Evaluation of Flame Retardancy in Low-GWP Foam Systems

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flame Retardancy Background and Objectives

Flame retardancy has evolved significantly over the past century, transitioning from simple chemical treatments to sophisticated engineered solutions. The history of flame retardants dates back to ancient Egypt, but modern scientific approaches emerged in the 1950s with the development of halogenated compounds. These early solutions, while effective, have increasingly faced scrutiny due to environmental and health concerns, creating a technological inflection point in the industry.

The evolution of flame retardancy technology has been driven by a dual focus on performance and sustainability. Traditional flame retardants containing bromine and chlorine compounds have demonstrated excellent fire-inhibiting properties but pose significant environmental challenges due to bioaccumulation and persistence. This tension has accelerated research into alternative solutions, particularly for foam applications which represent a critical fire safety challenge in multiple industries.

Low Global Warming Potential (GWP) foam systems have emerged as an environmentally responsible alternative to traditional foam insulation and cushioning materials. These systems utilize blowing agents with reduced climate impact compared to hydrofluorocarbons (HFCs) and other high-GWP compounds. However, the transition to these more sustainable foam formulations has created new technical challenges in maintaining adequate flame retardancy without compromising the environmental benefits or physical properties of the foam.

The primary objective of this technical research is to comprehensively evaluate flame retardancy solutions specifically designed for low-GWP foam systems. This evaluation aims to identify approaches that can deliver regulatory-compliant fire performance while maintaining the environmental advantages of low-GWP formulations. The research will examine both established and emerging flame retardant technologies, with particular attention to phosphorus-based compounds, inorganic additives, and novel nano-composite solutions.

Secondary objectives include quantifying the relationship between flame retardant loading levels and foam physical properties, assessing the long-term stability of flame retardant performance in low-GWP systems, and identifying potential synergistic combinations that may deliver enhanced protection with reduced environmental impact. The research will also explore the compatibility challenges between various flame retardants and the new generation of low-GWP blowing agents, including hydrofluoroolefins (HFOs) and hydrocarbon-based alternatives.

This technical evaluation is positioned at the intersection of regulatory compliance, environmental sustainability, and material performance—three critical factors driving innovation in modern industrial applications. The findings will inform strategic development decisions for manufacturers across multiple sectors, including construction, automotive, furniture, and electronics, where foam materials with both low environmental impact and reliable fire safety performance are increasingly demanded.

The evolution of flame retardancy technology has been driven by a dual focus on performance and sustainability. Traditional flame retardants containing bromine and chlorine compounds have demonstrated excellent fire-inhibiting properties but pose significant environmental challenges due to bioaccumulation and persistence. This tension has accelerated research into alternative solutions, particularly for foam applications which represent a critical fire safety challenge in multiple industries.

Low Global Warming Potential (GWP) foam systems have emerged as an environmentally responsible alternative to traditional foam insulation and cushioning materials. These systems utilize blowing agents with reduced climate impact compared to hydrofluorocarbons (HFCs) and other high-GWP compounds. However, the transition to these more sustainable foam formulations has created new technical challenges in maintaining adequate flame retardancy without compromising the environmental benefits or physical properties of the foam.

The primary objective of this technical research is to comprehensively evaluate flame retardancy solutions specifically designed for low-GWP foam systems. This evaluation aims to identify approaches that can deliver regulatory-compliant fire performance while maintaining the environmental advantages of low-GWP formulations. The research will examine both established and emerging flame retardant technologies, with particular attention to phosphorus-based compounds, inorganic additives, and novel nano-composite solutions.

Secondary objectives include quantifying the relationship between flame retardant loading levels and foam physical properties, assessing the long-term stability of flame retardant performance in low-GWP systems, and identifying potential synergistic combinations that may deliver enhanced protection with reduced environmental impact. The research will also explore the compatibility challenges between various flame retardants and the new generation of low-GWP blowing agents, including hydrofluoroolefins (HFOs) and hydrocarbon-based alternatives.

This technical evaluation is positioned at the intersection of regulatory compliance, environmental sustainability, and material performance—three critical factors driving innovation in modern industrial applications. The findings will inform strategic development decisions for manufacturers across multiple sectors, including construction, automotive, furniture, and electronics, where foam materials with both low environmental impact and reliable fire safety performance are increasingly demanded.

Market Analysis for Low-GWP Foam Solutions

The global market for low-GWP foam solutions is experiencing significant growth driven by stringent environmental regulations and increasing awareness of climate change impacts. The foam insulation market, valued at approximately $26.3 billion in 2022, is projected to reach $38.2 billion by 2028, with low-GWP solutions representing the fastest-growing segment at a CAGR of 8.7%.

Regulatory frameworks worldwide are accelerating market transformation. The Kigali Amendment to the Montreal Protocol mandates an 85% reduction in HFC consumption by 2036 for developed countries and by 2047 for developing nations. The European F-Gas Regulation has already banned HFCs with GWP above 150 in various applications, while the U.S. AIM Act requires a 40% reduction in HFC production by 2024 and 85% by 2036.

Construction and building applications currently dominate the low-GWP foam market, accounting for 62% of total demand. This sector's growth is further propelled by green building certifications like LEED and BREEAM, which award points for using sustainable insulation materials. The automotive sector represents the second-largest market segment at 18%, with demand primarily driven by electric vehicle thermal management systems.

Regional market analysis reveals North America holds 34% market share, with the U.S. being the largest consumer due to stringent EPA regulations. Europe follows at 31%, with particularly strong adoption in Germany, France, and Scandinavian countries. The Asia-Pacific region, while currently representing 27% of the market, is expected to show the highest growth rate of 10.2% annually through 2028, primarily led by China and Japan's environmental initiatives.

Consumer willingness to pay premiums for environmentally friendly products varies significantly by region and application. Commercial building developers demonstrate the highest acceptance of price premiums (15-20%), while residential consumers show more price sensitivity, accepting only 5-8% premiums. This price sensitivity remains a significant market barrier, particularly in developing economies.

The competitive landscape features both established chemical manufacturers pivoting toward low-GWP solutions and innovative startups focusing exclusively on sustainable alternatives. Major players include Honeywell, Chemours, and Arkema, who collectively hold approximately 45% market share. However, regional manufacturers in Asia are rapidly gaining ground with cost-competitive alternatives tailored to local markets.

Market forecasts indicate that hydrofluoroolefin (HFO) based foams will continue dominating the low-GWP segment through 2025, after which natural refrigerant-based solutions (particularly hydrocarbon and CO2-based systems) are expected to gain significant market share due to their ultra-low GWP values and improving flame retardancy profiles.

Regulatory frameworks worldwide are accelerating market transformation. The Kigali Amendment to the Montreal Protocol mandates an 85% reduction in HFC consumption by 2036 for developed countries and by 2047 for developing nations. The European F-Gas Regulation has already banned HFCs with GWP above 150 in various applications, while the U.S. AIM Act requires a 40% reduction in HFC production by 2024 and 85% by 2036.

Construction and building applications currently dominate the low-GWP foam market, accounting for 62% of total demand. This sector's growth is further propelled by green building certifications like LEED and BREEAM, which award points for using sustainable insulation materials. The automotive sector represents the second-largest market segment at 18%, with demand primarily driven by electric vehicle thermal management systems.

Regional market analysis reveals North America holds 34% market share, with the U.S. being the largest consumer due to stringent EPA regulations. Europe follows at 31%, with particularly strong adoption in Germany, France, and Scandinavian countries. The Asia-Pacific region, while currently representing 27% of the market, is expected to show the highest growth rate of 10.2% annually through 2028, primarily led by China and Japan's environmental initiatives.

Consumer willingness to pay premiums for environmentally friendly products varies significantly by region and application. Commercial building developers demonstrate the highest acceptance of price premiums (15-20%), while residential consumers show more price sensitivity, accepting only 5-8% premiums. This price sensitivity remains a significant market barrier, particularly in developing economies.

The competitive landscape features both established chemical manufacturers pivoting toward low-GWP solutions and innovative startups focusing exclusively on sustainable alternatives. Major players include Honeywell, Chemours, and Arkema, who collectively hold approximately 45% market share. However, regional manufacturers in Asia are rapidly gaining ground with cost-competitive alternatives tailored to local markets.

Market forecasts indicate that hydrofluoroolefin (HFO) based foams will continue dominating the low-GWP segment through 2025, after which natural refrigerant-based solutions (particularly hydrocarbon and CO2-based systems) are expected to gain significant market share due to their ultra-low GWP values and improving flame retardancy profiles.

Technical Challenges in Low-GWP Flame Retardant Systems

The development of low-Global Warming Potential (GWP) foam systems faces significant technical challenges, particularly in achieving adequate flame retardancy while maintaining environmental sustainability. Traditional flame retardants often contain halogenated compounds that, while effective, contribute to environmental persistence and toxicity concerns. The transition to low-GWP blowing agents has disrupted established flame retardancy mechanisms, necessitating comprehensive reformulation of these systems.

One primary challenge is the compatibility between new low-GWP blowing agents and existing flame retardant packages. Hydrofluoroolefins (HFOs) and hydrocarbon-based blowing agents exhibit different solubility parameters and chemical interactions compared to their high-GWP predecessors, often resulting in phase separation or reduced effectiveness of flame retardants within the polymer matrix.

Thermal conductivity differences present another significant hurdle. Low-GWP foams typically demonstrate altered thermal transfer properties, which directly impacts flame spread rates and ignition characteristics. This necessitates recalibration of flame retardant loading levels and distribution patterns within the foam structure to maintain adequate fire performance.

The cell structure morphology in low-GWP foams differs substantially from traditional systems, with variations in cell size, distribution, and wall thickness. These structural differences affect both the physical barrier properties and the release kinetics of flame retardants during combustion events, requiring novel approaches to flame retardant incorporation and activation.

Processing challenges further complicate development efforts. Many low-GWP blowing agents have narrower processing windows, creating difficulties in achieving uniform flame retardant dispersion throughout the foam matrix. This can lead to inconsistent fire performance across the material and potential regulatory compliance issues.

Aging and durability concerns represent another critical challenge. Low-GWP foam systems may experience different degradation pathways over time, potentially compromising long-term flame retardancy. Accelerated weathering studies indicate that some flame retardants migrate more readily in these new formulations, reducing effectiveness over the product lifecycle.

Regulatory compliance adds complexity to technical development. As global regulations increasingly restrict both high-GWP blowing agents and certain flame retardants simultaneously, formulators face a narrowing window of permissible ingredients. This regulatory pressure intensifies the need for innovative approaches that can satisfy both environmental and safety requirements without performance compromises.

Cost-effectiveness remains a persistent challenge, as many alternative flame retardants for low-GWP systems currently command premium prices due to limited production scale and specialized synthesis requirements. This economic barrier slows industry-wide adoption despite technical feasibility.

One primary challenge is the compatibility between new low-GWP blowing agents and existing flame retardant packages. Hydrofluoroolefins (HFOs) and hydrocarbon-based blowing agents exhibit different solubility parameters and chemical interactions compared to their high-GWP predecessors, often resulting in phase separation or reduced effectiveness of flame retardants within the polymer matrix.

Thermal conductivity differences present another significant hurdle. Low-GWP foams typically demonstrate altered thermal transfer properties, which directly impacts flame spread rates and ignition characteristics. This necessitates recalibration of flame retardant loading levels and distribution patterns within the foam structure to maintain adequate fire performance.

The cell structure morphology in low-GWP foams differs substantially from traditional systems, with variations in cell size, distribution, and wall thickness. These structural differences affect both the physical barrier properties and the release kinetics of flame retardants during combustion events, requiring novel approaches to flame retardant incorporation and activation.

Processing challenges further complicate development efforts. Many low-GWP blowing agents have narrower processing windows, creating difficulties in achieving uniform flame retardant dispersion throughout the foam matrix. This can lead to inconsistent fire performance across the material and potential regulatory compliance issues.

Aging and durability concerns represent another critical challenge. Low-GWP foam systems may experience different degradation pathways over time, potentially compromising long-term flame retardancy. Accelerated weathering studies indicate that some flame retardants migrate more readily in these new formulations, reducing effectiveness over the product lifecycle.

Regulatory compliance adds complexity to technical development. As global regulations increasingly restrict both high-GWP blowing agents and certain flame retardants simultaneously, formulators face a narrowing window of permissible ingredients. This regulatory pressure intensifies the need for innovative approaches that can satisfy both environmental and safety requirements without performance compromises.

Cost-effectiveness remains a persistent challenge, as many alternative flame retardants for low-GWP systems currently command premium prices due to limited production scale and specialized synthesis requirements. This economic barrier slows industry-wide adoption despite technical feasibility.

Current Flame Retardancy Solutions for Low-GWP Foams

01 Halogen-free flame retardants for low-GWP foam systems

Halogen-free flame retardants are increasingly being incorporated into low-GWP foam systems to reduce environmental impact while maintaining flame retardancy. These alternatives include phosphorus-based compounds, nitrogen-containing additives, and mineral-based flame retardants that can effectively suppress combustion without the use of halogenated compounds that contribute to ozone depletion. These environmentally friendly flame retardants can be formulated to achieve comparable fire performance to traditional systems while supporting the transition to more sustainable foam insulation materials.- Halogen-free flame retardants for low-GWP foam systems: Halogen-free flame retardants are increasingly being incorporated into low-GWP foam systems to meet environmental regulations while maintaining fire safety standards. These flame retardants include phosphorus-based compounds, nitrogen-containing additives, and mineral fillers that provide effective flame retardancy without contributing to ozone depletion or global warming. These environmentally friendly alternatives can be formulated to achieve comparable or superior flame retardancy performance compared to traditional halogenated flame retardants.

- Phosphorus-based flame retardants for polyurethane foams: Phosphorus-based flame retardants are particularly effective in low-GWP polyurethane foam systems. These compounds work through char formation and gas phase inhibition mechanisms, creating a protective barrier that prevents the spread of flames. Various phosphorus compounds including phosphate esters, phosphonates, and reactive phosphorus polyols can be incorporated into foam formulations to achieve desired flame retardancy levels while maintaining the physical properties of the foam and compatibility with environmentally friendly blowing agents.

- Synergistic flame retardant combinations: Synergistic combinations of different flame retardant types can significantly enhance the flame retardancy of low-GWP foam systems while minimizing the total additive loading. These combinations often include phosphorus compounds with nitrogen-containing additives, metal hydroxides, or expandable graphite. The synergistic effect allows for reduced overall flame retardant content while meeting stringent flammability standards, which helps maintain the physical properties and insulation performance of the foam while reducing environmental impact.

- Reactive flame retardants for low-GWP foam systems: Reactive flame retardants that chemically bond to the polymer matrix offer advantages for low-GWP foam systems by preventing migration and leaching of the flame retardant. These compounds are incorporated into the polymer backbone during foam formation, resulting in permanent flame retardancy without negatively affecting the foam's physical properties or long-term performance. Reactive phosphorus-containing polyols and nitrogen-functionalized compounds are commonly used in this approach, providing durable flame protection while maintaining compatibility with environmentally friendly blowing agents.

- Intumescent flame retardant systems for low-GWP foams: Intumescent flame retardant systems create an expanded carbonaceous char layer when exposed to heat, providing an effective barrier against flame spread in low-GWP foam systems. These systems typically consist of a carbon source, an acid source, and a blowing agent that work together to form a protective insulating layer. The intumescent approach is particularly effective for rigid foam insulation applications where maintaining thermal resistance properties is critical while meeting fire safety requirements and environmental regulations for low global warming potential.

02 Synergistic flame retardant combinations for polyurethane foams

Synergistic combinations of flame retardants have been developed specifically for low-GWP polyurethane foam systems. These combinations typically include primary flame retardants with secondary additives that enhance overall performance through complementary mechanisms. For example, phosphorus compounds combined with nitrogen-based materials or expandable graphite with metal hydroxides can achieve superior flame retardancy at lower overall loading levels. These synergistic systems help maintain the physical properties of the foam while meeting stringent fire safety standards and environmental requirements.Expand Specific Solutions03 Reactive flame retardants incorporated into polymer backbone

Reactive flame retardants that chemically bond to the polymer backbone represent an advanced approach for low-GWP foam systems. Unlike traditional additive flame retardants, these compounds become part of the polymer structure, preventing migration and leaching while providing permanent flame retardancy. Phosphorus-containing polyols and nitrogen-functionalized isocyanates can be incorporated during foam formation, resulting in inherently flame-retardant materials. This approach reduces the need for high loadings of additives that might compromise foam physical properties or increase density.Expand Specific Solutions04 Intumescent systems for enhanced fire protection

Intumescent flame retardant systems have been developed for low-GWP foam applications to provide enhanced fire protection through the formation of a protective char layer when exposed to heat. These systems typically contain three key components: a carbon source, an acid source, and a blowing agent that work together to create an expanded carbonaceous barrier that insulates the underlying material. The intumescent approach is particularly effective for rigid foam insulation applications where maintaining structural integrity during fire exposure is critical.Expand Specific Solutions05 Nano-additives for improved flame retardancy

Nano-scale additives are being incorporated into low-GWP foam systems to enhance flame retardancy with minimal impact on foam properties. Materials such as nano-clays, carbon nanotubes, graphene, and metal oxide nanoparticles can significantly improve fire performance at very low loading levels. These nano-additives work through various mechanisms including barrier formation, heat absorption, and radical trapping. The small particle size allows for better dispersion throughout the polymer matrix, resulting in more efficient flame retardancy while maintaining the foam's insulation performance and physical properties.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The flame retardancy evaluation in low-GWP foam systems market is currently in a growth phase, with increasing regulatory pressure driving innovation. The market is expanding at approximately 5-7% annually, valued at over $3 billion globally. Leading players include BASF, Albemarle, and ICL-IP America dominating the chemical solutions segment, while Dow Global Technologies and Covestro focus on system integration. Asian manufacturers like PetroChina, Sinopec, and DKS are rapidly gaining market share through cost-effective solutions. Research institutions such as Sichuan University and CSIRO are advancing next-generation technologies. The industry is transitioning from traditional halogenated flame retardants toward sustainable alternatives with reduced environmental impact, though technical challenges in maintaining performance while reducing global warming potential remain.

BASF Corp.

Technical Solution: BASF has developed innovative flame retardant solutions specifically designed for low-GWP foam systems, focusing on sustainable polyurethane applications. Their Elastopor® H flame retardant technology incorporates halogen-free flame retardants that are compatible with HFO and HFC-based blowing agents, achieving optimal flame retardancy while maintaining the thermal insulation properties of the foam. BASF's approach combines reactive and additive flame retardants, including phosphorus-based compounds and melamine derivatives, which are chemically integrated into the polymer matrix. Their systems have demonstrated compliance with stringent fire safety standards such as ASTM E84 and UL 94, while simultaneously addressing environmental concerns by reducing the Global Warming Potential (GWP) by up to 99% compared to traditional systems. BASF has also pioneered the development of flame retardants specifically optimized for cyclopentane-blown rigid polyurethane foams, which represent a significant advancement in low-GWP foam technology.

Strengths: Comprehensive integration of flame retardancy with low-GWP blowing agents without compromising insulation performance; extensive testing capabilities across multiple industry standards; global manufacturing footprint enabling consistent supply. Weaknesses: Higher initial cost compared to conventional systems; potential for increased viscosity in some formulations requiring processing adjustments; performance variations across different foam densities.

ICL-IP America, Inc.

Technical Solution: ICL-IP America has developed a comprehensive suite of brominated flame retardants specifically engineered for low-GWP foam applications. Their SAYTEX® product line includes polymeric flame retardants that provide excellent thermal stability and compatibility with next-generation HFO and HFC blowing agents. ICL's technology focuses on reactive brominated compounds that chemically bond to the polymer matrix, reducing potential for migration and environmental leaching while maintaining flame retardancy performance. Their FR-122P and FR-1206 products have demonstrated particular effectiveness in rigid polyurethane foam systems using low-GWP blowing agents, achieving UL 94 V-0 ratings at reduced loadings compared to traditional flame retardants. ICL has conducted extensive studies on the interaction between their flame retardants and various low-GWP blowing agents, optimizing formulations to maintain dimensional stability and insulation properties while meeting increasingly stringent fire safety regulations. Their solutions have been successfully implemented in construction, automotive, and refrigeration applications.

Strengths: Extensive expertise in halogenated flame retardants with proven effectiveness; products specifically designed for compatibility with low-GWP blowing agents; strong technical support and customization capabilities. Weaknesses: Environmental concerns regarding brominated compounds despite their effectiveness; potential regulatory challenges in some markets; higher loading levels sometimes required compared to phosphorus-based alternatives.

Critical Patents and Technical Literature Review

Foam products and their production

PatentPendingUS20250282905A1

Innovation

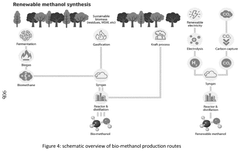

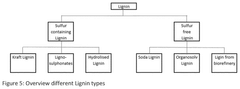

- A foam product comprising at least 5% by weight of components from renewable sources, such as lignin and bio-based formaldehyde, combined with blowing agents and other additives, to achieve thermal conductivities of 0.025 W/m·K or less over a 25-year life span, with a total Global Warming Potential (GWP) below 1.0 kg CO2 eq/kg and a closed cell content of at least 90%, while maintaining fire performance and mechanical strength.

Improved polyurethane foam using HFO propellants

PatentPendingUS20220348709A1

Innovation

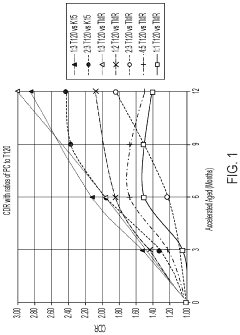

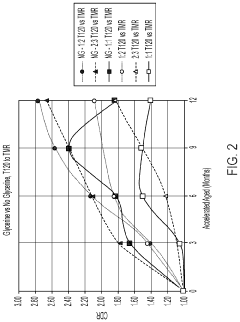

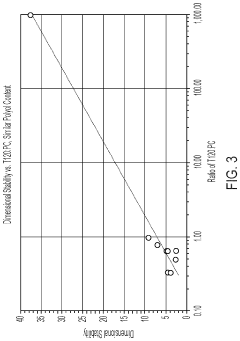

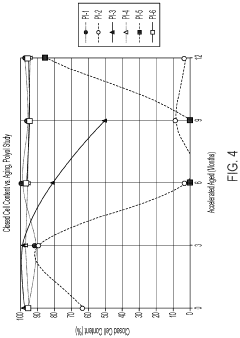

- A polyurethane foam composition using a catalyst package with a defined Sn/K ratio, optionally including glycerol, to stabilize the reaction and maintain foam properties when using HFO propellants, ensuring shelf-life stability and superior performance.

Environmental Regulations Impact Assessment

The global regulatory landscape for foam systems has undergone significant transformation in recent years, primarily driven by environmental concerns related to global warming potential (GWP) and fire safety requirements. The Montreal Protocol and subsequent amendments have progressively phased out high-GWP blowing agents, compelling manufacturers to transition to low-GWP alternatives while maintaining flame retardancy performance.

The European Union's REACH regulation and the Restriction of Hazardous Substances (RoHS) Directive have imposed stringent limitations on certain halogenated flame retardants commonly used in foam systems. These regulations have created a complex compliance framework that manufacturers must navigate, particularly when formulating low-GWP foam systems that meet fire safety standards. The EU's Construction Products Regulation (CPR) further establishes harmonized technical specifications for construction materials, including specific requirements for fire performance.

In North America, the U.S. Environmental Protection Agency's Significant New Alternatives Policy (SNAP) program has approved various low-GWP blowing agents while simultaneously addressing flame retardant concerns. California's Proposition 65 and Technical Bulletin 117-2013 have set precedents for flame retardant disclosure and flammability standards that influence national practices. The recent federal legislation restricting certain PFAS compounds has further complicated formulation options for flame-retardant foam systems.

Asian markets present a diverse regulatory environment, with Japan's Chemical Substances Control Law and China's Restriction of Hazardous Substances (China RoHS) imposing region-specific requirements. These variations create challenges for global manufacturers seeking to develop standardized low-GWP foam formulations with consistent flame retardancy properties across international markets.

The regulatory trend toward circular economy principles is introducing additional considerations. The EU's Circular Economy Action Plan and similar initiatives worldwide are pushing manufacturers to consider end-of-life management for flame retardants in foam systems, favoring solutions that enable recycling or safe disposal. This trend is accelerating the shift toward inherently flame-retardant polymer systems that reduce reliance on additive flame retardants.

Climate-focused regulations, including carbon pricing mechanisms and extended producer responsibility schemes, are creating economic incentives that favor low-GWP foam systems with sustainable flame retardancy solutions. These market-based instruments are expected to accelerate innovation in environmentally preferable flame retardants that maintain performance while reducing environmental impact throughout the product lifecycle.

The European Union's REACH regulation and the Restriction of Hazardous Substances (RoHS) Directive have imposed stringent limitations on certain halogenated flame retardants commonly used in foam systems. These regulations have created a complex compliance framework that manufacturers must navigate, particularly when formulating low-GWP foam systems that meet fire safety standards. The EU's Construction Products Regulation (CPR) further establishes harmonized technical specifications for construction materials, including specific requirements for fire performance.

In North America, the U.S. Environmental Protection Agency's Significant New Alternatives Policy (SNAP) program has approved various low-GWP blowing agents while simultaneously addressing flame retardant concerns. California's Proposition 65 and Technical Bulletin 117-2013 have set precedents for flame retardant disclosure and flammability standards that influence national practices. The recent federal legislation restricting certain PFAS compounds has further complicated formulation options for flame-retardant foam systems.

Asian markets present a diverse regulatory environment, with Japan's Chemical Substances Control Law and China's Restriction of Hazardous Substances (China RoHS) imposing region-specific requirements. These variations create challenges for global manufacturers seeking to develop standardized low-GWP foam formulations with consistent flame retardancy properties across international markets.

The regulatory trend toward circular economy principles is introducing additional considerations. The EU's Circular Economy Action Plan and similar initiatives worldwide are pushing manufacturers to consider end-of-life management for flame retardants in foam systems, favoring solutions that enable recycling or safe disposal. This trend is accelerating the shift toward inherently flame-retardant polymer systems that reduce reliance on additive flame retardants.

Climate-focused regulations, including carbon pricing mechanisms and extended producer responsibility schemes, are creating economic incentives that favor low-GWP foam systems with sustainable flame retardancy solutions. These market-based instruments are expected to accelerate innovation in environmentally preferable flame retardants that maintain performance while reducing environmental impact throughout the product lifecycle.

Performance Testing Methodologies and Standards

The evaluation of flame retardancy in low-GWP foam systems requires standardized testing methodologies to ensure consistent and reliable performance assessment. Current industry standards primarily include ASTM E84 (Surface Burning Characteristics), UL 94 (Flammability of Plastic Materials), and NFPA 286 (Room Corner Test), which provide frameworks for measuring flame spread, smoke development, and overall fire resistance properties.

Small-scale testing methods such as the Cone Calorimeter (ISO 5660) have become increasingly important for preliminary assessments, measuring heat release rate, time to ignition, and mass loss rate under controlled conditions. These parameters offer valuable insights into material behavior during combustion while requiring minimal sample quantities, making them cost-effective for initial screening of foam formulations.

Medium-scale tests like the Single Burning Item test (EN 13823) bridge the gap between laboratory and real-world scenarios by evaluating how foam materials respond to localized flame exposure. This test measures fire growth rate, total heat release, and lateral flame spread, providing more comprehensive data on potential fire hazards in practical applications.

For low-GWP foam systems specifically, modified testing protocols have emerged to address unique characteristics of these environmentally friendly formulations. The Ohio State University (OSU) Heat Release Rate Test (ASTM E906) has been adapted to better evaluate the performance of foams containing alternative blowing agents, accounting for their different thermal decomposition behaviors compared to traditional HFC-based systems.

Correlation studies between laboratory tests and real-world fire scenarios have revealed that standard testing methods sometimes require adjustment factors when applied to low-GWP foams. Research by Underwriters Laboratories has demonstrated that certain hydrofluoroolefin (HFO) and hydrocarbon-blown foams exhibit different burning characteristics than predicted by conventional test methods, necessitating the development of new calibration parameters.

International harmonization efforts are underway to standardize flame retardancy testing specifically for low-GWP foam systems. The International Organization for Standardization (ISO) Technical Committee 61 is currently developing a specialized testing framework that accounts for the unique combustion properties of foams containing next-generation blowing agents, aiming to establish globally recognized performance benchmarks that balance fire safety requirements with environmental considerations.

Small-scale testing methods such as the Cone Calorimeter (ISO 5660) have become increasingly important for preliminary assessments, measuring heat release rate, time to ignition, and mass loss rate under controlled conditions. These parameters offer valuable insights into material behavior during combustion while requiring minimal sample quantities, making them cost-effective for initial screening of foam formulations.

Medium-scale tests like the Single Burning Item test (EN 13823) bridge the gap between laboratory and real-world scenarios by evaluating how foam materials respond to localized flame exposure. This test measures fire growth rate, total heat release, and lateral flame spread, providing more comprehensive data on potential fire hazards in practical applications.

For low-GWP foam systems specifically, modified testing protocols have emerged to address unique characteristics of these environmentally friendly formulations. The Ohio State University (OSU) Heat Release Rate Test (ASTM E906) has been adapted to better evaluate the performance of foams containing alternative blowing agents, accounting for their different thermal decomposition behaviors compared to traditional HFC-based systems.

Correlation studies between laboratory tests and real-world fire scenarios have revealed that standard testing methods sometimes require adjustment factors when applied to low-GWP foams. Research by Underwriters Laboratories has demonstrated that certain hydrofluoroolefin (HFO) and hydrocarbon-blown foams exhibit different burning characteristics than predicted by conventional test methods, necessitating the development of new calibration parameters.

International harmonization efforts are underway to standardize flame retardancy testing specifically for low-GWP foam systems. The International Organization for Standardization (ISO) Technical Committee 61 is currently developing a specialized testing framework that accounts for the unique combustion properties of foams containing next-generation blowing agents, aiming to establish globally recognized performance benchmarks that balance fire safety requirements with environmental considerations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!