SST in Fast Charging Hubs: Architectures, Fault Management and Safety

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SST Technology Evolution and Fast Charging Objectives

Solid-State Transformer (SST) technology has evolved significantly over the past two decades, transitioning from theoretical concepts to practical implementations. Initially developed as a solution to address the limitations of conventional transformers, SSTs have emerged as a critical component in modern power distribution systems. The evolution began with basic power electronic building blocks in the early 2000s, progressing through various topologies including cascaded H-bridge converters, dual active bridge configurations, and modular multilevel converters.

The integration of wide bandgap semiconductors, particularly silicon carbide (SiC) and gallium nitride (GaN), marked a pivotal advancement in SST technology around 2010. These materials enabled higher switching frequencies, reduced losses, and more compact designs compared to traditional silicon-based components. By 2015, the focus shifted toward improving control algorithms and system integration, leading to enhanced reliability and efficiency in real-world applications.

Recent developments have concentrated on modular designs that offer scalability and redundancy, critical features for fast charging infrastructure. The modular approach allows for flexible power capacity expansion and improved fault tolerance, addressing key requirements for high-power charging hubs. Additionally, advancements in thermal management systems have enabled SSTs to operate reliably under high-power conditions, essential for fast charging applications.

In the context of fast charging hubs, the primary objectives for SST implementation include achieving ultra-high power density to minimize spatial footprint in urban environments. Current targets aim for power densities exceeding 4 kW/L, representing a fourfold improvement over conventional transformer-based solutions. This compact design facilitates installation in space-constrained locations such as urban parking structures and roadside service areas.

Another critical objective is to enable bidirectional power flow capabilities, supporting vehicle-to-grid (V2G) functionality. This feature allows electric vehicles to serve as distributed energy resources, providing grid services during peak demand periods and enhancing overall grid stability. The bidirectional capability also supports integration with renewable energy sources, enabling charging hubs to function as energy management nodes within smart grid ecosystems.

Efficiency optimization remains a paramount goal, with current SST designs targeting conversion efficiencies above 98% across varying load conditions. This high efficiency is essential for reducing operational costs and minimizing thermal management requirements in fast charging applications. Additionally, SST technology aims to provide galvanic isolation while maintaining dynamic response characteristics necessary for rapid power delivery adjustments in multi-vehicle charging scenarios.

Future technological objectives include enhanced fault management capabilities through predictive diagnostics and self-healing functionalities, further improving system reliability and reducing maintenance requirements in fast charging infrastructure deployments.

The integration of wide bandgap semiconductors, particularly silicon carbide (SiC) and gallium nitride (GaN), marked a pivotal advancement in SST technology around 2010. These materials enabled higher switching frequencies, reduced losses, and more compact designs compared to traditional silicon-based components. By 2015, the focus shifted toward improving control algorithms and system integration, leading to enhanced reliability and efficiency in real-world applications.

Recent developments have concentrated on modular designs that offer scalability and redundancy, critical features for fast charging infrastructure. The modular approach allows for flexible power capacity expansion and improved fault tolerance, addressing key requirements for high-power charging hubs. Additionally, advancements in thermal management systems have enabled SSTs to operate reliably under high-power conditions, essential for fast charging applications.

In the context of fast charging hubs, the primary objectives for SST implementation include achieving ultra-high power density to minimize spatial footprint in urban environments. Current targets aim for power densities exceeding 4 kW/L, representing a fourfold improvement over conventional transformer-based solutions. This compact design facilitates installation in space-constrained locations such as urban parking structures and roadside service areas.

Another critical objective is to enable bidirectional power flow capabilities, supporting vehicle-to-grid (V2G) functionality. This feature allows electric vehicles to serve as distributed energy resources, providing grid services during peak demand periods and enhancing overall grid stability. The bidirectional capability also supports integration with renewable energy sources, enabling charging hubs to function as energy management nodes within smart grid ecosystems.

Efficiency optimization remains a paramount goal, with current SST designs targeting conversion efficiencies above 98% across varying load conditions. This high efficiency is essential for reducing operational costs and minimizing thermal management requirements in fast charging applications. Additionally, SST technology aims to provide galvanic isolation while maintaining dynamic response characteristics necessary for rapid power delivery adjustments in multi-vehicle charging scenarios.

Future technological objectives include enhanced fault management capabilities through predictive diagnostics and self-healing functionalities, further improving system reliability and reducing maintenance requirements in fast charging infrastructure deployments.

Market Analysis for Fast Charging Infrastructure

The global electric vehicle (EV) charging infrastructure market is experiencing unprecedented growth, driven by increasing EV adoption rates worldwide. As of 2023, the fast charging infrastructure market was valued at approximately $12.3 billion, with projections indicating a compound annual growth rate (CAGR) of 26.8% through 2030. This remarkable expansion is primarily fueled by government initiatives promoting clean energy transportation, automotive manufacturers' commitments to electrification, and growing consumer acceptance of EVs as viable alternatives to internal combustion engine vehicles.

Regional analysis reveals significant disparities in market development. China leads with the largest installed base of fast charging stations, accounting for over 55% of global deployment, followed by Europe and North America. European markets, particularly Norway, the Netherlands, and Germany, demonstrate the highest penetration rates relative to population density. The United States market, while currently trailing, is poised for accelerated growth following substantial federal infrastructure investments.

Consumer behavior studies indicate that charging infrastructure availability directly correlates with EV adoption rates. Research shows that "range anxiety" remains a primary barrier to EV purchases, with 78% of potential buyers citing concerns about charging accessibility. Fast charging hubs, which can reduce charging times to 15-30 minutes, are proving critical in addressing these concerns and accelerating market acceptance.

The competitive landscape features diverse stakeholders including utility companies, dedicated charging network operators, automotive manufacturers, and technology providers. Major players include Tesla, ChargePoint, EVgo, Electrify America, ABB, and IONITY, with market consolidation increasing through strategic partnerships and acquisitions. Tesla's proprietary network remains dominant in North America, while open standards-based networks prevail in Europe and Asia.

Revenue models in the fast charging sector continue to evolve, with current approaches including direct charging fees, subscription services, advertising, retail partnerships, and grid services. The most successful operators are implementing hybrid models that diversify revenue streams while optimizing asset utilization rates, which typically range from 15-30% but can reach 60-70% in high-traffic urban locations.

Technological advancements in solid-state transformer (SST) technology are poised to revolutionize fast charging infrastructure by enabling higher power delivery, improved grid integration, and enhanced safety features. Market forecasts suggest that SST-enabled charging stations could capture 35% market share by 2028, offering competitive advantages through reduced footprint, lower operational costs, and superior fault management capabilities.

Regional analysis reveals significant disparities in market development. China leads with the largest installed base of fast charging stations, accounting for over 55% of global deployment, followed by Europe and North America. European markets, particularly Norway, the Netherlands, and Germany, demonstrate the highest penetration rates relative to population density. The United States market, while currently trailing, is poised for accelerated growth following substantial federal infrastructure investments.

Consumer behavior studies indicate that charging infrastructure availability directly correlates with EV adoption rates. Research shows that "range anxiety" remains a primary barrier to EV purchases, with 78% of potential buyers citing concerns about charging accessibility. Fast charging hubs, which can reduce charging times to 15-30 minutes, are proving critical in addressing these concerns and accelerating market acceptance.

The competitive landscape features diverse stakeholders including utility companies, dedicated charging network operators, automotive manufacturers, and technology providers. Major players include Tesla, ChargePoint, EVgo, Electrify America, ABB, and IONITY, with market consolidation increasing through strategic partnerships and acquisitions. Tesla's proprietary network remains dominant in North America, while open standards-based networks prevail in Europe and Asia.

Revenue models in the fast charging sector continue to evolve, with current approaches including direct charging fees, subscription services, advertising, retail partnerships, and grid services. The most successful operators are implementing hybrid models that diversify revenue streams while optimizing asset utilization rates, which typically range from 15-30% but can reach 60-70% in high-traffic urban locations.

Technological advancements in solid-state transformer (SST) technology are poised to revolutionize fast charging infrastructure by enabling higher power delivery, improved grid integration, and enhanced safety features. Market forecasts suggest that SST-enabled charging stations could capture 35% market share by 2028, offering competitive advantages through reduced footprint, lower operational costs, and superior fault management capabilities.

SST Implementation Challenges in Charging Hubs

The implementation of Solid-State Transformers (SSTs) in fast charging hubs presents several significant challenges that must be addressed for successful deployment. One primary obstacle is the high cost associated with SST technology compared to conventional transformers. The semiconductor devices, advanced control systems, and specialized magnetic materials required for SSTs contribute to capital expenditures that can be 2-3 times higher than traditional solutions, creating a substantial barrier to widespread adoption.

Thermal management represents another critical challenge in SST implementation. The high-frequency operation of power electronic converters generates considerable heat that must be efficiently dissipated to prevent component degradation and ensure reliable operation. This is particularly problematic in charging hub environments where multiple SSTs may operate simultaneously in confined spaces, creating thermal hotspots that can compromise system integrity.

Reliability concerns also pose significant implementation hurdles. The increased component count in SSTs—particularly semiconductor switches and capacitors—introduces more potential failure points compared to conventional transformers. In charging hub applications where continuous operation is essential, these reliability issues can lead to decreased system availability and increased maintenance requirements, affecting the overall quality of service.

Control complexity presents another substantial challenge. SSTs require sophisticated control algorithms to manage bidirectional power flow, maintain voltage stability, and respond to grid disturbances. Implementing these control systems demands specialized expertise and advanced computational resources, which may not be readily available in all deployment scenarios.

Grid integration issues further complicate SST implementation in charging hubs. The high-frequency switching operations of SSTs can introduce harmonics and electromagnetic interference into the grid, potentially affecting nearby equipment and violating grid codes. Ensuring compliance with relevant standards while maintaining optimal performance requires careful design considerations and potentially additional filtering components.

Standardization gaps represent a significant barrier to widespread SST adoption. Unlike conventional transformers with well-established standards, SST technology lacks comprehensive standardization for design, testing, and operation. This absence of standards creates uncertainty for manufacturers and system integrators, hindering interoperability and complicating maintenance procedures in charging hub deployments.

Finally, the limited field experience with SST technology in charging applications creates implementation challenges related to operational knowledge and best practices. Without extensive real-world deployment data, predicting long-term performance, maintenance requirements, and failure modes remains difficult, increasing the perceived risk for early adopters of this technology in critical charging infrastructure.

Thermal management represents another critical challenge in SST implementation. The high-frequency operation of power electronic converters generates considerable heat that must be efficiently dissipated to prevent component degradation and ensure reliable operation. This is particularly problematic in charging hub environments where multiple SSTs may operate simultaneously in confined spaces, creating thermal hotspots that can compromise system integrity.

Reliability concerns also pose significant implementation hurdles. The increased component count in SSTs—particularly semiconductor switches and capacitors—introduces more potential failure points compared to conventional transformers. In charging hub applications where continuous operation is essential, these reliability issues can lead to decreased system availability and increased maintenance requirements, affecting the overall quality of service.

Control complexity presents another substantial challenge. SSTs require sophisticated control algorithms to manage bidirectional power flow, maintain voltage stability, and respond to grid disturbances. Implementing these control systems demands specialized expertise and advanced computational resources, which may not be readily available in all deployment scenarios.

Grid integration issues further complicate SST implementation in charging hubs. The high-frequency switching operations of SSTs can introduce harmonics and electromagnetic interference into the grid, potentially affecting nearby equipment and violating grid codes. Ensuring compliance with relevant standards while maintaining optimal performance requires careful design considerations and potentially additional filtering components.

Standardization gaps represent a significant barrier to widespread SST adoption. Unlike conventional transformers with well-established standards, SST technology lacks comprehensive standardization for design, testing, and operation. This absence of standards creates uncertainty for manufacturers and system integrators, hindering interoperability and complicating maintenance procedures in charging hub deployments.

Finally, the limited field experience with SST technology in charging applications creates implementation challenges related to operational knowledge and best practices. Without extensive real-world deployment data, predicting long-term performance, maintenance requirements, and failure modes remains difficult, increasing the perceived risk for early adopters of this technology in critical charging infrastructure.

Current SST Architectures for Fast Charging

01 SST Architecture and Topology Designs

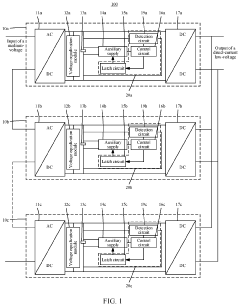

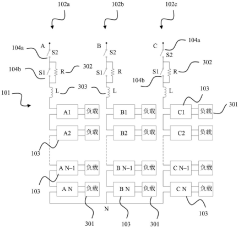

Solid State Transformers (SSTs) can be designed with various architectures and topologies to optimize power conversion efficiency and system performance. These designs include modular multilevel converters, dual active bridge configurations, and cascaded H-bridge structures. The architecture selection impacts power density, efficiency, and reliability of the SST system. Advanced topologies incorporate semiconductor devices like SiC and GaN to achieve higher switching frequencies and reduced losses.- SST Architectures and Topologies: Solid State Transformers (SSTs) can be designed with various architectures and topologies to optimize power conversion efficiency and system performance. These architectures include single-stage, two-stage, and three-stage configurations with different power electronic converters such as AC-DC, DC-DC, and DC-AC stages. Advanced topologies may incorporate modular multilevel converters (MMC), dual active bridge (DAB) converters, or matrix converters to achieve high-frequency isolation, bidirectional power flow, and voltage regulation capabilities.

- Fault Detection and Management Systems: Fault management in SSTs involves sophisticated detection, isolation, and mitigation strategies to ensure system reliability. These systems employ sensors and algorithms to monitor critical parameters such as voltage, current, temperature, and switching states. When abnormalities are detected, the control system can implement protective measures including fault current limiting, bypass operations, or controlled shutdown sequences to prevent cascading failures and protect connected equipment.

- Safety and Protection Mechanisms: Safety features in SST designs include multiple layers of protection mechanisms to address thermal, electrical, and electromagnetic hazards. These mechanisms incorporate galvanic isolation, overvoltage protection, overcurrent protection, and thermal management systems. Advanced safety designs may include redundant control circuits, fail-safe modes, and self-diagnostic capabilities that continuously monitor the health of critical components to prevent catastrophic failures and ensure personnel safety.

- Grid Integration and Stability Control: SSTs play a crucial role in modern grid integration by providing advanced control capabilities for power flow management and grid stability. These transformers can implement reactive power compensation, harmonic filtering, and voltage regulation functions to improve power quality. Additionally, they can facilitate the integration of renewable energy sources and energy storage systems by managing bidirectional power flow and providing voltage/frequency support during grid disturbances.

- Thermal Management and Reliability Enhancement: Effective thermal management is critical for SST reliability and longevity. Advanced cooling techniques including forced air, liquid cooling, phase change materials, and heat pipe technologies are employed to dissipate heat from power electronic components. Reliability enhancement strategies incorporate component derating, redundant designs, and advanced materials with higher temperature capabilities. Condition monitoring systems track thermal performance over time to predict potential failures and schedule preventive maintenance.

02 Fault Detection and Management Systems

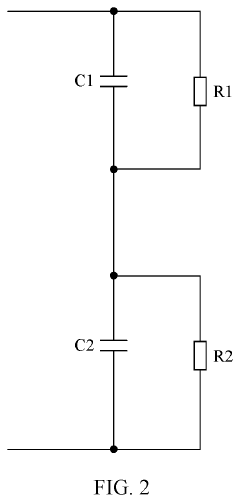

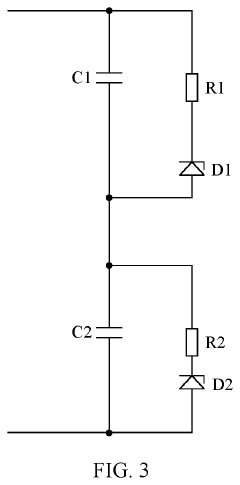

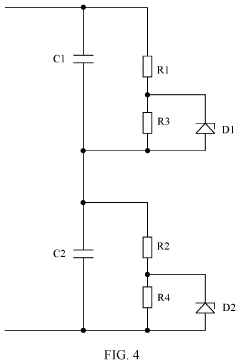

Fault management systems for SSTs incorporate real-time monitoring and detection mechanisms to identify abnormal operating conditions. These systems utilize sensors and algorithms to detect various fault types including short circuits, open circuits, and thermal issues. Advanced fault management approaches implement predictive diagnostics to anticipate potential failures before they occur, enabling preventive maintenance. The systems also include isolation mechanisms to contain faults and prevent cascading failures throughout the power distribution network.Expand Specific Solutions03 Safety Protection Mechanisms

Safety protection mechanisms in SSTs are designed to ensure operational safety under various conditions. These include overvoltage protection, overcurrent protection, and thermal management systems. Isolation barriers between high and low voltage sides prevent hazardous voltage transfer. Emergency shutdown systems can rapidly disconnect the SST from the grid during critical failures. Advanced safety features incorporate redundant protection layers and fail-safe designs to maintain system integrity even when components fail.Expand Specific Solutions04 Control Strategies and Algorithms

Control strategies for SSTs implement sophisticated algorithms to manage power flow, voltage regulation, and system stability. These include model predictive control, sliding mode control, and adaptive control techniques that respond to changing grid conditions. Digital control platforms enable real-time monitoring and adjustment of operating parameters. Advanced control algorithms provide grid support functions such as reactive power compensation, harmonic mitigation, and voltage sag compensation, enhancing grid stability and power quality.Expand Specific Solutions05 Grid Integration and Communication Interfaces

SSTs incorporate communication interfaces and grid integration features to enable smart grid functionality. These systems support bidirectional communication with grid operators and other power system components. Standardized protocols facilitate interoperability with existing grid infrastructure and management systems. Advanced SSTs include grid-supporting features such as frequency regulation, voltage support, and islanding detection. The communication interfaces enable remote monitoring, control, and firmware updates to adapt to evolving grid requirements.Expand Specific Solutions

Leading Manufacturers and Industry Ecosystem

The fast charging hub market is experiencing rapid growth, driven by increasing EV adoption worldwide. Currently in an early expansion phase, the market is projected to grow significantly as charging infrastructure becomes critical for widespread EV acceptance. Technology maturity varies across key players, with established industrial giants like ABB Group, Schneider Electric, and Robert Bosch leading with comprehensive fault management systems. Emerging specialists like ChargePoint and Huawei Digital Power are advancing SST (Solid State Transformer) architectures for improved efficiency. State Grid entities in China are developing integrated safety protocols, while research institutions like Southeast University and Battelle Memorial Institute focus on next-generation safety technologies. The competitive landscape shows a blend of traditional power companies and technology-focused entrants competing to establish standards in this evolving sector.

ABB Group

Technical Solution: ABB has developed advanced Solid-State Transformer (SST) technology for fast charging hubs that integrates medium voltage power electronics with high-frequency transformers. Their architecture employs a modular multi-level converter (MMC) topology with silicon carbide (SiC) power semiconductors, enabling direct conversion from medium voltage AC to low voltage DC without conventional bulky transformers. ABB's system incorporates intelligent fault management through real-time monitoring with distributed sensors that detect thermal anomalies, voltage fluctuations, and current imbalances. Their predictive maintenance algorithms can identify potential failures before they occur, with response times under 100 microseconds for critical faults. Safety features include galvanic isolation between grid and vehicle side, redundant protection layers, and compliance with IEC 61851 and ISO 15118 standards for EV charging safety.

Strengths: Superior power density (40% smaller footprint than conventional solutions), higher efficiency (97%+ at full load), and faster dynamic response for grid stabilization. Weaknesses: Higher initial capital costs compared to traditional transformer systems and requires specialized maintenance personnel with power electronics expertise.

Huawei Digital Power Technologies Co Ltd

Technical Solution: Huawei Digital Power has pioneered an integrated SST architecture for fast charging hubs that combines medium-frequency isolation with bidirectional power flow capabilities. Their solution utilizes a three-stage conversion process: AC-DC rectification, DC-DC conversion via medium-frequency transformers, and DC output regulation. The system incorporates SiC MOSFETs operating at switching frequencies of 20-50 kHz, significantly reducing transformer size while maintaining 96.5% efficiency. Huawei's fault management system employs a hierarchical approach with three protection levels: device-level protection through gate drivers with desaturation detection, module-level protection via current/voltage/temperature monitoring, and system-level protection through a central controller. Their FusionCharge solution integrates these technologies with cloud-based monitoring that enables remote diagnostics and over-the-air updates to address emerging fault patterns. Safety features include reinforced insulation design, active thermal management with liquid cooling, and compliance with GB/T 20234 and IEC standards.

Strengths: Exceptional scalability allowing flexible power configurations from 60kW to 600kW, advanced thermal management enabling operation in extreme environments (-40°C to +55°C), and seamless integration with renewable energy sources. Weaknesses: Proprietary communication protocols may limit interoperability with third-party systems, and the complex power electronics require sophisticated cooling solutions that increase maintenance requirements.

Critical Patents in SST Fault Management

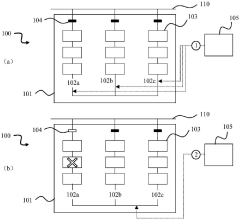

Fault handling system of solid-state transformer

PatentActiveUS11888309B2

Innovation

- A fault handling system is implemented, where cascaded power units with detection and control modules communicate to close auxiliary supplies when voltage thresholds are exceeded, reducing busbar capacitor voltage in faulty units and preventing fault propagation.

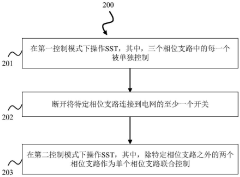

Fault tolerant control of solid state transformers

PatentPendingCN117616679A

Innovation

- Using a three-phase parallel SST structure, each phase branch is independently controlled. In case of a fault, the fault branch is disconnected and switched to the fault-tolerant control mode. The reference voltage of the phase branch unit is adjusted through discontinuous pulse width modulation (DPWM) voltage to maintain voltage balancing and reduced switching losses.

Thermal Management Strategies in SST Charging Hubs

Thermal management represents a critical aspect of Solid-State Transformer (SST) implementation in fast charging hubs. As power density increases in these compact installations, heat dissipation becomes a paramount concern affecting both performance and longevity of the system components.

Conventional cooling methods employed in traditional transformers prove insufficient for SST applications due to their higher power density and semiconductor-based architecture. Liquid cooling systems have emerged as a preferred solution, offering superior thermal conductivity compared to air-based approaches. These systems typically utilize a combination of cold plates directly attached to power electronic modules and a closed-loop circulation system with heat exchangers.

Advanced thermal modeling techniques have become essential tools for SST thermal management design. Computational Fluid Dynamics (CFD) simulations allow engineers to predict hotspots and optimize cooling channel designs before physical prototyping. These models incorporate detailed semiconductor loss models and can account for transient thermal behaviors during variable charging loads.

Temperature monitoring systems form an integral part of thermal management strategies, with distributed sensor networks providing real-time temperature data across critical components. Modern implementations utilize fiber optic temperature sensors that remain immune to electromagnetic interference prevalent in high-power environments. This data feeds into thermal management control algorithms that can dynamically adjust cooling system parameters.

Thermal interface materials (TIMs) play a crucial role in heat transfer efficiency between semiconductor devices and cooling systems. Recent developments in nano-enhanced thermal greases and phase-change materials have significantly reduced thermal resistance at these critical junctions, allowing for more efficient heat extraction from power electronic components.

Modular thermal management approaches have gained traction in larger charging hub installations. These designs segment the cooling system to match the modular nature of SST architectures, enabling more targeted cooling for high-heat components while improving maintenance accessibility and system redundancy.

Passive cooling elements continue to complement active systems, with advanced heat sink designs incorporating phase-change materials and thermosiphon principles to provide thermal buffering during peak load conditions. These hybrid approaches help reduce energy consumption of the cooling system while maintaining safe operating temperatures.

Conventional cooling methods employed in traditional transformers prove insufficient for SST applications due to their higher power density and semiconductor-based architecture. Liquid cooling systems have emerged as a preferred solution, offering superior thermal conductivity compared to air-based approaches. These systems typically utilize a combination of cold plates directly attached to power electronic modules and a closed-loop circulation system with heat exchangers.

Advanced thermal modeling techniques have become essential tools for SST thermal management design. Computational Fluid Dynamics (CFD) simulations allow engineers to predict hotspots and optimize cooling channel designs before physical prototyping. These models incorporate detailed semiconductor loss models and can account for transient thermal behaviors during variable charging loads.

Temperature monitoring systems form an integral part of thermal management strategies, with distributed sensor networks providing real-time temperature data across critical components. Modern implementations utilize fiber optic temperature sensors that remain immune to electromagnetic interference prevalent in high-power environments. This data feeds into thermal management control algorithms that can dynamically adjust cooling system parameters.

Thermal interface materials (TIMs) play a crucial role in heat transfer efficiency between semiconductor devices and cooling systems. Recent developments in nano-enhanced thermal greases and phase-change materials have significantly reduced thermal resistance at these critical junctions, allowing for more efficient heat extraction from power electronic components.

Modular thermal management approaches have gained traction in larger charging hub installations. These designs segment the cooling system to match the modular nature of SST architectures, enabling more targeted cooling for high-heat components while improving maintenance accessibility and system redundancy.

Passive cooling elements continue to complement active systems, with advanced heat sink designs incorporating phase-change materials and thermosiphon principles to provide thermal buffering during peak load conditions. These hybrid approaches help reduce energy consumption of the cooling system while maintaining safe operating temperatures.

Standardization Efforts for SST Charging Protocols

The standardization landscape for Solid-State Transformer (SST) charging protocols is rapidly evolving to address the growing demands of fast charging infrastructure. Several international organizations are actively developing frameworks to ensure interoperability, safety, and efficiency across different charging systems.

The IEEE Power Electronics Society has established the IEEE P2030.12 working group specifically focused on SST standards for power conversion applications, including EV charging. This initiative aims to create unified specifications for SST interfaces, control protocols, and communication requirements between charging stations and vehicles.

IEC Technical Committee 69 has expanded its scope to incorporate SST technology within its IEC 61851 series, which governs electric vehicle conductive charging systems. The committee is developing new provisions that address the unique characteristics of SST-based charging, including higher power densities and enhanced isolation requirements.

The CharIN association, responsible for the Combined Charging System (CCS), has formed a dedicated task force to integrate SST capabilities into their roadmap. Their efforts focus on extending existing protocols to support the higher power levels and advanced grid services that SST technology enables, while maintaining backward compatibility with conventional charging infrastructure.

On the regional level, China's National Technical Committee of Auto Standardization (NTCAS) has published draft standards for SST implementation in ultra-fast charging stations, emphasizing grid integration and power quality management. Similarly, the European Committee for Electrotechnical Standardization (CENELEC) is developing standards that align SST charging protocols with European grid codes and safety regulations.

Standardization efforts are particularly concentrated on four critical areas: communication protocols between SST modules and energy management systems; fault detection and isolation procedures specific to multi-stage power conversion; harmonization of grid-support functions; and safety certification requirements for high-frequency operation.

Industry consortia are also contributing significantly to these standardization efforts. The Open Charge Alliance is extending the Open Charge Point Protocol (OCPP) to incorporate SST-specific commands and monitoring capabilities, while the EPRI and NEMA collaboration is developing testing procedures to verify compliance with emerging SST standards.

These standardization initiatives are essential for market adoption, as they reduce investment risks, ensure safety compliance, and facilitate the integration of SST technology into existing charging infrastructure. The convergence toward unified protocols will be crucial for the widespread deployment of SST-based fast charging hubs in the coming years.

The IEEE Power Electronics Society has established the IEEE P2030.12 working group specifically focused on SST standards for power conversion applications, including EV charging. This initiative aims to create unified specifications for SST interfaces, control protocols, and communication requirements between charging stations and vehicles.

IEC Technical Committee 69 has expanded its scope to incorporate SST technology within its IEC 61851 series, which governs electric vehicle conductive charging systems. The committee is developing new provisions that address the unique characteristics of SST-based charging, including higher power densities and enhanced isolation requirements.

The CharIN association, responsible for the Combined Charging System (CCS), has formed a dedicated task force to integrate SST capabilities into their roadmap. Their efforts focus on extending existing protocols to support the higher power levels and advanced grid services that SST technology enables, while maintaining backward compatibility with conventional charging infrastructure.

On the regional level, China's National Technical Committee of Auto Standardization (NTCAS) has published draft standards for SST implementation in ultra-fast charging stations, emphasizing grid integration and power quality management. Similarly, the European Committee for Electrotechnical Standardization (CENELEC) is developing standards that align SST charging protocols with European grid codes and safety regulations.

Standardization efforts are particularly concentrated on four critical areas: communication protocols between SST modules and energy management systems; fault detection and isolation procedures specific to multi-stage power conversion; harmonization of grid-support functions; and safety certification requirements for high-frequency operation.

Industry consortia are also contributing significantly to these standardization efforts. The Open Charge Alliance is extending the Open Charge Point Protocol (OCPP) to incorporate SST-specific commands and monitoring capabilities, while the EPRI and NEMA collaboration is developing testing procedures to verify compliance with emerging SST standards.

These standardization initiatives are essential for market adoption, as they reduce investment risks, ensure safety compliance, and facilitate the integration of SST technology into existing charging infrastructure. The convergence toward unified protocols will be crucial for the widespread deployment of SST-based fast charging hubs in the coming years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!