How to Design Magnetics for High-Frequency Isolation — Core, Gap and Cooling

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Frequency Magnetic Isolation Background and Objectives

High-frequency magnetic isolation technology has evolved significantly over the past decades, transforming from simple low-frequency transformers to sophisticated high-frequency isolation components essential in modern power electronics. This evolution has been driven by the increasing demand for smaller, more efficient power conversion systems in applications ranging from renewable energy systems to electric vehicles and data centers.

The fundamental principle of magnetic isolation involves transferring electrical energy across a barrier without direct electrical connection, primarily using electromagnetic induction through transformers. As switching frequencies have increased from kilohertz to megahertz ranges, the design challenges have multiplied, necessitating innovative approaches to core materials, geometries, and thermal management.

Historically, ferrite materials dominated low to medium frequency applications due to their high resistivity and low eddy current losses. However, the push toward higher frequencies has led to the development of advanced materials such as nanocrystalline, amorphous metals, and powder cores, each offering specific advantages in different frequency ranges and power levels.

The objectives of high-frequency magnetic isolation design center around four key parameters: power density, efficiency, reliability, and cost. Modern applications demand unprecedented power density, requiring designers to maximize energy transfer while minimizing the physical footprint. This challenge is compounded by the need to maintain high efficiency, as losses in magnetic components manifest as heat, which can compromise system reliability.

Gap design has emerged as a critical aspect of high-frequency magnetics, particularly in power inductors and transformers where energy storage is required. Properly designed gaps can control inductance, prevent core saturation, and manage flux distribution, but they introduce their own challenges including fringing flux and increased electromagnetic interference (EMI).

Thermal management represents perhaps the most significant challenge in high-frequency magnetic design. As frequencies increase, core and winding losses generate substantial heat in compact volumes. Innovative cooling strategies including advanced materials, novel winding techniques, and integrated cooling systems have become essential to prevent thermal runaway and ensure component longevity.

The industry is currently witnessing a convergence of computational design tools, advanced materials science, and innovative manufacturing techniques that promise to overcome these challenges. Electromagnetic field simulation software, coupled with thermal analysis tools, now enables designers to optimize magnetic components before physical prototyping, significantly accelerating development cycles.

Looking forward, the trajectory of high-frequency magnetic isolation technology points toward even higher frequencies, smaller form factors, and more integrated solutions that combine multiple functions into single components, driving the next generation of power electronics.

The fundamental principle of magnetic isolation involves transferring electrical energy across a barrier without direct electrical connection, primarily using electromagnetic induction through transformers. As switching frequencies have increased from kilohertz to megahertz ranges, the design challenges have multiplied, necessitating innovative approaches to core materials, geometries, and thermal management.

Historically, ferrite materials dominated low to medium frequency applications due to their high resistivity and low eddy current losses. However, the push toward higher frequencies has led to the development of advanced materials such as nanocrystalline, amorphous metals, and powder cores, each offering specific advantages in different frequency ranges and power levels.

The objectives of high-frequency magnetic isolation design center around four key parameters: power density, efficiency, reliability, and cost. Modern applications demand unprecedented power density, requiring designers to maximize energy transfer while minimizing the physical footprint. This challenge is compounded by the need to maintain high efficiency, as losses in magnetic components manifest as heat, which can compromise system reliability.

Gap design has emerged as a critical aspect of high-frequency magnetics, particularly in power inductors and transformers where energy storage is required. Properly designed gaps can control inductance, prevent core saturation, and manage flux distribution, but they introduce their own challenges including fringing flux and increased electromagnetic interference (EMI).

Thermal management represents perhaps the most significant challenge in high-frequency magnetic design. As frequencies increase, core and winding losses generate substantial heat in compact volumes. Innovative cooling strategies including advanced materials, novel winding techniques, and integrated cooling systems have become essential to prevent thermal runaway and ensure component longevity.

The industry is currently witnessing a convergence of computational design tools, advanced materials science, and innovative manufacturing techniques that promise to overcome these challenges. Electromagnetic field simulation software, coupled with thermal analysis tools, now enables designers to optimize magnetic components before physical prototyping, significantly accelerating development cycles.

Looking forward, the trajectory of high-frequency magnetic isolation technology points toward even higher frequencies, smaller form factors, and more integrated solutions that combine multiple functions into single components, driving the next generation of power electronics.

Market Analysis for High-Frequency Isolation Applications

The high-frequency isolation market is experiencing robust growth driven by the increasing adoption of power electronics across multiple industries. The global market for high-frequency magnetic components used in isolation applications is projected to reach $5.2 billion by 2026, growing at a CAGR of 8.7% from 2021. This growth is primarily fueled by the rapid expansion of renewable energy systems, electric vehicles, and data centers, all of which require efficient power conversion with galvanic isolation.

Electric vehicle charging infrastructure represents one of the fastest-growing segments, with demand for high-frequency isolation transformers increasing as charging speeds continue to advance. The market for EV-related magnetic components is expected to grow at 12.3% annually through 2025, creating significant opportunities for advanced magnetic design solutions that can handle higher switching frequencies while maintaining thermal stability.

Renewable energy applications, particularly solar inverters and wind power converters, constitute approximately 24% of the current market. These applications increasingly demand compact isolation solutions capable of operating at frequencies above 100 kHz to reduce system size while improving efficiency. The trend toward higher power density has pushed manufacturers to develop innovative core materials and cooling techniques specifically optimized for high-frequency operation.

Industrial automation and medical equipment sectors together account for roughly 18% of market demand, with stringent safety requirements driving the need for reliable isolation solutions. These sectors particularly value magnetic components with excellent thermal management capabilities and long operational lifetimes, often willing to pay premium prices for solutions that offer superior performance characteristics.

Geographically, Asia-Pacific dominates the market with approximately 42% share, led by manufacturing hubs in China, Japan, and South Korea. North America follows at 28%, with particularly strong demand in the data center and telecommunications sectors. Europe represents 24% of the market, with its growth primarily driven by automotive and renewable energy applications.

Customer requirements are increasingly focused on size reduction, efficiency improvement, and thermal management capabilities. Market research indicates that 76% of design engineers consider thermal management as a critical factor when selecting magnetic components for high-frequency isolation applications. This has created a competitive advantage for manufacturers who can provide comprehensive design solutions addressing core selection, gap optimization, and effective cooling strategies as integrated offerings rather than isolated components.

Electric vehicle charging infrastructure represents one of the fastest-growing segments, with demand for high-frequency isolation transformers increasing as charging speeds continue to advance. The market for EV-related magnetic components is expected to grow at 12.3% annually through 2025, creating significant opportunities for advanced magnetic design solutions that can handle higher switching frequencies while maintaining thermal stability.

Renewable energy applications, particularly solar inverters and wind power converters, constitute approximately 24% of the current market. These applications increasingly demand compact isolation solutions capable of operating at frequencies above 100 kHz to reduce system size while improving efficiency. The trend toward higher power density has pushed manufacturers to develop innovative core materials and cooling techniques specifically optimized for high-frequency operation.

Industrial automation and medical equipment sectors together account for roughly 18% of market demand, with stringent safety requirements driving the need for reliable isolation solutions. These sectors particularly value magnetic components with excellent thermal management capabilities and long operational lifetimes, often willing to pay premium prices for solutions that offer superior performance characteristics.

Geographically, Asia-Pacific dominates the market with approximately 42% share, led by manufacturing hubs in China, Japan, and South Korea. North America follows at 28%, with particularly strong demand in the data center and telecommunications sectors. Europe represents 24% of the market, with its growth primarily driven by automotive and renewable energy applications.

Customer requirements are increasingly focused on size reduction, efficiency improvement, and thermal management capabilities. Market research indicates that 76% of design engineers consider thermal management as a critical factor when selecting magnetic components for high-frequency isolation applications. This has created a competitive advantage for manufacturers who can provide comprehensive design solutions addressing core selection, gap optimization, and effective cooling strategies as integrated offerings rather than isolated components.

Technical Challenges in High-Frequency Magnetic Design

High-frequency magnetic design faces several significant technical challenges that must be addressed to achieve optimal performance in power conversion systems. Core material selection represents a primary challenge, as traditional ferrite materials exhibit increasing core losses at frequencies above 100 kHz. Advanced materials like nanocrystalline and amorphous alloys offer improved performance but come with higher costs and manufacturing complexities. The trade-off between saturation flux density, permeability, and loss characteristics becomes increasingly critical as frequencies rise.

Thermal management presents another substantial hurdle in high-frequency magnetic design. As switching frequencies increase, core and winding losses concentrate in smaller volumes, creating thermal hotspots that can lead to premature component failure. Conventional cooling methods become insufficient, necessitating innovative approaches such as integrated cooling channels, phase-change materials, or even liquid cooling systems for high-power applications.

Gap design and fringing flux effects introduce complex electromagnetic challenges. At high frequencies, the air gap in magnetic components creates significant fringing flux that increases proximity losses in nearby windings. This phenomenon becomes more pronounced as frequencies increase, requiring careful positioning of windings and potentially the use of distributed gap designs to minimize these effects.

Winding configurations face limitations due to skin and proximity effects, which dramatically increase AC resistance at high frequencies. Litz wire offers a partial solution but introduces its own challenges in termination and manufacturing. Advanced winding techniques like planar magnetics provide benefits in thermal performance and repeatability but limit design flexibility and increase production costs.

Parasitic elements become increasingly problematic at high frequencies. Interwinding capacitance and leakage inductance, often negligible at lower frequencies, can significantly impact isolation performance and create resonant circuits that affect system stability. These parasitic elements must be carefully modeled and minimized through strategic winding arrangements and shielding techniques.

Measurement and characterization of high-frequency magnetic components present additional challenges. Traditional measurement equipment and methodologies become less accurate as frequencies increase, requiring specialized instrumentation and calibration techniques. The complex impedance characteristics of high-frequency magnetics necessitate sophisticated modeling approaches that account for frequency-dependent parameters and non-linear behaviors.

Manufacturing repeatability becomes critical as component tolerances have a greater impact on performance at high frequencies. Small variations in core gaps, winding positions, or material properties can significantly alter the electrical characteristics of the finished component, necessitating tighter quality control processes and potentially automated manufacturing techniques.

Thermal management presents another substantial hurdle in high-frequency magnetic design. As switching frequencies increase, core and winding losses concentrate in smaller volumes, creating thermal hotspots that can lead to premature component failure. Conventional cooling methods become insufficient, necessitating innovative approaches such as integrated cooling channels, phase-change materials, or even liquid cooling systems for high-power applications.

Gap design and fringing flux effects introduce complex electromagnetic challenges. At high frequencies, the air gap in magnetic components creates significant fringing flux that increases proximity losses in nearby windings. This phenomenon becomes more pronounced as frequencies increase, requiring careful positioning of windings and potentially the use of distributed gap designs to minimize these effects.

Winding configurations face limitations due to skin and proximity effects, which dramatically increase AC resistance at high frequencies. Litz wire offers a partial solution but introduces its own challenges in termination and manufacturing. Advanced winding techniques like planar magnetics provide benefits in thermal performance and repeatability but limit design flexibility and increase production costs.

Parasitic elements become increasingly problematic at high frequencies. Interwinding capacitance and leakage inductance, often negligible at lower frequencies, can significantly impact isolation performance and create resonant circuits that affect system stability. These parasitic elements must be carefully modeled and minimized through strategic winding arrangements and shielding techniques.

Measurement and characterization of high-frequency magnetic components present additional challenges. Traditional measurement equipment and methodologies become less accurate as frequencies increase, requiring specialized instrumentation and calibration techniques. The complex impedance characteristics of high-frequency magnetics necessitate sophisticated modeling approaches that account for frequency-dependent parameters and non-linear behaviors.

Manufacturing repeatability becomes critical as component tolerances have a greater impact on performance at high frequencies. Small variations in core gaps, winding positions, or material properties can significantly alter the electrical characteristics of the finished component, necessitating tighter quality control processes and potentially automated manufacturing techniques.

Current Core, Gap and Cooling Design Methodologies

01 Core material selection for high-frequency isolation

The selection of appropriate core materials is crucial for high-frequency isolation transformers. Materials such as ferrite, nanocrystalline, and amorphous alloys offer superior magnetic properties at high frequencies, including low core losses and high permeability. These materials help maintain efficiency while providing the necessary isolation between primary and secondary circuits. The composition and structure of these materials significantly impact the transformer's performance in terms of power density, temperature stability, and frequency response.- Core materials for high-frequency isolation: Various materials are used for high-frequency isolation cores to optimize magnetic performance. These include ferrite materials, nanocrystalline alloys, and amorphous metals that offer high permeability and low core losses at high frequencies. The selection of appropriate core materials is crucial for efficient power transfer and minimizing energy losses in high-frequency applications such as power converters and transformers.

- Air gap design and optimization: Air gaps in magnetic cores are strategically designed to prevent core saturation, store energy, and control inductance in high-frequency applications. The size, shape, and placement of these gaps significantly impact the performance of magnetic components. Advanced gap designs include distributed gaps, stepped gaps, and precision-engineered gaps that help maintain consistent magnetic properties while reducing fringing flux and associated losses.

- Thermal management and cooling techniques: Effective cooling solutions are essential for high-frequency magnetic components to maintain performance and reliability. Cooling techniques include forced air cooling, liquid cooling systems, heat sinks, and thermally conductive materials that efficiently dissipate heat generated during operation. Advanced designs incorporate cooling channels, thermal interfaces, and optimized component layouts to manage temperature rise and prevent thermal degradation of magnetic properties.

- Winding configurations for high-frequency isolation: Specialized winding techniques are employed to enhance isolation and reduce parasitic effects in high-frequency magnetic components. These include interleaved windings, sectional windings, and Litz wire constructions that minimize proximity effects and skin effect losses. The arrangement of primary and secondary windings affects leakage inductance, capacitance, and overall isolation performance, which are critical factors in high-frequency power conversion applications.

- Integrated shielding and isolation structures: Advanced magnetic components incorporate integrated shielding and isolation structures to minimize electromagnetic interference and improve performance. These designs feature electromagnetic shields, flux barriers, and specialized geometries that contain magnetic fields and prevent unwanted coupling. Isolation barriers made from high-dielectric materials enhance safety and compliance with regulatory standards while maintaining efficient power transfer at high frequencies.

02 Air gap design for magnetic flux control

Strategic air gap design in magnetic cores is essential for controlling saturation, storing energy, and optimizing magnetic flux distribution in high-frequency applications. The size, shape, and position of air gaps affect inductance, saturation characteristics, and overall performance. Distributed gaps can reduce fringing flux and associated losses, while precision gap techniques help maintain consistent magnetic properties across production batches. Advanced gap designs incorporate special materials or structures to enhance performance while minimizing electromagnetic interference.Expand Specific Solutions03 Thermal management and cooling techniques

Effective cooling solutions are critical for high-frequency magnetic components to maintain performance and reliability. Techniques include passive cooling through optimized component geometry and material selection, active cooling systems using air or liquid circulation, and advanced thermal interface materials to improve heat transfer. Heat dissipation paths are designed to efficiently remove heat from core and windings, while thermal modeling helps predict hotspots and optimize cooling strategies. Some designs incorporate integrated cooling channels or specialized heat sinks directly into the magnetic assembly.Expand Specific Solutions04 Winding configurations for high-frequency operation

Specialized winding techniques are employed to minimize losses and parasitic effects in high-frequency isolation transformers. These include interleaved windings to reduce leakage inductance, Litz wire to mitigate skin and proximity effects, and sectional winding approaches to control capacitive coupling. The physical arrangement of primary and secondary windings impacts isolation performance, while specialized insulation materials maintain dielectric strength at high frequencies. Advanced winding geometries help balance electrical performance with thermal management requirements.Expand Specific Solutions05 Integrated shielding and EMI reduction

Electromagnetic interference (EMI) management is essential in high-frequency isolation applications. Integrated shielding techniques include electrostatic shields between windings, flux containment structures, and specialized core geometries that minimize stray fields. Common-mode noise reduction is achieved through balanced winding configurations and strategic placement of shielding materials. Some designs incorporate ferrite beads or specialized absorbing materials to attenuate high-frequency noise components. These shielding approaches must balance EMI suppression with thermal management and overall size constraints.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The high-frequency magnetic isolation technology market is currently in a growth phase, with increasing demand driven by power electronics applications in renewable energy, electric vehicles, and industrial automation. The market size is expanding rapidly, projected to reach several billion dollars by 2025. Technologically, companies like Texas Instruments, Mitsubishi Electric, and ABB Group lead with mature solutions, while Allegro MicroSystems and Delta Electronics are advancing in core design optimization. Toshiba and Proterial are making significant progress in magnetic material development, while thermal management innovations come from Lite-On and LG Innotek. The competitive landscape shows established players focusing on integration and efficiency, with emerging players specializing in niche applications requiring advanced magnetic isolation solutions.

Delta Electronics (Thailand) Public Co. Ltd.

Technical Solution: Delta Electronics has developed comprehensive solutions for high-frequency isolation magnetics focused on power density optimization and efficiency. Their approach centers on custom-designed planar magnetic structures utilizing advanced ferrite materials optimized for operation at frequencies between 200kHz and 2MHz. Delta's magnetic designs incorporate precisely calculated partial air gaps with specialized geometries to control leakage inductance while maintaining isolation requirements. For thermal management, they've implemented innovative cooling solutions including direct-bonded copper (DBC) substrates that serve both as winding structures and thermal management layers. Their winding designs utilize multi-layer PCB techniques with optimized copper distribution to balance current density and thermal performance. Delta has pioneered automated manufacturing processes for consistent production of complex magnetic assemblies with tight tolerances. Their isolation strategy incorporates specialized insulation materials and construction techniques that maintain safety requirements while minimizing the impact on thermal performance. Delta's designs also feature integrated EMI suppression structures including common-mode chokes and specialized shielding techniques to maintain electromagnetic compatibility while preserving isolation integrity[6][7].

Strengths: Extensive manufacturing expertise allows for cost-effective mass production; vertical integration from materials to finished components ensures quality control; strong focus on practical, commercially viable solutions. Weaknesses: May prioritize cost-effectiveness over absolute performance in some designs; solutions sometimes optimized for specific applications rather than general-purpose use.

Eaton Intelligent Power Ltd.

Technical Solution: Eaton has developed sophisticated approaches to high-frequency isolation magnetics focusing on reliability and performance in demanding applications. Their designs utilize advanced core materials including custom-formulated ferrite compositions optimized for specific frequency ranges between 100kHz and 500kHz. Eaton's magnetic structures incorporate precisely calculated air gaps with specialized geometries that minimize fringing flux while optimizing energy storage capabilities for specific application requirements. For thermal management, they've implemented comprehensive cooling solutions including potted designs with thermally conductive compounds that maintain isolation while efficiently transferring heat from windings to external heat sinks. Their winding techniques include specialized litz wire constructions with optimized strand counts and diameters to minimize AC losses at target frequencies. Eaton has developed proprietary impregnation processes that eliminate air voids within windings to improve thermal conductivity and dielectric strength. Their isolation designs incorporate multiple layers of insulation materials with graduated dielectric constants to optimize electric field distribution and prevent partial discharge. Eaton also employs advanced 3D electromagnetic and thermal simulation tools to optimize designs before prototyping, ensuring performance across temperature extremes and over product lifetime[8][9].

Strengths: Exceptional focus on reliability and long-term performance; comprehensive understanding of safety standards and certification requirements; robust designs suitable for harsh environments. Weaknesses: Solutions may be overengineered for some applications, resulting in higher costs; design approach sometimes favors proven technologies over cutting-edge innovations.

Key Patents and Research in Magnetic Isolation

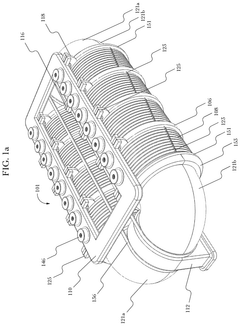

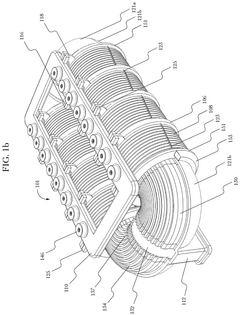

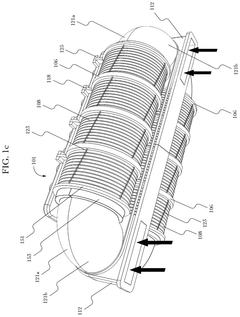

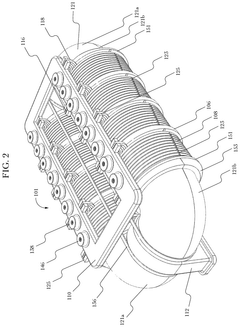

Fluid cooled magnetic element

PatentActiveUS12125628B2

Innovation

- A fluid-cooled magnetic element design featuring helically wound coils over a ferromagnetic core with optimized coolant flow paths, including an annular gap for core cooling and radial gaps between coil turns for winding cooling, allowing for efficient heat transfer and high current densities.

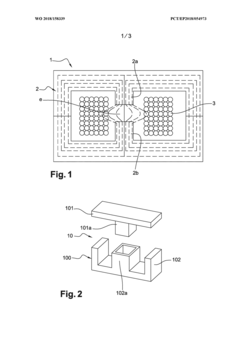

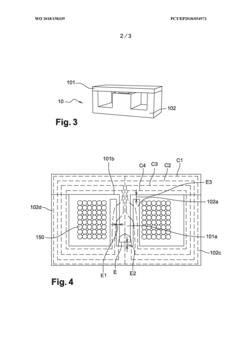

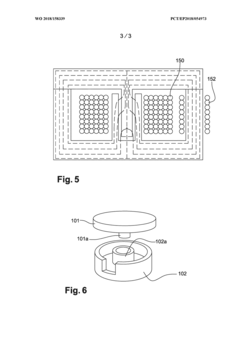

Magnetic component and voltage converter comprising same

PatentWO2018158339A1

Innovation

- A magnetic component design featuring a magnetic core with a radially located air gap between a male and female contact formed by interlocking parts, optionally filled with an electrical and non-magnetic insulating material, to minimize the impact of the magnetic field on the winding and reduce losses.

Thermal Management Strategies for High-Frequency Magnetics

Effective thermal management is critical for high-frequency magnetic components, as excessive heat can significantly degrade performance and reliability. The primary heat sources in high-frequency magnetics include core losses, winding losses, and gap losses, all of which increase substantially at higher frequencies. Without proper thermal management, these components can experience reduced efficiency, accelerated aging, and even catastrophic failure.

Conduction cooling represents the most fundamental thermal management approach, involving direct heat transfer through physical contact. This method typically employs thermally conductive materials like aluminum or copper heat sinks attached to the magnetic component. For enhanced performance, thermal interface materials such as gap pads or thermal greases can be applied to minimize contact resistance between surfaces, significantly improving heat transfer efficiency.

Convection cooling utilizes air or liquid movement to dissipate heat. Natural convection relies on ambient air circulation, while forced convection employs fans or blowers to accelerate heat removal. In high-power applications, liquid cooling systems using water, dielectric fluids, or specialized coolants offer superior thermal performance, though at the cost of increased system complexity and maintenance requirements.

Radiation cooling becomes increasingly important at higher temperatures, where components emit heat as infrared energy. While less efficient than other methods at typical operating temperatures, radiation can be enhanced through surface treatments that increase emissivity, such as specialized coatings or finishes.

Integrated cooling approaches that combine multiple techniques often yield optimal results. These may include potting compounds with high thermal conductivity, embedded heat pipes, or vapor chambers. Advanced designs might incorporate phase-change materials that absorb heat during temperature spikes, providing thermal buffering during transient load conditions.

Temperature monitoring and adaptive control systems represent the cutting edge of thermal management. These systems employ temperature sensors and feedback loops to adjust operating parameters in real-time, preventing thermal runaway conditions. Some sophisticated designs incorporate predictive algorithms that anticipate thermal issues based on operating conditions and adjust accordingly before problems occur.

For high-frequency isolation applications specifically, thermal management must address the unique challenges of maintaining electrical isolation while providing effective cooling. This often necessitates careful selection of thermally conductive yet electrically insulating materials, strategic component placement, and thoughtful system-level thermal design that considers the entire power conversion chain.

Conduction cooling represents the most fundamental thermal management approach, involving direct heat transfer through physical contact. This method typically employs thermally conductive materials like aluminum or copper heat sinks attached to the magnetic component. For enhanced performance, thermal interface materials such as gap pads or thermal greases can be applied to minimize contact resistance between surfaces, significantly improving heat transfer efficiency.

Convection cooling utilizes air or liquid movement to dissipate heat. Natural convection relies on ambient air circulation, while forced convection employs fans or blowers to accelerate heat removal. In high-power applications, liquid cooling systems using water, dielectric fluids, or specialized coolants offer superior thermal performance, though at the cost of increased system complexity and maintenance requirements.

Radiation cooling becomes increasingly important at higher temperatures, where components emit heat as infrared energy. While less efficient than other methods at typical operating temperatures, radiation can be enhanced through surface treatments that increase emissivity, such as specialized coatings or finishes.

Integrated cooling approaches that combine multiple techniques often yield optimal results. These may include potting compounds with high thermal conductivity, embedded heat pipes, or vapor chambers. Advanced designs might incorporate phase-change materials that absorb heat during temperature spikes, providing thermal buffering during transient load conditions.

Temperature monitoring and adaptive control systems represent the cutting edge of thermal management. These systems employ temperature sensors and feedback loops to adjust operating parameters in real-time, preventing thermal runaway conditions. Some sophisticated designs incorporate predictive algorithms that anticipate thermal issues based on operating conditions and adjust accordingly before problems occur.

For high-frequency isolation applications specifically, thermal management must address the unique challenges of maintaining electrical isolation while providing effective cooling. This often necessitates careful selection of thermally conductive yet electrically insulating materials, strategic component placement, and thoughtful system-level thermal design that considers the entire power conversion chain.

Material Selection Criteria for Optimal Performance

The selection of magnetic materials for high-frequency isolation applications requires careful consideration of multiple factors to achieve optimal performance. Core material properties significantly impact efficiency, thermal management, and overall system reliability. Ferrite materials remain the predominant choice for frequencies above 50kHz due to their high resistivity and low eddy current losses. Among these, MnZn ferrites excel in the 50kHz-3MHz range, while NiZn ferrites demonstrate superior performance at frequencies extending beyond 3MHz.

Saturation flux density (Bsat) represents a critical parameter when evaluating core materials, as it directly determines the power handling capability per unit volume. Materials with higher Bsat values allow for more compact designs but often come with trade-offs in other performance metrics. For high-frequency applications, the relationship between core loss and frequency becomes particularly important, with losses typically increasing exponentially with frequency according to the Steinmetz equation.

Temperature stability must be carefully assessed when selecting magnetic materials. The Curie temperature, beyond which magnetic properties deteriorate significantly, should be substantially higher than the expected operating temperature range. Additionally, the temperature coefficient of permeability impacts the consistency of performance across varying thermal conditions, with some advanced materials offering near-zero temperature coefficients over specified ranges.

Mechanical stability represents another crucial consideration, particularly in applications subject to vibration or mechanical stress. Brittle materials may develop microcracks over time, leading to increased losses and potential catastrophic failure. Composite materials incorporating polymer binders with distributed air gaps often provide improved mechanical resilience while maintaining acceptable electrical performance.

Cost-effectiveness must be balanced against performance requirements, especially in high-volume applications. While nanocrystalline and amorphous materials offer superior performance in many metrics, their higher cost may be prohibitive for certain applications. The total cost of ownership calculation should include not only material costs but also manufacturing complexity, cooling requirements, and expected service life.

Environmental considerations are increasingly important in material selection. RoHS compliance and end-of-life recyclability now factor into design decisions alongside traditional performance metrics. Some newer magnetic materials offer improved environmental profiles while maintaining competitive performance characteristics, though often at premium price points.

Saturation flux density (Bsat) represents a critical parameter when evaluating core materials, as it directly determines the power handling capability per unit volume. Materials with higher Bsat values allow for more compact designs but often come with trade-offs in other performance metrics. For high-frequency applications, the relationship between core loss and frequency becomes particularly important, with losses typically increasing exponentially with frequency according to the Steinmetz equation.

Temperature stability must be carefully assessed when selecting magnetic materials. The Curie temperature, beyond which magnetic properties deteriorate significantly, should be substantially higher than the expected operating temperature range. Additionally, the temperature coefficient of permeability impacts the consistency of performance across varying thermal conditions, with some advanced materials offering near-zero temperature coefficients over specified ranges.

Mechanical stability represents another crucial consideration, particularly in applications subject to vibration or mechanical stress. Brittle materials may develop microcracks over time, leading to increased losses and potential catastrophic failure. Composite materials incorporating polymer binders with distributed air gaps often provide improved mechanical resilience while maintaining acceptable electrical performance.

Cost-effectiveness must be balanced against performance requirements, especially in high-volume applications. While nanocrystalline and amorphous materials offer superior performance in many metrics, their higher cost may be prohibitive for certain applications. The total cost of ownership calculation should include not only material costs but also manufacturing complexity, cooling requirements, and expected service life.

Environmental considerations are increasingly important in material selection. RoHS compliance and end-of-life recyclability now factor into design decisions alongside traditional performance metrics. Some newer magnetic materials offer improved environmental profiles while maintaining competitive performance characteristics, though often at premium price points.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!