Comparative Study of Hydrofluoroolefin and CO2 Blowing Agents

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HFO and CO2 Blowing Agents Background and Objectives

Blowing agents have been a critical component in the production of foams for insulation, packaging, and various industrial applications for decades. The evolution of these agents has been driven by environmental concerns, regulatory changes, and technological advancements. Initially, chlorofluorocarbons (CFCs) dominated the market until their ozone-depleting properties were discovered, leading to their phase-out under the Montreal Protocol in the late 1980s.

Hydrochlorofluorocarbons (HCFCs) and hydrofluorocarbons (HFCs) subsequently emerged as alternatives, but these too faced scrutiny due to their high global warming potential (GWP). This environmental challenge has propelled the industry toward more sustainable options, with hydrofluoroolefins (HFOs) and carbon dioxide (CO2) emerging as promising alternatives in recent years.

HFOs represent a fourth-generation blowing agent technology, characterized by their zero ozone depletion potential and significantly lower GWP compared to their predecessors. The development of HFOs began in the early 2000s, with commercial applications gaining traction in the 2010s. These compounds feature an unsaturated molecular structure that allows them to break down more rapidly in the atmosphere, reducing their environmental impact.

CO2 as a blowing agent has a parallel but distinct developmental trajectory. While natural CO2 has been used in various applications for decades, its refinement as an effective blowing agent for diverse foam applications has accelerated in response to environmental regulations. CO2 offers the advantage of being naturally occurring, non-toxic, and having a GWP of 1, making it a benchmark against which other blowing agents are measured.

The technical objectives of this comparative study are multifaceted. First, we aim to evaluate the performance characteristics of HFOs and CO2 across different foam applications, including thermal insulation efficiency, mechanical properties, and long-term stability. Second, we seek to quantify the environmental impact of both agents throughout their lifecycle, from production to end-of-life considerations.

Additionally, this study will assess the economic implications of transitioning to these newer blowing agents, including production costs, equipment modifications, and potential market advantages. The regulatory landscape surrounding these technologies will also be examined, as compliance with evolving environmental standards remains a driving force in the industry.

Finally, we intend to identify potential synergies between HFOs and CO2, exploring hybrid systems that might leverage the strengths of each agent while mitigating their respective limitations. This holistic approach aims to provide a comprehensive understanding of these technologies to guide future research, development, and industrial applications in the foam manufacturing sector.

Hydrochlorofluorocarbons (HCFCs) and hydrofluorocarbons (HFCs) subsequently emerged as alternatives, but these too faced scrutiny due to their high global warming potential (GWP). This environmental challenge has propelled the industry toward more sustainable options, with hydrofluoroolefins (HFOs) and carbon dioxide (CO2) emerging as promising alternatives in recent years.

HFOs represent a fourth-generation blowing agent technology, characterized by their zero ozone depletion potential and significantly lower GWP compared to their predecessors. The development of HFOs began in the early 2000s, with commercial applications gaining traction in the 2010s. These compounds feature an unsaturated molecular structure that allows them to break down more rapidly in the atmosphere, reducing their environmental impact.

CO2 as a blowing agent has a parallel but distinct developmental trajectory. While natural CO2 has been used in various applications for decades, its refinement as an effective blowing agent for diverse foam applications has accelerated in response to environmental regulations. CO2 offers the advantage of being naturally occurring, non-toxic, and having a GWP of 1, making it a benchmark against which other blowing agents are measured.

The technical objectives of this comparative study are multifaceted. First, we aim to evaluate the performance characteristics of HFOs and CO2 across different foam applications, including thermal insulation efficiency, mechanical properties, and long-term stability. Second, we seek to quantify the environmental impact of both agents throughout their lifecycle, from production to end-of-life considerations.

Additionally, this study will assess the economic implications of transitioning to these newer blowing agents, including production costs, equipment modifications, and potential market advantages. The regulatory landscape surrounding these technologies will also be examined, as compliance with evolving environmental standards remains a driving force in the industry.

Finally, we intend to identify potential synergies between HFOs and CO2, exploring hybrid systems that might leverage the strengths of each agent while mitigating their respective limitations. This holistic approach aims to provide a comprehensive understanding of these technologies to guide future research, development, and industrial applications in the foam manufacturing sector.

Market Demand Analysis for Sustainable Blowing Agents

The global market for blowing agents is experiencing a significant shift towards sustainable alternatives, driven by environmental regulations and corporate sustainability commitments. The combined market for foam insulation and packaging materials, where blowing agents are primarily used, was valued at approximately $87 billion in 2022 and is projected to grow at a CAGR of 5.8% through 2030, creating substantial demand for eco-friendly blowing agents.

Hydrofluoroolefins (HFOs) and CO2 as blowing agents are gaining traction due to their low Global Warming Potential (GWP) compared to traditional hydrofluorocarbons (HFCs). The phase-down of HFCs under the Kigali Amendment to the Montreal Protocol has created an immediate market need for sustainable alternatives, with over 140 countries committed to reducing HFC consumption by more than 80% over the next 30 years.

The construction industry represents the largest market segment for sustainable blowing agents, accounting for nearly 45% of total demand. This is primarily driven by stringent building energy efficiency standards in Europe, North America, and increasingly in Asia. The European Union's Energy Performance of Buildings Directive and similar regulations worldwide have created a robust demand for high-performance insulation materials that utilize environmentally friendly blowing agents.

Automotive and appliance manufacturing sectors collectively contribute about 30% of the market demand for sustainable blowing agents. These industries are increasingly adopting HFO and CO2-based foams to meet consumer preferences for environmentally responsible products and to comply with corporate carbon reduction targets.

Regional analysis reveals that Europe leads in sustainable blowing agent adoption with approximately 38% market share, followed by North America (29%) and Asia-Pacific (24%). The Asia-Pacific region, particularly China and India, is expected to show the highest growth rate in the coming decade due to rapid industrialization coupled with increasing environmental awareness and regulations.

Consumer packaged goods companies are increasingly willing to pay premium prices for sustainable packaging solutions, with surveys indicating that 73% of global consumers would change their consumption habits to reduce environmental impact. This consumer-driven demand is creating new market opportunities for CO2 and HFO blowing agents in food packaging and protective packaging applications.

The economic feasibility of sustainable blowing agents has improved significantly, with the price gap between traditional HFCs and newer alternatives narrowing from over 200% in 2015 to approximately 30-50% in 2023. This trend is expected to continue as production scales up and technology matures, further accelerating market adoption across various industry segments.

Hydrofluoroolefins (HFOs) and CO2 as blowing agents are gaining traction due to their low Global Warming Potential (GWP) compared to traditional hydrofluorocarbons (HFCs). The phase-down of HFCs under the Kigali Amendment to the Montreal Protocol has created an immediate market need for sustainable alternatives, with over 140 countries committed to reducing HFC consumption by more than 80% over the next 30 years.

The construction industry represents the largest market segment for sustainable blowing agents, accounting for nearly 45% of total demand. This is primarily driven by stringent building energy efficiency standards in Europe, North America, and increasingly in Asia. The European Union's Energy Performance of Buildings Directive and similar regulations worldwide have created a robust demand for high-performance insulation materials that utilize environmentally friendly blowing agents.

Automotive and appliance manufacturing sectors collectively contribute about 30% of the market demand for sustainable blowing agents. These industries are increasingly adopting HFO and CO2-based foams to meet consumer preferences for environmentally responsible products and to comply with corporate carbon reduction targets.

Regional analysis reveals that Europe leads in sustainable blowing agent adoption with approximately 38% market share, followed by North America (29%) and Asia-Pacific (24%). The Asia-Pacific region, particularly China and India, is expected to show the highest growth rate in the coming decade due to rapid industrialization coupled with increasing environmental awareness and regulations.

Consumer packaged goods companies are increasingly willing to pay premium prices for sustainable packaging solutions, with surveys indicating that 73% of global consumers would change their consumption habits to reduce environmental impact. This consumer-driven demand is creating new market opportunities for CO2 and HFO blowing agents in food packaging and protective packaging applications.

The economic feasibility of sustainable blowing agents has improved significantly, with the price gap between traditional HFCs and newer alternatives narrowing from over 200% in 2015 to approximately 30-50% in 2023. This trend is expected to continue as production scales up and technology matures, further accelerating market adoption across various industry segments.

Technical Status and Challenges in Foam Blowing Technology

The global foam blowing agent market has undergone significant transformation over the past decades, primarily driven by environmental regulations targeting ozone depletion and global warming. Currently, the industry faces a complex landscape where traditional blowing agents like chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs) have been largely phased out, while hydrofluorocarbons (HFCs) are under increasing regulatory pressure due to their high global warming potential (GWP).

Hydrofluoroolefins (HFOs) represent the newest generation of blowing agents, offering significantly reduced GWP compared to HFCs while maintaining similar performance characteristics. Leading HFO products such as HFO-1234ze and HFO-1336mzz-Z have GWP values below 10, compared to values exceeding 1,000 for many HFCs. Meanwhile, CO2-based blowing agents, both in liquid form and as supercritical CO2, have gained traction as natural alternatives with minimal environmental impact.

The technical challenges facing HFO implementation include higher production costs, which can be 3-5 times greater than traditional HFCs, creating significant market barriers particularly in price-sensitive regions. Additionally, some HFOs exhibit mild flammability characteristics that require modified handling procedures and safety systems, especially in manufacturing environments with high temperatures.

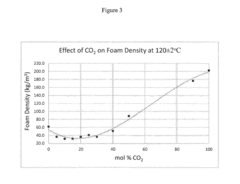

For CO2 blowing agents, the primary technical hurdles involve controlling cellular structure due to CO2's rapid diffusion rate, which can lead to dimensional instability in finished foam products. The high pressure requirements for CO2 systems also necessitate specialized equipment investments, limiting adoption among smaller manufacturers. Furthermore, CO2-blown foams typically exhibit lower insulation performance (approximately 5-10% reduction in R-value) compared to HFO alternatives.

Geographically, North America and Europe lead in HFO adoption due to stringent regulatory frameworks, while Asia-Pacific markets show greater diversity in blowing agent usage with continued reliance on transitional substances. Japan and South Korea have demonstrated faster adoption of next-generation blowing agents compared to other Asian markets.

Research institutions and chemical manufacturers are actively addressing these challenges through various approaches. Blending technologies that combine HFOs with CO2 or other co-blowing agents show promise in optimizing cost-performance ratios. Advanced cell stabilization additives are being developed to improve the dimensional stability of CO2-blown foams, while catalyst innovations are enhancing the reaction profiles for both blowing agent types.

The technical landscape is further complicated by application-specific requirements, as spray foam, rigid board stock, flexible foams, and integral skin foams each present unique processing challenges and performance criteria that influence blowing agent selection and formulation.

Hydrofluoroolefins (HFOs) represent the newest generation of blowing agents, offering significantly reduced GWP compared to HFCs while maintaining similar performance characteristics. Leading HFO products such as HFO-1234ze and HFO-1336mzz-Z have GWP values below 10, compared to values exceeding 1,000 for many HFCs. Meanwhile, CO2-based blowing agents, both in liquid form and as supercritical CO2, have gained traction as natural alternatives with minimal environmental impact.

The technical challenges facing HFO implementation include higher production costs, which can be 3-5 times greater than traditional HFCs, creating significant market barriers particularly in price-sensitive regions. Additionally, some HFOs exhibit mild flammability characteristics that require modified handling procedures and safety systems, especially in manufacturing environments with high temperatures.

For CO2 blowing agents, the primary technical hurdles involve controlling cellular structure due to CO2's rapid diffusion rate, which can lead to dimensional instability in finished foam products. The high pressure requirements for CO2 systems also necessitate specialized equipment investments, limiting adoption among smaller manufacturers. Furthermore, CO2-blown foams typically exhibit lower insulation performance (approximately 5-10% reduction in R-value) compared to HFO alternatives.

Geographically, North America and Europe lead in HFO adoption due to stringent regulatory frameworks, while Asia-Pacific markets show greater diversity in blowing agent usage with continued reliance on transitional substances. Japan and South Korea have demonstrated faster adoption of next-generation blowing agents compared to other Asian markets.

Research institutions and chemical manufacturers are actively addressing these challenges through various approaches. Blending technologies that combine HFOs with CO2 or other co-blowing agents show promise in optimizing cost-performance ratios. Advanced cell stabilization additives are being developed to improve the dimensional stability of CO2-blown foams, while catalyst innovations are enhancing the reaction profiles for both blowing agent types.

The technical landscape is further complicated by application-specific requirements, as spray foam, rigid board stock, flexible foams, and integral skin foams each present unique processing challenges and performance criteria that influence blowing agent selection and formulation.

Current Technical Solutions for HFO and CO2 Applications

01 Hydrofluoroolefin (HFO) and CO2 blends for foam production

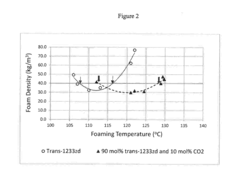

Blends of hydrofluoroolefins (HFOs) and carbon dioxide (CO2) can be used as environmentally friendly blowing agents for producing polymer foams. These blends provide improved thermal insulation properties while reducing global warming potential compared to traditional blowing agents. The combination allows for optimal foam cell structure and density control, making them suitable for applications in construction, automotive, and appliance industries.- Hydrofluoroolefin (HFO) and CO2 blends as environmentally friendly blowing agents: Blends of hydrofluoroolefins (HFOs) and carbon dioxide (CO2) are used as environmentally friendly blowing agents in foam production. These blends offer reduced global warming potential compared to traditional blowing agents while maintaining good insulation properties. The combination leverages CO2's cost-effectiveness with HFOs' stability and performance characteristics, creating a synergistic effect that addresses environmental regulations while meeting industry performance standards.

- Polyurethane foam applications using HFO and CO2 blowing agents: HFO and CO2 blowing agent combinations are specifically formulated for polyurethane foam applications, including rigid insulation foams, spray foams, and flexible foams. These formulations optimize cell structure, thermal conductivity, and dimensional stability while reducing environmental impact. The blends can be adjusted to achieve specific foam properties such as density, compression strength, and thermal resistance required for various industrial and construction applications.

- Formulation techniques for HFO-CO2 blowing agent systems: Specific formulation techniques have been developed for HFO-CO2 blowing agent systems, including precise mixing ratios, addition of co-blowing agents, and incorporation of stabilizers. These techniques address challenges such as solubility differences, reaction kinetics, and phase separation during foam production. Advanced formulation approaches enable manufacturers to optimize processing parameters, improve foam quality, and ensure consistent performance across different production conditions.

- Equipment and process modifications for HFO-CO2 blowing systems: Specialized equipment and process modifications are required for effectively utilizing HFO-CO2 blowing agent systems in foam manufacturing. These include modified mixing heads, pressure control systems, and temperature management technologies that accommodate the unique physical properties of these blowing agent combinations. Process adaptations such as adjusted reaction profiles, modified cure times, and specialized dispensing techniques ensure optimal foam expansion and cell structure formation.

- Performance comparison with traditional blowing agents: Comparative studies between HFO-CO2 blowing agent systems and traditional blowing agents (such as HCFCs and HFCs) demonstrate performance differences in thermal insulation, aging characteristics, and mechanical properties. While HFO-CO2 systems generally show environmental advantages, they may require formulation adjustments to match certain performance aspects of conventional blowing agents. Research indicates that with proper optimization, these environmentally friendly alternatives can achieve comparable or superior performance in most applications.

02 Polyurethane foam systems using HFO/CO2 blowing agents

Polyurethane foam formulations specifically designed to work with hydrofluoroolefin and carbon dioxide blowing agent combinations. These systems include specialized catalysts, surfactants, and polyol blends that optimize the reaction kinetics when using HFO/CO2 blowing agents. The resulting foams exhibit excellent dimensional stability, uniform cell structure, and enhanced energy efficiency properties while meeting environmental regulations.Expand Specific Solutions03 Equipment and methods for applying HFO/CO2 blowing agent systems

Specialized equipment and processing techniques for effectively applying hydrofluoroolefin and carbon dioxide blowing agent mixtures in foam manufacturing. These include modified dispensing systems, pressure control mechanisms, and mixing technologies that ensure proper blending and distribution of the blowing agents. The methods address challenges such as the different physical properties of HFOs and CO2, ensuring consistent foam quality and production efficiency.Expand Specific Solutions04 Environmental benefits and regulatory compliance of HFO/CO2 systems

Hydrofluoroolefin and carbon dioxide blowing agent combinations offer significant environmental advantages including zero ozone depletion potential and substantially reduced global warming impact compared to traditional blowing agents. These systems help manufacturers comply with international regulations such as the Montreal Protocol and Kigali Amendment while maintaining or improving product performance. The transition to these environmentally friendly alternatives supports sustainable manufacturing practices and carbon footprint reduction.Expand Specific Solutions05 Specific HFO compounds and their CO2 compatibility

Various specific hydrofluoroolefin compounds and their compatibility characteristics when used with carbon dioxide as co-blowing agents. Different HFO types (such as HFO-1234ze, HFO-1234yf, and others) exhibit varying solubility, vapor pressure, and reactivity profiles when combined with CO2. These properties affect foam quality, thermal conductivity, and stability. Formulation adjustments based on the specific HFO compound selected can optimize performance for different applications and processing conditions.Expand Specific Solutions

Key Industry Players in Blowing Agent Manufacturing

The hydrofluoroolefin (HFO) and CO2 blowing agents market is currently in a growth phase, driven by environmental regulations phasing out high-GWP alternatives. The global market is estimated at $1.5-2 billion, expanding at 6-8% CAGR as industries transition to sustainable solutions. Technologically, major players have achieved varying degrees of maturity: Honeywell, Arkema, and Chemours lead with commercial HFO products, while Daikin and Central Glass focus on next-generation formulations. Companies like DuPont and 3M are advancing CO2-based systems, particularly for polyurethane applications. Emerging players such as Quanzhou YUJI and Shanghai Dongda are developing cost-effective regional alternatives, while established manufacturers like Owens Corning and Air Products are integrating these blowing agents into comprehensive insulation solutions, creating a competitive landscape balanced between innovation and commercial scalability.

Arkema, Inc.

Technical Solution: Arkema has developed Forane® FBA 1233zd, an HFO-based blowing agent technology specifically engineered for polyurethane foam applications. Their solution features a boiling point of 19°C, making it particularly suitable for spray foam applications where controlled expansion is critical. Arkema's technology incorporates proprietary stabilizers that enhance cell structure uniformity and prevent thermal conductivity degradation over time. Their comparative studies have demonstrated that HFO-1233zd based foams maintain dimensional stability at temperatures ranging from -30°C to 100°C, outperforming CO2-blown alternatives which typically show more significant dimensional changes across temperature extremes. Arkema has also pioneered co-blowing systems that combine HFOs with small amounts of CO2 to optimize cost-performance ratios while maintaining low GWP profiles. Their technology has been implemented in commercial building insulation projects across Europe and North America, demonstrating 8-10% energy efficiency improvements compared to traditional insulation systems.

Strengths: Excellent dimensional stability across wide temperature ranges; Superior cell structure uniformity leading to better long-term insulation performance; Versatile application in both continuous and discontinuous manufacturing processes. Weaknesses: Higher raw material cost compared to CO2 blowing agents; Requires careful handling due to specific physical properties; Limited performance in applications requiring extremely rapid cure rates.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has pioneered the development of Solstice® Liquid Blowing Agent (LBA), a hydrofluoroolefin-based (HFO) blowing agent with ultra-low global warming potential (GWP) of <1, which is 99.9% lower than traditional HFC blowing agents. Their technology utilizes HFO-1233zd(E) as the primary component, which offers superior thermal insulation properties while meeting stringent environmental regulations. Honeywell's solution achieves up to 10-12% better insulation performance compared to hydrocarbon alternatives, enabling foam manufacturers to reduce material thickness while maintaining thermal efficiency. The company has invested in large-scale production facilities in Louisiana to ensure global supply chain reliability and has developed specialized application systems that optimize the blowing agent's dispersion in various polyurethane and polyisocyanurate foam formulations. Their technology has been validated through extensive field testing showing long-term thermal performance stability over 5+ years of accelerated aging tests.

Strengths: Industry-leading low GWP (<1) with no ozone depletion potential; Superior insulation performance allowing material reduction; Non-flammable formulation enhancing manufacturing safety. Weaknesses: Higher initial cost compared to hydrocarbon alternatives; Requires specialized equipment modifications for optimal processing; Limited performance in extremely low-temperature applications.

Critical Patents and Innovations in Blowing Agent Technology

Blowing agent compositions of carbon dioxide and hydrochlorofluoroolefins

PatentActiveUS20170321027A1

Innovation

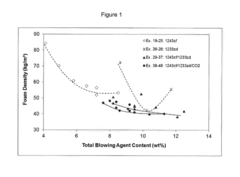

- The use of blends comprising hydrochlorofluoroolefins (HCFO) and hydrofluoroolefins (HFO) with carbon dioxide as blowing agents in thermoplastic foam compositions, which can produce foams with decreased density and improved k-factor, suitable for thermal insulation, by optimizing the ratio and combination of HCFO, HFO, and carbon dioxide.

Blowing agent compositions of hydrofluoroolefins and hydrochlorofluoroolefins

PatentActiveEP2129711A1

Innovation

- The use of blowing agent compositions comprising hydrofluoroolefins (HFOs) and hydrochlorofluoroolefins (HCFOs), specifically combinations like 3,3,3-trifluoropropene (HFO-1243zf), (cis/trans)-1,3,3,3-tetrafluoropropene (HFO-1234ze), and (cis/trans)-1-chloro-3,3,3-trifluoropropene (HCFO-1233zd), which are blended with foamable polymer resins to produce foams with reduced density and enhanced k-factor for thermal insulation.

Environmental Impact Assessment of Blowing Agents

The environmental impact of blowing agents has become a critical consideration in the foam manufacturing industry, with significant implications for global climate change mitigation efforts. Traditional blowing agents such as chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs) have been phased out due to their ozone depletion potential, leading to the adoption of alternatives like hydrofluorocarbons (HFCs).

However, HFCs themselves have high global warming potential (GWP), prompting the industry to transition toward more environmentally friendly options such as hydrofluoroolefins (HFOs) and CO2. When comparing these two alternatives, HFOs demonstrate significantly lower GWP values, typically less than 10, compared to traditional HFCs which can have GWP values in the thousands. CO2 as a blowing agent has a GWP of 1, making it theoretically the most climate-friendly option from a direct emissions perspective.

Life cycle assessment (LCA) studies reveal that the environmental footprint of blowing agents extends beyond their direct GWP values. The production processes for HFOs require more energy and resources than CO2 extraction and processing, potentially offsetting some of their environmental benefits. However, HFOs generally provide superior insulation performance in foam products, which can lead to greater energy efficiency and reduced carbon emissions over the product lifecycle.

Atmospheric persistence is another crucial factor in environmental impact evaluation. HFOs typically break down in the atmosphere within days or weeks, while CO2 can persist for centuries. This short atmospheric lifetime of HFOs reduces their long-term climate impact, despite their initially higher GWP compared to CO2.

Regulatory frameworks worldwide are increasingly recognizing the importance of transitioning to low-GWP blowing agents. The Kigali Amendment to the Montreal Protocol specifically targets the reduction of HFCs, indirectly promoting alternatives like HFOs and CO2. The European F-Gas Regulation and similar policies in North America and Asia are accelerating this transition through phasedown schedules and usage restrictions.

Water consumption and potential for water pollution also differ between these blowing agents. HFO production typically requires more water resources and carries greater potential for water contamination than CO2 capture and purification processes. Additionally, end-of-life considerations reveal that foam products blown with CO2 may be more readily recyclable than those containing HFOs, though this varies depending on specific formulations and regional recycling infrastructure.

Recent technological advancements have focused on optimizing blends of HFOs and CO2 to leverage the strengths of both while minimizing their respective environmental drawbacks. These blended systems represent a promising approach to further reducing the environmental footprint of foam insulation products while maintaining or improving their performance characteristics.

However, HFCs themselves have high global warming potential (GWP), prompting the industry to transition toward more environmentally friendly options such as hydrofluoroolefins (HFOs) and CO2. When comparing these two alternatives, HFOs demonstrate significantly lower GWP values, typically less than 10, compared to traditional HFCs which can have GWP values in the thousands. CO2 as a blowing agent has a GWP of 1, making it theoretically the most climate-friendly option from a direct emissions perspective.

Life cycle assessment (LCA) studies reveal that the environmental footprint of blowing agents extends beyond their direct GWP values. The production processes for HFOs require more energy and resources than CO2 extraction and processing, potentially offsetting some of their environmental benefits. However, HFOs generally provide superior insulation performance in foam products, which can lead to greater energy efficiency and reduced carbon emissions over the product lifecycle.

Atmospheric persistence is another crucial factor in environmental impact evaluation. HFOs typically break down in the atmosphere within days or weeks, while CO2 can persist for centuries. This short atmospheric lifetime of HFOs reduces their long-term climate impact, despite their initially higher GWP compared to CO2.

Regulatory frameworks worldwide are increasingly recognizing the importance of transitioning to low-GWP blowing agents. The Kigali Amendment to the Montreal Protocol specifically targets the reduction of HFCs, indirectly promoting alternatives like HFOs and CO2. The European F-Gas Regulation and similar policies in North America and Asia are accelerating this transition through phasedown schedules and usage restrictions.

Water consumption and potential for water pollution also differ between these blowing agents. HFO production typically requires more water resources and carries greater potential for water contamination than CO2 capture and purification processes. Additionally, end-of-life considerations reveal that foam products blown with CO2 may be more readily recyclable than those containing HFOs, though this varies depending on specific formulations and regional recycling infrastructure.

Recent technological advancements have focused on optimizing blends of HFOs and CO2 to leverage the strengths of both while minimizing their respective environmental drawbacks. These blended systems represent a promising approach to further reducing the environmental footprint of foam insulation products while maintaining or improving their performance characteristics.

Regulatory Framework for Foam Insulation Technologies

The regulatory landscape governing foam insulation technologies has undergone significant transformation in recent decades, primarily driven by environmental concerns related to blowing agents. The Montreal Protocol of 1987 marked the first major international agreement targeting the phase-out of ozone-depleting substances, including chlorofluorocarbons (CFCs) that were commonly used as blowing agents in foam insulation. This was followed by amendments addressing hydrochlorofluorocarbons (HCFCs) and later hydrofluorocarbons (HFCs).

Currently, the Kigali Amendment to the Montreal Protocol, adopted in 2016, specifically targets HFCs with high global warming potential (GWP), establishing a gradual reduction schedule for developed and developing nations. This has directly impacted the foam insulation industry, accelerating the transition toward more environmentally friendly alternatives such as hydrofluoroolefins (HFOs) and CO2-based blowing agents.

In the United States, the Environmental Protection Agency's Significant New Alternatives Policy (SNAP) program regulates substitutes for ozone-depleting substances, with specific rules affecting foam blowing agents. The EPA has progressively restricted high-GWP HFCs in various foam applications, creating regulatory pressure for adoption of HFOs and CO2 technologies. Simultaneously, the Department of Energy has established increasingly stringent energy efficiency standards for buildings and appliances, indirectly influencing insulation requirements.

The European Union has implemented even more aggressive regulations through the F-Gas Regulation (EU No 517/2014), which mandates specific phase-down schedules for HFCs and prohibits their use in certain foam applications. The EU's circular economy initiatives also emphasize end-of-life considerations for foam products, adding another regulatory dimension that manufacturers must address.

Asian markets present a varied regulatory landscape. Japan and South Korea have established HFC phase-down schedules aligned with international agreements, while China—the world's largest producer of insulation materials—has committed to HFC reduction under the Kigali Amendment but maintains longer implementation timelines as a developing nation.

Building codes and standards worldwide are increasingly incorporating sustainability metrics that favor low-GWP blowing agents. The Leadership in Energy and Environmental Design (LEED) certification system awards points for using insulation materials with reduced environmental impact, creating market incentives that complement regulatory requirements.

Industry stakeholders must navigate this complex regulatory environment while balancing performance requirements, cost considerations, and regional compliance variations. The comparative advantages of HFOs versus CO2 blowing agents are significantly influenced by these evolving regulations, with compliance timelines often determining technology adoption rates across different markets.

Currently, the Kigali Amendment to the Montreal Protocol, adopted in 2016, specifically targets HFCs with high global warming potential (GWP), establishing a gradual reduction schedule for developed and developing nations. This has directly impacted the foam insulation industry, accelerating the transition toward more environmentally friendly alternatives such as hydrofluoroolefins (HFOs) and CO2-based blowing agents.

In the United States, the Environmental Protection Agency's Significant New Alternatives Policy (SNAP) program regulates substitutes for ozone-depleting substances, with specific rules affecting foam blowing agents. The EPA has progressively restricted high-GWP HFCs in various foam applications, creating regulatory pressure for adoption of HFOs and CO2 technologies. Simultaneously, the Department of Energy has established increasingly stringent energy efficiency standards for buildings and appliances, indirectly influencing insulation requirements.

The European Union has implemented even more aggressive regulations through the F-Gas Regulation (EU No 517/2014), which mandates specific phase-down schedules for HFCs and prohibits their use in certain foam applications. The EU's circular economy initiatives also emphasize end-of-life considerations for foam products, adding another regulatory dimension that manufacturers must address.

Asian markets present a varied regulatory landscape. Japan and South Korea have established HFC phase-down schedules aligned with international agreements, while China—the world's largest producer of insulation materials—has committed to HFC reduction under the Kigali Amendment but maintains longer implementation timelines as a developing nation.

Building codes and standards worldwide are increasingly incorporating sustainability metrics that favor low-GWP blowing agents. The Leadership in Energy and Environmental Design (LEED) certification system awards points for using insulation materials with reduced environmental impact, creating market incentives that complement regulatory requirements.

Industry stakeholders must navigate this complex regulatory environment while balancing performance requirements, cost considerations, and regional compliance variations. The comparative advantages of HFOs versus CO2 blowing agents are significantly influenced by these evolving regulations, with compliance timelines often determining technology adoption rates across different markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!