How to Cool MV Power Modules in SSTs — Cold Plates, Immersion and Reliability

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MV Power Module Cooling Evolution and Objectives

Medium Voltage (MV) power module cooling technology has evolved significantly over the past decades, driven by the increasing power density requirements in Solid State Transformers (SSTs). The journey began with simple air cooling methods in the 1980s, which proved inadequate as power modules became more compact and generated higher heat loads. This limitation led to the development of basic liquid cooling techniques in the 1990s, utilizing water or glycol mixtures circulating through simple cold plates.

The early 2000s marked a significant advancement with the introduction of more sophisticated cold plate designs featuring micro-channels and optimized flow patterns, substantially improving thermal performance. By the 2010s, direct liquid cooling technologies emerged, where coolant directly contacted the semiconductor die or substrate, eliminating thermal interface materials and reducing thermal resistance.

Most recently, two-phase cooling systems utilizing the phase change of the coolant and immersion cooling technologies have gained prominence, offering unprecedented cooling capabilities for high-power density applications. This evolution reflects the industry's response to the thermal management challenges posed by increasingly powerful and compact MV power modules in SST applications.

The primary objective of MV power module cooling in SSTs is to maintain semiconductor junction temperatures below critical thresholds while ensuring long-term reliability. Current silicon-based devices typically require operating temperatures below 150°C, while wide bandgap semiconductors like SiC and GaN can operate at higher temperatures but still require effective cooling to maximize efficiency and lifespan.

Additional objectives include minimizing thermal gradients across power modules to prevent mechanical stress from thermal expansion, reducing thermal cycling effects that can lead to solder fatigue and wire bond failures, and ensuring rapid response to transient thermal loads during switching events. The cooling system must also be compact to maintain the size advantage of SSTs over traditional transformers.

Looking forward, the industry aims to develop cooling solutions that can handle power densities exceeding 500 W/cm² while maintaining reliability standards. There is also a push toward environmentally friendly coolants with low global warming potential and systems that can operate efficiently across varying ambient conditions. Integration of advanced thermal monitoring and predictive maintenance capabilities represents another frontier, enabling real-time optimization of cooling performance and early detection of potential thermal issues.

The early 2000s marked a significant advancement with the introduction of more sophisticated cold plate designs featuring micro-channels and optimized flow patterns, substantially improving thermal performance. By the 2010s, direct liquid cooling technologies emerged, where coolant directly contacted the semiconductor die or substrate, eliminating thermal interface materials and reducing thermal resistance.

Most recently, two-phase cooling systems utilizing the phase change of the coolant and immersion cooling technologies have gained prominence, offering unprecedented cooling capabilities for high-power density applications. This evolution reflects the industry's response to the thermal management challenges posed by increasingly powerful and compact MV power modules in SST applications.

The primary objective of MV power module cooling in SSTs is to maintain semiconductor junction temperatures below critical thresholds while ensuring long-term reliability. Current silicon-based devices typically require operating temperatures below 150°C, while wide bandgap semiconductors like SiC and GaN can operate at higher temperatures but still require effective cooling to maximize efficiency and lifespan.

Additional objectives include minimizing thermal gradients across power modules to prevent mechanical stress from thermal expansion, reducing thermal cycling effects that can lead to solder fatigue and wire bond failures, and ensuring rapid response to transient thermal loads during switching events. The cooling system must also be compact to maintain the size advantage of SSTs over traditional transformers.

Looking forward, the industry aims to develop cooling solutions that can handle power densities exceeding 500 W/cm² while maintaining reliability standards. There is also a push toward environmentally friendly coolants with low global warming potential and systems that can operate efficiently across varying ambient conditions. Integration of advanced thermal monitoring and predictive maintenance capabilities represents another frontier, enabling real-time optimization of cooling performance and early detection of potential thermal issues.

Market Demand Analysis for SST Cooling Solutions

The global market for Solid-State Transformer (SST) cooling solutions is experiencing robust growth, driven primarily by the increasing adoption of SSTs in renewable energy integration, electric vehicle charging infrastructure, and smart grid applications. As power densities continue to rise in medium voltage (MV) power modules, effective thermal management has become a critical factor influencing market demand.

Current market analysis indicates that the SST cooling solutions market is expected to grow at a compound annual growth rate of over 20% through 2030, with the highest demand coming from regions with aggressive renewable energy targets such as Europe, North America, and parts of Asia. This growth is directly correlated with the expanding renewable energy sector, which requires efficient power conversion technologies like SSTs.

The demand for cooling solutions is segmented based on application requirements. Grid-tied applications, which typically operate continuously, prioritize reliability and efficiency over initial cost considerations. In contrast, industrial applications often balance performance with total cost of ownership, creating distinct market segments with different value propositions for cooling technologies.

Cold plate cooling solutions currently dominate the market due to their established technology base and relatively lower implementation costs. However, immersion cooling solutions are gaining significant traction, particularly in high-power density applications where traditional cooling methods reach their thermal limits. Market research indicates that immersion cooling solutions could capture up to 30% of the SST cooling market by 2028.

End-user preferences are increasingly shifting toward cooling solutions that not only provide effective thermal management but also contribute to overall system reliability and longevity. This trend is particularly evident in critical infrastructure applications where downtime costs are substantial. Consequently, manufacturers are experiencing growing demand for cooling solutions with integrated monitoring capabilities and predictive maintenance features.

Regional market variations are notable, with European customers showing stronger preference for environmentally friendly cooling solutions with minimal environmental impact, while North American markets prioritize scalability and integration with existing systems. Emerging markets in Asia and Africa demonstrate greater price sensitivity but represent the fastest-growing segment for SST cooling solutions.

The market is also being shaped by regulatory factors, with increasingly stringent efficiency standards and safety regulations driving demand for advanced cooling technologies that can help SST systems meet these requirements while maintaining competitive pricing. This regulatory landscape is creating both challenges and opportunities for cooling solution providers in the global marketplace.

Current market analysis indicates that the SST cooling solutions market is expected to grow at a compound annual growth rate of over 20% through 2030, with the highest demand coming from regions with aggressive renewable energy targets such as Europe, North America, and parts of Asia. This growth is directly correlated with the expanding renewable energy sector, which requires efficient power conversion technologies like SSTs.

The demand for cooling solutions is segmented based on application requirements. Grid-tied applications, which typically operate continuously, prioritize reliability and efficiency over initial cost considerations. In contrast, industrial applications often balance performance with total cost of ownership, creating distinct market segments with different value propositions for cooling technologies.

Cold plate cooling solutions currently dominate the market due to their established technology base and relatively lower implementation costs. However, immersion cooling solutions are gaining significant traction, particularly in high-power density applications where traditional cooling methods reach their thermal limits. Market research indicates that immersion cooling solutions could capture up to 30% of the SST cooling market by 2028.

End-user preferences are increasingly shifting toward cooling solutions that not only provide effective thermal management but also contribute to overall system reliability and longevity. This trend is particularly evident in critical infrastructure applications where downtime costs are substantial. Consequently, manufacturers are experiencing growing demand for cooling solutions with integrated monitoring capabilities and predictive maintenance features.

Regional market variations are notable, with European customers showing stronger preference for environmentally friendly cooling solutions with minimal environmental impact, while North American markets prioritize scalability and integration with existing systems. Emerging markets in Asia and Africa demonstrate greater price sensitivity but represent the fastest-growing segment for SST cooling solutions.

The market is also being shaped by regulatory factors, with increasingly stringent efficiency standards and safety regulations driving demand for advanced cooling technologies that can help SST systems meet these requirements while maintaining competitive pricing. This regulatory landscape is creating both challenges and opportunities for cooling solution providers in the global marketplace.

Current Cooling Technologies and Thermal Management Challenges

The thermal management of Medium Voltage (MV) power modules in Solid-State Transformers (SSTs) presents significant engineering challenges due to the high power densities and switching frequencies involved. Current cooling technologies for these applications can be broadly categorized into air cooling, liquid cooling with cold plates, and immersion cooling methods, each with distinct advantages and limitations.

Air cooling, the most traditional approach, utilizes forced convection with fans or blowers to dissipate heat from heat sinks attached to power modules. While simple and cost-effective, this method has become increasingly inadequate for modern MV power modules in SSTs, which can generate heat fluxes exceeding 100 W/cm². The thermal resistance of air cooling systems limits their effectiveness in high-power density applications.

Liquid cooling with cold plates has emerged as the predominant solution for MV power modules. These systems circulate coolants (typically water, water-glycol mixtures, or dielectric fluids) through channels in metal plates that contact the power modules. Advanced cold plate designs incorporate micro-channels, jet impingement, or pin-fin structures to enhance heat transfer coefficients. Current state-of-the-art cold plates can achieve thermal resistances below 0.1 K/W, enabling the cooling of power modules with losses exceeding 1 kW.

Immersion cooling, where power modules are directly submerged in dielectric fluids, represents the cutting edge of cooling technology. Two-phase immersion cooling, utilizing the latent heat of vaporization, can achieve even higher heat transfer rates than single-phase systems. Recent developments in engineered dielectric fluids have addressed historical concerns regarding fluid degradation and compatibility with module materials.

Despite these advancements, significant thermal management challenges persist. Junction temperature control remains critical, as exceeding temperature limits (typically 150-175°C for silicon and 175-200°C for wide-bandgap semiconductors) dramatically reduces reliability. Thermal cycling due to load variations induces thermo-mechanical stress, accelerating failure mechanisms such as solder fatigue and bond wire lift-off.

Thermal interface materials (TIMs) between power modules and cooling systems present another challenge, often becoming the limiting factor in overall thermal performance. Current TIMs exhibit trade-offs between thermal conductivity, electrical isolation requirements, and long-term reliability under thermal cycling conditions.

Additionally, the integration of cooling systems with high-voltage isolation requirements complicates design, as cooling solutions must maintain dielectric strength while providing effective thermal paths. This becomes particularly challenging in compact SST designs where power density requirements are stringent.

Air cooling, the most traditional approach, utilizes forced convection with fans or blowers to dissipate heat from heat sinks attached to power modules. While simple and cost-effective, this method has become increasingly inadequate for modern MV power modules in SSTs, which can generate heat fluxes exceeding 100 W/cm². The thermal resistance of air cooling systems limits their effectiveness in high-power density applications.

Liquid cooling with cold plates has emerged as the predominant solution for MV power modules. These systems circulate coolants (typically water, water-glycol mixtures, or dielectric fluids) through channels in metal plates that contact the power modules. Advanced cold plate designs incorporate micro-channels, jet impingement, or pin-fin structures to enhance heat transfer coefficients. Current state-of-the-art cold plates can achieve thermal resistances below 0.1 K/W, enabling the cooling of power modules with losses exceeding 1 kW.

Immersion cooling, where power modules are directly submerged in dielectric fluids, represents the cutting edge of cooling technology. Two-phase immersion cooling, utilizing the latent heat of vaporization, can achieve even higher heat transfer rates than single-phase systems. Recent developments in engineered dielectric fluids have addressed historical concerns regarding fluid degradation and compatibility with module materials.

Despite these advancements, significant thermal management challenges persist. Junction temperature control remains critical, as exceeding temperature limits (typically 150-175°C for silicon and 175-200°C for wide-bandgap semiconductors) dramatically reduces reliability. Thermal cycling due to load variations induces thermo-mechanical stress, accelerating failure mechanisms such as solder fatigue and bond wire lift-off.

Thermal interface materials (TIMs) between power modules and cooling systems present another challenge, often becoming the limiting factor in overall thermal performance. Current TIMs exhibit trade-offs between thermal conductivity, electrical isolation requirements, and long-term reliability under thermal cycling conditions.

Additionally, the integration of cooling systems with high-voltage isolation requirements complicates design, as cooling solutions must maintain dielectric strength while providing effective thermal paths. This becomes particularly challenging in compact SST designs where power density requirements are stringent.

Cold Plate and Immersion Cooling Implementation Strategies

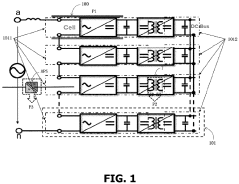

01 Liquid cooling systems for MV power modules in SSTs

Liquid cooling systems are employed to efficiently manage heat in medium voltage power modules used in solid-state transformers. These systems typically use coolants like water or dielectric fluids circulating through channels or plates in direct contact with power semiconductor devices. This approach enables higher power density and improved thermal management compared to traditional air cooling methods, allowing the power modules to operate at optimal temperatures even under high load conditions.- Liquid cooling systems for MV power modules in SSTs: Liquid cooling systems are employed for medium voltage power modules in solid-state transformers to efficiently dissipate heat. These systems use coolants circulating through channels or plates in direct contact with power semiconductor devices. The liquid cooling approach provides superior thermal management compared to air cooling, allowing for higher power densities and improved reliability of the power modules in SST applications.

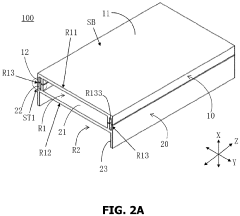

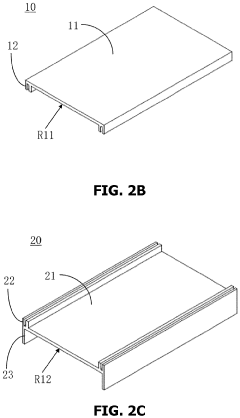

- Modular design approaches for SST power modules: Modular design approaches for solid-state transformer power modules facilitate easier maintenance, replacement, and scalability. These designs feature standardized power module units that can be assembled in various configurations to meet different voltage and power requirements. The modular architecture improves manufacturing efficiency, reduces costs, and enhances the overall reliability of the SST system by allowing for redundancy and hot-swapping capabilities.

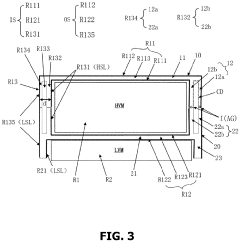

- Thermal management integration with enclosure design: Thermal management systems for MV power modules in SSTs are integrated with enclosure designs to optimize cooling efficiency while maintaining electrical isolation and protection. These integrated approaches include strategically placed heat sinks, thermal interface materials, and airflow channels within the module housing. The enclosure design considers both the cooling requirements and the electrical isolation needs of medium voltage applications, ensuring safe and efficient operation.

- Advanced cooling technologies for high power density SSTs: Advanced cooling technologies are implemented in high power density solid-state transformers to manage the increased thermal loads. These include phase-change materials, heat pipes, jet impingement cooling, and micro-channel heat sinks. Such technologies enable more compact SST designs while maintaining safe operating temperatures for the power semiconductor devices, thereby increasing the power density and efficiency of the overall system.

- Control and monitoring systems for thermal management: Control and monitoring systems are employed to optimize the thermal management of MV power modules in SSTs. These systems include temperature sensors, flow meters, and intelligent control algorithms that adjust cooling parameters based on operating conditions. The implementation of these monitoring and control systems ensures optimal cooling performance, prevents thermal runaway, and extends the lifespan of power semiconductor devices by maintaining them within safe operating temperature ranges.

02 Modular design approaches for cooling MV power modules

Modular design approaches for cooling medium voltage power modules in solid-state transformers involve creating standardized cooling units that can be easily integrated, replaced, or scaled. These modular cooling systems often feature plug-and-play capabilities, allowing for flexible configuration based on specific power requirements. The modular approach enhances maintenance accessibility, system reliability, and enables efficient heat dissipation across multiple power modules operating at different load conditions.Expand Specific Solutions03 Integrated thermal management for MV power modules

Integrated thermal management solutions combine multiple cooling technologies within the same system to optimize heat dissipation in medium voltage power modules. These solutions may incorporate heat pipes, phase-change materials, forced convection, and thermal interface materials working together to create comprehensive cooling systems. The integration of various cooling mechanisms allows for more effective temperature control across different components of the power module, enhancing overall system efficiency and reliability.Expand Specific Solutions04 Advanced materials for thermal interfaces in SST power modules

Advanced thermal interface materials are used to improve heat transfer between medium voltage power modules and cooling systems in solid-state transformers. These materials include specialized thermal greases, phase-change materials, graphene-based compounds, and metal matrix composites with enhanced thermal conductivity. By reducing thermal resistance at interfaces, these materials enable more efficient heat dissipation, lower junction temperatures, and improved reliability of power semiconductor devices operating at medium voltage levels.Expand Specific Solutions05 Control systems for adaptive cooling of MV power modules

Adaptive cooling control systems dynamically adjust cooling parameters based on real-time operating conditions of medium voltage power modules in solid-state transformers. These systems utilize temperature sensors, flow meters, and power load monitoring to optimize cooling efficiency. Advanced algorithms can predict thermal behavior and preemptively adjust cooling intensity, while also managing energy consumption of the cooling system itself. This approach ensures optimal thermal management across varying load profiles and ambient conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions in SST Cooling

The cooling of MV power modules in Solid-State Transformers (SSTs) is currently in a transitional growth phase, with the market expanding rapidly due to increasing demand for efficient power conversion solutions. The global market for advanced cooling technologies in power electronics is projected to reach significant scale as industries prioritize energy efficiency and reliability. Technologically, the field is maturing with various cooling approaches competing for dominance. Companies like Infineon Technologies and Hitachi Energy lead in semiconductor power module development, while thermal management specialists such as Iceotope Group focus on innovative liquid cooling solutions. CRRC Yongji and ZF Friedrichshafen are advancing application-specific implementations, particularly in transportation sectors. Meanwhile, research divisions of major corporations like ABB Research and IBM are pushing boundaries in immersion cooling reliability, creating a competitive landscape where technological differentiation is key to market leadership.

Infineon Technologies AG

Technical Solution: Infineon has developed an integrated cooling solution for MV power modules in SST applications combining advanced packaging technology with optimized cold plate designs. Their CoolSiC and CoolMOS power semiconductor modules feature direct copper bonded (DCB) substrates with specially designed thermal interfaces to maximize heat transfer to cooling systems. For SST applications, Infineon implements pin-fin cold plates with turbulent flow patterns that significantly enhance heat transfer coefficients. Their solution incorporates temperature and flow sensors for real-time monitoring and predictive maintenance. Testing has demonstrated thermal resistance values below 0.15 K/W for their high-power modules[5], enabling reliable operation at junction temperatures up to 175°C. Infineon's cooling technology supports power cycling capability exceeding 100,000 cycles, critical for the long-term reliability requirements of SST installations.

Strengths: Comprehensive thermal solution integrating semiconductor packaging and cooling system design; extensive reliability testing and validation; advanced monitoring capabilities for predictive maintenance. Weaknesses: Premium pricing compared to standard cooling solutions; requires specialized system integration knowledge; potential compatibility limitations with third-party components.

Semikron Elektronik GmbH & Co. KG

Technical Solution: Semikron has developed advanced cold plate cooling solutions specifically optimized for MV power modules in SST applications. Their SkiN technology integrates sintered connections between semiconductor chips and direct liquid-cooled baseplates, eliminating thermal interface materials that typically create bottlenecks in heat dissipation. For SST implementations, Semikron's approach features micro-channel cold plates with optimized flow geometries that maximize heat transfer efficiency while minimizing pressure drop. Their power modules incorporate double-sided cooling architecture where coolant removes heat from both sides of semiconductor devices. Testing has shown this approach reduces thermal resistance by up to 40% compared to conventional cooling methods[4]. Semikron's technology enables power densities exceeding 50 kW/L in SST applications while maintaining junction temperatures below critical thresholds.

Strengths: Highly optimized thermal performance through advanced materials and geometries; proven reliability with over 5 million power modules in field operation; compact design enabling high power density. Weaknesses: Requires precise manufacturing tolerances; potential for channel clogging in systems with poor fluid filtration; higher production costs compared to simpler cooling solutions.

Critical Patents and Research in Power Module Thermal Management

Shielded insulating shell and electronic device

PatentPendingEP4312474A1

Innovation

- A shielded insulating shell with a structured assembly including inner and outer shielding layers, insulating layers, and air gap layers forming a creepage path, which reduces electrical field stress and enhances insulation efficiency by increasing the creepage distance and spacing between high and low voltage shielding layers.

A coil and a transformer that have improved electromagnetic shielding

PatentWO2022136634A1

Innovation

- A coil design with varying cross-sections of the conductor around the magnetic core, combining foil conductors with rounded or Litz wire sections to shield magnetic and electric fields, reducing eddy currents and electric field hotspots, and optimizing material usage.

Reliability Testing and Performance Metrics for Cooling Systems

Reliability testing and performance metrics are essential components in evaluating cooling systems for Medium Voltage (MV) power modules in Solid-State Transformers (SSTs). These metrics provide quantifiable data to assess cooling system effectiveness, durability, and long-term performance under various operating conditions.

Standard reliability tests for cooling systems include thermal cycling, which subjects the cooling system to repeated temperature fluctuations to simulate real-world operation. These tests typically range from -40°C to 125°C for automotive-grade applications, with cycle counts ranging from 1,000 to 5,000 depending on the expected service life. Power cycling tests specifically evaluate the cooling system's ability to manage rapid changes in heat load, which is particularly relevant for SST applications where power demands can fluctuate significantly.

Humidity and environmental testing expose cooling systems to controlled humidity levels (typically 85% relative humidity) and temperatures around 85°C for extended periods (1,000+ hours) to assess corrosion resistance and material degradation. For liquid cooling systems, additional tests include pressure cycling, flow rate stability, and chemical compatibility with coolants.

Key performance metrics for cooling systems include thermal resistance (Rth), measured in °C/W, which quantifies how effectively heat transfers from the power module to the cooling medium. Lower values indicate better cooling performance, with state-of-the-art cold plates achieving values below 0.1°C/W. Thermal uniformity across the cooling surface is equally important, as temperature gradients below 5°C are generally desired to prevent thermal stress.

For immersion cooling systems, specific metrics include coolant breakdown rate, measured through dielectric strength testing over time, and heat transfer coefficient (HTC) values, typically ranging from 500-2,000 W/m²K depending on the fluid and flow characteristics. Pumping power efficiency, expressed as cooling capacity per unit of pumping power (W/W), helps evaluate the energy efficiency of the overall cooling solution.

Accelerated life testing protocols have been developed to predict long-term reliability, with the Arrhenius equation commonly used to extrapolate failure rates at normal operating temperatures from data collected at elevated temperatures. Mean Time Between Failures (MTBF) for cooling systems in industrial applications typically targets 50,000+ hours, while Failure In Time (FIT) rates below 100 are considered acceptable for critical power applications.

Industry standards such as IEC 60068 (environmental testing), JEDEC JESD22-A104 (temperature cycling), and MIL-STD-810 provide standardized testing methodologies that ensure consistency in reliability assessment across different cooling technologies and manufacturers. These standardized approaches facilitate meaningful comparisons between cold plate and immersion cooling solutions for MV power modules in SST applications.

Standard reliability tests for cooling systems include thermal cycling, which subjects the cooling system to repeated temperature fluctuations to simulate real-world operation. These tests typically range from -40°C to 125°C for automotive-grade applications, with cycle counts ranging from 1,000 to 5,000 depending on the expected service life. Power cycling tests specifically evaluate the cooling system's ability to manage rapid changes in heat load, which is particularly relevant for SST applications where power demands can fluctuate significantly.

Humidity and environmental testing expose cooling systems to controlled humidity levels (typically 85% relative humidity) and temperatures around 85°C for extended periods (1,000+ hours) to assess corrosion resistance and material degradation. For liquid cooling systems, additional tests include pressure cycling, flow rate stability, and chemical compatibility with coolants.

Key performance metrics for cooling systems include thermal resistance (Rth), measured in °C/W, which quantifies how effectively heat transfers from the power module to the cooling medium. Lower values indicate better cooling performance, with state-of-the-art cold plates achieving values below 0.1°C/W. Thermal uniformity across the cooling surface is equally important, as temperature gradients below 5°C are generally desired to prevent thermal stress.

For immersion cooling systems, specific metrics include coolant breakdown rate, measured through dielectric strength testing over time, and heat transfer coefficient (HTC) values, typically ranging from 500-2,000 W/m²K depending on the fluid and flow characteristics. Pumping power efficiency, expressed as cooling capacity per unit of pumping power (W/W), helps evaluate the energy efficiency of the overall cooling solution.

Accelerated life testing protocols have been developed to predict long-term reliability, with the Arrhenius equation commonly used to extrapolate failure rates at normal operating temperatures from data collected at elevated temperatures. Mean Time Between Failures (MTBF) for cooling systems in industrial applications typically targets 50,000+ hours, while Failure In Time (FIT) rates below 100 are considered acceptable for critical power applications.

Industry standards such as IEC 60068 (environmental testing), JEDEC JESD22-A104 (temperature cycling), and MIL-STD-810 provide standardized testing methodologies that ensure consistency in reliability assessment across different cooling technologies and manufacturers. These standardized approaches facilitate meaningful comparisons between cold plate and immersion cooling solutions for MV power modules in SST applications.

Environmental Impact and Sustainability of Cooling Technologies

The environmental impact of cooling technologies for MV power modules in Solid-State Transformers (SSTs) represents a critical consideration in modern power electronics design. Traditional cooling methods often rely on materials and processes that carry significant environmental footprints, necessitating a comprehensive sustainability assessment of emerging alternatives.

Cold plate cooling systems, while efficient for thermal management, present several environmental challenges. The manufacturing of cold plates typically involves energy-intensive processes and materials with high embodied carbon, such as aluminum and copper. Additionally, many cold plate systems utilize glycol-water mixtures or specialized coolants that may contain environmentally harmful chemicals, posing risks during production, operation, and disposal phases.

Immersion cooling technologies offer potential sustainability advantages through improved energy efficiency and extended component lifespans. By eliminating the need for additional cooling infrastructure like fans and reducing thermal cycling stress, immersion cooling can significantly reduce the overall environmental impact of SST systems. However, the dielectric fluids used in immersion cooling warrant careful consideration, as some synthetic options may present environmental hazards if leaked or improperly disposed of.

The lifecycle assessment of cooling technologies reveals important sustainability metrics. Biodegradable dielectric fluids are emerging as environmentally preferable alternatives to traditional synthetic options, with reduced persistence in ecosystems and lower toxicity profiles. Similarly, closed-loop cooling systems that minimize fluid loss and contamination represent a significant advancement in environmental protection strategies for power electronics cooling.

Energy efficiency remains perhaps the most significant environmental factor in cooling system selection. Advanced cooling technologies that reduce operational energy consumption not only lower direct carbon emissions but also minimize the thermal management overhead in SST installations. This efficiency translates to substantial environmental benefits over the operational lifetime of medium-voltage power modules.

Regulatory frameworks increasingly influence cooling technology selection, with global initiatives restricting the use of certain refrigerants and coolants with high global warming potential. These regulations are driving innovation toward more sustainable cooling solutions, including natural refrigerants and engineered fluids with minimal environmental impact. Manufacturers are responding by developing cooling systems that comply with evolving environmental standards while maintaining thermal performance requirements.

Recycling and end-of-life considerations present another dimension of environmental impact. The recoverability of materials from cold plates versus immersion cooling systems varies significantly, affecting the overall sustainability profile of each approach. Designing cooling systems with component recovery and material recycling in mind represents an emerging best practice in environmentally conscious power electronics development.

Cold plate cooling systems, while efficient for thermal management, present several environmental challenges. The manufacturing of cold plates typically involves energy-intensive processes and materials with high embodied carbon, such as aluminum and copper. Additionally, many cold plate systems utilize glycol-water mixtures or specialized coolants that may contain environmentally harmful chemicals, posing risks during production, operation, and disposal phases.

Immersion cooling technologies offer potential sustainability advantages through improved energy efficiency and extended component lifespans. By eliminating the need for additional cooling infrastructure like fans and reducing thermal cycling stress, immersion cooling can significantly reduce the overall environmental impact of SST systems. However, the dielectric fluids used in immersion cooling warrant careful consideration, as some synthetic options may present environmental hazards if leaked or improperly disposed of.

The lifecycle assessment of cooling technologies reveals important sustainability metrics. Biodegradable dielectric fluids are emerging as environmentally preferable alternatives to traditional synthetic options, with reduced persistence in ecosystems and lower toxicity profiles. Similarly, closed-loop cooling systems that minimize fluid loss and contamination represent a significant advancement in environmental protection strategies for power electronics cooling.

Energy efficiency remains perhaps the most significant environmental factor in cooling system selection. Advanced cooling technologies that reduce operational energy consumption not only lower direct carbon emissions but also minimize the thermal management overhead in SST installations. This efficiency translates to substantial environmental benefits over the operational lifetime of medium-voltage power modules.

Regulatory frameworks increasingly influence cooling technology selection, with global initiatives restricting the use of certain refrigerants and coolants with high global warming potential. These regulations are driving innovation toward more sustainable cooling solutions, including natural refrigerants and engineered fluids with minimal environmental impact. Manufacturers are responding by developing cooling systems that comply with evolving environmental standards while maintaining thermal performance requirements.

Recycling and end-of-life considerations present another dimension of environmental impact. The recoverability of materials from cold plates versus immersion cooling systems varies significantly, affecting the overall sustainability profile of each approach. Designing cooling systems with component recovery and material recycling in mind represents an emerging best practice in environmentally conscious power electronics development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!