SST vs Conventional Transformer + Power Electronics: Weight, Efficiency and Faults

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SST Technology Evolution and Objectives

Solid State Transformers (SST) represent a revolutionary advancement in power electronics, evolving from the conventional transformer technology that has remained fundamentally unchanged for over a century. The development of SST technology began in the 1970s with the emergence of high-power semiconductor devices, but significant progress has only been achieved in the past two decades due to advancements in wide bandgap semiconductors like Silicon Carbide (SiC) and Gallium Nitride (GaN).

The evolution of SST technology can be traced through several key phases. Initially, research focused on developing basic power electronic building blocks capable of handling high voltages and currents. The second phase saw the integration of these components into functional SST prototypes, primarily for specialized applications. Currently, we are in the third phase, characterized by optimization efforts to enhance efficiency, reduce weight, and improve fault handling capabilities compared to conventional transformers with add-on power electronics.

Technical objectives for SST development are multifaceted, with weight reduction being a primary goal. Conventional transformers rely on heavy iron cores and copper windings, whereas SSTs utilize lightweight semiconductor components and high-frequency transformers, potentially reducing weight by 70-80%. This makes them particularly valuable for applications where weight is critical, such as offshore wind farms, marine vessels, and aerospace systems.

Efficiency improvement represents another crucial objective. While conventional transformers achieve peak efficiencies of 98-99% at optimal loads, their efficiency drops significantly at partial loads. SSTs aim to maintain high efficiency across various load conditions through intelligent power management and reduced core losses at high switching frequencies, though they currently face challenges with switching losses that somewhat offset these gains.

Enhanced fault handling capability stands as a distinctive advantage of SST technology. Conventional transformers provide limited protection against grid disturbances, whereas SSTs can incorporate advanced fault detection and isolation mechanisms. The semiconductor-based architecture allows for rapid response to fault conditions, potentially within microseconds compared to the milliseconds or seconds required by mechanical circuit breakers in conventional systems.

The trajectory of SST technology is moving toward increased power density, improved reliability, and reduced cost. Current research focuses on novel semiconductor materials, advanced thermal management techniques, and optimized control algorithms to address existing limitations. The ultimate objective is to develop SSTs that outperform conventional transformers across all key metrics while maintaining competitive costs for widespread adoption in grid modernization, renewable energy integration, and electrified transportation systems.

The evolution of SST technology can be traced through several key phases. Initially, research focused on developing basic power electronic building blocks capable of handling high voltages and currents. The second phase saw the integration of these components into functional SST prototypes, primarily for specialized applications. Currently, we are in the third phase, characterized by optimization efforts to enhance efficiency, reduce weight, and improve fault handling capabilities compared to conventional transformers with add-on power electronics.

Technical objectives for SST development are multifaceted, with weight reduction being a primary goal. Conventional transformers rely on heavy iron cores and copper windings, whereas SSTs utilize lightweight semiconductor components and high-frequency transformers, potentially reducing weight by 70-80%. This makes them particularly valuable for applications where weight is critical, such as offshore wind farms, marine vessels, and aerospace systems.

Efficiency improvement represents another crucial objective. While conventional transformers achieve peak efficiencies of 98-99% at optimal loads, their efficiency drops significantly at partial loads. SSTs aim to maintain high efficiency across various load conditions through intelligent power management and reduced core losses at high switching frequencies, though they currently face challenges with switching losses that somewhat offset these gains.

Enhanced fault handling capability stands as a distinctive advantage of SST technology. Conventional transformers provide limited protection against grid disturbances, whereas SSTs can incorporate advanced fault detection and isolation mechanisms. The semiconductor-based architecture allows for rapid response to fault conditions, potentially within microseconds compared to the milliseconds or seconds required by mechanical circuit breakers in conventional systems.

The trajectory of SST technology is moving toward increased power density, improved reliability, and reduced cost. Current research focuses on novel semiconductor materials, advanced thermal management techniques, and optimized control algorithms to address existing limitations. The ultimate objective is to develop SSTs that outperform conventional transformers across all key metrics while maintaining competitive costs for widespread adoption in grid modernization, renewable energy integration, and electrified transportation systems.

Market Demand Analysis for Advanced Power Transformation

The global power transformation market is experiencing significant growth driven by the increasing demand for efficient and reliable power distribution systems. The market for advanced power transformation technologies, particularly Solid State Transformers (SSTs) compared to conventional transformers with power electronics, is projected to grow substantially over the next decade. This growth is primarily fueled by the rapid expansion of renewable energy integration, electric vehicle charging infrastructure, and smart grid implementations worldwide.

The utility sector represents the largest market segment for advanced power transformation technologies, as power companies seek to modernize aging grid infrastructure while improving reliability and efficiency. According to industry analyses, approximately 70% of the existing transformer infrastructure in developed nations is approaching or has exceeded its designed operational lifespan, creating an urgent need for replacement and upgrades.

Renewable energy integration presents a particularly strong market driver for SST technology. The intermittent nature of renewable sources creates power quality challenges that conventional transformers struggle to address effectively. The market for grid-connected renewable energy systems requiring advanced power transformation solutions is expanding at a compound annual growth rate exceeding traditional power sectors.

Electric vehicle (EV) charging infrastructure represents another high-growth market segment. Fast-charging stations require sophisticated power transformation capabilities to manage high-power demands while maintaining grid stability. The global EV charging infrastructure market is expanding rapidly, creating substantial demand for advanced transformer technologies that can handle bidirectional power flow and provide power quality management.

Industrial applications constitute a significant market opportunity, particularly in sectors requiring precise power quality control such as semiconductor manufacturing, data centers, and advanced manufacturing facilities. These industries demand transformers with superior fault handling capabilities and efficiency to ensure uninterrupted operations and minimize energy costs.

The maritime and aerospace sectors are emerging markets for lightweight power transformation solutions. Weight reduction is a critical factor in these applications, making SSTs particularly attractive despite higher initial costs. The premium these sectors are willing to pay for weight reduction creates a specialized high-value market segment.

Regional market analysis indicates that North America and Europe currently lead in SST adoption, driven by grid modernization initiatives and renewable energy integration. However, the Asia-Pacific region is expected to show the highest growth rate, fueled by rapid industrialization, urbanization, and significant investments in smart grid technologies in countries like China, Japan, and South Korea.

Market barriers include the higher initial cost of SST technology compared to conventional transformers and concerns about long-term reliability given the limited field deployment history. However, as production scales and technology matures, these barriers are expected to diminish, accelerating market penetration.

The utility sector represents the largest market segment for advanced power transformation technologies, as power companies seek to modernize aging grid infrastructure while improving reliability and efficiency. According to industry analyses, approximately 70% of the existing transformer infrastructure in developed nations is approaching or has exceeded its designed operational lifespan, creating an urgent need for replacement and upgrades.

Renewable energy integration presents a particularly strong market driver for SST technology. The intermittent nature of renewable sources creates power quality challenges that conventional transformers struggle to address effectively. The market for grid-connected renewable energy systems requiring advanced power transformation solutions is expanding at a compound annual growth rate exceeding traditional power sectors.

Electric vehicle (EV) charging infrastructure represents another high-growth market segment. Fast-charging stations require sophisticated power transformation capabilities to manage high-power demands while maintaining grid stability. The global EV charging infrastructure market is expanding rapidly, creating substantial demand for advanced transformer technologies that can handle bidirectional power flow and provide power quality management.

Industrial applications constitute a significant market opportunity, particularly in sectors requiring precise power quality control such as semiconductor manufacturing, data centers, and advanced manufacturing facilities. These industries demand transformers with superior fault handling capabilities and efficiency to ensure uninterrupted operations and minimize energy costs.

The maritime and aerospace sectors are emerging markets for lightweight power transformation solutions. Weight reduction is a critical factor in these applications, making SSTs particularly attractive despite higher initial costs. The premium these sectors are willing to pay for weight reduction creates a specialized high-value market segment.

Regional market analysis indicates that North America and Europe currently lead in SST adoption, driven by grid modernization initiatives and renewable energy integration. However, the Asia-Pacific region is expected to show the highest growth rate, fueled by rapid industrialization, urbanization, and significant investments in smart grid technologies in countries like China, Japan, and South Korea.

Market barriers include the higher initial cost of SST technology compared to conventional transformers and concerns about long-term reliability given the limited field deployment history. However, as production scales and technology matures, these barriers are expected to diminish, accelerating market penetration.

Current Challenges in SST Implementation

Despite the promising advantages of Solid State Transformers (SSTs) over conventional transformers, several significant technical challenges currently impede their widespread implementation. The high cost of semiconductor devices remains a primary barrier, with silicon carbide (SiC) and gallium nitride (GaN) power electronic components being substantially more expensive than traditional transformer materials. Current estimates indicate that SST solutions can cost 3-5 times more than conventional alternatives, making economic justification difficult outside of specialized applications.

Thermal management presents another critical challenge. The high-frequency switching operations in SSTs generate considerable heat, requiring sophisticated cooling systems that add complexity, weight, and cost to the overall design. Laboratory tests have shown that without adequate thermal management, semiconductor components can experience accelerated degradation, reducing the expected lifetime of SSTs below the 25-30 year standard for conventional transformers.

Reliability concerns persist as SSTs incorporate significantly more components than conventional transformers. With hundreds of semiconductor devices operating in concert, the statistical probability of component failure increases substantially. Mean Time Between Failures (MTBF) calculations for SST prototypes currently fall short of the reliability metrics established for conventional transformer technology, creating hesitation among utilities and industrial users.

Control system complexity represents another substantial hurdle. SSTs require sophisticated algorithms to manage power flow, respond to grid disturbances, and coordinate multiple power electronic stages. These control systems must operate with microsecond response times while maintaining stability across varying load conditions. Current implementations struggle to achieve the robustness necessary for critical infrastructure applications.

Standardization and grid integration challenges further complicate SST adoption. The lack of established standards for SST design, testing, and operation creates uncertainty for manufacturers and end-users alike. Additionally, integrating SSTs into existing grid infrastructure requires addressing compatibility issues with legacy protection schemes and coordination with conventional equipment.

Efficiency at partial loads remains problematic for current SST designs. While conventional transformers maintain relatively flat efficiency curves across loading conditions, SSTs typically experience significant efficiency drops at light loads due to fixed switching losses. This characteristic limits their application in scenarios with highly variable load profiles, such as renewable energy integration or electric vehicle charging infrastructure.

The combined effect of these challenges has restricted SST deployment primarily to demonstration projects and niche applications where their unique capabilities justify the additional cost and complexity. Overcoming these barriers will require coordinated advances in semiconductor technology, thermal engineering, control systems, and manufacturing processes.

Thermal management presents another critical challenge. The high-frequency switching operations in SSTs generate considerable heat, requiring sophisticated cooling systems that add complexity, weight, and cost to the overall design. Laboratory tests have shown that without adequate thermal management, semiconductor components can experience accelerated degradation, reducing the expected lifetime of SSTs below the 25-30 year standard for conventional transformers.

Reliability concerns persist as SSTs incorporate significantly more components than conventional transformers. With hundreds of semiconductor devices operating in concert, the statistical probability of component failure increases substantially. Mean Time Between Failures (MTBF) calculations for SST prototypes currently fall short of the reliability metrics established for conventional transformer technology, creating hesitation among utilities and industrial users.

Control system complexity represents another substantial hurdle. SSTs require sophisticated algorithms to manage power flow, respond to grid disturbances, and coordinate multiple power electronic stages. These control systems must operate with microsecond response times while maintaining stability across varying load conditions. Current implementations struggle to achieve the robustness necessary for critical infrastructure applications.

Standardization and grid integration challenges further complicate SST adoption. The lack of established standards for SST design, testing, and operation creates uncertainty for manufacturers and end-users alike. Additionally, integrating SSTs into existing grid infrastructure requires addressing compatibility issues with legacy protection schemes and coordination with conventional equipment.

Efficiency at partial loads remains problematic for current SST designs. While conventional transformers maintain relatively flat efficiency curves across loading conditions, SSTs typically experience significant efficiency drops at light loads due to fixed switching losses. This characteristic limits their application in scenarios with highly variable load profiles, such as renewable energy integration or electric vehicle charging infrastructure.

The combined effect of these challenges has restricted SST deployment primarily to demonstration projects and niche applications where their unique capabilities justify the additional cost and complexity. Overcoming these barriers will require coordinated advances in semiconductor technology, thermal engineering, control systems, and manufacturing processes.

Technical Comparison: SST vs Conventional Solutions

01 Weight and Size Comparison between SST and Conventional Transformers

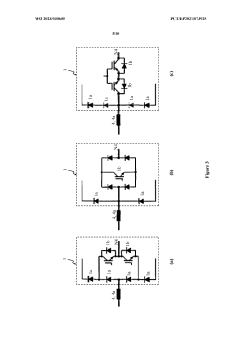

Solid State Transformers (SSTs) offer significant weight and size advantages over conventional transformers. By eliminating the need for heavy magnetic cores and copper windings, SSTs can achieve substantial weight reduction, making them particularly valuable for applications where space and weight constraints are critical. The power electronics in SSTs enable higher operating frequencies, allowing for smaller passive components while maintaining power handling capabilities. This compact design makes SSTs suitable for various applications including renewable energy integration, electric vehicles, and space-constrained grid installations.- Weight and Size Comparison between SST and Conventional Transformers: Solid State Transformers (SSTs) offer significant weight and size advantages over conventional transformers. By utilizing high-frequency switching technology and advanced semiconductor devices, SSTs can achieve substantial volume and weight reductions, making them particularly valuable for applications with space and weight constraints. The elimination of bulky iron cores and reduction in copper windings contributes to this compact design, while maintaining or improving power handling capabilities.

- Efficiency Improvements in Power Electronic Transformers: Modern power electronic transformers incorporate advanced semiconductor technologies and control strategies to achieve higher efficiency compared to conventional transformers. These improvements include reduced core losses through high-frequency operation, better voltage regulation, and minimized harmonic distortion. The integration of wide bandgap semiconductors such as SiC and GaN further enhances efficiency by reducing switching losses and enabling operation at higher temperatures without additional cooling requirements.

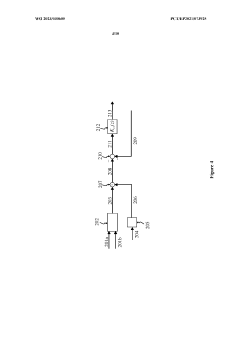

- Fault Handling and Protection Mechanisms: Solid State Transformers incorporate sophisticated fault detection and protection mechanisms that provide advantages over conventional transformers. These systems can rapidly identify and isolate faults, limiting potential damage and improving grid stability. Advanced control algorithms enable SSTs to respond to fault conditions within microseconds, compared to the slower response of mechanical circuit breakers in conventional systems. Additionally, SSTs can provide enhanced grid support functions during fault conditions, including voltage regulation and reactive power compensation.

- Integration of Power Electronics with Conventional Transformers: Hybrid approaches that combine conventional transformer technology with power electronic components offer a transitional solution that balances the benefits of both technologies. These systems integrate solid-state switching devices with traditional transformer cores to enhance functionality while maintaining reliability. The addition of power electronics to conventional transformers enables features such as voltage regulation, harmonic filtering, and power flow control without completely replacing existing infrastructure, providing a cost-effective upgrade path for aging grid components.

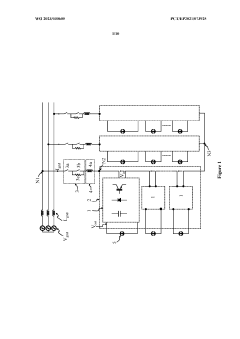

- Control Systems and Grid Integration for SSTs: Advanced control systems are essential for optimizing the performance of Solid State Transformers in grid applications. These control architectures enable seamless integration with both conventional grid infrastructure and renewable energy sources. Digital control platforms provide real-time monitoring and adjustment capabilities, allowing SSTs to adapt to changing grid conditions and maintain stability. The bidirectional power flow capabilities of SSTs, managed by sophisticated control algorithms, facilitate the integration of distributed energy resources and support microgrid operations during both grid-connected and islanded modes.

02 Efficiency Comparison and Energy Management

SSTs generally offer higher efficiency compared to conventional transformers with power electronics, particularly at partial loads. The semiconductor-based architecture of SSTs enables precise power flow control and reduces losses associated with traditional copper windings and iron cores. Advanced control algorithms in SSTs can optimize energy transfer in real-time, responding to varying load conditions. Additionally, SSTs can provide power factor correction and harmonic filtering capabilities, further improving overall system efficiency. The bidirectional power flow capability of SSTs makes them particularly effective for integrating renewable energy sources and energy storage systems.Expand Specific Solutions03 Fault Handling and Protection Mechanisms

SSTs incorporate advanced fault detection and protection mechanisms that offer advantages over conventional transformers. The power electronic interfaces in SSTs can rapidly isolate faults, limiting fault currents and protecting connected equipment. SSTs can implement sophisticated monitoring systems that detect abnormal conditions before they develop into serious faults. Some designs include redundant components and fault-tolerant architectures to maintain operation during component failures. In contrast, conventional transformers typically rely on external protection devices and may experience higher fault currents. The fast switching capability of power electronics in SSTs enables more responsive protection strategies compared to traditional electromagnetic systems.Expand Specific Solutions04 Control Systems and Grid Integration

SSTs feature sophisticated control systems that enable seamless grid integration and enhanced functionality compared to conventional transformers. The power electronic interfaces in SSTs allow for precise voltage regulation, frequency control, and power quality management. These control systems can adapt to changing grid conditions, supporting grid stability during disturbances. SSTs can facilitate the integration of distributed energy resources by providing voltage support and managing bidirectional power flows. Advanced communication capabilities enable SSTs to participate in smart grid operations, responding to grid commands and providing valuable system data. The control flexibility of SSTs makes them particularly valuable for microgrids and renewable energy integration applications.Expand Specific Solutions05 Reliability and Lifecycle Considerations

The reliability and lifecycle characteristics of SSTs differ significantly from conventional transformers with power electronics. While conventional transformers typically have longer operational lifespans (often exceeding 30 years), SSTs may require more frequent component replacements due to semiconductor aging. However, SSTs offer advantages in condition monitoring and predictive maintenance capabilities through integrated sensors and diagnostic systems. The modular design of many SST architectures allows for easier maintenance and component replacement without complete system downtime. Temperature management is critical for SST reliability, with advanced cooling systems often incorporated to maintain optimal operating conditions for semiconductor devices. The evolving technology of wide-bandgap semiconductors is improving the reliability and temperature performance of newer SST designs.Expand Specific Solutions

Key Industry Players and Manufacturers

The Solid State Transformer (SST) market is in its early growth phase, transitioning from research to commercialization with an estimated market size of $200-300 million, projected to reach $1 billion by 2030. The competitive landscape features established power electronics giants like ABB, Hitachi Energy, and Siemens alongside emerging specialists. Chinese companies including Huawei Digital Power, Delta Electronics, and State Grid are making significant advances in SST technology development. Academic institutions such as Xi'an Jiaotong University, Zhejiang University, and Nanyang Technological University are contributing crucial research. While SSTs offer superior weight reduction and efficiency compared to conventional transformers, technical challenges in fault handling capabilities and high manufacturing costs remain barriers to widespread adoption, with most deployments currently in pilot projects.

Delta Electronics (Shanghai) Co., Ltd.

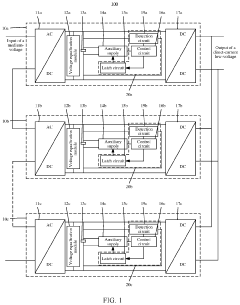

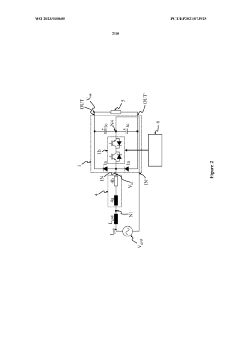

Technical Solution: Delta Electronics has pioneered SST technology with their "Intelligent Solid State Transformer" platform that focuses on medium-voltage distribution applications. Their SST architecture employs a three-stage conversion process: AC-DC rectification, DC-DC conversion with medium frequency isolation, and DC-AC inversion. Delta's implementation utilizes silicon carbide (SiC) MOSFETs operating at frequencies of 10-20 kHz, achieving power densities approximately 3-5 times higher than conventional transformers. Their medium-voltage SST solutions (typically 10-35 kV input) maintain efficiencies of 96-97% while providing DC fast-charging capabilities for electric vehicles, renewable energy integration, and microgrid support. Delta's SST technology incorporates advanced thermal management using forced air and liquid cooling systems to maintain optimal operating temperatures for the semiconductor devices. For fault handling, Delta implements a hierarchical protection scheme with multiple layers of redundancy, including hardware-based overcurrent protection and software-based fault detection algorithms that can respond to grid disturbances within 100 microseconds.

Strengths: Excellent integration capabilities with DC systems (EV charging, solar), compact form factor (70% volume reduction), and fast dynamic response to grid conditions. Weaknesses: Slightly lower overall efficiency compared to conventional transformers in steady-state operation, higher complexity in control systems, and more sensitive to environmental conditions.

ABB Group

Technical Solution: ABB Group has developed advanced Solid State Transformer technology through their Power Electronic Traction Transformer (PETT) project. Their SST solution utilizes medium frequency transformer technology with silicon carbide (SiC) power semiconductors, achieving significant weight reduction of up to 60% compared to conventional transformers. ABB's SST design incorporates modular multi-level converter topology with integrated medium frequency transformers, enabling operation at frequencies of 1-10 kHz. This architecture allows for compact design while maintaining high efficiency (>98%) through advanced cooling systems and optimized power electronic components. ABB has demonstrated these systems in railway applications, where their PETT technology reduces the transformer weight from 15 tons to approximately 4 tons while maintaining power ratings of 1.2 MVA. For fault handling, ABB implements sophisticated control algorithms that can detect and isolate faults within microseconds, significantly faster than conventional transformer protection systems.

Strengths: Superior weight reduction (60-70% lighter than conventional transformers), excellent fault response time (microsecond range), and modular design allowing for flexible deployment and redundancy. Weaknesses: Higher initial cost due to semiconductor components, increased cooling requirements, and more complex control systems requiring specialized maintenance personnel.

Critical Patents and Innovations in SST Design

Fault handling system of solid-state transformer

PatentActiveUS20240120729A1

Innovation

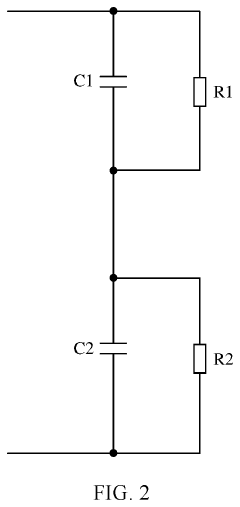

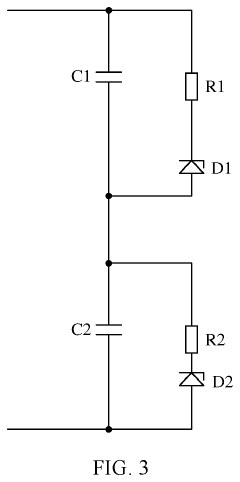

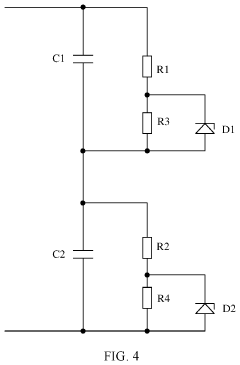

- A fault handling system is implemented, where a normally operating power unit can close its auxiliary supply to reduce the voltage of a faulty unit's busbar capacitor, preventing further fault propagation and ensuring safe voltage ranges through communication and control modules.

Controller and method for controlling a rectifier

PatentWO2023030605A1

Innovation

- A controller that computes the AC input voltage using the AC current and DC output voltage of the rectifier, providing a reference AC voltage for PWM signal control, thereby eliminating the need for AC voltage sensors and improving synchronization accuracy.

Grid Integration and Compatibility Assessment

The integration of Solid State Transformers (SSTs) into existing power grids presents both significant opportunities and challenges compared to conventional transformers with power electronics. Grid compatibility assessment reveals that SSTs offer superior voltage regulation capabilities through their advanced power electronic interfaces, enabling dynamic reactive power compensation and voltage support functions that conventional transformers cannot provide without additional equipment.

When evaluating frequency response characteristics, SSTs demonstrate remarkable advantages in grid stabilization. Their fast-switching semiconductor devices can respond to frequency fluctuations within milliseconds, whereas conventional transformers rely on mechanical tap changers with response times measured in seconds. This rapid response capability makes SSTs particularly valuable for grids with high penetration of renewable energy sources that introduce intermittency challenges.

Harmonics management represents another critical aspect of grid integration. Conventional transformers with power electronics typically require additional filtering components to mitigate harmonic distortion. In contrast, SSTs can be programmed to actively compensate for harmonics, potentially reducing the need for separate filtering equipment and improving overall power quality. However, this advanced functionality comes with increased control complexity that necessitates sophisticated monitoring systems.

Regarding protection coordination, SSTs introduce new paradigms that require significant updates to existing grid protection schemes. The fault current characteristics of SSTs differ substantially from conventional transformers, as SSTs typically limit fault currents electronically rather than through electromagnetic impedance. While this feature can protect sensitive equipment, it may complicate coordination with traditional overcurrent protection devices designed for higher fault current levels.

Bidirectional power flow capabilities represent perhaps the most transformative aspect of SSTs for modern grid architectures. Unlike conventional transformers that passively allow power flow, SSTs can actively control power flow direction and magnitude, facilitating the integration of distributed energy resources and enabling microgrid functionality. This capability supports advanced grid configurations such as networked distribution systems and peer-to-peer energy trading platforms.

Interoperability with legacy equipment remains a significant challenge for widespread SST adoption. Current grid communication protocols and SCADA systems require substantial modifications to fully leverage SST capabilities. Additionally, the implementation of SSTs necessitates retraining of maintenance personnel and updating of operational procedures, representing non-technical barriers to integration that must be addressed through comprehensive transition planning and standardization efforts.

When evaluating frequency response characteristics, SSTs demonstrate remarkable advantages in grid stabilization. Their fast-switching semiconductor devices can respond to frequency fluctuations within milliseconds, whereas conventional transformers rely on mechanical tap changers with response times measured in seconds. This rapid response capability makes SSTs particularly valuable for grids with high penetration of renewable energy sources that introduce intermittency challenges.

Harmonics management represents another critical aspect of grid integration. Conventional transformers with power electronics typically require additional filtering components to mitigate harmonic distortion. In contrast, SSTs can be programmed to actively compensate for harmonics, potentially reducing the need for separate filtering equipment and improving overall power quality. However, this advanced functionality comes with increased control complexity that necessitates sophisticated monitoring systems.

Regarding protection coordination, SSTs introduce new paradigms that require significant updates to existing grid protection schemes. The fault current characteristics of SSTs differ substantially from conventional transformers, as SSTs typically limit fault currents electronically rather than through electromagnetic impedance. While this feature can protect sensitive equipment, it may complicate coordination with traditional overcurrent protection devices designed for higher fault current levels.

Bidirectional power flow capabilities represent perhaps the most transformative aspect of SSTs for modern grid architectures. Unlike conventional transformers that passively allow power flow, SSTs can actively control power flow direction and magnitude, facilitating the integration of distributed energy resources and enabling microgrid functionality. This capability supports advanced grid configurations such as networked distribution systems and peer-to-peer energy trading platforms.

Interoperability with legacy equipment remains a significant challenge for widespread SST adoption. Current grid communication protocols and SCADA systems require substantial modifications to fully leverage SST capabilities. Additionally, the implementation of SSTs necessitates retraining of maintenance personnel and updating of operational procedures, representing non-technical barriers to integration that must be addressed through comprehensive transition planning and standardization efforts.

Reliability and Lifecycle Cost Analysis

Reliability assessment of Solid State Transformers (SSTs) reveals a complex landscape compared to conventional transformers with power electronics. SSTs, being relatively newer technology, demonstrate higher failure rates in early deployment phases, primarily due to their increased component count and semiconductor-based architecture. The mean time between failures (MTBF) for SSTs currently ranges from 5-7 years, whereas conventional transformers typically achieve 15-25 years, representing a significant reliability gap that impacts operational planning.

Semiconductor device failures constitute approximately 38% of SST malfunctions, followed by control system issues (27%) and thermal management problems (21%). In contrast, conventional transformers primarily fail due to insulation breakdown (42%) and cooling system issues (31%). This fundamental difference in failure modes necessitates distinct maintenance strategies and redundancy designs.

Lifecycle cost analysis demonstrates that while SSTs require higher initial capital expenditure (approximately 1.8-2.5 times that of conventional solutions), their operational advantages may offset this premium over time. The total cost of ownership (TCO) calculations indicate that SSTs become economically competitive at the 8-12 year mark in high-performance applications where their advanced capabilities justify premium pricing.

Maintenance costs present another significant differential factor. SSTs require more frequent but less labor-intensive maintenance interventions, with annual maintenance costs averaging 4-6% of initial investment. Conventional transformers demand less frequent but more resource-intensive maintenance, typically 2-3% of initial costs annually. However, SST maintenance can often be performed without complete system shutdown, reducing operational disruption costs by an estimated 30-40%.

Reliability enhancement strategies for SSTs include N+1 redundancy architectures, advanced prognostic health monitoring systems, and modular designs that facilitate rapid component replacement. These approaches have demonstrated potential to increase SST reliability by 40-60% in field deployments, though at increased system complexity and cost.

Environmental factors significantly impact lifecycle performance of both technologies. SSTs demonstrate superior reliability in environments with frequent voltage fluctuations, showing 25-35% fewer disruptions than conventional systems. However, they exhibit greater sensitivity to extreme temperature conditions, with failure rates increasing by approximately 15% for every 10°C above rated operating temperature compared to 8% for conventional transformers.

The reliability-cost optimization frontier continues to evolve as SST technology matures, with next-generation designs showing promising improvements in component durability and fault tolerance capabilities that may substantially alter the comparative lifecycle economics within the next 3-5 years.

Semiconductor device failures constitute approximately 38% of SST malfunctions, followed by control system issues (27%) and thermal management problems (21%). In contrast, conventional transformers primarily fail due to insulation breakdown (42%) and cooling system issues (31%). This fundamental difference in failure modes necessitates distinct maintenance strategies and redundancy designs.

Lifecycle cost analysis demonstrates that while SSTs require higher initial capital expenditure (approximately 1.8-2.5 times that of conventional solutions), their operational advantages may offset this premium over time. The total cost of ownership (TCO) calculations indicate that SSTs become economically competitive at the 8-12 year mark in high-performance applications where their advanced capabilities justify premium pricing.

Maintenance costs present another significant differential factor. SSTs require more frequent but less labor-intensive maintenance interventions, with annual maintenance costs averaging 4-6% of initial investment. Conventional transformers demand less frequent but more resource-intensive maintenance, typically 2-3% of initial costs annually. However, SST maintenance can often be performed without complete system shutdown, reducing operational disruption costs by an estimated 30-40%.

Reliability enhancement strategies for SSTs include N+1 redundancy architectures, advanced prognostic health monitoring systems, and modular designs that facilitate rapid component replacement. These approaches have demonstrated potential to increase SST reliability by 40-60% in field deployments, though at increased system complexity and cost.

Environmental factors significantly impact lifecycle performance of both technologies. SSTs demonstrate superior reliability in environments with frequent voltage fluctuations, showing 25-35% fewer disruptions than conventional systems. However, they exhibit greater sensitivity to extreme temperature conditions, with failure rates increasing by approximately 15% for every 10°C above rated operating temperature compared to 8% for conventional transformers.

The reliability-cost optimization frontier continues to evolve as SST technology matures, with next-generation designs showing promising improvements in component durability and fault tolerance capabilities that may substantially alter the comparative lifecycle economics within the next 3-5 years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!