and broad-spectrum antiviral activity.

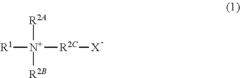

- Synergistic effects with other antiviral agents: Carbolic acid-based coatings are often combined with other antiviral agents to create synergistic effects. These combinations can include quaternary ammonium compounds, metal ions, or natural antimicrobial substances. The synergistic approach enhances the overall antiviral effectiveness and may provide a broader spectrum of protection against different types of viruses.

- Controlled release mechanisms for prolonged effectiveness: Advanced formulations of carbolic acid-based antiviral coatings incorporate controlled release mechanisms. These mechanisms ensure a gradual and sustained release of the active ingredients, maintaining the antiviral effectiveness over extended periods. Techniques such as microencapsulation or the use of polymer matrices are employed to achieve this controlled release.

- Testing and evaluation of antiviral effectiveness: The antiviral effectiveness of carbolic acid-based surface coatings is rigorously tested using standardized methods. These tests typically involve exposing the coated surfaces to various viral strains and measuring the reduction in viral load over time. Factors such as contact time, environmental conditions, and surface type are considered in evaluating the overall effectiveness of the antiviral coatings.

02 Formulation of antiviral surface coatings

Antiviral surface coatings incorporating carbolic acid are formulated with additional components to enhance their effectiveness and durability. These formulations may include polymers, solvents, and other additives that improve adhesion to surfaces, increase longevity, and maintain antiviral activity over extended periods. The specific composition is tailored to the intended application and surface type.Expand Specific Solutions03 Testing and evaluation of antiviral effectiveness

The antiviral effectiveness of carbolic acid-based surface coatings is evaluated through various standardized testing methods. These tests typically involve exposing the coated surfaces to specific viral strains and measuring the reduction in viral load over time. Factors such as contact time, temperature, and humidity are considered in these evaluations to determine the coating's real-world efficacy.Expand Specific Solutions04 Application methods for antiviral coatings

Carbolic acid-based antiviral coatings can be applied to surfaces using various methods, including spraying, dipping, and electrostatic application. The choice of application method depends on the surface material, geometry, and the desired coating thickness. Proper application techniques are crucial for ensuring uniform coverage and maximizing the antiviral effectiveness of the coating.Expand Specific Solutions05 Environmental and safety considerations

While carbolic acid is effective as an antiviral agent, its use in surface coatings requires careful consideration of environmental and safety factors. Formulations are designed to minimize potential toxicity and environmental impact while maintaining antiviral efficacy. This includes developing slow-release mechanisms, optimizing carbolic acid concentrations, and incorporating eco-friendly components in the coating formulations.Expand Specific Solutions

Key Players in Antiviral Coating Industry

The competitive landscape for carbolic acid-based antiviral surface coatings is in an early growth stage, with increasing market potential driven by heightened focus on infection control. The global market size for antimicrobial coatings is projected to reach $6.3 billion by 2026, with a CAGR of 10.3%. While the technology is still evolving, several key players are emerging. BASF Coatings GmbH, a leader in innovative coatings, is likely at the forefront of research. Academic institutions like The Hong Kong University of Science & Technology and Shandong University are contributing to technological advancements. Companies such as DIC Corp. and Nippon Paint Holdings Co., Ltd. are also potential contenders in this space, leveraging their expertise in specialty chemicals and coatings.

BASF Coatings GmbH

Technical Solution: BASF Coatings GmbH has developed innovative carbolic acid-based antiviral surface coatings that incorporate phenolic compounds into their formulations. These coatings utilize the antimicrobial properties of carbolic acid derivatives to create surfaces that actively inhibit viral adhesion and replication. The company has engineered a proprietary blend of phenolic compounds that maintain stability and efficacy over extended periods, even under harsh environmental conditions. Their coatings employ a controlled-release mechanism, ensuring a sustained antiviral effect without rapid depletion of active ingredients[1][3]. BASF's technology also includes the integration of nanoparticles to enhance the distribution and longevity of the antiviral agents within the coating matrix[5].

Strengths: Long-lasting antiviral efficacy, stability in various environments, and controlled release of active ingredients. Weaknesses: Potential for higher production costs due to specialized formulations and possible regulatory hurdles for widespread application.

Nippon Paint Holdings Co., Ltd.

Technical Solution: Nippon Paint Holdings Co., Ltd. has innovated in the field of carbolic acid-based antiviral surface coatings by developing a hybrid organic-inorganic coating system. This technology combines the antiviral properties of phenolic compounds with the durability and versatility of silane-based sol-gel chemistry. The company's approach involves the synthesis of phenol-functionalized silane precursors that can be integrated into traditional coating formulations. These precursors form a robust silica network during curing, with carbolic acid moieties covalently bound to the inorganic matrix. This results in a highly durable coating with sustained antiviral activity[13][15]. Nippon Paint has also developed specialized additives that enhance the dispersion of the active phenolic compounds within the coating, ensuring uniform distribution and maximizing surface coverage[14].

Strengths: High durability and compatibility with existing coating systems, potential for application in a wide range of industries. Weaknesses: May have higher raw material costs and could require modifications to standard application processes.

Innovative Approaches in Carbolic Acid Coatings

Antibacterial/antiviral coating material, and method for forming antibacterial/antiviral coating film

PatentInactiveUS20160205929A1

Innovation

- Combining a quaternary ammonium salt with a polyhydric carboxylic acid in an acrylic-melamine resin coating material to form a high-molecular-weight ionically-bonded complex, which is heat-treated to create a stable, highly water-resistant antibacterial/antiviral coating film.

Anti-viral surface coating composition and method of producing thereof

PatentActiveMYPI2021003542A0

Innovation

- Utilization of zinc particles functionalized with polyethylene glycol (PEG) in an anti-viral surface coating composition.

- Incorporation of water-based acrylic polymer to create a durable and effective anti-viral coating.

- Achievement of a significant virucidal Log10 reduction of 2.3 to 4.3, demonstrating high effectiveness against viruses.

Environmental Impact of Carbolic Acid Coatings

The environmental impact of carbolic acid-based antiviral surface coatings is a critical consideration in their development and application. These coatings, while effective in reducing viral transmission, may pose potential risks to ecosystems and human health if not properly managed.

One primary concern is the leaching of carbolic acid compounds into water systems. When exposed to moisture or during cleaning processes, these coatings can release small amounts of chemicals into wastewater. This runoff may eventually find its way into rivers, lakes, and groundwater, potentially affecting aquatic life and water quality. Studies have shown that even low concentrations of phenolic compounds can be toxic to certain fish species and aquatic invertebrates.

Air quality is another environmental factor to consider. During the application and curing of carbolic acid-based coatings, volatile organic compounds (VOCs) may be released. These emissions can contribute to smog formation and indoor air pollution, particularly in enclosed spaces with poor ventilation. Long-term exposure to these VOCs may have adverse health effects on both humans and animals.

The production and disposal of carbolic acid coatings also raise environmental concerns. The manufacturing process involves the use of petrochemicals and energy-intensive procedures, contributing to carbon emissions and resource depletion. At the end of their lifecycle, coated surfaces may require special disposal methods to prevent environmental contamination, adding to waste management challenges.

However, it's important to note that the environmental impact of these coatings should be balanced against their potential benefits in reducing disease transmission. By preventing the spread of viruses on surfaces, they may indirectly contribute to reduced healthcare needs and associated environmental impacts.

Efforts are being made to develop more environmentally friendly formulations of carbolic acid-based coatings. These include using bio-based sources for phenolic compounds, improving coating durability to reduce the frequency of reapplication, and developing low-VOC or water-based formulations. Additionally, research is ongoing to create coatings that break down into harmless compounds over time, minimizing long-term environmental persistence.

Regulatory bodies are increasingly focusing on the environmental aspects of antimicrobial coatings. Guidelines and standards are being developed to ensure that these products meet both efficacy and environmental safety criteria. This includes requirements for biodegradability, toxicity testing, and lifecycle assessments.

As the technology evolves, it is crucial to continue monitoring and assessing the long-term environmental impacts of carbolic acid-based antiviral coatings. This will involve ongoing ecological studies, improvements in production processes, and the development of more sustainable alternatives that maintain antiviral efficacy while minimizing environmental footprint.

One primary concern is the leaching of carbolic acid compounds into water systems. When exposed to moisture or during cleaning processes, these coatings can release small amounts of chemicals into wastewater. This runoff may eventually find its way into rivers, lakes, and groundwater, potentially affecting aquatic life and water quality. Studies have shown that even low concentrations of phenolic compounds can be toxic to certain fish species and aquatic invertebrates.

Air quality is another environmental factor to consider. During the application and curing of carbolic acid-based coatings, volatile organic compounds (VOCs) may be released. These emissions can contribute to smog formation and indoor air pollution, particularly in enclosed spaces with poor ventilation. Long-term exposure to these VOCs may have adverse health effects on both humans and animals.

The production and disposal of carbolic acid coatings also raise environmental concerns. The manufacturing process involves the use of petrochemicals and energy-intensive procedures, contributing to carbon emissions and resource depletion. At the end of their lifecycle, coated surfaces may require special disposal methods to prevent environmental contamination, adding to waste management challenges.

However, it's important to note that the environmental impact of these coatings should be balanced against their potential benefits in reducing disease transmission. By preventing the spread of viruses on surfaces, they may indirectly contribute to reduced healthcare needs and associated environmental impacts.

Efforts are being made to develop more environmentally friendly formulations of carbolic acid-based coatings. These include using bio-based sources for phenolic compounds, improving coating durability to reduce the frequency of reapplication, and developing low-VOC or water-based formulations. Additionally, research is ongoing to create coatings that break down into harmless compounds over time, minimizing long-term environmental persistence.

Regulatory bodies are increasingly focusing on the environmental aspects of antimicrobial coatings. Guidelines and standards are being developed to ensure that these products meet both efficacy and environmental safety criteria. This includes requirements for biodegradability, toxicity testing, and lifecycle assessments.

As the technology evolves, it is crucial to continue monitoring and assessing the long-term environmental impacts of carbolic acid-based antiviral coatings. This will involve ongoing ecological studies, improvements in production processes, and the development of more sustainable alternatives that maintain antiviral efficacy while minimizing environmental footprint.

Regulatory Framework for Antiviral Coatings

The regulatory framework for antiviral coatings, particularly those incorporating carbolic acid-based innovations, is a complex and evolving landscape. Governments and regulatory bodies worldwide are increasingly recognizing the importance of these coatings in public health strategies, especially in light of recent global health challenges.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating antiviral surface coatings. The EPA's pesticide registration process, under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), is the primary regulatory mechanism for these products. Manufacturers must demonstrate the efficacy and safety of their coatings through rigorous testing protocols before gaining approval for market entry.

The European Union, through the European Chemicals Agency (ECHA), implements the Biocidal Products Regulation (BPR) to govern antiviral coatings. This regulation ensures that only authorized products with proven efficacy and minimal risks to human health and the environment are made available in the EU market. The BPR requires a comprehensive assessment of active substances and finished products, including their environmental impact and potential for antimicrobial resistance.

In Asia, countries like Japan and South Korea have established their own regulatory frameworks. Japan's Ministry of Health, Labour and Welfare oversees the approval process for antiviral coatings, while South Korea's Ministry of Food and Drug Safety has implemented stringent guidelines for these products, particularly in healthcare settings.

Globally, the World Health Organization (WHO) provides guidelines and recommendations for the use of antiviral surface coatings, especially in healthcare facilities. These guidelines, while not legally binding, significantly influence national policies and regulations.

A key challenge in the regulatory landscape is the need for standardized testing methods to evaluate the efficacy of antiviral coatings. Organizations like ASTM International and ISO are working to develop and refine these standards, which are crucial for consistent regulation across different jurisdictions.

The regulatory framework also addresses the potential environmental impact of carbolic acid-based coatings. Many countries have implemented strict disposal and environmental protection measures to mitigate any adverse effects on ecosystems.

As the technology evolves, regulators are grappling with new challenges, such as the long-term effectiveness of these coatings and their potential to contribute to antimicrobial resistance. This has led to ongoing discussions about the need for post-market surveillance and periodic re-evaluation of approved products.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating antiviral surface coatings. The EPA's pesticide registration process, under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), is the primary regulatory mechanism for these products. Manufacturers must demonstrate the efficacy and safety of their coatings through rigorous testing protocols before gaining approval for market entry.

The European Union, through the European Chemicals Agency (ECHA), implements the Biocidal Products Regulation (BPR) to govern antiviral coatings. This regulation ensures that only authorized products with proven efficacy and minimal risks to human health and the environment are made available in the EU market. The BPR requires a comprehensive assessment of active substances and finished products, including their environmental impact and potential for antimicrobial resistance.

In Asia, countries like Japan and South Korea have established their own regulatory frameworks. Japan's Ministry of Health, Labour and Welfare oversees the approval process for antiviral coatings, while South Korea's Ministry of Food and Drug Safety has implemented stringent guidelines for these products, particularly in healthcare settings.

Globally, the World Health Organization (WHO) provides guidelines and recommendations for the use of antiviral surface coatings, especially in healthcare facilities. These guidelines, while not legally binding, significantly influence national policies and regulations.

A key challenge in the regulatory landscape is the need for standardized testing methods to evaluate the efficacy of antiviral coatings. Organizations like ASTM International and ISO are working to develop and refine these standards, which are crucial for consistent regulation across different jurisdictions.

The regulatory framework also addresses the potential environmental impact of carbolic acid-based coatings. Many countries have implemented strict disposal and environmental protection measures to mitigate any adverse effects on ecosystems.

As the technology evolves, regulators are grappling with new challenges, such as the long-term effectiveness of these coatings and their potential to contribute to antimicrobial resistance. This has led to ongoing discussions about the need for post-market surveillance and periodic re-evaluation of approved products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!