SST Safety Cases: MV Enclosures, Arc Flash and Codes

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SST Safety Background and Objectives

Solid-State Transformer (SST) technology represents a revolutionary advancement in power electronics, offering a modern alternative to traditional transformers through semiconductor-based power conversion. The evolution of SST technology began in the early 2000s, with significant acceleration in research and development over the past decade due to advancements in wide-bandgap semiconductor materials like Silicon Carbide (SiC) and Gallium Nitride (GaN).

Safety considerations for Medium Voltage (MV) enclosures housing SSTs have become increasingly critical as deployment expands across utility, industrial, and renewable energy applications. Historically, conventional transformers relied on passive safety mechanisms, whereas SSTs introduce active electronic components operating at medium voltage levels, creating new safety paradigms that traditional standards may not fully address.

The primary technical objective for SST safety development is to establish comprehensive protection against arc flash incidents—dangerous electrical explosions that pose severe risks to personnel and equipment. These incidents are particularly hazardous in MV applications where SSTs typically operate (3.3kV to 36kV range), with potential to release energy exceeding 40 cal/cm² in worst-case scenarios.

Current safety codes and standards were largely developed for conventional transformer technologies, creating a regulatory gap for SST implementations. The International Electrotechnical Commission (IEC), Institute of Electrical and Electronics Engineers (IEEE), and National Fire Protection Association (NFPA) have begun addressing these gaps, but comprehensive standards specific to SST technology remain under development.

The technological trajectory aims to develop SST enclosures that provide superior arc flash protection while maintaining the compact form factor that makes SSTs advantageous over conventional transformers. This includes innovations in rapid fault detection systems capable of identifying potential arc conditions within microseconds, and ultra-fast isolation mechanisms that can contain or prevent arc flash events before they escalate to dangerous levels.

Another critical objective is the development of predictive diagnostic capabilities that can identify potential failure modes before they manifest as safety incidents. This involves implementing advanced sensor networks and machine learning algorithms to monitor key parameters such as thermal conditions, partial discharges, and electromagnetic signatures that might indicate impending failures.

The ultimate goal is to establish SST safety standards that achieve or exceed the protection levels of conventional transformers while enabling the additional benefits of SSTs, including higher efficiency, reduced size, enhanced power quality, and grid integration capabilities. This requires a multidisciplinary approach combining power electronics, materials science, thermal management, and safety engineering to create holistic solutions that address the unique challenges of MV SST implementations.

Safety considerations for Medium Voltage (MV) enclosures housing SSTs have become increasingly critical as deployment expands across utility, industrial, and renewable energy applications. Historically, conventional transformers relied on passive safety mechanisms, whereas SSTs introduce active electronic components operating at medium voltage levels, creating new safety paradigms that traditional standards may not fully address.

The primary technical objective for SST safety development is to establish comprehensive protection against arc flash incidents—dangerous electrical explosions that pose severe risks to personnel and equipment. These incidents are particularly hazardous in MV applications where SSTs typically operate (3.3kV to 36kV range), with potential to release energy exceeding 40 cal/cm² in worst-case scenarios.

Current safety codes and standards were largely developed for conventional transformer technologies, creating a regulatory gap for SST implementations. The International Electrotechnical Commission (IEC), Institute of Electrical and Electronics Engineers (IEEE), and National Fire Protection Association (NFPA) have begun addressing these gaps, but comprehensive standards specific to SST technology remain under development.

The technological trajectory aims to develop SST enclosures that provide superior arc flash protection while maintaining the compact form factor that makes SSTs advantageous over conventional transformers. This includes innovations in rapid fault detection systems capable of identifying potential arc conditions within microseconds, and ultra-fast isolation mechanisms that can contain or prevent arc flash events before they escalate to dangerous levels.

Another critical objective is the development of predictive diagnostic capabilities that can identify potential failure modes before they manifest as safety incidents. This involves implementing advanced sensor networks and machine learning algorithms to monitor key parameters such as thermal conditions, partial discharges, and electromagnetic signatures that might indicate impending failures.

The ultimate goal is to establish SST safety standards that achieve or exceed the protection levels of conventional transformers while enabling the additional benefits of SSTs, including higher efficiency, reduced size, enhanced power quality, and grid integration capabilities. This requires a multidisciplinary approach combining power electronics, materials science, thermal management, and safety engineering to create holistic solutions that address the unique challenges of MV SST implementations.

Market Requirements for MV Enclosure Safety

The medium voltage (MV) enclosure market is experiencing significant growth driven by increasing safety concerns and regulatory requirements across various industries. Current market analysis indicates that safety has become the primary consideration for end-users when selecting MV equipment, surpassing traditional factors such as cost and performance. This shift in priorities stems from heightened awareness of arc flash hazards and their potentially catastrophic consequences in industrial environments.

Industry surveys reveal that facility managers and electrical engineers consistently rank personnel safety as their top requirement for MV enclosures, with particular emphasis on arc flash protection capabilities. The market demands comprehensive safety features including passive protection through robust enclosure design, active protection systems for rapid fault detection and mitigation, and clear safety indicators and interlocks to prevent operator errors.

Regional variations in safety requirements are notable, with North American markets placing greater emphasis on NFPA 70E compliance and arc-resistant designs, while European markets focus on IEC standards implementation. Emerging markets in Asia and the Middle East are rapidly adopting international safety standards as their industrial infrastructure expands, creating significant growth opportunities for manufacturers offering advanced safety solutions.

The utility sector represents the largest market segment for MV enclosure safety systems, followed closely by oil and gas, mining, and data center applications. These industries operate in particularly hazardous environments where arc flash incidents pose severe risks to both personnel and equipment. Consequently, these sectors demonstrate willingness to invest in premium safety features despite higher initial costs.

Market research indicates a growing demand for retrofittable safety solutions that can upgrade existing MV installations to meet current safety standards without complete system replacement. This trend is particularly strong in mature markets with aging electrical infrastructure, where complete replacement is often cost-prohibitive or logistically challenging.

Remote monitoring and diagnostic capabilities have emerged as increasingly important market requirements, allowing operators to assess equipment condition and potential safety issues without direct exposure to hazardous areas. This trend aligns with broader industry movements toward digitalization and predictive maintenance strategies.

Customer feedback consistently highlights the need for safety solutions that minimize operational disruption and maintenance requirements. The market increasingly favors designs that facilitate safe inspection and maintenance procedures without compromising protection levels or requiring extensive downtime. This balance between accessibility and safety represents a key differentiator for manufacturers in the competitive MV enclosure market.

Industry surveys reveal that facility managers and electrical engineers consistently rank personnel safety as their top requirement for MV enclosures, with particular emphasis on arc flash protection capabilities. The market demands comprehensive safety features including passive protection through robust enclosure design, active protection systems for rapid fault detection and mitigation, and clear safety indicators and interlocks to prevent operator errors.

Regional variations in safety requirements are notable, with North American markets placing greater emphasis on NFPA 70E compliance and arc-resistant designs, while European markets focus on IEC standards implementation. Emerging markets in Asia and the Middle East are rapidly adopting international safety standards as their industrial infrastructure expands, creating significant growth opportunities for manufacturers offering advanced safety solutions.

The utility sector represents the largest market segment for MV enclosure safety systems, followed closely by oil and gas, mining, and data center applications. These industries operate in particularly hazardous environments where arc flash incidents pose severe risks to both personnel and equipment. Consequently, these sectors demonstrate willingness to invest in premium safety features despite higher initial costs.

Market research indicates a growing demand for retrofittable safety solutions that can upgrade existing MV installations to meet current safety standards without complete system replacement. This trend is particularly strong in mature markets with aging electrical infrastructure, where complete replacement is often cost-prohibitive or logistically challenging.

Remote monitoring and diagnostic capabilities have emerged as increasingly important market requirements, allowing operators to assess equipment condition and potential safety issues without direct exposure to hazardous areas. This trend aligns with broader industry movements toward digitalization and predictive maintenance strategies.

Customer feedback consistently highlights the need for safety solutions that minimize operational disruption and maintenance requirements. The market increasingly favors designs that facilitate safe inspection and maintenance procedures without compromising protection levels or requiring extensive downtime. This balance between accessibility and safety represents a key differentiator for manufacturers in the competitive MV enclosure market.

Current Challenges in Arc Flash Protection

Arc flash protection in medium voltage (MV) enclosures faces significant challenges despite advancements in safety technologies. The primary challenge remains the unpredictable nature of arc flash events, which can release enormous energy in milliseconds, causing catastrophic damage to equipment and severe injuries to personnel. Current protection systems struggle with detection speed limitations, often requiring 50-100ms to identify and respond to arc events, while the most destructive damage occurs within the first 10-20ms.

Material limitations present another substantial challenge. Traditional enclosure materials may not withstand the extreme temperatures (up to 20,000°C) and pressure waves generated during arc flash events. While specialized arc-resistant enclosures exist, they significantly increase costs and spatial requirements, creating implementation barriers for many facilities, particularly those with space constraints or retrofit applications.

Coordination between protective devices remains problematic in complex electrical systems. Achieving proper selectivity while maintaining adequate arc flash protection often creates competing objectives. Systems designed for maximum operational continuity may inadvertently increase arc flash hazards by delaying fault clearing times. Conversely, systems optimized for arc flash safety may experience nuisance tripping and reduced reliability.

Regulatory compliance adds another layer of complexity. The landscape of arc flash protection is governed by multiple, sometimes overlapping standards including IEEE 1584, NFPA 70E, IEC 61482, and various regional codes. These standards continue to evolve, creating challenges for manufacturers and facility managers to maintain compliance across different jurisdictions. The 2018 update to IEEE 1584 significantly changed arc flash calculation methodologies, requiring substantial revisions to existing safety protocols and documentation.

Cost-benefit analysis presents difficult decisions for organizations. Advanced protection systems like optical detection, differential relaying, and active arc quenching technologies offer superior protection but at substantially higher implementation costs. Many facilities struggle to justify these investments, particularly when retrofitting existing installations where modifications may require extended downtime.

Maintenance and testing of arc flash protection systems introduce additional challenges. Regular verification of protection systems is essential but often requires equipment shutdown. Proper testing procedures for modern arc flash protection systems require specialized knowledge and equipment that may not be readily available in many maintenance departments, creating potential gaps in safety assurance.

Human factors and training deficiencies compound these technical challenges. Even with advanced protection systems, personnel must understand arc flash risks, properly interpret hazard labels, select appropriate PPE, and follow safe work practices. Training programs often fail to adequately address the specific challenges of MV enclosures, where hazards are significantly greater than in low-voltage applications.

Material limitations present another substantial challenge. Traditional enclosure materials may not withstand the extreme temperatures (up to 20,000°C) and pressure waves generated during arc flash events. While specialized arc-resistant enclosures exist, they significantly increase costs and spatial requirements, creating implementation barriers for many facilities, particularly those with space constraints or retrofit applications.

Coordination between protective devices remains problematic in complex electrical systems. Achieving proper selectivity while maintaining adequate arc flash protection often creates competing objectives. Systems designed for maximum operational continuity may inadvertently increase arc flash hazards by delaying fault clearing times. Conversely, systems optimized for arc flash safety may experience nuisance tripping and reduced reliability.

Regulatory compliance adds another layer of complexity. The landscape of arc flash protection is governed by multiple, sometimes overlapping standards including IEEE 1584, NFPA 70E, IEC 61482, and various regional codes. These standards continue to evolve, creating challenges for manufacturers and facility managers to maintain compliance across different jurisdictions. The 2018 update to IEEE 1584 significantly changed arc flash calculation methodologies, requiring substantial revisions to existing safety protocols and documentation.

Cost-benefit analysis presents difficult decisions for organizations. Advanced protection systems like optical detection, differential relaying, and active arc quenching technologies offer superior protection but at substantially higher implementation costs. Many facilities struggle to justify these investments, particularly when retrofitting existing installations where modifications may require extended downtime.

Maintenance and testing of arc flash protection systems introduce additional challenges. Regular verification of protection systems is essential but often requires equipment shutdown. Proper testing procedures for modern arc flash protection systems require specialized knowledge and equipment that may not be readily available in many maintenance departments, creating potential gaps in safety assurance.

Human factors and training deficiencies compound these technical challenges. Even with advanced protection systems, personnel must understand arc flash risks, properly interpret hazard labels, select appropriate PPE, and follow safe work practices. Training programs often fail to adequately address the specific challenges of MV enclosures, where hazards are significantly greater than in low-voltage applications.

Existing Arc Flash Mitigation Techniques

01 Electrical isolation and protection mechanisms

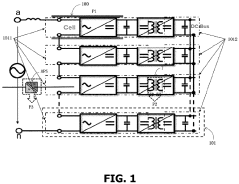

Solid State Transformers (SSTs) incorporate various isolation and protection mechanisms to ensure safety during operation. These include galvanic isolation between input and output circuits, overcurrent protection systems, and fault detection mechanisms that can quickly disconnect the transformer in case of abnormal conditions. Advanced designs feature multiple isolation barriers and redundant protection circuits to prevent electrical hazards and maintain safe operation even during fault conditions.- Electrical isolation and protection mechanisms: Solid State Transformers (SSTs) incorporate various electrical isolation and protection mechanisms to ensure safety during operation. These include galvanic isolation between input and output circuits, overcurrent protection systems, and fault detection mechanisms that can quickly disconnect the transformer in case of abnormal conditions. Advanced designs implement multiple protection layers to prevent electrical hazards and protect both the equipment and users from potential electrical failures.

- Thermal management and cooling systems: Effective thermal management is critical for SST safety as semiconductor components generate significant heat during operation. Advanced cooling systems including heat sinks, thermal interface materials, and active cooling mechanisms are implemented to maintain safe operating temperatures. Proper thermal design prevents overheating that could lead to component degradation, reduced reliability, or catastrophic failure. Temperature monitoring systems provide real-time feedback to control systems to adjust operation or initiate shutdown procedures when temperature thresholds are exceeded.

- Electromagnetic compatibility and interference mitigation: SSTs must comply with electromagnetic compatibility (EMC) standards to ensure they don't interfere with other electronic equipment and are themselves resistant to external electromagnetic interference. Shielding techniques, proper grounding, and filter circuits are employed to minimize electromagnetic emissions. Advanced designs incorporate specialized components and circuit layouts to reduce common-mode noise and prevent electromagnetic interference that could compromise safety or performance of nearby systems.

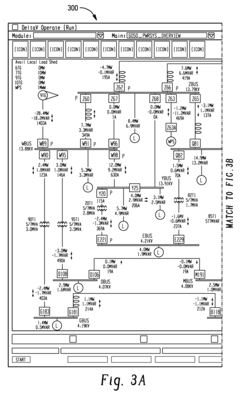

- Fault detection and diagnostic systems: Modern SSTs incorporate sophisticated fault detection and diagnostic systems that continuously monitor operational parameters. These systems can detect abnormalities such as voltage spikes, current imbalances, or component degradation before they lead to safety hazards. Real-time monitoring combined with predictive analytics allows for early identification of potential failures. When faults are detected, the systems can initiate appropriate responses ranging from operational adjustments to complete shutdown, enhancing overall safety and reliability.

- Safety certification and regulatory compliance: SST designs must adhere to various international safety standards and undergo rigorous certification processes before deployment. These standards cover aspects such as electrical safety, thermal performance, mechanical integrity, and environmental considerations. Compliance with regulations like IEC, UL, and IEEE standards ensures that SSTs meet minimum safety requirements for their intended applications. The certification process typically involves extensive testing under normal and fault conditions to verify that safety mechanisms function as designed and that the transformer can withstand expected operational stresses.

02 Thermal management and cooling systems

Effective thermal management is crucial for SST safety as semiconductor components generate significant heat during operation. Advanced cooling systems including liquid cooling, heat sinks, and thermal interface materials are implemented to maintain safe operating temperatures. Temperature monitoring sensors and automatic shutdown mechanisms prevent overheating scenarios, while thermal modeling techniques help optimize component placement and cooling channel design to eliminate hotspots that could lead to device failure or safety hazards.Expand Specific Solutions03 EMI/EMC compliance and shielding

Electromagnetic interference (EMI) and electromagnetic compatibility (EMC) are important safety considerations in SST design. Shielding techniques, proper grounding methods, and filter circuits are employed to minimize electromagnetic emissions that could interfere with nearby equipment. Compliance with international EMC standards ensures that SSTs operate safely within electromagnetic environments without causing disruption to other systems or being susceptible to external electromagnetic disturbances that could compromise their safety functions.Expand Specific Solutions04 Fault detection and management systems

Advanced fault detection and management systems are integrated into SSTs to identify potential safety issues before they escalate. These systems monitor critical parameters such as voltage, current, temperature, and switching behavior in real-time. When abnormal conditions are detected, the systems can implement appropriate responses ranging from adjusting operating parameters to complete shutdown. Some designs incorporate self-diagnostic capabilities, predictive failure analysis, and remote monitoring features to enhance safety through early intervention.Expand Specific Solutions05 Safety certification and regulatory compliance

SST designs must adhere to various safety standards and regulatory requirements to ensure safe operation in different applications. This includes compliance with electrical safety codes, grid interconnection standards, and industry-specific regulations. Safety certification processes involve rigorous testing under normal and fault conditions, documentation of safety features, and validation of isolation barriers. Regulatory frameworks may specify additional requirements for SSTs used in specific environments such as residential buildings, industrial facilities, or critical infrastructure.Expand Specific Solutions

Leading Manufacturers in MV Safety Solutions

The SST Safety Cases market for MV Enclosures and Arc Flash protection is currently in a growth phase, driven by increasing safety regulations and industrial automation demands. The market size is expanding significantly as industries prioritize electrical safety compliance. Leading players include Eaton Intelligent Power and Schneider Electric, who have developed mature arc flash protection technologies, while Rockwell Automation and ABB Group offer comprehensive safety solutions with advanced diagnostic capabilities. Companies like Littelfuse and 3M Innovative Properties are focusing on specialized protection components. The technology landscape shows varying maturity levels, with established manufacturers (Eaton, Schneider, ABB) offering integrated solutions, while newer entrants are developing niche innovations to address specific code compliance challenges in medium voltage applications.

Eaton Intelligent Power Ltd.

Technical Solution: Eaton's SST safety case solution for MV enclosures incorporates a multi-layered approach to arc flash protection. Their ArcGard MV switchgear utilizes pressure-sensitive design that channels arc energy upward through specialized vents, significantly reducing frontal exposure risks. The system features patented isolation technology that creates physical barriers between energized components, reducing arc flash incident energy by up to 65% compared to traditional designs. Eaton's solution complies with IEEE 1584-2018 standards for arc flash calculations and NFPA 70E requirements for electrical safety in the workplace. Their arc-resistant switchgear is tested to ANSI C37.20.7 standards, providing Type 2 accessibility protection that safeguards personnel on all sides of the equipment during an arc event.

Strengths: Comprehensive compliance with multiple safety codes (NFPA 70E, IEEE 1584, ANSI C37.20.7); Reduced incident energy levels through innovative design; Multi-directional protection for maintenance personnel. Weaknesses: Higher initial investment compared to non-arc-resistant alternatives; Requires more installation space due to venting requirements; May need supplementary systems in extremely high-risk environments.

Rockwell Automation Technologies, Inc.

Technical Solution: Rockwell Automation's approach to SST safety cases for MV enclosures centers on their CENTERLINE arc-resistant motor control centers and PowerFlex medium voltage drives with integrated safety features. Their solution implements a zone-selective interlocking system that can reduce arc flash incident energy by up to 85% by limiting fault clearing time to 100ms or less. The technology incorporates predictive diagnostics that monitor equipment conditions in real-time, identifying potential arc flash triggers before they occur. Rockwell's ArcShield technology provides Type 2 accessibility protection in accordance with IEEE C37.20.7, featuring reinforced enclosures, pressure relief channels, and specialized hinges and latches designed to contain arc flash energy. Their systems integrate with Allen-Bradley Guardmaster safety relays to create comprehensive protection that meets both IEC 62061 and ISO 13849-1 safety standards while maintaining operational efficiency.

Strengths: Exceptional reduction in incident energy through advanced timing coordination; Integration with existing automation systems for comprehensive facility safety; Predictive capabilities that help prevent arc events before they occur. Weaknesses: Complex implementation requiring specialized configuration expertise; Higher maintenance requirements for diagnostic systems; May require significant retrofitting in existing installations.

Key Safety Technologies for MV Enclosures

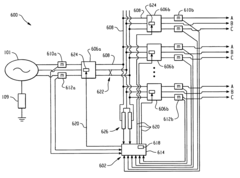

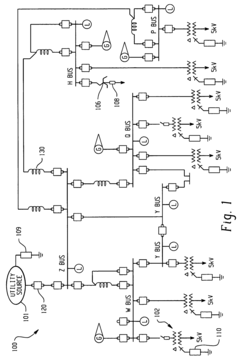

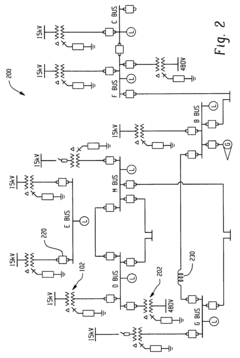

Arc-flash hazard protection system for three-phase electrical distribution system

PatentActiveUS7852605B2

Innovation

- The implementation of microprocessor-based bus differential protection systems using current transformers and bus differential relays that communicate with two out of the three phases of switchgear, providing a low-impedance protection scheme and real-time monitoring and control capabilities, enabling fast fault clearing and detection of arc-flash conditions.

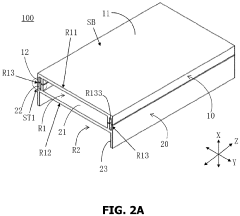

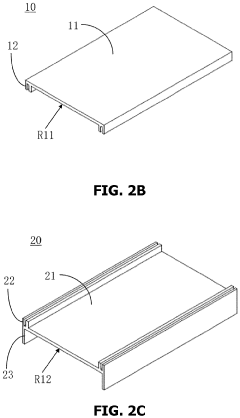

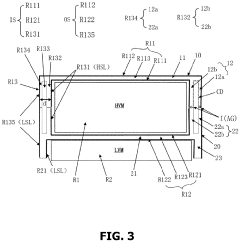

Shielded insulating shell and electronic device

PatentPendingEP4312474A1

Innovation

- A shielded insulating shell with a structured assembly including inner and outer shielding layers, insulating layers, and air gap layers forming a creepage path, which reduces electrical field stress and enhances insulation efficiency by increasing the creepage distance and spacing between high and low voltage shielding layers.

Regulatory Compliance Framework

The regulatory landscape governing Medium Voltage (MV) enclosures and arc flash safety is complex and multifaceted, comprising international standards, national regulations, and industry-specific codes. At the international level, the International Electrotechnical Commission (IEC) provides foundational standards such as IEC 62271 for high-voltage switchgear and controlgear, which establishes baseline requirements for MV enclosure design and arc flash protection. These standards are often adopted or referenced by national regulatory bodies worldwide.

In the United States, the regulatory framework is primarily defined by NFPA 70E (Standard for Electrical Safety in the Workplace) and the National Electrical Code (NEC), which mandate specific requirements for electrical equipment installation, maintenance, and operation. OSHA regulations (29 CFR 1910.269 and 1910.303-1910.308) enforce these standards by requiring employers to assess workplace electrical hazards and implement appropriate protective measures.

The IEEE 1584 Guide for Performing Arc Flash Hazard Calculations provides the methodological framework for calculating arc flash incident energy and establishing appropriate safety boundaries. This technical standard has been incorporated into regulatory compliance requirements across multiple jurisdictions and serves as the scientific basis for many arc flash protection programs.

European regulations follow the EN 61439 series for low-voltage and MV switchgear assemblies, complemented by the Machinery Directive 2006/42/EC and Low Voltage Directive 2014/35/EU. These directives establish essential health and safety requirements that manufacturers must meet before placing electrical equipment on the European market.

Compliance verification mechanisms vary by jurisdiction but typically include third-party certification, self-declaration of conformity, and regular inspections. Organizations such as UL (Underwriters Laboratories), CSA (Canadian Standards Association), and TÜV provide testing and certification services to verify that MV enclosures meet applicable safety standards.

Recent regulatory trends indicate a movement toward more stringent arc flash protection requirements, with increased emphasis on predictive maintenance, remote monitoring capabilities, and quantitative risk assessment methodologies. The integration of digital technologies has also prompted regulatory bodies to develop new guidelines addressing cybersecurity concerns in industrial control systems connected to MV equipment.

Industry-specific regulations add another layer of complexity, with specialized requirements for sectors such as oil and gas (API standards), maritime applications (IMO regulations), and nuclear facilities (IAEA safety standards). These sector-specific codes often impose additional safety measures beyond general electrical safety regulations.

In the United States, the regulatory framework is primarily defined by NFPA 70E (Standard for Electrical Safety in the Workplace) and the National Electrical Code (NEC), which mandate specific requirements for electrical equipment installation, maintenance, and operation. OSHA regulations (29 CFR 1910.269 and 1910.303-1910.308) enforce these standards by requiring employers to assess workplace electrical hazards and implement appropriate protective measures.

The IEEE 1584 Guide for Performing Arc Flash Hazard Calculations provides the methodological framework for calculating arc flash incident energy and establishing appropriate safety boundaries. This technical standard has been incorporated into regulatory compliance requirements across multiple jurisdictions and serves as the scientific basis for many arc flash protection programs.

European regulations follow the EN 61439 series for low-voltage and MV switchgear assemblies, complemented by the Machinery Directive 2006/42/EC and Low Voltage Directive 2014/35/EU. These directives establish essential health and safety requirements that manufacturers must meet before placing electrical equipment on the European market.

Compliance verification mechanisms vary by jurisdiction but typically include third-party certification, self-declaration of conformity, and regular inspections. Organizations such as UL (Underwriters Laboratories), CSA (Canadian Standards Association), and TÜV provide testing and certification services to verify that MV enclosures meet applicable safety standards.

Recent regulatory trends indicate a movement toward more stringent arc flash protection requirements, with increased emphasis on predictive maintenance, remote monitoring capabilities, and quantitative risk assessment methodologies. The integration of digital technologies has also prompted regulatory bodies to develop new guidelines addressing cybersecurity concerns in industrial control systems connected to MV equipment.

Industry-specific regulations add another layer of complexity, with specialized requirements for sectors such as oil and gas (API standards), maritime applications (IMO regulations), and nuclear facilities (IAEA safety standards). These sector-specific codes often impose additional safety measures beyond general electrical safety regulations.

Risk Assessment Methodologies

Risk assessment methodologies for Medium Voltage (MV) enclosures and arc flash hazards require systematic approaches to identify, evaluate, and mitigate potential safety risks. The IEC/ISO 31010 framework provides a comprehensive foundation for risk assessment in electrical systems, establishing a structured process that includes risk identification, analysis, evaluation, and treatment phases specifically applicable to MV environments.

Quantitative risk assessment techniques such as Failure Mode and Effects Analysis (FMEA) and Fault Tree Analysis (FTA) are particularly valuable for MV enclosure safety evaluations. FMEA systematically identifies potential failure modes in MV components and assesses their consequences, while FTA employs Boolean logic to analyze complex system failures that could lead to arc flash incidents. These methodologies enable engineers to prioritize risk mitigation efforts based on calculated risk priority numbers.

IEEE 1584 provides specialized methodologies for arc flash hazard calculations, offering empirical formulas to determine incident energy levels and appropriate safety boundaries. This standard incorporates variables such as working distance, available fault current, and clearing time to quantify potential arc flash energy. Complementing this, NFPA 70E outlines risk assessment procedures specifically for electrical work, introducing the concept of likelihood and severity matrices for hazard evaluation.

The Hierarchy of Controls methodology, endorsed by safety standards worldwide, establishes a prioritized approach to risk mitigation in MV environments. This framework prioritizes elimination of hazards, followed by substitution, engineering controls, administrative controls, and personal protective equipment as a last line of defense. For MV enclosures, this often translates to implementing remote operation capabilities, installing arc-resistant switchgear, and establishing robust maintenance protocols.

Layer of Protection Analysis (LOPA) offers another valuable methodology, particularly for complex MV installations. LOPA evaluates the effectiveness of independent protection layers, calculating the probability of failure on demand for each safety barrier. This approach helps determine whether sufficient safeguards exist to mitigate arc flash risks to acceptable levels, often revealing gaps in protection strategies that might be overlooked by less systematic methods.

Dynamic risk assessment methodologies are increasingly important for MV enclosures, recognizing that risk factors change throughout equipment lifecycle. These approaches incorporate real-time monitoring data, maintenance history, and environmental conditions to continuously update risk profiles. Advanced systems now employ machine learning algorithms to predict potential failure conditions before they manifest as dangerous arc flash events.

Quantitative risk assessment techniques such as Failure Mode and Effects Analysis (FMEA) and Fault Tree Analysis (FTA) are particularly valuable for MV enclosure safety evaluations. FMEA systematically identifies potential failure modes in MV components and assesses their consequences, while FTA employs Boolean logic to analyze complex system failures that could lead to arc flash incidents. These methodologies enable engineers to prioritize risk mitigation efforts based on calculated risk priority numbers.

IEEE 1584 provides specialized methodologies for arc flash hazard calculations, offering empirical formulas to determine incident energy levels and appropriate safety boundaries. This standard incorporates variables such as working distance, available fault current, and clearing time to quantify potential arc flash energy. Complementing this, NFPA 70E outlines risk assessment procedures specifically for electrical work, introducing the concept of likelihood and severity matrices for hazard evaluation.

The Hierarchy of Controls methodology, endorsed by safety standards worldwide, establishes a prioritized approach to risk mitigation in MV environments. This framework prioritizes elimination of hazards, followed by substitution, engineering controls, administrative controls, and personal protective equipment as a last line of defense. For MV enclosures, this often translates to implementing remote operation capabilities, installing arc-resistant switchgear, and establishing robust maintenance protocols.

Layer of Protection Analysis (LOPA) offers another valuable methodology, particularly for complex MV installations. LOPA evaluates the effectiveness of independent protection layers, calculating the probability of failure on demand for each safety barrier. This approach helps determine whether sufficient safeguards exist to mitigate arc flash risks to acceptable levels, often revealing gaps in protection strategies that might be overlooked by less systematic methods.

Dynamic risk assessment methodologies are increasingly important for MV enclosures, recognizing that risk factors change throughout equipment lifecycle. These approaches incorporate real-time monitoring data, maintenance history, and environmental conditions to continuously update risk profiles. Advanced systems now employ machine learning algorithms to predict potential failure conditions before they manifest as dangerous arc flash events.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!