Mechanical Properties of Polyurethane Foams with Low-GWP Blowing Agents

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PU Foam Technology Evolution and Objectives

Polyurethane (PU) foam technology has evolved significantly since its inception in the 1940s, with Otto Bayer's pioneering work on polyurethane polymers. The initial applications were limited, but by the 1960s, PU foams had become widely used in furniture, automotive, and insulation industries due to their versatile properties. The evolution of PU foam technology has been largely driven by environmental regulations and performance requirements, particularly in terms of blowing agents used in the manufacturing process.

The first generation of PU foams utilized chlorofluorocarbons (CFCs) as blowing agents, which provided excellent insulation properties and dimensional stability. However, the discovery of CFCs' ozone-depleting potential led to their phase-out under the Montreal Protocol in the 1990s. This regulatory shift prompted the industry to transition to hydrochlorofluorocarbons (HCFCs) and subsequently to hydrofluorocarbons (HFCs) as alternative blowing agents.

While HFCs addressed the ozone depletion concern, they were later identified as potent greenhouse gases with high Global Warming Potential (GWP). The Kigali Amendment to the Montreal Protocol in 2016 established a timeline for the phase-down of HFCs, creating an urgent need for low-GWP alternatives. This regulatory pressure has accelerated research into hydrofluoroolefins (HFOs), hydrocarbons, water-blown systems, and other environmentally friendly blowing agents.

The current technological focus is on developing PU foam systems that utilize low-GWP blowing agents while maintaining or enhancing the mechanical properties that make PU foams valuable across various applications. These properties include compressive strength, tensile strength, dimensional stability, thermal insulation performance, and durability. The challenge lies in the fact that blowing agents significantly influence the cellular structure of foams, which directly impacts their mechanical behavior.

The primary objective of current research is to understand the relationship between low-GWP blowing agents and the resulting mechanical properties of PU foams. This includes investigating how different blowing agents affect cell morphology, density distribution, and crosslinking density, which are critical factors determining mechanical performance. Additionally, researchers aim to develop formulation strategies that can compensate for any potential negative impacts of low-GWP blowing agents on foam properties.

Another important goal is to establish standardized testing methodologies for evaluating the mechanical properties of PU foams with new blowing agents, ensuring consistency across the industry and facilitating the adoption of sustainable alternatives. The ultimate aim is to develop environmentally responsible PU foam systems that meet or exceed the performance standards of traditional systems, supporting the transition to a more sustainable future while maintaining the versatility and utility that have made PU foams indispensable in modern applications.

The first generation of PU foams utilized chlorofluorocarbons (CFCs) as blowing agents, which provided excellent insulation properties and dimensional stability. However, the discovery of CFCs' ozone-depleting potential led to their phase-out under the Montreal Protocol in the 1990s. This regulatory shift prompted the industry to transition to hydrochlorofluorocarbons (HCFCs) and subsequently to hydrofluorocarbons (HFCs) as alternative blowing agents.

While HFCs addressed the ozone depletion concern, they were later identified as potent greenhouse gases with high Global Warming Potential (GWP). The Kigali Amendment to the Montreal Protocol in 2016 established a timeline for the phase-down of HFCs, creating an urgent need for low-GWP alternatives. This regulatory pressure has accelerated research into hydrofluoroolefins (HFOs), hydrocarbons, water-blown systems, and other environmentally friendly blowing agents.

The current technological focus is on developing PU foam systems that utilize low-GWP blowing agents while maintaining or enhancing the mechanical properties that make PU foams valuable across various applications. These properties include compressive strength, tensile strength, dimensional stability, thermal insulation performance, and durability. The challenge lies in the fact that blowing agents significantly influence the cellular structure of foams, which directly impacts their mechanical behavior.

The primary objective of current research is to understand the relationship between low-GWP blowing agents and the resulting mechanical properties of PU foams. This includes investigating how different blowing agents affect cell morphology, density distribution, and crosslinking density, which are critical factors determining mechanical performance. Additionally, researchers aim to develop formulation strategies that can compensate for any potential negative impacts of low-GWP blowing agents on foam properties.

Another important goal is to establish standardized testing methodologies for evaluating the mechanical properties of PU foams with new blowing agents, ensuring consistency across the industry and facilitating the adoption of sustainable alternatives. The ultimate aim is to develop environmentally responsible PU foam systems that meet or exceed the performance standards of traditional systems, supporting the transition to a more sustainable future while maintaining the versatility and utility that have made PU foams indispensable in modern applications.

Market Demand for Low-GWP Foam Solutions

The global market for low-GWP (Global Warming Potential) foam solutions has experienced significant growth driven by stringent environmental regulations and increasing corporate sustainability commitments. The polyurethane foam industry, valued at approximately $73 billion in 2022, is projected to grow at a CAGR of 7.2% through 2030, with low-GWP solutions representing the fastest-growing segment.

Regulatory frameworks like the Kigali Amendment to the Montreal Protocol, EU F-Gas Regulation, and U.S. EPA SNAP Program have created immediate market demand by mandating the phase-down of high-GWP blowing agents. These regulations have established clear timelines for transitioning to environmentally friendly alternatives, creating both compliance requirements and market opportunities.

Consumer preferences have shifted dramatically toward environmentally responsible products, with surveys indicating that 73% of global consumers are willing to pay premium prices for sustainable offerings. This trend is particularly pronounced in construction, automotive, and appliance sectors, where end-users increasingly demand products with reduced environmental footprints.

The construction industry represents the largest application segment for low-GWP polyurethane foams, accounting for 42% of market demand. Building insulation requirements have become more stringent worldwide, with energy efficiency standards driving adoption of high-performance insulation materials that maintain excellent mechanical properties while using environmentally friendly blowing agents.

Automotive manufacturers face dual pressures of weight reduction for fuel efficiency and environmental compliance, creating substantial demand for low-GWP foam components. The sector requires foams that maintain mechanical integrity under varying temperature and pressure conditions, with particular emphasis on compression strength and dimensional stability.

The appliance industry has emerged as another significant market driver, with refrigeration and HVAC manufacturers seeking compliant insulation solutions that maintain thermal efficiency without compromising structural integrity. This sector values consistent cell structure and long-term dimensional stability in foam products.

Regional market analysis reveals varying adoption rates, with Europe leading implementation due to aggressive regulatory timelines, followed by North America and rapidly growing demand in Asia-Pacific markets, particularly China and Japan. Developing economies present significant growth potential as they implement their own HFC phase-down schedules.

Price sensitivity remains a market challenge, with low-GWP solutions typically commanding 15-30% price premiums over traditional formulations. However, this gap has narrowed significantly since 2018 as production scales and formulation expertise improves, accelerating market penetration across all segments.

Regulatory frameworks like the Kigali Amendment to the Montreal Protocol, EU F-Gas Regulation, and U.S. EPA SNAP Program have created immediate market demand by mandating the phase-down of high-GWP blowing agents. These regulations have established clear timelines for transitioning to environmentally friendly alternatives, creating both compliance requirements and market opportunities.

Consumer preferences have shifted dramatically toward environmentally responsible products, with surveys indicating that 73% of global consumers are willing to pay premium prices for sustainable offerings. This trend is particularly pronounced in construction, automotive, and appliance sectors, where end-users increasingly demand products with reduced environmental footprints.

The construction industry represents the largest application segment for low-GWP polyurethane foams, accounting for 42% of market demand. Building insulation requirements have become more stringent worldwide, with energy efficiency standards driving adoption of high-performance insulation materials that maintain excellent mechanical properties while using environmentally friendly blowing agents.

Automotive manufacturers face dual pressures of weight reduction for fuel efficiency and environmental compliance, creating substantial demand for low-GWP foam components. The sector requires foams that maintain mechanical integrity under varying temperature and pressure conditions, with particular emphasis on compression strength and dimensional stability.

The appliance industry has emerged as another significant market driver, with refrigeration and HVAC manufacturers seeking compliant insulation solutions that maintain thermal efficiency without compromising structural integrity. This sector values consistent cell structure and long-term dimensional stability in foam products.

Regional market analysis reveals varying adoption rates, with Europe leading implementation due to aggressive regulatory timelines, followed by North America and rapidly growing demand in Asia-Pacific markets, particularly China and Japan. Developing economies present significant growth potential as they implement their own HFC phase-down schedules.

Price sensitivity remains a market challenge, with low-GWP solutions typically commanding 15-30% price premiums over traditional formulations. However, this gap has narrowed significantly since 2018 as production scales and formulation expertise improves, accelerating market penetration across all segments.

Technical Challenges in Low-GWP Blowing Agents

The transition to low-GWP (Global Warming Potential) blowing agents in polyurethane foam manufacturing presents significant technical challenges that impact the mechanical properties of the resulting foams. Traditional high-GWP blowing agents like hydrofluorocarbons (HFCs) have been optimized over decades, creating a high performance benchmark that newer alternatives must meet or exceed.

One primary challenge lies in the thermal conductivity differences between traditional and low-GWP blowing agents. Low-GWP alternatives typically exhibit higher thermal conductivity, which directly affects the insulation performance of polyurethane foams. This fundamental property difference requires reformulation of foam systems to maintain equivalent R-values, often necessitating increased foam thickness or density to compensate.

Cell structure formation presents another critical challenge. Low-GWP blowing agents frequently demonstrate different solubility parameters and vapor pressures compared to their high-GWP counterparts. These differences affect nucleation, cell growth dynamics, and ultimate cell size distribution. The resulting altered cellular morphology directly impacts mechanical properties including compressive strength, tensile strength, and dimensional stability.

Compatibility issues between low-GWP blowing agents and existing polyol and isocyanate systems create formulation challenges. Many established catalyst packages and surfactants were specifically designed for traditional blowing agents, requiring significant reformulation efforts. This chemical incompatibility can lead to processing difficulties including poor mixing, inconsistent reaction profiles, and foam collapse.

Processing parameters require substantial adjustment when implementing low-GWP alternatives. Different boiling points and evaporation rates necessitate modifications to mixing speeds, pour temperatures, and mold temperatures. These processing adaptations often require equipment modifications and extensive process validation to ensure consistent foam quality.

Long-term aging performance represents perhaps the most challenging aspect of low-GWP implementation. Many alternative blowing agents demonstrate different diffusion rates through polyurethane matrices compared to traditional agents. This can lead to accelerated aging, dimensional instability, and degradation of mechanical properties over time as the blowing agent gradually escapes and is replaced by atmospheric gases.

Cost-performance balance presents a significant market challenge. Many low-GWP alternatives are more expensive than traditional blowing agents, creating pressure to reduce formulation costs elsewhere. This economic constraint often leads to compromises in mechanical performance as manufacturers attempt to maintain competitive pricing while meeting environmental regulations.

One primary challenge lies in the thermal conductivity differences between traditional and low-GWP blowing agents. Low-GWP alternatives typically exhibit higher thermal conductivity, which directly affects the insulation performance of polyurethane foams. This fundamental property difference requires reformulation of foam systems to maintain equivalent R-values, often necessitating increased foam thickness or density to compensate.

Cell structure formation presents another critical challenge. Low-GWP blowing agents frequently demonstrate different solubility parameters and vapor pressures compared to their high-GWP counterparts. These differences affect nucleation, cell growth dynamics, and ultimate cell size distribution. The resulting altered cellular morphology directly impacts mechanical properties including compressive strength, tensile strength, and dimensional stability.

Compatibility issues between low-GWP blowing agents and existing polyol and isocyanate systems create formulation challenges. Many established catalyst packages and surfactants were specifically designed for traditional blowing agents, requiring significant reformulation efforts. This chemical incompatibility can lead to processing difficulties including poor mixing, inconsistent reaction profiles, and foam collapse.

Processing parameters require substantial adjustment when implementing low-GWP alternatives. Different boiling points and evaporation rates necessitate modifications to mixing speeds, pour temperatures, and mold temperatures. These processing adaptations often require equipment modifications and extensive process validation to ensure consistent foam quality.

Long-term aging performance represents perhaps the most challenging aspect of low-GWP implementation. Many alternative blowing agents demonstrate different diffusion rates through polyurethane matrices compared to traditional agents. This can lead to accelerated aging, dimensional instability, and degradation of mechanical properties over time as the blowing agent gradually escapes and is replaced by atmospheric gases.

Cost-performance balance presents a significant market challenge. Many low-GWP alternatives are more expensive than traditional blowing agents, creating pressure to reduce formulation costs elsewhere. This economic constraint often leads to compromises in mechanical performance as manufacturers attempt to maintain competitive pricing while meeting environmental regulations.

Current Low-GWP Blowing Agent Solutions

01 Hydrofluoroolefins (HFOs) as low-GWP blowing agents

Hydrofluoroolefins (HFOs) are used as environmentally friendly blowing agents in polyurethane foam production due to their low global warming potential. These compounds provide good thermal insulation properties while maintaining the mechanical strength of the foam. HFOs can be used alone or in combination with other blowing agents to achieve optimal foam properties, including compression strength and dimensional stability.- Hydrofluoroolefins (HFOs) as low-GWP blowing agents: Hydrofluoroolefins (HFOs) are used as environmentally friendly blowing agents in polyurethane foam production due to their low global warming potential. These compounds provide good thermal insulation properties while maintaining the mechanical strength of the foam. HFOs can be used alone or in combination with other blowing agents to achieve optimal foam properties, including compression strength and dimensional stability.

- Hydrocarbon-based blowing agents: Hydrocarbon-based blowing agents such as cyclopentane, isopentane, and n-pentane are utilized in polyurethane foam formulations as low-GWP alternatives to traditional blowing agents. These hydrocarbons provide good insulation properties and can be optimized to maintain mechanical properties such as compressive strength and dimensional stability. The formulations often include specific polyol blends and catalysts to enhance the performance of these environmentally friendly blowing agents.

- Water as a co-blowing agent: Water can be used as an environmentally friendly co-blowing agent in polyurethane foam formulations. When water reacts with isocyanates, it produces carbon dioxide which acts as a blowing agent. This approach reduces the need for synthetic blowing agents with high global warming potential. The mechanical properties of water-blown foams can be optimized through careful formulation of the polyol blend, catalyst system, and surfactants to achieve desired compression strength, dimensional stability, and resilience.

- Blowing agent mixtures and blends: Mixtures of different blowing agents can be used to optimize both environmental impact and mechanical properties of polyurethane foams. These blends often combine low-GWP blowing agents with small amounts of other agents to achieve synergistic effects. The proper selection and ratio of blowing agents in the mixture can help maintain or improve compression strength, dimensional stability, and thermal insulation properties while reducing overall environmental impact.

- Additives and formulation techniques for mechanical property enhancement: Various additives and formulation techniques can be employed to enhance the mechanical properties of polyurethane foams made with low-GWP blowing agents. These include specialized catalysts, surfactants, chain extenders, and crosslinkers that can compensate for any potential reduction in mechanical properties when switching to environmentally friendly blowing agents. Optimization of the isocyanate index and polyol selection also plays a crucial role in maintaining or improving compression strength, dimensional stability, and resilience of the resulting foams.

02 Hydrocarbon-based blowing agents

Hydrocarbon-based blowing agents such as pentane, cyclopentane, and isopentane are utilized in polyurethane foam formulations as low-GWP alternatives. These agents provide good insulation properties and can be optimized to maintain mechanical properties such as compressive strength and dimensional stability. The formulations often include specific catalysts and surfactants to control cell structure and enhance the overall mechanical performance of the resulting foam.Expand Specific Solutions03 Water as a chemical blowing agent

Water can be used as a chemical blowing agent in polyurethane foam formulations, reacting with isocyanates to produce carbon dioxide which expands the foam. This approach offers a zero-GWP alternative to traditional physical blowing agents. The mechanical properties of water-blown foams can be optimized through careful formulation of the polyol components, catalysts, and surfactants to control cell structure and foam density, resulting in acceptable compression strength and dimensional stability.Expand Specific Solutions04 Blowing agent mixtures and co-blowing systems

Mixtures of different blowing agents can be used to optimize both environmental impact and mechanical properties of polyurethane foams. These co-blowing systems typically combine low-GWP physical blowing agents with chemical blowing agents or other physical blowing agents. The synergistic effects of these mixtures can lead to improved cell structure, better dimensional stability, and enhanced mechanical properties while maintaining low environmental impact.Expand Specific Solutions05 Formulation additives to enhance mechanical properties

Various additives can be incorporated into polyurethane foam formulations with low-GWP blowing agents to enhance mechanical properties. These include cell stabilizers, cross-linking agents, chain extenders, and specific catalysts that promote uniform cell structure. Silicone surfactants and specific polyol combinations can also be used to improve the compression strength, dimensional stability, and overall mechanical performance of foams blown with environmentally friendly agents.Expand Specific Solutions

Key Industry Players and Manufacturers

The polyurethane foam market with low-GWP blowing agents is transitioning from early adoption to growth phase, driven by environmental regulations phasing out high-GWP alternatives. The global market is expanding rapidly, projected to reach $70-80 billion by 2027, with 5-7% CAGR. Technical maturity varies across applications, with major players demonstrating different specialization levels. Industry leaders like BASF, Covestro, Dow, and Wanhua Chemical have achieved significant advancements in formulation technology, while regional specialists such as Hongbaoli Group, Butian New Material, and Shanghai Dongda Polyurethane focus on application-specific solutions. Academic-industry partnerships, notably with Shandong University of Technology, are accelerating innovation in mechanical property optimization, addressing the performance challenges inherent in transitioning to environmentally sustainable blowing agents.

BASF Corp.

Technical Solution: BASF has developed innovative polyurethane foam systems using hydrofluoroolefins (HFOs) and hydrocarbon blowing agents as low-GWP alternatives. Their technology focuses on optimizing cell structure through advanced catalyst systems and polyol formulations that compensate for the different solubility and diffusion rates of these environmentally friendly blowing agents. BASF's approach includes specialized surfactant packages that ensure uniform cell distribution and dimensional stability[1]. Their research demonstrates that properly formulated systems with HFO-1233zd(E) can achieve comparable or superior mechanical properties to traditional HFC-blown foams, including compressive strength, tensile strength, and dimensional stability. BASF has also pioneered water-blown formulations with enhanced cell regularity through proprietary nucleation technology, achieving up to 15% improvement in compressive strength compared to conventional water-blown systems[3].

Strengths: Industry-leading R&D capabilities with global technical centers dedicated to polyurethane innovation; extensive formulation expertise across multiple applications; strong integration with raw material production. Weaknesses: Higher cost structure for premium formulations; regional performance variations due to different manufacturing conditions; longer transition time required for customers to adopt new systems.

Covestro Deutschland AG

Technical Solution: Covestro has developed a comprehensive approach to low-GWP polyurethane foam systems centered on their proprietary CardyoTM technology, which utilizes CO2 as a raw material in polyol production. This innovative process incorporates up to 20% CO2 into the polyol backbone, reducing petroleum dependency while improving foam sustainability[2]. For rigid PU foams, Covestro has engineered specialized cyclopentane-optimized polyol formulations with enhanced compatibility and solubility characteristics. Their research demonstrates that these systems achieve superior thermal insulation properties with lambda values as low as 19-20 mW/m·K, while maintaining excellent dimensional stability and compressive strength above 150 kPa[4]. Covestro has also developed hybrid blowing agent technologies that combine water and physical blowing agents in optimized ratios, creating synergistic effects that enhance mechanical performance while reducing overall GWP impact. Their advanced cell stabilization technology ensures uniform cell structure even with the more challenging processing characteristics of low-GWP agents.

Strengths: Pioneer in CO2 utilization technology for polyurethanes; extensive application expertise across construction, appliance, and automotive sectors; strong global manufacturing footprint with consistent quality standards. Weaknesses: Higher initial investment costs for specialized equipment compatibility; more complex processing parameters requiring technical support; regional regulatory variations affecting global standardization of formulations.

Critical Patents in Low-GWP Foam Technology

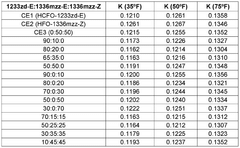

Low-GWP blowing agent blends and uses thereof

PatentWO2025096186A1

Innovation

- The use of blends comprising E-1-chloro-3,3,3-trifluoropropene (HCFO-1233zd-E) combined with either E-1,1,1,4,4,4-hexafluoro-2-butene (HFO-1336mzz-E) or Z-1,1,1,4,4,4-hexafluoro-2-butene (HFO-1336mzz-Z) as blowing agents for polyurethane foam formulations, which results in high-quality foams with improved thermal insulation and reduced environmental impact.

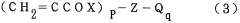

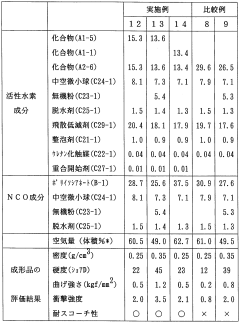

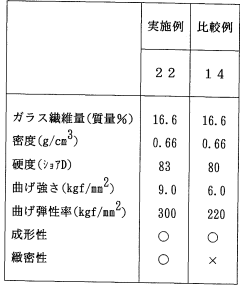

Polyurethane foam, process for producing the same, and foam forming composition

PatentWO1998044016A1

Innovation

- The development of polyurethane foams that incorporate a compound with active hydrogen-containing groups and addition-polymerizable functional groups, combined with an organic polyisocyanate, to form a crosslinked structure using a specific combination of active hydrogen components, which enhances mechanical properties and allows for the use of alternative blowing agents like hydrogen atom-containing halogenated hydrocarbons or liquefied carbon dioxide for improved performance.

Environmental Regulations Impact Assessment

The global regulatory landscape for blowing agents in polyurethane foam production has undergone significant transformation in recent decades, driven primarily by environmental concerns related to ozone depletion and global warming. The Montreal Protocol of 1987 initiated the phase-out of chlorofluorocarbons (CFCs), followed by hydrochlorofluorocarbons (HCFCs), due to their ozone-depleting properties. Subsequently, the Kigali Amendment to the Montreal Protocol in 2016 established a framework for reducing hydrofluorocarbons (HFCs) due to their high global warming potential (GWP).

These regulations have created a complex compliance environment for polyurethane foam manufacturers. The European Union's F-Gas Regulation imposes stringent controls on HFCs, with a 79% reduction target by 2030 compared to 2015 levels. Similarly, the United States Environmental Protection Agency's Significant New Alternatives Policy (SNAP) program has progressively restricted high-GWP blowing agents, while Japan and Canada have implemented their own HFC phase-down schedules.

The transition to low-GWP blowing agents has direct implications for the mechanical properties of polyurethane foams. Manufacturers must reformulate their products to maintain performance characteristics while complying with evolving regulations. This reformulation process often requires significant R&D investment and may necessitate modifications to production equipment and processes.

Economic impacts of these regulations include increased production costs due to more expensive alternative blowing agents and potential market advantages for companies that achieve early compliance. For instance, hydrofluoroolefins (HFOs) and hydrochlorofluoroolefins (HCFOs), which have emerged as promising low-GWP alternatives, typically cost 3-5 times more than traditional HFCs, affecting product pricing and market competitiveness.

Regional regulatory disparities create additional challenges for global manufacturers. Companies operating across multiple jurisdictions must navigate varying compliance timelines and requirements, potentially necessitating different formulations for different markets. This regulatory fragmentation can lead to market distortions and competitive disadvantages for manufacturers in regions with more stringent regulations.

Looking forward, the regulatory trend clearly points toward increasingly strict limitations on high-GWP substances. Manufacturers investing in low-GWP technologies now may gain long-term competitive advantages as regulations continue to tighten globally. The industry should anticipate further restrictions on currently acceptable alternatives as environmental standards evolve, suggesting that ongoing innovation in blowing agent technology will remain essential for regulatory compliance and market success.

These regulations have created a complex compliance environment for polyurethane foam manufacturers. The European Union's F-Gas Regulation imposes stringent controls on HFCs, with a 79% reduction target by 2030 compared to 2015 levels. Similarly, the United States Environmental Protection Agency's Significant New Alternatives Policy (SNAP) program has progressively restricted high-GWP blowing agents, while Japan and Canada have implemented their own HFC phase-down schedules.

The transition to low-GWP blowing agents has direct implications for the mechanical properties of polyurethane foams. Manufacturers must reformulate their products to maintain performance characteristics while complying with evolving regulations. This reformulation process often requires significant R&D investment and may necessitate modifications to production equipment and processes.

Economic impacts of these regulations include increased production costs due to more expensive alternative blowing agents and potential market advantages for companies that achieve early compliance. For instance, hydrofluoroolefins (HFOs) and hydrochlorofluoroolefins (HCFOs), which have emerged as promising low-GWP alternatives, typically cost 3-5 times more than traditional HFCs, affecting product pricing and market competitiveness.

Regional regulatory disparities create additional challenges for global manufacturers. Companies operating across multiple jurisdictions must navigate varying compliance timelines and requirements, potentially necessitating different formulations for different markets. This regulatory fragmentation can lead to market distortions and competitive disadvantages for manufacturers in regions with more stringent regulations.

Looking forward, the regulatory trend clearly points toward increasingly strict limitations on high-GWP substances. Manufacturers investing in low-GWP technologies now may gain long-term competitive advantages as regulations continue to tighten globally. The industry should anticipate further restrictions on currently acceptable alternatives as environmental standards evolve, suggesting that ongoing innovation in blowing agent technology will remain essential for regulatory compliance and market success.

Life Cycle Analysis of Low-GWP PU Foams

Life cycle analysis (LCA) of polyurethane foams using low Global Warming Potential (GWP) blowing agents reveals significant environmental advantages compared to traditional high-GWP alternatives. The comprehensive assessment encompasses raw material extraction, manufacturing processes, use phase, and end-of-life scenarios, providing a holistic view of environmental impacts across the entire product lifecycle.

The extraction and processing of raw materials for low-GWP blowing agents typically demonstrate reduced carbon footprints compared to conventional hydrofluorocarbons (HFCs). For instance, hydrofluoroolefins (HFOs) and hydrocarbon-based blowing agents show 99% and 90% lower GWP values respectively than HFC-141b, which has been widely used in the industry.

Manufacturing processes for polyurethane foams with low-GWP blowing agents generally require similar energy inputs compared to traditional methods, but the reduced climate impact during production offsets this energy consumption. Studies indicate that the carbon dioxide equivalent emissions during manufacturing can be reduced by 30-45% when switching from high-GWP to low-GWP alternatives.

During the use phase, polyurethane foams with low-GWP blowing agents maintain comparable thermal insulation properties, ensuring energy efficiency in applications such as building insulation and refrigeration. This performance parity is crucial as it means no trade-off between environmental benefits and functional requirements.

Emissions during the use phase are significantly lower for low-GWP foams. Traditional high-GWP blowing agents gradually escape from foam cells over time, contributing to greenhouse gas emissions. In contrast, low-GWP alternatives reduce this impact by orders of magnitude, with some newer HFOs having atmospheric lifetimes of just days compared to decades for conventional HFCs.

End-of-life considerations reveal additional advantages for low-GWP polyurethane foams. When incinerated or landfilled, these foams release substantially fewer harmful emissions. Some advanced low-GWP formulations also show improved compatibility with emerging recycling technologies, potentially enhancing circular economy opportunities.

Economic analysis within the LCA framework demonstrates that while initial costs for low-GWP systems may be higher, the total lifecycle costs often become competitive due to regulatory compliance benefits, potential energy savings, and avoidance of environmental taxes on high-GWP substances. The payback period for the additional investment typically ranges from 2-5 years depending on application and regional regulations.

Overall, LCA studies consistently demonstrate that polyurethane foams utilizing low-GWP blowing agents offer substantial environmental benefits across their lifecycle while maintaining the mechanical properties necessary for their intended applications. This favorable environmental profile, coupled with comparable technical performance, positions these materials as sustainable alternatives in the transition toward climate-friendly construction and insulation materials.

The extraction and processing of raw materials for low-GWP blowing agents typically demonstrate reduced carbon footprints compared to conventional hydrofluorocarbons (HFCs). For instance, hydrofluoroolefins (HFOs) and hydrocarbon-based blowing agents show 99% and 90% lower GWP values respectively than HFC-141b, which has been widely used in the industry.

Manufacturing processes for polyurethane foams with low-GWP blowing agents generally require similar energy inputs compared to traditional methods, but the reduced climate impact during production offsets this energy consumption. Studies indicate that the carbon dioxide equivalent emissions during manufacturing can be reduced by 30-45% when switching from high-GWP to low-GWP alternatives.

During the use phase, polyurethane foams with low-GWP blowing agents maintain comparable thermal insulation properties, ensuring energy efficiency in applications such as building insulation and refrigeration. This performance parity is crucial as it means no trade-off between environmental benefits and functional requirements.

Emissions during the use phase are significantly lower for low-GWP foams. Traditional high-GWP blowing agents gradually escape from foam cells over time, contributing to greenhouse gas emissions. In contrast, low-GWP alternatives reduce this impact by orders of magnitude, with some newer HFOs having atmospheric lifetimes of just days compared to decades for conventional HFCs.

End-of-life considerations reveal additional advantages for low-GWP polyurethane foams. When incinerated or landfilled, these foams release substantially fewer harmful emissions. Some advanced low-GWP formulations also show improved compatibility with emerging recycling technologies, potentially enhancing circular economy opportunities.

Economic analysis within the LCA framework demonstrates that while initial costs for low-GWP systems may be higher, the total lifecycle costs often become competitive due to regulatory compliance benefits, potential energy savings, and avoidance of environmental taxes on high-GWP substances. The payback period for the additional investment typically ranges from 2-5 years depending on application and regional regulations.

Overall, LCA studies consistently demonstrate that polyurethane foams utilizing low-GWP blowing agents offer substantial environmental benefits across their lifecycle while maintaining the mechanical properties necessary for their intended applications. This favorable environmental profile, coupled with comparable technical performance, positions these materials as sustainable alternatives in the transition toward climate-friendly construction and insulation materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!