Carbolic Acid Impact on Maritime Biofouling Prevention Coatings

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbolic Acid Antifouling Background and Objectives

Carbolic acid, also known as phenol, has a long history in maritime applications, particularly in the realm of biofouling prevention. The use of this compound in antifouling coatings dates back to the early 20th century when researchers first recognized its potential to inhibit the growth of marine organisms on ship hulls and other submerged structures. Over the years, the understanding of carbolic acid's mechanisms and effectiveness has evolved, leading to its incorporation in various antifouling formulations.

The primary objective of utilizing carbolic acid in maritime biofouling prevention coatings is to create a hostile environment for marine organisms, thereby deterring their attachment and growth on treated surfaces. This approach aims to reduce drag on vessels, minimize fuel consumption, and extend the intervals between dry-docking for hull cleaning and maintenance. Additionally, effective antifouling measures contribute to the prevention of invasive species transfer across different marine ecosystems.

As environmental concerns have gained prominence, the focus of antifouling technology has shifted towards developing more sustainable and eco-friendly solutions. This has led to increased scrutiny of traditional biocides, including carbolic acid, and a push for alternatives that offer comparable performance with reduced environmental impact. The challenge lies in balancing the efficacy of antifouling properties with ecological considerations and regulatory compliance.

Recent technological advancements have opened new avenues for enhancing the performance of carbolic acid-based antifouling coatings. These include the development of controlled-release mechanisms, the exploration of synergistic effects with other compounds, and the integration of nanotechnology to improve the durability and effectiveness of coatings. Such innovations aim to address the limitations of earlier formulations while maintaining the proven antifouling capabilities of carbolic acid.

The ongoing research in this field seeks to optimize the use of carbolic acid in antifouling applications, focusing on aspects such as longevity, broad-spectrum effectiveness against various fouling organisms, and minimization of environmental leaching. Furthermore, there is a growing interest in understanding the potential of carbolic acid derivatives and analogues that may offer improved performance or reduced environmental impact.

As the maritime industry continues to evolve, with increasing emphasis on sustainability and operational efficiency, the role of carbolic acid in biofouling prevention remains a subject of significant interest. The technology's future development trajectory is likely to be shaped by a combination of regulatory pressures, environmental considerations, and the ongoing quest for more effective and sustainable antifouling solutions.

The primary objective of utilizing carbolic acid in maritime biofouling prevention coatings is to create a hostile environment for marine organisms, thereby deterring their attachment and growth on treated surfaces. This approach aims to reduce drag on vessels, minimize fuel consumption, and extend the intervals between dry-docking for hull cleaning and maintenance. Additionally, effective antifouling measures contribute to the prevention of invasive species transfer across different marine ecosystems.

As environmental concerns have gained prominence, the focus of antifouling technology has shifted towards developing more sustainable and eco-friendly solutions. This has led to increased scrutiny of traditional biocides, including carbolic acid, and a push for alternatives that offer comparable performance with reduced environmental impact. The challenge lies in balancing the efficacy of antifouling properties with ecological considerations and regulatory compliance.

Recent technological advancements have opened new avenues for enhancing the performance of carbolic acid-based antifouling coatings. These include the development of controlled-release mechanisms, the exploration of synergistic effects with other compounds, and the integration of nanotechnology to improve the durability and effectiveness of coatings. Such innovations aim to address the limitations of earlier formulations while maintaining the proven antifouling capabilities of carbolic acid.

The ongoing research in this field seeks to optimize the use of carbolic acid in antifouling applications, focusing on aspects such as longevity, broad-spectrum effectiveness against various fouling organisms, and minimization of environmental leaching. Furthermore, there is a growing interest in understanding the potential of carbolic acid derivatives and analogues that may offer improved performance or reduced environmental impact.

As the maritime industry continues to evolve, with increasing emphasis on sustainability and operational efficiency, the role of carbolic acid in biofouling prevention remains a subject of significant interest. The technology's future development trajectory is likely to be shaped by a combination of regulatory pressures, environmental considerations, and the ongoing quest for more effective and sustainable antifouling solutions.

Maritime Coating Market Analysis

The maritime coating market has experienced significant growth in recent years, driven by the expansion of global trade and the increasing demand for efficient and environmentally friendly shipping solutions. This market segment is primarily focused on protective coatings for ships, offshore structures, and port facilities, with a particular emphasis on antifouling and anticorrosive properties.

The global maritime coating market was valued at approximately $3.3 billion in 2020 and is projected to reach $4.5 billion by 2026, growing at a compound annual growth rate (CAGR) of around 5.2% during the forecast period. This growth is attributed to several factors, including the rising number of commercial vessels, increased maritime trade activities, and stringent environmental regulations.

Asia-Pacific dominates the maritime coating market, accounting for over 40% of the global market share. This is primarily due to the presence of major shipbuilding nations such as China, South Korea, and Japan. Europe and North America follow as the second and third largest markets, respectively, driven by their strong maritime industries and focus on technological advancements in coating solutions.

The market is segmented based on resin type, with epoxy-based coatings holding the largest market share due to their excellent adhesion and corrosion resistance properties. Other significant segments include polyurethane, alkyd, and acrylic-based coatings. In terms of application, the antifouling segment is experiencing the highest growth rate, driven by the increasing focus on fuel efficiency and environmental regulations.

Key players in the maritime coating market include AkzoNobel, PPG Industries, Hempel, Sherwin-Williams, Jotun, Chugoku Marine Paints, and Nippon Paint Marine Coatings. These companies are investing heavily in research and development to create innovative coating solutions that address the evolving needs of the maritime industry, particularly in terms of biofouling prevention and environmental sustainability.

The impact of carbolic acid on maritime biofouling prevention coatings is an area of growing interest within the market. As traditional antifouling coatings face increasing scrutiny due to their environmental impact, there is a shift towards more sustainable solutions. Carbolic acid, also known as phenol, has shown promise as a potential alternative or additive in antifouling formulations due to its antimicrobial properties.

Market trends indicate a growing demand for eco-friendly coating solutions that comply with international regulations such as the International Maritime Organization's (IMO) guidelines on biofouling management. This has led to increased research and development efforts focused on incorporating natural biocides like carbolic acid into coating formulations, potentially opening new market opportunities for innovative products that balance performance with environmental considerations.

The global maritime coating market was valued at approximately $3.3 billion in 2020 and is projected to reach $4.5 billion by 2026, growing at a compound annual growth rate (CAGR) of around 5.2% during the forecast period. This growth is attributed to several factors, including the rising number of commercial vessels, increased maritime trade activities, and stringent environmental regulations.

Asia-Pacific dominates the maritime coating market, accounting for over 40% of the global market share. This is primarily due to the presence of major shipbuilding nations such as China, South Korea, and Japan. Europe and North America follow as the second and third largest markets, respectively, driven by their strong maritime industries and focus on technological advancements in coating solutions.

The market is segmented based on resin type, with epoxy-based coatings holding the largest market share due to their excellent adhesion and corrosion resistance properties. Other significant segments include polyurethane, alkyd, and acrylic-based coatings. In terms of application, the antifouling segment is experiencing the highest growth rate, driven by the increasing focus on fuel efficiency and environmental regulations.

Key players in the maritime coating market include AkzoNobel, PPG Industries, Hempel, Sherwin-Williams, Jotun, Chugoku Marine Paints, and Nippon Paint Marine Coatings. These companies are investing heavily in research and development to create innovative coating solutions that address the evolving needs of the maritime industry, particularly in terms of biofouling prevention and environmental sustainability.

The impact of carbolic acid on maritime biofouling prevention coatings is an area of growing interest within the market. As traditional antifouling coatings face increasing scrutiny due to their environmental impact, there is a shift towards more sustainable solutions. Carbolic acid, also known as phenol, has shown promise as a potential alternative or additive in antifouling formulations due to its antimicrobial properties.

Market trends indicate a growing demand for eco-friendly coating solutions that comply with international regulations such as the International Maritime Organization's (IMO) guidelines on biofouling management. This has led to increased research and development efforts focused on incorporating natural biocides like carbolic acid into coating formulations, potentially opening new market opportunities for innovative products that balance performance with environmental considerations.

Current Antifouling Technologies and Challenges

The current landscape of antifouling technologies is characterized by a diverse array of solutions, each with its own set of advantages and challenges. Traditional biocide-based coatings, such as those containing copper compounds, remain widely used due to their proven effectiveness. However, these coatings face increasing scrutiny due to environmental concerns and regulatory pressures, as they can negatively impact non-target marine organisms.

Foul-release coatings represent a more environmentally friendly alternative, utilizing silicone or fluoropolymer-based materials to create a low surface energy that prevents organisms from adhering strongly to the hull. While effective, these coatings are generally more expensive and can be less durable than biocide-based options, particularly in low-speed vessels or those with extended idle periods.

Biomimetic approaches, inspired by natural antifouling mechanisms found in marine organisms, are gaining traction. These include surfaces mimicking shark skin or lotus leaves, which physically deter fouling organisms. However, scaling these technologies for large-scale application and ensuring long-term effectiveness remain significant challenges.

Emerging technologies such as ultraviolet light-emitting coatings and electrically conductive paints show promise but are still in early stages of development and face hurdles in practical implementation and cost-effectiveness. Additionally, nanotechnology-based solutions, incorporating nanoparticles or nanostructured surfaces, are being explored for their potential to enhance antifouling properties without relying on traditional biocides.

One of the primary challenges in the field is developing antifouling solutions that are simultaneously effective, environmentally benign, and economically viable. The marine environment's complexity and the diversity of fouling organisms make it difficult to create a one-size-fits-all solution. Furthermore, the long-term performance of new technologies in real-world conditions is often uncertain, requiring extensive testing and validation.

Regulatory compliance presents another significant challenge, as environmental regulations governing antifouling coatings continue to evolve and become more stringent. This necessitates ongoing research and development to find alternatives that meet both performance requirements and environmental standards.

The integration of carbolic acid into maritime biofouling prevention coatings introduces additional complexities. While carbolic acid (phenol) has known antimicrobial properties, its potential environmental impact and regulatory status must be carefully considered. Research is needed to determine its efficacy in marine environments, its longevity in coating formulations, and its ecological effects when released into water bodies.

Foul-release coatings represent a more environmentally friendly alternative, utilizing silicone or fluoropolymer-based materials to create a low surface energy that prevents organisms from adhering strongly to the hull. While effective, these coatings are generally more expensive and can be less durable than biocide-based options, particularly in low-speed vessels or those with extended idle periods.

Biomimetic approaches, inspired by natural antifouling mechanisms found in marine organisms, are gaining traction. These include surfaces mimicking shark skin or lotus leaves, which physically deter fouling organisms. However, scaling these technologies for large-scale application and ensuring long-term effectiveness remain significant challenges.

Emerging technologies such as ultraviolet light-emitting coatings and electrically conductive paints show promise but are still in early stages of development and face hurdles in practical implementation and cost-effectiveness. Additionally, nanotechnology-based solutions, incorporating nanoparticles or nanostructured surfaces, are being explored for their potential to enhance antifouling properties without relying on traditional biocides.

One of the primary challenges in the field is developing antifouling solutions that are simultaneously effective, environmentally benign, and economically viable. The marine environment's complexity and the diversity of fouling organisms make it difficult to create a one-size-fits-all solution. Furthermore, the long-term performance of new technologies in real-world conditions is often uncertain, requiring extensive testing and validation.

Regulatory compliance presents another significant challenge, as environmental regulations governing antifouling coatings continue to evolve and become more stringent. This necessitates ongoing research and development to find alternatives that meet both performance requirements and environmental standards.

The integration of carbolic acid into maritime biofouling prevention coatings introduces additional complexities. While carbolic acid (phenol) has known antimicrobial properties, its potential environmental impact and regulatory status must be carefully considered. Research is needed to determine its efficacy in marine environments, its longevity in coating formulations, and its ecological effects when released into water bodies.

Carbolic Acid-based Antifouling Solutions

01 Antifouling coatings with biocidal agents

These coatings incorporate biocidal compounds that prevent the attachment and growth of marine organisms on ship hulls and other submerged structures. The biocides are slowly released into the surrounding water, creating a protective layer that inhibits biofouling. Common biocidal agents include copper compounds and organic biocides.- Antifouling coatings with biocidal agents: These coatings incorporate biocidal compounds that prevent the attachment and growth of marine organisms on ship hulls and other submerged structures. The biocides are slowly released into the water, creating a protective layer that inhibits biofouling. Common biocidal agents include copper compounds and organic biocides.

- Fouling-release coatings: These coatings utilize low surface energy materials that make it difficult for marine organisms to adhere to the surface. The slippery nature of these coatings allows fouling organisms to be easily removed by the water flow as the vessel moves through the water, reducing the need for frequent cleaning.

- Nanostructured and textured surfaces: This approach involves creating microscopic surface patterns or textures that discourage the settlement of marine organisms. These surfaces can be inspired by natural antifouling surfaces found in marine organisms. The nanostructures can be combined with other antifouling technologies for enhanced performance.

- Biodegradable and environmentally friendly coatings: These coatings are designed to provide effective antifouling protection while minimizing environmental impact. They may incorporate natural compounds derived from marine organisms or use biodegradable polymers as the coating matrix. These coatings aim to reduce the release of harmful substances into the marine environment.

- Smart and responsive antifouling systems: These advanced systems can adapt to changing environmental conditions or fouling pressures. They may incorporate sensors to detect the presence of fouling organisms and trigger the release of antifouling agents or changes in surface properties. Some systems use electrical currents or other physical mechanisms to prevent fouling attachment.

02 Non-toxic, environmentally friendly coatings

In response to environmental concerns, researchers have developed non-toxic alternatives to traditional biocide-based coatings. These eco-friendly solutions often utilize natural compounds, physical deterrents, or surface modifications to prevent biofouling without harming marine ecosystems.Expand Specific Solutions03 Self-polishing copolymer coatings

These advanced coatings use specially designed polymers that gradually erode in seawater, continuously exposing a fresh surface. This controlled erosion helps maintain a smooth hull surface and can be combined with biocides or other antifouling agents for enhanced performance.Expand Specific Solutions04 Nanostructured and biomimetic surfaces

Inspired by natural antifouling surfaces like shark skin or lotus leaves, these coatings use nano-scale structures or patterns to create surfaces that are inherently resistant to biofouling. The unique surface topography makes it difficult for marine organisms to attach and colonize.Expand Specific Solutions05 Active hull cleaning and maintenance systems

These systems involve mechanical devices or robotic systems that actively clean the hull surface to remove biofouling. Some designs incorporate brushes, water jets, or other cleaning mechanisms that can be deployed while the vessel is in operation, reducing the need for dry-docking and manual cleaning.Expand Specific Solutions

Key Players in Marine Coating Industry

The maritime biofouling prevention coatings industry is in a mature stage, with a global market size estimated at several billion dollars annually. The technology for carbolic acid impact on these coatings is still evolving, indicating a moderate level of technological maturity. Key players like Chugoku Marine Paints and Repela Tech are driving innovation in eco-friendly solutions, while research institutions such as NDSU Research Foundation and South China Sea Institute of Oceanology contribute to advancing the field. The competitive landscape is diverse, with established companies, startups, and academic institutions collaborating and competing to develop more effective and environmentally sustainable antifouling coatings.

Chugoku Marine Paints, Ltd.

Technical Solution: Chugoku Marine Paints has developed advanced antifouling coatings incorporating carbolic acid derivatives. Their technology utilizes controlled release mechanisms to gradually disperse biocides, including carbolic acid compounds, from the paint matrix. This approach ensures long-term effectiveness against marine biofouling organisms. The company has optimized the formulation to balance the release rate of active ingredients with the erosion of the coating surface, maintaining a consistently smooth hull for improved fuel efficiency[1][3]. Their latest products also incorporate nano-scale additives to enhance the durability and performance of the coatings in harsh maritime environments.

Strengths: Proven track record in marine coatings, advanced controlled release technology, and integration of nanotechnology. Weaknesses: Potential environmental concerns due to biocide use, and the need for periodic reapplication.

Repela Tech LLC

Technical Solution: Repela Tech has pioneered a novel approach to maritime biofouling prevention using carbolic acid-inspired compounds. Their technology mimics the natural antifouling properties of certain marine organisms by incorporating synthetic analogues of carbolic acid into a non-toxic, biodegradable polymer matrix. This biomimetic coating creates a surface that discourages the attachment of marine organisms without relying on the release of harmful chemicals. The company has demonstrated that their coatings can maintain effectiveness for up to 18 months in field trials, significantly reducing the need for frequent dry-docking and reapplication[2][5]. Additionally, Repela Tech's formulation includes self-healing properties that can repair minor damage to the coating, further extending its lifespan.

Strengths: Environmentally friendly approach, long-lasting effectiveness, and self-healing capabilities. Weaknesses: Potentially higher initial cost compared to traditional coatings, and limited long-term performance data in various marine environments.

Innovations in Carbolic Acid Coating Technology

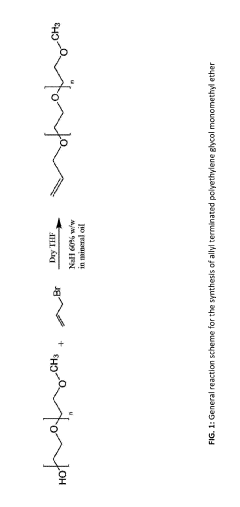

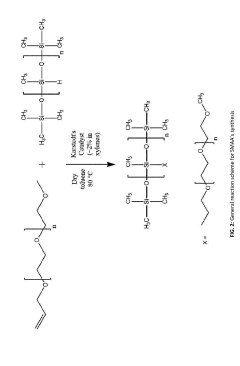

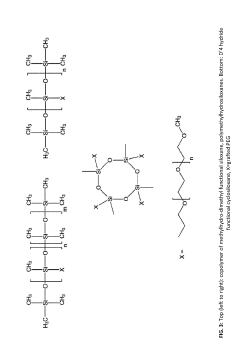

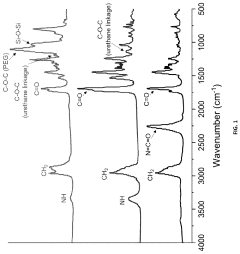

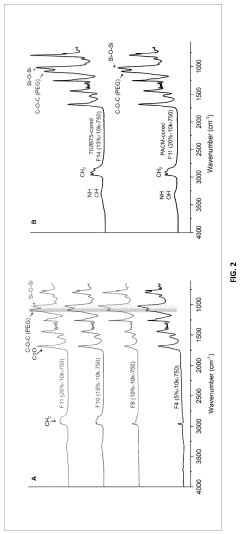

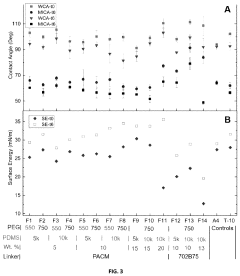

Use of amphiphilic surface modifying additives to improve performance of siloxane-polyurethane fouling-release coatings

PatentActiveUS20190309187A1

Innovation

- Incorporation of non-reactive surface modifying amphiphilic additives (SMAAs) with a polydimethyl siloxane backbone and poly(ethylene glycol) chains into siloxane-polyurethane coatings to create a curable composition that enhances protein resistance and mechanical durability.

Curable coating compositions containing glycidyl carbamate resins and amphiphilic glycidyl-carbamate-functional prepolymers having fouling-release and anti-icing properties

PatentActiveUS11827804B2

Innovation

- Development of amphiphilic glycidyl-carbamate (GC)-based coatings that utilize self-stratification of covalently-bonded PEG and PDMS, optimizing molecular weights and cross-linking agents, and employing a single-step synthesis to create a curable coating composition comprising GC resin, amphiphilic GC-functional prepolymers, and a curing agent, which facilitates fouling-release and anti-icing performance.

Environmental Impact Assessment

The use of carbolic acid in maritime biofouling prevention coatings raises significant environmental concerns that require careful assessment. The primary environmental impact stems from the release of carbolic acid and its derivatives into marine ecosystems. As these coatings gradually wear off or leach into the surrounding water, they can have detrimental effects on marine life and water quality.

Carbolic acid, also known as phenol, is a toxic compound that can cause acute and chronic harm to aquatic organisms. When released into marine environments, it can lead to the mortality of fish, invertebrates, and microorganisms. Even at low concentrations, carbolic acid can disrupt the reproductive cycles and growth patterns of various marine species, potentially causing long-term ecological imbalances.

The bioaccumulation of carbolic acid in marine food chains is another critical concern. As smaller organisms absorb the compound, it can concentrate in higher trophic levels, potentially affecting larger predators and even human consumers of seafood. This bioaccumulation process may lead to far-reaching consequences beyond the immediate vicinity of treated vessels.

Water quality degradation is a significant issue associated with carbolic acid-based coatings. The compound can alter the pH levels of seawater, particularly in enclosed or poorly circulated areas such as harbors and marinas. This pH change can have cascading effects on marine ecosystems, impacting coral reefs, shellfish populations, and other pH-sensitive organisms.

The persistence of carbolic acid in marine environments is another factor that demands attention. While the compound can degrade over time, its breakdown products may also pose environmental risks. The rate of degradation can vary depending on environmental conditions, potentially leading to long-term contamination of sediments and water columns.

Regulatory bodies worldwide are increasingly scrutinizing the use of biocides in antifouling coatings. The environmental impacts of carbolic acid-based solutions may lead to stricter regulations or outright bans in certain jurisdictions. This regulatory landscape necessitates the development of more environmentally friendly alternatives to ensure compliance and minimize ecological harm.

To mitigate these environmental concerns, ongoing research is focusing on developing less toxic and more sustainable antifouling solutions. These include biomimetic coatings, controlled-release technologies, and non-toxic repellents. The environmental impact assessment of carbolic acid in maritime biofouling prevention coatings underscores the urgent need for innovation in this field to balance effective fouling prevention with environmental stewardship.

Carbolic acid, also known as phenol, is a toxic compound that can cause acute and chronic harm to aquatic organisms. When released into marine environments, it can lead to the mortality of fish, invertebrates, and microorganisms. Even at low concentrations, carbolic acid can disrupt the reproductive cycles and growth patterns of various marine species, potentially causing long-term ecological imbalances.

The bioaccumulation of carbolic acid in marine food chains is another critical concern. As smaller organisms absorb the compound, it can concentrate in higher trophic levels, potentially affecting larger predators and even human consumers of seafood. This bioaccumulation process may lead to far-reaching consequences beyond the immediate vicinity of treated vessels.

Water quality degradation is a significant issue associated with carbolic acid-based coatings. The compound can alter the pH levels of seawater, particularly in enclosed or poorly circulated areas such as harbors and marinas. This pH change can have cascading effects on marine ecosystems, impacting coral reefs, shellfish populations, and other pH-sensitive organisms.

The persistence of carbolic acid in marine environments is another factor that demands attention. While the compound can degrade over time, its breakdown products may also pose environmental risks. The rate of degradation can vary depending on environmental conditions, potentially leading to long-term contamination of sediments and water columns.

Regulatory bodies worldwide are increasingly scrutinizing the use of biocides in antifouling coatings. The environmental impacts of carbolic acid-based solutions may lead to stricter regulations or outright bans in certain jurisdictions. This regulatory landscape necessitates the development of more environmentally friendly alternatives to ensure compliance and minimize ecological harm.

To mitigate these environmental concerns, ongoing research is focusing on developing less toxic and more sustainable antifouling solutions. These include biomimetic coatings, controlled-release technologies, and non-toxic repellents. The environmental impact assessment of carbolic acid in maritime biofouling prevention coatings underscores the urgent need for innovation in this field to balance effective fouling prevention with environmental stewardship.

Regulatory Framework for Marine Coatings

The regulatory framework for marine coatings has evolved significantly in response to growing environmental concerns and the need to protect marine ecosystems. International organizations, such as the International Maritime Organization (IMO), play a crucial role in establishing global standards for marine coatings, particularly those used for biofouling prevention.

The IMO's International Convention on the Control of Harmful Anti-fouling Systems on Ships (AFS Convention), which entered into force in 2008, represents a cornerstone of the regulatory landscape. This convention prohibits the use of harmful organotins in anti-fouling paints used on ships and establishes a mechanism to prevent the potential future use of other harmful substances in anti-fouling systems.

In addition to the AFS Convention, regional and national regulations further shape the regulatory environment for marine coatings. The European Union's Biocidal Products Regulation (BPR) and the United States Environmental Protection Agency's (EPA) Vessel General Permit (VGP) program are examples of such regulations that impact the development and use of anti-fouling coatings.

These regulatory frameworks typically address several key aspects of marine coatings, including their chemical composition, environmental impact, and performance standards. They often require manufacturers to conduct extensive testing and provide detailed documentation on the safety and efficacy of their products before they can be approved for use.

The use of carbolic acid (phenol) in maritime biofouling prevention coatings is subject to these regulatory considerations. While carbolic acid has historically been used in various industrial applications due to its antimicrobial properties, its potential environmental impact and toxicity have led to increased scrutiny and restrictions on its use in marine environments.

Regulatory bodies often require comprehensive environmental risk assessments for substances like carbolic acid before they can be incorporated into marine coatings. These assessments typically evaluate factors such as bioaccumulation potential, persistence in the environment, and toxicity to marine organisms.

As the understanding of marine ecosystems and the long-term effects of chemical substances continues to grow, regulatory frameworks are likely to evolve. This may lead to more stringent requirements for the development and use of biofouling prevention coatings, potentially driving innovation towards more environmentally friendly alternatives to traditional biocides like carbolic acid.

The IMO's International Convention on the Control of Harmful Anti-fouling Systems on Ships (AFS Convention), which entered into force in 2008, represents a cornerstone of the regulatory landscape. This convention prohibits the use of harmful organotins in anti-fouling paints used on ships and establishes a mechanism to prevent the potential future use of other harmful substances in anti-fouling systems.

In addition to the AFS Convention, regional and national regulations further shape the regulatory environment for marine coatings. The European Union's Biocidal Products Regulation (BPR) and the United States Environmental Protection Agency's (EPA) Vessel General Permit (VGP) program are examples of such regulations that impact the development and use of anti-fouling coatings.

These regulatory frameworks typically address several key aspects of marine coatings, including their chemical composition, environmental impact, and performance standards. They often require manufacturers to conduct extensive testing and provide detailed documentation on the safety and efficacy of their products before they can be approved for use.

The use of carbolic acid (phenol) in maritime biofouling prevention coatings is subject to these regulatory considerations. While carbolic acid has historically been used in various industrial applications due to its antimicrobial properties, its potential environmental impact and toxicity have led to increased scrutiny and restrictions on its use in marine environments.

Regulatory bodies often require comprehensive environmental risk assessments for substances like carbolic acid before they can be incorporated into marine coatings. These assessments typically evaluate factors such as bioaccumulation potential, persistence in the environment, and toxicity to marine organisms.

As the understanding of marine ecosystems and the long-term effects of chemical substances continues to grow, regulatory frameworks are likely to evolve. This may lead to more stringent requirements for the development and use of biofouling prevention coatings, potentially driving innovation towards more environmentally friendly alternatives to traditional biocides like carbolic acid.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!