Carbolic Acid-Catalyzed Reactions in Organic Electronics Fabrication

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbolic Acid Catalysis in Organic Electronics: Background and Objectives

Carbolic acid, also known as phenol, has emerged as a significant catalyst in the field of organic electronics fabrication. This technology has its roots in the broader domain of organic chemistry and has evolved to play a crucial role in the development of advanced electronic devices. The journey of carbolic acid from a simple organic compound to a key player in electronics manufacturing exemplifies the interdisciplinary nature of modern technological advancements.

The evolution of carbolic acid catalysis in organic electronics is closely tied to the rapid growth of the organic electronics industry over the past few decades. As demand for flexible, lightweight, and cost-effective electronic devices increased, researchers began exploring novel materials and fabrication techniques. Carbolic acid, with its unique chemical properties, emerged as a promising candidate for catalyzing various reactions in the synthesis and processing of organic electronic materials.

The primary objective of utilizing carbolic acid catalysis in organic electronics fabrication is to enhance the efficiency and quality of device production while minimizing environmental impact. This aligns with the broader goals of the electronics industry to develop sustainable and high-performance technologies. Specifically, researchers aim to leverage carbolic acid's catalytic properties to improve the synthesis of organic semiconductors, optimize thin-film deposition processes, and enhance the overall performance of organic electronic devices.

One of the key technological trends in this field is the development of novel carbolic acid-based catalytic systems that can operate under milder conditions, reducing energy consumption and improving yield. Additionally, there is a growing focus on understanding the mechanistic aspects of carbolic acid catalysis at the molecular level, which is crucial for designing more efficient and selective catalytic processes.

The application of carbolic acid catalysis extends to various sectors of organic electronics, including organic light-emitting diodes (OLEDs), organic photovoltaics (OPVs), and organic field-effect transistors (OFETs). Each of these areas presents unique challenges and opportunities for the application of carbolic acid-catalyzed reactions, driving continuous innovation and research in the field.

As the technology continues to evolve, researchers are exploring the integration of carbolic acid catalysis with other emerging technologies, such as nanotechnology and artificial intelligence, to further enhance the fabrication processes of organic electronic devices. This convergence of technologies is expected to lead to breakthroughs in device performance, scalability, and cost-effectiveness.

The evolution of carbolic acid catalysis in organic electronics is closely tied to the rapid growth of the organic electronics industry over the past few decades. As demand for flexible, lightweight, and cost-effective electronic devices increased, researchers began exploring novel materials and fabrication techniques. Carbolic acid, with its unique chemical properties, emerged as a promising candidate for catalyzing various reactions in the synthesis and processing of organic electronic materials.

The primary objective of utilizing carbolic acid catalysis in organic electronics fabrication is to enhance the efficiency and quality of device production while minimizing environmental impact. This aligns with the broader goals of the electronics industry to develop sustainable and high-performance technologies. Specifically, researchers aim to leverage carbolic acid's catalytic properties to improve the synthesis of organic semiconductors, optimize thin-film deposition processes, and enhance the overall performance of organic electronic devices.

One of the key technological trends in this field is the development of novel carbolic acid-based catalytic systems that can operate under milder conditions, reducing energy consumption and improving yield. Additionally, there is a growing focus on understanding the mechanistic aspects of carbolic acid catalysis at the molecular level, which is crucial for designing more efficient and selective catalytic processes.

The application of carbolic acid catalysis extends to various sectors of organic electronics, including organic light-emitting diodes (OLEDs), organic photovoltaics (OPVs), and organic field-effect transistors (OFETs). Each of these areas presents unique challenges and opportunities for the application of carbolic acid-catalyzed reactions, driving continuous innovation and research in the field.

As the technology continues to evolve, researchers are exploring the integration of carbolic acid catalysis with other emerging technologies, such as nanotechnology and artificial intelligence, to further enhance the fabrication processes of organic electronic devices. This convergence of technologies is expected to lead to breakthroughs in device performance, scalability, and cost-effectiveness.

Market Analysis for Carbolic Acid-Based Organic Electronics

The market for carbolic acid-based organic electronics is experiencing significant growth, driven by the increasing demand for flexible, lightweight, and energy-efficient electronic devices. This market segment is closely tied to the broader organic electronics industry, which is projected to reach a substantial market value in the coming years. The application of carbolic acid-catalyzed reactions in organic electronics fabrication has opened up new possibilities for creating advanced materials with enhanced properties.

One of the key drivers of market demand is the growing adoption of organic light-emitting diodes (OLEDs) in displays for smartphones, televisions, and other consumer electronics. Carbolic acid-based materials play a crucial role in improving the efficiency and longevity of OLED devices, contributing to their widespread acceptance in the market. Additionally, the automotive industry is increasingly incorporating organic electronics in vehicle displays and lighting systems, further fueling the demand for carbolic acid-based solutions.

The photovoltaic sector represents another significant market opportunity for carbolic acid-based organic electronics. As the push for renewable energy sources intensifies, organic solar cells are gaining traction due to their potential for low-cost, large-area production. Carbolic acid-catalyzed reactions are instrumental in developing more efficient and stable organic photovoltaic materials, positioning this technology as a promising alternative to traditional silicon-based solar cells.

In the field of organic field-effect transistors (OFETs), carbolic acid-based materials are enabling the development of flexible and printable electronic circuits. This technology is particularly relevant for the emerging market of wearable electronics and Internet of Things (IoT) devices, where lightweight and conformable components are essential. The ability to fabricate OFETs using solution-processing techniques, facilitated by carbolic acid catalysis, offers significant cost advantages and scalability for mass production.

The healthcare sector is also emerging as a potential growth area for carbolic acid-based organic electronics. Biosensors and medical diagnostic devices utilizing organic electronic materials are becoming increasingly sophisticated, with applications ranging from point-of-care testing to continuous health monitoring. The biocompatibility and tunable properties of carbolic acid-derived materials make them particularly suitable for these sensitive applications.

Despite the promising outlook, the market faces challenges such as the need for improved material stability and device performance to compete with established inorganic technologies. However, ongoing research and development efforts are addressing these issues, with a focus on enhancing the longevity and efficiency of carbolic acid-based organic electronic devices. As these technical hurdles are overcome, the market is expected to expand further, penetrating new application areas and potentially disrupting traditional electronics markets.

One of the key drivers of market demand is the growing adoption of organic light-emitting diodes (OLEDs) in displays for smartphones, televisions, and other consumer electronics. Carbolic acid-based materials play a crucial role in improving the efficiency and longevity of OLED devices, contributing to their widespread acceptance in the market. Additionally, the automotive industry is increasingly incorporating organic electronics in vehicle displays and lighting systems, further fueling the demand for carbolic acid-based solutions.

The photovoltaic sector represents another significant market opportunity for carbolic acid-based organic electronics. As the push for renewable energy sources intensifies, organic solar cells are gaining traction due to their potential for low-cost, large-area production. Carbolic acid-catalyzed reactions are instrumental in developing more efficient and stable organic photovoltaic materials, positioning this technology as a promising alternative to traditional silicon-based solar cells.

In the field of organic field-effect transistors (OFETs), carbolic acid-based materials are enabling the development of flexible and printable electronic circuits. This technology is particularly relevant for the emerging market of wearable electronics and Internet of Things (IoT) devices, where lightweight and conformable components are essential. The ability to fabricate OFETs using solution-processing techniques, facilitated by carbolic acid catalysis, offers significant cost advantages and scalability for mass production.

The healthcare sector is also emerging as a potential growth area for carbolic acid-based organic electronics. Biosensors and medical diagnostic devices utilizing organic electronic materials are becoming increasingly sophisticated, with applications ranging from point-of-care testing to continuous health monitoring. The biocompatibility and tunable properties of carbolic acid-derived materials make them particularly suitable for these sensitive applications.

Despite the promising outlook, the market faces challenges such as the need for improved material stability and device performance to compete with established inorganic technologies. However, ongoing research and development efforts are addressing these issues, with a focus on enhancing the longevity and efficiency of carbolic acid-based organic electronic devices. As these technical hurdles are overcome, the market is expected to expand further, penetrating new application areas and potentially disrupting traditional electronics markets.

Current Challenges in Carbolic Acid-Catalyzed Reactions

Carbolic acid-catalyzed reactions in organic electronics fabrication face several significant challenges that hinder their widespread adoption and efficiency. One of the primary issues is the control of reaction kinetics and selectivity. The highly reactive nature of carbolic acid can lead to undesired side reactions, affecting the purity and yield of the target products. This is particularly problematic in the synthesis of complex organic semiconductors, where precise molecular structures are crucial for optimal electronic properties.

Another major challenge lies in the corrosive nature of carbolic acid. Its strong acidity can damage sensitive electronic components and substrates, limiting its applicability in certain fabrication processes. This necessitates the development of protective measures or alternative catalytic systems that maintain efficiency while reducing corrosiveness.

The environmental and safety concerns associated with carbolic acid pose significant hurdles in industrial-scale applications. Its toxicity and potential for environmental contamination require stringent handling protocols and waste management procedures, which can increase production costs and complexity.

Scalability remains a critical challenge for carbolic acid-catalyzed reactions in organic electronics. While these reactions may show promise in laboratory settings, translating them to large-scale manufacturing processes often encounters difficulties in maintaining reaction consistency and product quality across batches.

The stability of carbolic acid under various reaction conditions is another area of concern. Factors such as temperature, pressure, and the presence of other reactants can affect its catalytic activity and longevity, potentially leading to inconsistent results in organic electronics fabrication.

Furthermore, the integration of carbolic acid-catalyzed reactions with other fabrication steps in organic electronics production presents logistical and technical challenges. Ensuring compatibility with existing manufacturing processes and equipment requires careful optimization and often necessitates modifications to established protocols.

Lastly, the development of sustainable and green chemistry alternatives to carbolic acid catalysis is an ongoing challenge. As the electronics industry moves towards more environmentally friendly practices, finding catalytic systems that offer similar efficiency with reduced environmental impact becomes increasingly important.

Another major challenge lies in the corrosive nature of carbolic acid. Its strong acidity can damage sensitive electronic components and substrates, limiting its applicability in certain fabrication processes. This necessitates the development of protective measures or alternative catalytic systems that maintain efficiency while reducing corrosiveness.

The environmental and safety concerns associated with carbolic acid pose significant hurdles in industrial-scale applications. Its toxicity and potential for environmental contamination require stringent handling protocols and waste management procedures, which can increase production costs and complexity.

Scalability remains a critical challenge for carbolic acid-catalyzed reactions in organic electronics. While these reactions may show promise in laboratory settings, translating them to large-scale manufacturing processes often encounters difficulties in maintaining reaction consistency and product quality across batches.

The stability of carbolic acid under various reaction conditions is another area of concern. Factors such as temperature, pressure, and the presence of other reactants can affect its catalytic activity and longevity, potentially leading to inconsistent results in organic electronics fabrication.

Furthermore, the integration of carbolic acid-catalyzed reactions with other fabrication steps in organic electronics production presents logistical and technical challenges. Ensuring compatibility with existing manufacturing processes and equipment requires careful optimization and often necessitates modifications to established protocols.

Lastly, the development of sustainable and green chemistry alternatives to carbolic acid catalysis is an ongoing challenge. As the electronics industry moves towards more environmentally friendly practices, finding catalytic systems that offer similar efficiency with reduced environmental impact becomes increasingly important.

Existing Carbolic Acid-Catalyzed Fabrication Methods

01 Carbolic acid as a catalyst in organic reactions

Carbolic acid, also known as phenol, can be used as a catalyst in various organic reactions. Its acidic properties make it suitable for catalyzing reactions such as condensation, esterification, and polymerization. The use of carbolic acid as a catalyst can improve reaction rates and yields in certain chemical processes.- Carbolic acid as a catalyst in organic reactions: Carbolic acid, also known as phenol, can be used as a catalyst in various organic reactions. Its acidic properties make it suitable for catalyzing reactions such as condensations, esterifications, and polymerizations. The use of carbolic acid as a catalyst can improve reaction rates and yields in certain organic syntheses.

- Carbolic acid-catalyzed reactions in industrial processes: Carbolic acid-catalyzed reactions find applications in various industrial processes. These reactions are utilized in the production of plastics, resins, and other polymeric materials. The catalytic properties of carbolic acid contribute to the efficiency and cost-effectiveness of these industrial processes.

- Carbolic acid-catalyzed reactions in pharmaceutical synthesis: In pharmaceutical synthesis, carbolic acid-catalyzed reactions play a role in the production of certain drug intermediates and active pharmaceutical ingredients. The catalytic activity of carbolic acid can facilitate the formation of specific chemical bonds or functional groups required in pharmaceutical compounds.

- Carbolic acid as a catalyst in environmental applications: Carbolic acid-catalyzed reactions have potential applications in environmental processes. These reactions can be used in the treatment of wastewater, degradation of pollutants, or in the synthesis of environmentally friendly materials. The catalytic properties of carbolic acid contribute to the efficiency of these environmental applications.

- Modifications and improvements to carbolic acid-catalyzed reactions: Research efforts focus on modifying and improving carbolic acid-catalyzed reactions. This includes developing novel reaction conditions, exploring synergistic effects with other catalysts, and optimizing reaction parameters to enhance efficiency and selectivity. These advancements aim to expand the scope and applicability of carbolic acid-catalyzed reactions in various fields.

02 Carbolic acid-catalyzed reactions in pharmaceutical synthesis

In pharmaceutical synthesis, carbolic acid-catalyzed reactions play a role in the production of various drug intermediates and active pharmaceutical ingredients. These reactions can involve the formation of carbon-carbon bonds, functional group transformations, or the synthesis of heterocyclic compounds, which are important in drug development.Expand Specific Solutions03 Industrial applications of carbolic acid-catalyzed reactions

Carbolic acid-catalyzed reactions find applications in various industrial processes, including the production of plastics, resins, and other polymeric materials. These reactions can be used in the synthesis of phenolic resins, which have applications in adhesives, coatings, and molding compounds.Expand Specific Solutions04 Carbolic acid as a catalyst in environmental remediation

Carbolic acid-catalyzed reactions can be utilized in environmental remediation processes, such as the treatment of wastewater or the degradation of organic pollutants. These reactions may involve the oxidation or decomposition of harmful compounds, contributing to pollution control and environmental protection.Expand Specific Solutions05 Optimization and control of carbolic acid-catalyzed reactions

Research focuses on optimizing and controlling carbolic acid-catalyzed reactions to improve efficiency, selectivity, and yield. This includes studying reaction conditions, developing novel catalytic systems, and investigating the mechanisms of these reactions to enhance their practical applications in various fields.Expand Specific Solutions

Key Players in Carbolic Acid Catalysis Research

The field of carbolic acid-catalyzed reactions in organic electronics fabrication is in its early developmental stage, with significant potential for growth. The market size is relatively small but expanding rapidly due to increasing demand for advanced electronic materials. The technology's maturity is still evolving, with key players like Nanjing Tech University, National Research Council of Canada, and Chevron Phillips Chemical Co. LP leading research efforts. Universities such as Central South University and Nanyang Technological University are also contributing to advancements. Industry giants like BASF Corp. and NEC Corp. are investing in this area, indicating its strategic importance. The competitive landscape is characterized by a mix of academic institutions, government research bodies, and chemical companies, suggesting a collaborative approach to innovation in this emerging field.

Mitsubishi Gas Chemical Co., Inc.

Technical Solution: Mitsubishi Gas Chemical Co., Inc. has developed a carbolic acid-catalyzed process for the synthesis of high-purity organic semiconductors used in flexible electronics. Their approach utilizes a proprietary phenol-based catalyst system that enables the production of ultra-pure conjugated polymers with minimal defects[7]. The process incorporates a controlled living polymerization technique, allowing for precise control over polymer chain length and polydispersity[9]. Mitsubishi's technology also includes a purification step that removes trace metal impurities, resulting in improved charge transport properties in the final materials[11].

Strengths: High-purity materials, precise control over polymer properties, suitable for flexible electronics applications. Weaknesses: Potentially higher production costs, may require specialized handling of sensitive materials.

BASF Corp.

Technical Solution: BASF Corp. has developed a novel approach for carbolic acid-catalyzed reactions in organic electronics fabrication. Their method involves using phenol derivatives as catalysts for the synthesis of high-performance organic semiconductors[1]. The process utilizes a controlled polymerization technique, allowing for precise molecular weight control and improved charge carrier mobility in the resulting materials[3]. BASF's technology also incorporates environmentally friendly solvents and reduces the number of synthetic steps, leading to a more sustainable manufacturing process for organic electronic devices[5].

Strengths: Improved material performance, sustainable manufacturing process, precise control over molecular properties. Weaknesses: Potential scalability issues, may require specialized equipment for implementation.

Innovations in Carbolic Acid-Based Catalytic Systems

Acid functionalized organically-bridged polysilsesquioxanes as catalysts for acid catalyzed reactions

PatentInactiveUS5475162A

Innovation

- Development of acid-functionalized organically-bridged polysilsesquioxanes, where acid functionality is covalently bonded to the organic portion of an amorphous three-dimensional silicate-type framework, formed through sol-gel processing, offering a wide range of acid functionalities and enhanced thermal and structural stability.

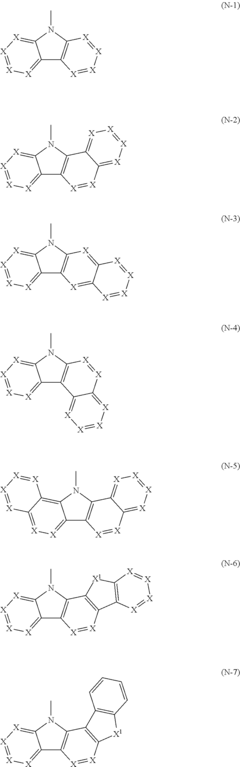

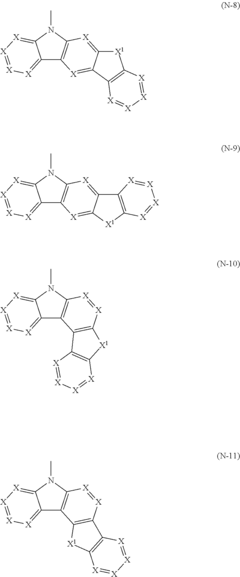

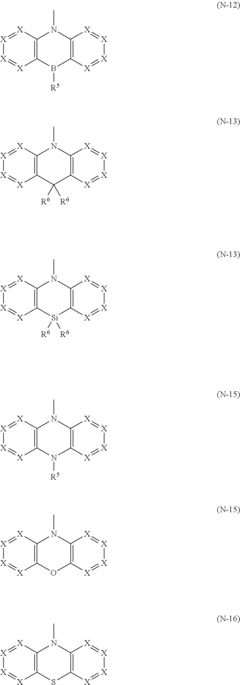

Phenyl derivatives substituted with at least two electron acceptors and at least two electron donors for use in organic electronic devices

PatentActiveUS20180226586A1

Innovation

- A phenyl-derivative compound substituted with at least two electron acceptors and two electron donors is developed, which can be used in organic electronic devices, including OLEDs, formulated with a solvent and produced through specific processes, enhancing material properties and expanding the material pool for these devices.

Environmental Impact of Carbolic Acid in Electronics Manufacturing

The use of carbolic acid (phenol) in organic electronics fabrication processes raises significant environmental concerns. As a toxic and corrosive substance, carbolic acid poses potential risks to ecosystems and human health if not properly managed throughout the manufacturing lifecycle.

During production, the release of carbolic acid vapors can contribute to air pollution, potentially affecting local air quality and posing respiratory hazards to workers and nearby communities. Proper ventilation systems and emission controls are crucial to mitigate these risks. Additionally, the disposal of carbolic acid-containing waste requires careful handling to prevent soil and water contamination.

Water pollution is a particular concern, as carbolic acid is highly soluble and can easily leach into groundwater or surface water systems if improperly disposed of. Even at low concentrations, it can be harmful to aquatic life and potentially enter the food chain. Wastewater treatment facilities must be equipped to handle and neutralize carbolic acid effectively before discharge.

The environmental impact extends beyond the immediate manufacturing process. The production of carbolic acid itself, typically derived from petroleum or coal tar, contributes to the carbon footprint of electronic devices. This upstream impact should be considered in lifecycle assessments of organic electronics.

In terms of product end-of-life, the presence of carbolic acid residues in electronic components complicates recycling efforts. Improper disposal or recycling of these components can lead to the release of carbolic acid into the environment, necessitating specialized handling and treatment processes.

To address these environmental challenges, the electronics industry is exploring greener alternatives and more sustainable manufacturing practices. This includes the development of bio-based phenol substitutes, closed-loop production systems to minimize waste, and advanced treatment technologies for carbolic acid-containing effluents.

Regulatory bodies worldwide are increasingly scrutinizing the use of hazardous substances in electronics manufacturing. Compliance with environmental regulations, such as the European Union's Restriction of Hazardous Substances (RoHS) directive, is driving innovation in safer production methods and materials.

As the demand for organic electronics continues to grow, balancing technological advancement with environmental stewardship becomes increasingly critical. The industry must invest in research and development of eco-friendly alternatives and improved waste management strategies to mitigate the environmental impact of carbolic acid use in electronics manufacturing.

During production, the release of carbolic acid vapors can contribute to air pollution, potentially affecting local air quality and posing respiratory hazards to workers and nearby communities. Proper ventilation systems and emission controls are crucial to mitigate these risks. Additionally, the disposal of carbolic acid-containing waste requires careful handling to prevent soil and water contamination.

Water pollution is a particular concern, as carbolic acid is highly soluble and can easily leach into groundwater or surface water systems if improperly disposed of. Even at low concentrations, it can be harmful to aquatic life and potentially enter the food chain. Wastewater treatment facilities must be equipped to handle and neutralize carbolic acid effectively before discharge.

The environmental impact extends beyond the immediate manufacturing process. The production of carbolic acid itself, typically derived from petroleum or coal tar, contributes to the carbon footprint of electronic devices. This upstream impact should be considered in lifecycle assessments of organic electronics.

In terms of product end-of-life, the presence of carbolic acid residues in electronic components complicates recycling efforts. Improper disposal or recycling of these components can lead to the release of carbolic acid into the environment, necessitating specialized handling and treatment processes.

To address these environmental challenges, the electronics industry is exploring greener alternatives and more sustainable manufacturing practices. This includes the development of bio-based phenol substitutes, closed-loop production systems to minimize waste, and advanced treatment technologies for carbolic acid-containing effluents.

Regulatory bodies worldwide are increasingly scrutinizing the use of hazardous substances in electronics manufacturing. Compliance with environmental regulations, such as the European Union's Restriction of Hazardous Substances (RoHS) directive, is driving innovation in safer production methods and materials.

As the demand for organic electronics continues to grow, balancing technological advancement with environmental stewardship becomes increasingly critical. The industry must invest in research and development of eco-friendly alternatives and improved waste management strategies to mitigate the environmental impact of carbolic acid use in electronics manufacturing.

Scalability and Industrial Application Prospects

The scalability and industrial application prospects of carbolic acid-catalyzed reactions in organic electronics fabrication are promising, with significant potential for large-scale production and diverse applications across various sectors. The use of carbolic acid as a catalyst offers several advantages that make it attractive for industrial-scale processes.

One of the key factors contributing to the scalability of this technology is the relatively low cost and wide availability of carbolic acid. This makes it economically viable for large-scale production, potentially reducing manufacturing costs for organic electronic devices. Additionally, the catalytic nature of carbolic acid means that only small quantities are required to facilitate reactions, further enhancing its cost-effectiveness in industrial applications.

The simplicity of carbolic acid-catalyzed reactions also lends itself well to scalability. These reactions often occur under mild conditions, requiring less energy input compared to some alternative methods. This not only reduces production costs but also aligns with growing industry trends towards more sustainable and environmentally friendly manufacturing processes.

In terms of industrial applications, the versatility of carbolic acid-catalyzed reactions opens up a wide range of possibilities in organic electronics fabrication. These reactions can be utilized in the production of various components, including organic light-emitting diodes (OLEDs), organic photovoltaics, and organic field-effect transistors. The ability to fine-tune reaction conditions allows for precise control over product properties, enabling the manufacture of high-performance electronic devices tailored to specific applications.

The potential for integration into existing manufacturing processes is another factor that enhances the industrial prospects of this technology. Many organic electronics fabrication facilities could potentially adapt their current setups to incorporate carbolic acid-catalyzed reactions without significant overhauls, reducing barriers to adoption.

Looking ahead, the scalability of this technology could lead to increased production efficiency and reduced costs in the organic electronics industry. This, in turn, may accelerate the development and commercialization of new organic electronic devices, potentially revolutionizing sectors such as display technology, renewable energy, and flexible electronics.

However, it is important to note that scaling up laboratory processes to industrial levels often presents unforeseen challenges. Further research and development will be necessary to optimize reaction conditions, ensure consistent product quality at larger scales, and address any potential environmental or safety concerns associated with industrial-scale use of carbolic acid.

One of the key factors contributing to the scalability of this technology is the relatively low cost and wide availability of carbolic acid. This makes it economically viable for large-scale production, potentially reducing manufacturing costs for organic electronic devices. Additionally, the catalytic nature of carbolic acid means that only small quantities are required to facilitate reactions, further enhancing its cost-effectiveness in industrial applications.

The simplicity of carbolic acid-catalyzed reactions also lends itself well to scalability. These reactions often occur under mild conditions, requiring less energy input compared to some alternative methods. This not only reduces production costs but also aligns with growing industry trends towards more sustainable and environmentally friendly manufacturing processes.

In terms of industrial applications, the versatility of carbolic acid-catalyzed reactions opens up a wide range of possibilities in organic electronics fabrication. These reactions can be utilized in the production of various components, including organic light-emitting diodes (OLEDs), organic photovoltaics, and organic field-effect transistors. The ability to fine-tune reaction conditions allows for precise control over product properties, enabling the manufacture of high-performance electronic devices tailored to specific applications.

The potential for integration into existing manufacturing processes is another factor that enhances the industrial prospects of this technology. Many organic electronics fabrication facilities could potentially adapt their current setups to incorporate carbolic acid-catalyzed reactions without significant overhauls, reducing barriers to adoption.

Looking ahead, the scalability of this technology could lead to increased production efficiency and reduced costs in the organic electronics industry. This, in turn, may accelerate the development and commercialization of new organic electronic devices, potentially revolutionizing sectors such as display technology, renewable energy, and flexible electronics.

However, it is important to note that scaling up laboratory processes to industrial levels often presents unforeseen challenges. Further research and development will be necessary to optimize reaction conditions, ensure consistent product quality at larger scales, and address any potential environmental or safety concerns associated with industrial-scale use of carbolic acid.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!