Kinetic Modeling of Gas Expansion in Low-GWP Foams

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Low-GWP Foam Gas Expansion Background and Objectives

The evolution of foam insulation technology has been significantly influenced by environmental regulations aimed at reducing greenhouse gas emissions. Historically, foam blowing agents have transitioned from chlorofluorocarbons (CFCs) to hydrochlorofluorocarbons (HCFCs), and then to hydrofluorocarbons (HFCs). However, despite their zero ozone depletion potential, HFCs possess high global warming potential (GWP), prompting the development of low-GWP alternatives.

Low-GWP foam blowing agents, including hydrofluoroolefins (HFOs), hydrochlorofluoroolefins (HCFOs), hydrocarbons, and natural substances like CO2 and water, represent the latest evolution in this technological progression. These alternatives aim to maintain or enhance foam performance while minimizing environmental impact, aligning with global climate agreements such as the Kigali Amendment to the Montreal Protocol, which mandates the phase-down of high-GWP substances.

The kinetic modeling of gas expansion in these low-GWP foams represents a critical frontier in insulation technology. Understanding the expansion dynamics is essential for optimizing foam properties, including thermal conductivity, mechanical strength, and dimensional stability. The technical objective of this research area is to develop comprehensive mathematical models that accurately predict gas expansion behavior in various low-GWP foam systems under different processing conditions.

These models must account for complex physicochemical interactions between the polymer matrix and blowing agents, including phase transitions, diffusion rates, and nucleation phenomena. The ultimate goal is to establish predictive frameworks that enable foam manufacturers to design formulations with optimal thermal insulation properties while meeting environmental regulations.

Current technological trends indicate a growing emphasis on multi-scale modeling approaches that integrate molecular dynamics simulations with macroscopic continuum models. This integration allows for more accurate predictions of foam cell structure development and gas diffusion behavior, which directly influence the long-term insulation performance of the final product.

Additionally, there is increasing interest in developing models that can predict the aging characteristics of low-GWP foams, as the gradual diffusion of blowing agents and air exchange significantly affects the thermal performance over the product lifecycle. This aspect is particularly important for building insulation applications where long-term performance is critical.

The advancement of kinetic modeling capabilities for low-GWP foams is expected to accelerate the industry transition away from high-GWP alternatives, supporting global efforts to mitigate climate change while maintaining or improving the energy efficiency benefits that foam insulation provides across various sectors, including construction, refrigeration, and transportation.

Low-GWP foam blowing agents, including hydrofluoroolefins (HFOs), hydrochlorofluoroolefins (HCFOs), hydrocarbons, and natural substances like CO2 and water, represent the latest evolution in this technological progression. These alternatives aim to maintain or enhance foam performance while minimizing environmental impact, aligning with global climate agreements such as the Kigali Amendment to the Montreal Protocol, which mandates the phase-down of high-GWP substances.

The kinetic modeling of gas expansion in these low-GWP foams represents a critical frontier in insulation technology. Understanding the expansion dynamics is essential for optimizing foam properties, including thermal conductivity, mechanical strength, and dimensional stability. The technical objective of this research area is to develop comprehensive mathematical models that accurately predict gas expansion behavior in various low-GWP foam systems under different processing conditions.

These models must account for complex physicochemical interactions between the polymer matrix and blowing agents, including phase transitions, diffusion rates, and nucleation phenomena. The ultimate goal is to establish predictive frameworks that enable foam manufacturers to design formulations with optimal thermal insulation properties while meeting environmental regulations.

Current technological trends indicate a growing emphasis on multi-scale modeling approaches that integrate molecular dynamics simulations with macroscopic continuum models. This integration allows for more accurate predictions of foam cell structure development and gas diffusion behavior, which directly influence the long-term insulation performance of the final product.

Additionally, there is increasing interest in developing models that can predict the aging characteristics of low-GWP foams, as the gradual diffusion of blowing agents and air exchange significantly affects the thermal performance over the product lifecycle. This aspect is particularly important for building insulation applications where long-term performance is critical.

The advancement of kinetic modeling capabilities for low-GWP foams is expected to accelerate the industry transition away from high-GWP alternatives, supporting global efforts to mitigate climate change while maintaining or improving the energy efficiency benefits that foam insulation provides across various sectors, including construction, refrigeration, and transportation.

Market Analysis for Low-GWP Foam Applications

The global market for low-GWP (Global Warming Potential) foam applications has experienced significant growth in recent years, driven primarily by stringent environmental regulations and increasing awareness of climate change impacts. The foam insulation market, valued at approximately $27.8 billion in 2022, is projected to reach $38.2 billion by 2028, with low-GWP foams representing the fastest-growing segment at a CAGR of 6.5%.

Regulatory frameworks such as the Kigali Amendment to the Montreal Protocol and regional regulations like the EU F-Gas Regulation have created strong market pull for low-GWP alternatives. These regulations have established clear phase-down schedules for high-GWP blowing agents, creating immediate market opportunities for advanced kinetic modeling solutions that can optimize gas expansion in low-GWP foam formulations.

Construction and building insulation represents the largest application segment, accounting for approximately 45% of the low-GWP foam market. This sector's demand is particularly sensitive to thermal efficiency parameters that can be optimized through accurate kinetic modeling of gas expansion behaviors. The automotive sector follows at 22%, where lightweight materials with precise thermal and mechanical properties are increasingly sought after.

Geographically, Europe leads the market adoption of low-GWP foam technologies with a 38% market share, followed by North America (29%) and Asia-Pacific (24%). The Asia-Pacific region, however, demonstrates the highest growth rate at 8.2% annually, presenting significant opportunities for technology deployment in emerging economies.

Customer pain points in the low-GWP foam market center around performance trade-offs when transitioning from traditional blowing agents. Specifically, many low-GWP alternatives exhibit different diffusion rates and thermal conductivity properties, resulting in up to 10% reduced insulation performance. Advanced kinetic modeling that can accurately predict gas expansion behavior addresses this critical market need by enabling formulation optimization.

Market research indicates that foam manufacturers are willing to invest 15-20% premium for solutions that can demonstrably improve the performance of low-GWP formulations to match or exceed traditional HFC-based products. This pricing tolerance creates a viable commercial pathway for sophisticated modeling technologies.

The competitive landscape features chemical suppliers (Honeywell, Chemours), equipment manufacturers (Cannon, Hennecke), and specialized software solution providers. However, comprehensive solutions that integrate kinetic modeling of gas expansion with practical manufacturing parameters remain underrepresented, indicating a market gap that aligns with the technical focus of this research.

Regulatory frameworks such as the Kigali Amendment to the Montreal Protocol and regional regulations like the EU F-Gas Regulation have created strong market pull for low-GWP alternatives. These regulations have established clear phase-down schedules for high-GWP blowing agents, creating immediate market opportunities for advanced kinetic modeling solutions that can optimize gas expansion in low-GWP foam formulations.

Construction and building insulation represents the largest application segment, accounting for approximately 45% of the low-GWP foam market. This sector's demand is particularly sensitive to thermal efficiency parameters that can be optimized through accurate kinetic modeling of gas expansion behaviors. The automotive sector follows at 22%, where lightweight materials with precise thermal and mechanical properties are increasingly sought after.

Geographically, Europe leads the market adoption of low-GWP foam technologies with a 38% market share, followed by North America (29%) and Asia-Pacific (24%). The Asia-Pacific region, however, demonstrates the highest growth rate at 8.2% annually, presenting significant opportunities for technology deployment in emerging economies.

Customer pain points in the low-GWP foam market center around performance trade-offs when transitioning from traditional blowing agents. Specifically, many low-GWP alternatives exhibit different diffusion rates and thermal conductivity properties, resulting in up to 10% reduced insulation performance. Advanced kinetic modeling that can accurately predict gas expansion behavior addresses this critical market need by enabling formulation optimization.

Market research indicates that foam manufacturers are willing to invest 15-20% premium for solutions that can demonstrably improve the performance of low-GWP formulations to match or exceed traditional HFC-based products. This pricing tolerance creates a viable commercial pathway for sophisticated modeling technologies.

The competitive landscape features chemical suppliers (Honeywell, Chemours), equipment manufacturers (Cannon, Hennecke), and specialized software solution providers. However, comprehensive solutions that integrate kinetic modeling of gas expansion with practical manufacturing parameters remain underrepresented, indicating a market gap that aligns with the technical focus of this research.

Current Kinetic Modeling Challenges

The current state of kinetic modeling for gas expansion in low-GWP foams faces several significant challenges that impede accurate prediction and optimization of foam properties. Traditional models developed for high-GWP blowing agents often fail to accurately represent the behavior of newer, environmentally friendly alternatives due to fundamental differences in molecular structure, polarity, and interaction with polymer matrices.

One primary challenge lies in the accurate representation of diffusion coefficients for low-GWP blowing agents. These coefficients exhibit strong temperature and concentration dependencies that are inadequately captured by existing models. The non-linear relationships between diffusion rates and cell structure development create computational complexities that current numerical methods struggle to resolve efficiently, particularly during the critical nucleation and early growth phases.

The multi-phase, multi-component nature of foam expansion presents another significant modeling hurdle. Low-GWP blowing agents often form complex mixtures with co-blowing agents, creating thermodynamic interactions that are difficult to characterize. Current models typically employ simplifying assumptions that fail to account for the full complexity of phase equilibria and interfacial phenomena occurring during the expansion process.

Reaction kinetics modeling presents additional complications, as the catalytic systems optimized for traditional blowing agents may interact differently with low-GWP alternatives. The coupling between polymerization reactions and gas generation/expansion creates feedback loops that are challenging to represent mathematically, especially when considering the influence of various additives present in commercial formulations.

Scale-bridging represents another fundamental challenge, as phenomena occurring at molecular scales must be effectively translated to predict macroscopic foam properties. Current models struggle to integrate molecular dynamics simulations with continuum mechanics approaches in a computationally efficient manner that maintains physical accuracy across multiple length scales.

Validation methodologies also present significant obstacles. The transient nature of foam expansion makes in-situ measurement of key parameters extremely difficult, limiting the availability of experimental data for model calibration and validation. Non-invasive measurement techniques often lack the spatial or temporal resolution needed to capture critical phenomena during rapid expansion phases.

Finally, the computational resources required for fully coupled, three-dimensional simulations of foam expansion remain prohibitive for routine industrial applications. This forces compromises in model complexity and resolution that can significantly impact predictive accuracy, particularly for complex geometries or specialized applications where local variations in foam properties are critical to performance.

One primary challenge lies in the accurate representation of diffusion coefficients for low-GWP blowing agents. These coefficients exhibit strong temperature and concentration dependencies that are inadequately captured by existing models. The non-linear relationships between diffusion rates and cell structure development create computational complexities that current numerical methods struggle to resolve efficiently, particularly during the critical nucleation and early growth phases.

The multi-phase, multi-component nature of foam expansion presents another significant modeling hurdle. Low-GWP blowing agents often form complex mixtures with co-blowing agents, creating thermodynamic interactions that are difficult to characterize. Current models typically employ simplifying assumptions that fail to account for the full complexity of phase equilibria and interfacial phenomena occurring during the expansion process.

Reaction kinetics modeling presents additional complications, as the catalytic systems optimized for traditional blowing agents may interact differently with low-GWP alternatives. The coupling between polymerization reactions and gas generation/expansion creates feedback loops that are challenging to represent mathematically, especially when considering the influence of various additives present in commercial formulations.

Scale-bridging represents another fundamental challenge, as phenomena occurring at molecular scales must be effectively translated to predict macroscopic foam properties. Current models struggle to integrate molecular dynamics simulations with continuum mechanics approaches in a computationally efficient manner that maintains physical accuracy across multiple length scales.

Validation methodologies also present significant obstacles. The transient nature of foam expansion makes in-situ measurement of key parameters extremely difficult, limiting the availability of experimental data for model calibration and validation. Non-invasive measurement techniques often lack the spatial or temporal resolution needed to capture critical phenomena during rapid expansion phases.

Finally, the computational resources required for fully coupled, three-dimensional simulations of foam expansion remain prohibitive for routine industrial applications. This forces compromises in model complexity and resolution that can significantly impact predictive accuracy, particularly for complex geometries or specialized applications where local variations in foam properties are critical to performance.

Current Kinetic Modeling Methodologies

01 Low-GWP blowing agents for foam expansion

Various low global warming potential (GWP) blowing agents are used in foam formulations to replace traditional high-GWP agents. These environmentally friendly alternatives include hydrofluoroolefins (HFOs), hydrochlorofluoroolefins (HCFOs), and natural blowing agents. The kinetic modeling of gas expansion with these agents focuses on their thermodynamic properties, expansion rates, and environmental impact, ensuring effective foam formation while reducing climate effects.- Low-GWP blowing agents for foam expansion: Various low global warming potential (GWP) blowing agents are used in foam production to replace traditional high-GWP agents like HFCs. These environmentally friendly alternatives include hydrofluoroolefins (HFOs), hydrocarbons, CO2, and water-based systems. The kinetic modeling of these blowing agents focuses on their expansion behavior, thermal conductivity, and overall environmental impact during the foaming process.

- Kinetic modeling of foam cell formation and growth: Kinetic modeling approaches are used to predict and optimize the nucleation, growth, and stabilization of foam cells during the expansion process. These models incorporate parameters such as gas diffusion rates, surface tension, viscosity changes during polymerization, and temperature effects. Advanced computational methods help in understanding the relationship between processing conditions and final foam structure in low-GWP systems.

- Temperature and pressure effects on gas expansion: The expansion behavior of low-GWP blowing agents is significantly influenced by temperature and pressure conditions during foam formation. Kinetic models account for how these parameters affect gas solubility, diffusion rates, and phase transitions. Optimizing temperature profiles and pressure conditions is crucial for achieving desired foam properties while maintaining efficient expansion with environmentally friendly blowing agents.

- Catalyst systems for controlled foam expansion: Specialized catalyst systems are developed to control the reaction kinetics in low-GWP foam production. These catalysts help balance the polymerization reaction with gas generation and expansion rates, ensuring optimal cell structure. The kinetic modeling of catalyst behavior includes reaction rate constants, activation energies, and interactions with different low-GWP blowing agents to achieve desired foam properties.

- Computational methods for predicting foam expansion dynamics: Advanced computational methods and simulation techniques are employed to predict the complex dynamics of gas expansion in low-GWP foams. These include computational fluid dynamics (CFD), finite element analysis, and machine learning approaches to model bubble nucleation, growth, and coalescence. Such computational tools help optimize formulations and processing conditions to achieve desired foam properties while minimizing environmental impact.

02 Kinetic modeling techniques for foam expansion processes

Advanced kinetic modeling approaches are employed to understand and predict gas expansion behavior in low-GWP foams. These models incorporate reaction kinetics, diffusion coefficients, and phase transition dynamics to simulate the foam formation process. Computational fluid dynamics (CFD) and molecular dynamics simulations help optimize formulations by predicting cell structure development, expansion rates, and final foam properties based on different blowing agent characteristics.Expand Specific Solutions03 Cell structure control in low-GWP foam systems

Controlling cell structure during gas expansion is critical for foam performance. Techniques include optimizing nucleation agents, surfactants, and catalyst systems specifically designed for low-GWP blowing agents. The kinetic modeling of cell formation accounts for factors such as gas diffusion rates, surface tension effects, and polymerization kinetics to achieve uniform cell size distribution, improved thermal insulation properties, and mechanical strength in the final foam product.Expand Specific Solutions04 Temperature and pressure effects on low-GWP foam expansion

The influence of processing conditions, particularly temperature and pressure profiles, significantly affects gas expansion behavior in low-GWP foam systems. Kinetic models incorporate these parameters to predict expansion rates, cell nucleation, and growth dynamics. Optimized temperature and pressure control strategies are developed to enhance foam quality, reduce density variations, and improve overall performance while maintaining the environmental benefits of low-GWP blowing agents.Expand Specific Solutions05 Catalyst systems for controlled gas release in low-GWP foams

Specialized catalyst systems are designed to control the reaction kinetics and gas release timing in low-GWP foam formulations. These catalysts optimize the balance between polymer formation and gas expansion to achieve desired foam properties. Kinetic modeling of catalyst behavior helps predict reaction rates, gas evolution profiles, and curing characteristics, enabling the development of foam systems with improved dimensional stability, thermal performance, and mechanical properties.Expand Specific Solutions

Key Industry Players in Low-GWP Foam Technology

The kinetic modeling of gas expansion in low-GWP foams market is currently in a growth phase, with increasing regulatory pressure driving adoption of environmentally friendly blowing agents. The global market is estimated at $2-3 billion annually, expanding at 5-7% CAGR as industries transition from high-GWP alternatives. Technologically, the field shows moderate maturity with ongoing innovation. Leading players include DuPont, BASF, and Dow Global Technologies focusing on chemical formulations; Hennecke GmbH and Afros SpA developing processing equipment; while Owens Corning and Sekisui Chemical concentrate on commercial applications. Academic institutions like Sichuan University and Southeast University contribute fundamental research, creating a competitive landscape balanced between established chemical corporations and specialized foam technology providers.

Bayer AG

Technical Solution: Bayer has developed sophisticated kinetic modeling approaches for low-GWP foam expansion that integrate molecular-level simulations with macroscopic expansion dynamics. Their modeling framework, applied to their BAYTHERM® polyurethane systems, incorporates detailed reaction mechanisms for isocyanate-polyol reactions alongside phase equilibrium calculations for next-generation blowing agents like HFO-1234ze and HFO-1336mzz. Bayer's models uniquely account for the different solubility behaviors and vaporization kinetics of these low-GWP agents, which significantly impact nucleation rates and cell growth dynamics. Their approach includes computational fluid dynamics simulations that capture the complex rheological changes during foam expansion, with particular attention to the viscoelastic properties of the polymer matrix as it transitions from liquid to solid state. The models incorporate heat transfer equations that account for the exothermic polymerization reaction, blowing agent vaporization, and conductive/convective heat losses during expansion. Bayer has validated these models through extensive experimental studies using specialized pressure-volume-temperature cells that monitor foam expansion in real-time, achieving prediction accuracies within 5% for key parameters like expansion ratio and cell size distribution.

Strengths: Bayer's models excel at predicting the complex interplay between chemical kinetics and physical expansion processes, allowing for precise formulation optimization without extensive trial-and-error testing. Their approach enables accurate prediction of final foam properties based on initial formulation parameters. Weaknesses: The models require significant computational resources and specialized expertise to implement effectively. Some aspects of the nucleation phenomena with low-GWP blowing agents remain challenging to model with complete accuracy.

Hennecke GmbH

Technical Solution: Hennecke has developed advanced kinetic modeling capabilities specifically tailored for low-GWP foam expansion processes in their high-pressure metering machines and mold technologies. Their approach combines computational fluid dynamics with detailed chemical kinetics to simulate the complex interactions between polymerization reactions and gas expansion dynamics. Hennecke's models incorporate the unique thermophysical properties of low-GWP blowing agents like HFO-1234ze and HFO-1336mzz-Z, accounting for their different vapor pressures, solubility parameters, and diffusion coefficients compared to traditional HFCs. Their simulation framework captures the nucleation, growth, and stabilization phases of cell formation, with particular attention to the impact of mixing dynamics on initial bubble distribution. The models integrate heat transfer equations that account for the exothermic reaction heat, blowing agent vaporization enthalpy, and mold surface temperature effects. Hennecke has validated these models through extensive experimental studies using their HIGHLINE series machines equipped with specialized sensors that monitor pressure, temperature, and foam rise profiles in real-time. Their approach enables precise prediction of foam density distributions, cell structure uniformity, and thermal insulation properties based on initial formulation parameters and processing conditions.

Strengths: Hennecke's models excel at capturing the influence of equipment-specific parameters (mixing head design, injection pressure, etc.) on foam expansion dynamics, enabling optimization of both formulation and processing parameters. Their approach allows for virtual prototyping of new foam systems with minimal physical testing. Weaknesses: The models require extensive calibration for each specific machine configuration and material system. Some aspects of the complex rheological behavior during the gel phase of foam formation remain challenging to predict with complete accuracy.

Critical Patents in Gas Expansion Modeling

Methods for making foams using blowing agents comprising unsaturated fluorocarbons

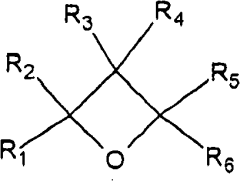

PatentInactiveCN101316885A

Innovation

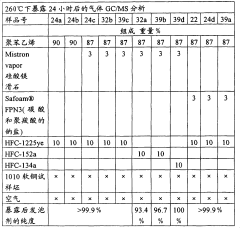

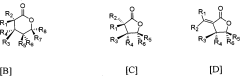

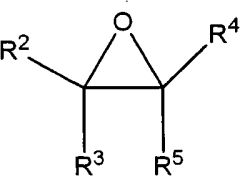

- Use unsaturated fluorocarbons or hydrofluorocarbons as foaming agents, such as E-R1CH=CHR2 compounds, where R1 and R2 are C1-C6 perfluoroalkyl groups, to form closed-cell foam by reacting with polyols and polyisocyanates. Providing foam materials with low global warming potential and low ozone depletion.

Compositions comprising fluoroolefins and uses thereof

PatentActiveCN101346450A

Innovation

- Development of refrigerant or heat transfer fluid compositions containing specific fluoroolefins, such as E- or Z-R1CH=CHR2 fluoroolefins and cyclic fluoroolefins, for use as heat transfer fluids in refrigeration, air conditioning or heat pump systems or refrigerants with low ozone depletion and low global warming potential.

Environmental Regulations Impact on Foam Technology

Environmental regulations have become a primary driver of innovation in foam technology, particularly concerning blowing agents used in foam production. The phase-out of high Global Warming Potential (GWP) substances under international agreements like the Montreal Protocol and its Kigap Amendment has fundamentally reshaped the foam industry's technological landscape. These regulations have established aggressive timelines for transitioning away from hydrofluorocarbons (HFCs) and other high-GWP blowing agents, creating both challenges and opportunities for foam manufacturers worldwide.

The European Union's F-Gas Regulation and similar legislation in North America have accelerated the adoption of low-GWP alternatives, with many regions implementing stepwise reduction schedules based on application sectors. These regulatory frameworks have created a complex global patchwork of compliance requirements, with developing nations often granted longer transition periods while developed economies face more immediate deadlines.

Regulatory pressure has directly influenced the kinetic modeling approaches for gas expansion in foam systems. As manufacturers pivot to low-GWP alternatives like hydrofluoroolefins (HFOs), hydrochlorofluoroolefins (HCFOs), and natural blowing agents, they must recalibrate expansion models to account for different thermodynamic properties, diffusion rates, and cell structure formation dynamics. The solubility parameters and phase behavior of these new blowing agents often differ significantly from their high-GWP predecessors.

Financial mechanisms embedded in environmental regulations have further shaped technology development. Carbon taxes, cap-and-trade systems, and direct subsidies for environmentally preferable technologies have altered the economic calculus for foam manufacturers. These market-based instruments have accelerated investment in low-GWP research and development, particularly in kinetic modeling tools that can optimize formulations while minimizing environmental impact.

Regulatory reporting requirements have also enhanced data collection practices across the industry. Manufacturers must now track and document emissions throughout the product lifecycle, necessitating more sophisticated modeling approaches that can predict not only initial foam formation but also long-term blowing agent retention and eventual release. This expanded scope has driven integration between kinetic expansion models and lifecycle assessment methodologies.

The regulatory landscape continues to evolve, with increasing focus on circular economy principles and end-of-life considerations. Future regulations may extend beyond GWP concerns to address broader sustainability metrics, potentially requiring further refinements to gas expansion modeling to incorporate biodegradability, recyclability, and overall environmental footprint considerations alongside traditional performance parameters.

The European Union's F-Gas Regulation and similar legislation in North America have accelerated the adoption of low-GWP alternatives, with many regions implementing stepwise reduction schedules based on application sectors. These regulatory frameworks have created a complex global patchwork of compliance requirements, with developing nations often granted longer transition periods while developed economies face more immediate deadlines.

Regulatory pressure has directly influenced the kinetic modeling approaches for gas expansion in foam systems. As manufacturers pivot to low-GWP alternatives like hydrofluoroolefins (HFOs), hydrochlorofluoroolefins (HCFOs), and natural blowing agents, they must recalibrate expansion models to account for different thermodynamic properties, diffusion rates, and cell structure formation dynamics. The solubility parameters and phase behavior of these new blowing agents often differ significantly from their high-GWP predecessors.

Financial mechanisms embedded in environmental regulations have further shaped technology development. Carbon taxes, cap-and-trade systems, and direct subsidies for environmentally preferable technologies have altered the economic calculus for foam manufacturers. These market-based instruments have accelerated investment in low-GWP research and development, particularly in kinetic modeling tools that can optimize formulations while minimizing environmental impact.

Regulatory reporting requirements have also enhanced data collection practices across the industry. Manufacturers must now track and document emissions throughout the product lifecycle, necessitating more sophisticated modeling approaches that can predict not only initial foam formation but also long-term blowing agent retention and eventual release. This expanded scope has driven integration between kinetic expansion models and lifecycle assessment methodologies.

The regulatory landscape continues to evolve, with increasing focus on circular economy principles and end-of-life considerations. Future regulations may extend beyond GWP concerns to address broader sustainability metrics, potentially requiring further refinements to gas expansion modeling to incorporate biodegradability, recyclability, and overall environmental footprint considerations alongside traditional performance parameters.

Computational Simulation Approaches

Computational simulation approaches have become indispensable tools for understanding the complex kinetics of gas expansion in low-GWP (Global Warming Potential) foams. These approaches leverage mathematical models and computational algorithms to predict foam behavior under various conditions, significantly reducing the need for extensive experimental testing.

Finite Element Analysis (FEA) represents one of the primary simulation methodologies employed in this domain. FEA discretizes the foam structure into smaller elements, allowing researchers to model gas diffusion, bubble growth, and cell structure development with high spatial resolution. Commercial software packages such as ANSYS, COMSOL Multiphysics, and Abaqus have developed specialized modules for polymer foaming simulations that incorporate the unique properties of low-GWP blowing agents.

Computational Fluid Dynamics (CFD) techniques complement FEA by focusing specifically on the fluid dynamics aspects of gas expansion. These simulations can capture the complex interactions between the polymer matrix and expanding gas bubbles, including surface tension effects, viscosity changes during expansion, and pressure gradients. OpenFOAM and FLOW-3D have emerged as popular open-source and commercial platforms, respectively, for such simulations.

Molecular Dynamics (MD) simulations offer insights at the microscopic level by modeling interactions between individual molecules. This approach is particularly valuable for understanding how different low-GWP blowing agents interact with polymer chains during nucleation and early bubble growth stages. Software packages like LAMMPS and GROMACS enable researchers to investigate these molecular-level phenomena with increasing accuracy.

Monte Carlo methods provide probabilistic frameworks for modeling stochastic aspects of foam formation, such as nucleation events and cell coalescence. These methods are especially useful when dealing with uncertainties in material properties or processing conditions, offering statistical distributions of possible outcomes rather than single deterministic results.

Machine learning approaches have recently gained traction in foam modeling, with neural networks and genetic algorithms being trained on experimental data to predict foam properties and optimize formulations. These data-driven models can identify complex relationships between processing parameters and foam characteristics that might be missed by traditional physics-based models.

Multi-scale modeling frameworks that integrate simulations across different length and time scales represent the cutting edge of computational approaches. These frameworks connect molecular-level interactions to macroscopic foam properties, providing comprehensive insights into the entire foaming process from nucleation to final cell structure development.

Finite Element Analysis (FEA) represents one of the primary simulation methodologies employed in this domain. FEA discretizes the foam structure into smaller elements, allowing researchers to model gas diffusion, bubble growth, and cell structure development with high spatial resolution. Commercial software packages such as ANSYS, COMSOL Multiphysics, and Abaqus have developed specialized modules for polymer foaming simulations that incorporate the unique properties of low-GWP blowing agents.

Computational Fluid Dynamics (CFD) techniques complement FEA by focusing specifically on the fluid dynamics aspects of gas expansion. These simulations can capture the complex interactions between the polymer matrix and expanding gas bubbles, including surface tension effects, viscosity changes during expansion, and pressure gradients. OpenFOAM and FLOW-3D have emerged as popular open-source and commercial platforms, respectively, for such simulations.

Molecular Dynamics (MD) simulations offer insights at the microscopic level by modeling interactions between individual molecules. This approach is particularly valuable for understanding how different low-GWP blowing agents interact with polymer chains during nucleation and early bubble growth stages. Software packages like LAMMPS and GROMACS enable researchers to investigate these molecular-level phenomena with increasing accuracy.

Monte Carlo methods provide probabilistic frameworks for modeling stochastic aspects of foam formation, such as nucleation events and cell coalescence. These methods are especially useful when dealing with uncertainties in material properties or processing conditions, offering statistical distributions of possible outcomes rather than single deterministic results.

Machine learning approaches have recently gained traction in foam modeling, with neural networks and genetic algorithms being trained on experimental data to predict foam properties and optimize formulations. These data-driven models can identify complex relationships between processing parameters and foam characteristics that might be missed by traditional physics-based models.

Multi-scale modeling frameworks that integrate simulations across different length and time scales represent the cutting edge of computational approaches. These frameworks connect molecular-level interactions to macroscopic foam properties, providing comprehensive insights into the entire foaming process from nucleation to final cell structure development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!