How to Validate MV Clearance/Creepage in Compact SSTs — Rules

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SST Clearance/Creepage Validation Background and Objectives

Solid State Transformers (SSTs) represent a revolutionary advancement in power electronics, combining semiconductor technology with traditional transformer principles to create more compact, efficient, and controllable power conversion systems. The evolution of SST technology has been driven by the increasing demands for grid modernization, renewable energy integration, and electric vehicle charging infrastructure, where traditional bulky transformers present significant limitations.

The validation of medium voltage (MV) clearance and creepage distances in compact SSTs presents a unique technical challenge at the intersection of power electronics and electrical insulation engineering. Historically, electrical insulation standards were developed for conventional transformers with well-established geometries and materials. However, the compact nature of SSTs introduces new complexities in ensuring proper electrical isolation while maintaining size advantages.

Recent technological trends show a clear movement toward higher power density in power electronic systems, with SSTs at the forefront of this evolution. The miniaturization of power conversion systems has accelerated over the past decade, with power density improvements of approximately 10-15% annually. This trend necessitates innovative approaches to electrical isolation that maintain safety while enabling further compactness.

The primary technical objective of this research is to establish clear, scientifically-based validation methodologies for MV clearance and creepage distances specifically tailored to the unique geometries and operating conditions of compact SSTs. This includes developing testing protocols that accurately reflect the combined effects of high-frequency operation, elevated temperatures, and complex three-dimensional field distributions characteristic of SST designs.

Secondary objectives include identifying potential modifications to existing standards (such as IEC 60664 and IEEE C57.12.01) that could better accommodate the unique characteristics of SSTs without compromising safety margins. Additionally, we aim to explore novel insulation materials and structures that could enable further miniaturization while maintaining or improving isolation performance.

The validation of clearance and creepage in SSTs must address multiple voltage stress mechanisms simultaneously, including temporary overvoltages, switching transients, and partial discharge phenomena that may behave differently in compact geometries compared to traditional transformers. Understanding these interactions is crucial for developing reliable validation methodologies.

This research also seeks to establish quantifiable relationships between design parameters and isolation performance, enabling more predictable scaling of SST technology across different voltage classes and power ratings. Such relationships would significantly accelerate the development cycle of future SST designs and facilitate their broader adoption across various applications.

The validation of medium voltage (MV) clearance and creepage distances in compact SSTs presents a unique technical challenge at the intersection of power electronics and electrical insulation engineering. Historically, electrical insulation standards were developed for conventional transformers with well-established geometries and materials. However, the compact nature of SSTs introduces new complexities in ensuring proper electrical isolation while maintaining size advantages.

Recent technological trends show a clear movement toward higher power density in power electronic systems, with SSTs at the forefront of this evolution. The miniaturization of power conversion systems has accelerated over the past decade, with power density improvements of approximately 10-15% annually. This trend necessitates innovative approaches to electrical isolation that maintain safety while enabling further compactness.

The primary technical objective of this research is to establish clear, scientifically-based validation methodologies for MV clearance and creepage distances specifically tailored to the unique geometries and operating conditions of compact SSTs. This includes developing testing protocols that accurately reflect the combined effects of high-frequency operation, elevated temperatures, and complex three-dimensional field distributions characteristic of SST designs.

Secondary objectives include identifying potential modifications to existing standards (such as IEC 60664 and IEEE C57.12.01) that could better accommodate the unique characteristics of SSTs without compromising safety margins. Additionally, we aim to explore novel insulation materials and structures that could enable further miniaturization while maintaining or improving isolation performance.

The validation of clearance and creepage in SSTs must address multiple voltage stress mechanisms simultaneously, including temporary overvoltages, switching transients, and partial discharge phenomena that may behave differently in compact geometries compared to traditional transformers. Understanding these interactions is crucial for developing reliable validation methodologies.

This research also seeks to establish quantifiable relationships between design parameters and isolation performance, enabling more predictable scaling of SST technology across different voltage classes and power ratings. Such relationships would significantly accelerate the development cycle of future SST designs and facilitate their broader adoption across various applications.

Market Demand Analysis for Compact Solid State Transformers

The global market for Solid State Transformers (SSTs) is experiencing significant growth, driven by the increasing demand for efficient power conversion solutions in various applications. The compact SST market segment is particularly promising, with an estimated annual growth rate of 20% over the next five years according to recent industry analyses. This growth is primarily fueled by the rapid expansion of renewable energy integration, electric vehicle charging infrastructure, and smart grid implementations.

The utility sector represents the largest market for compact SSTs, as power companies worldwide seek to modernize aging grid infrastructure. These organizations are increasingly recognizing the value of SSTs in enhancing grid resilience, improving power quality, and facilitating bidirectional power flow. The ability of compact SSTs to handle medium voltage (MV) applications while maintaining smaller footprints than traditional transformers makes them particularly attractive for urban substations and distributed energy resource integration.

Industrial applications constitute another significant market segment, where compact SSTs offer advantages in process optimization, power quality improvement, and energy efficiency. Manufacturing facilities with limited space but high power requirements are particularly interested in compact SST solutions that can handle MV clearance requirements while minimizing spatial footprint.

Transportation electrification represents a rapidly expanding market opportunity for compact SSTs. Fast-charging stations for electric vehicles require efficient power conversion from medium voltage distribution lines to the DC voltage needed for rapid charging. The compact nature of these transformers allows for installation in space-constrained urban environments where traditional transformers would be impractical.

Market research indicates that customers across these segments prioritize several key factors when considering compact SST adoption. Safety compliance ranks highest among these considerations, with proper MV clearance and creepage validation being critical requirements. This emphasis on safety validation represents both a market challenge and opportunity, as manufacturers who can demonstrate robust validation methodologies gain competitive advantage.

Cost remains a significant barrier to widespread adoption, with compact SSTs currently commanding premium prices compared to conventional transformers. However, as production scales and technology matures, industry analysts project price reductions of 30-40% within the next decade, potentially accelerating market penetration.

Regional analysis shows North America and Europe leading in compact SST adoption, primarily due to aggressive grid modernization initiatives and renewable energy targets. However, the Asia-Pacific region is expected to witness the fastest growth rate, driven by rapid industrialization, urbanization, and substantial investments in smart grid technologies across China, Japan, and South Korea.

The utility sector represents the largest market for compact SSTs, as power companies worldwide seek to modernize aging grid infrastructure. These organizations are increasingly recognizing the value of SSTs in enhancing grid resilience, improving power quality, and facilitating bidirectional power flow. The ability of compact SSTs to handle medium voltage (MV) applications while maintaining smaller footprints than traditional transformers makes them particularly attractive for urban substations and distributed energy resource integration.

Industrial applications constitute another significant market segment, where compact SSTs offer advantages in process optimization, power quality improvement, and energy efficiency. Manufacturing facilities with limited space but high power requirements are particularly interested in compact SST solutions that can handle MV clearance requirements while minimizing spatial footprint.

Transportation electrification represents a rapidly expanding market opportunity for compact SSTs. Fast-charging stations for electric vehicles require efficient power conversion from medium voltage distribution lines to the DC voltage needed for rapid charging. The compact nature of these transformers allows for installation in space-constrained urban environments where traditional transformers would be impractical.

Market research indicates that customers across these segments prioritize several key factors when considering compact SST adoption. Safety compliance ranks highest among these considerations, with proper MV clearance and creepage validation being critical requirements. This emphasis on safety validation represents both a market challenge and opportunity, as manufacturers who can demonstrate robust validation methodologies gain competitive advantage.

Cost remains a significant barrier to widespread adoption, with compact SSTs currently commanding premium prices compared to conventional transformers. However, as production scales and technology matures, industry analysts project price reductions of 30-40% within the next decade, potentially accelerating market penetration.

Regional analysis shows North America and Europe leading in compact SST adoption, primarily due to aggressive grid modernization initiatives and renewable energy targets. However, the Asia-Pacific region is expected to witness the fastest growth rate, driven by rapid industrialization, urbanization, and substantial investments in smart grid technologies across China, Japan, and South Korea.

Technical Challenges in MV Clearance/Creepage Validation

Validating medium voltage (MV) clearance and creepage distances in compact solid-state transformers (SSTs) presents significant technical challenges due to the unique operating conditions and design constraints of these advanced power electronic devices. Traditional clearance and creepage standards developed for conventional transformers often prove inadequate when applied to SSTs, which combine high-frequency operation with medium voltage levels in significantly reduced form factors.

The primary challenge stems from the fundamental conflict between miniaturization goals and safety requirements. As SSTs aim to achieve higher power densities through increased switching frequencies and advanced semiconductor technologies, the physical space available for insulation becomes increasingly constrained. This creates a direct tension with electrical safety standards that mandate minimum separation distances based on voltage levels rather than physical dimensions of the device.

Another significant obstacle is the complex electric field distribution within SSTs. Unlike conventional transformers with relatively uniform field patterns, solid-state transformers incorporate power electronic switches, gate drivers, and control circuitry in close proximity to medium voltage components. This creates non-uniform field distributions with potential hot spots that can lead to partial discharges and insulation degradation over time, even when nominal clearance distances are maintained.

The thermal management aspects further complicate clearance validation. SSTs generate significant heat during operation, with temperature gradients that can alter material properties and affect insulation performance. Traditional clearance rules rarely account for these dynamic thermal conditions, creating uncertainty in long-term reliability predictions based solely on room-temperature clearance measurements.

Environmental factors introduce additional validation challenges. SSTs deployed in various applications may encounter pollution, humidity, and altitude variations that affect insulation requirements. Current standards provide limited guidance on how to adjust clearance and creepage distances for these environmental factors specifically in the context of compact electronic devices operating at medium voltage levels.

The lack of harmonized testing methodologies represents another major hurdle. While conventional transformers benefit from well-established testing protocols, SSTs occupy a regulatory gray area between power electronics and traditional power equipment. This results in inconsistent validation approaches across the industry, making it difficult to establish comparable safety benchmarks or reliability data.

Finally, the accelerated aging mechanisms in SSTs differ significantly from conventional transformers. The combination of high-frequency voltage stress, thermal cycling, and compact design creates unique degradation patterns that are not well captured by existing lifetime models. This makes it challenging to validate whether a clearance distance that appears adequate during initial testing will maintain its insulation integrity throughout the expected service life of the device.

The primary challenge stems from the fundamental conflict between miniaturization goals and safety requirements. As SSTs aim to achieve higher power densities through increased switching frequencies and advanced semiconductor technologies, the physical space available for insulation becomes increasingly constrained. This creates a direct tension with electrical safety standards that mandate minimum separation distances based on voltage levels rather than physical dimensions of the device.

Another significant obstacle is the complex electric field distribution within SSTs. Unlike conventional transformers with relatively uniform field patterns, solid-state transformers incorporate power electronic switches, gate drivers, and control circuitry in close proximity to medium voltage components. This creates non-uniform field distributions with potential hot spots that can lead to partial discharges and insulation degradation over time, even when nominal clearance distances are maintained.

The thermal management aspects further complicate clearance validation. SSTs generate significant heat during operation, with temperature gradients that can alter material properties and affect insulation performance. Traditional clearance rules rarely account for these dynamic thermal conditions, creating uncertainty in long-term reliability predictions based solely on room-temperature clearance measurements.

Environmental factors introduce additional validation challenges. SSTs deployed in various applications may encounter pollution, humidity, and altitude variations that affect insulation requirements. Current standards provide limited guidance on how to adjust clearance and creepage distances for these environmental factors specifically in the context of compact electronic devices operating at medium voltage levels.

The lack of harmonized testing methodologies represents another major hurdle. While conventional transformers benefit from well-established testing protocols, SSTs occupy a regulatory gray area between power electronics and traditional power equipment. This results in inconsistent validation approaches across the industry, making it difficult to establish comparable safety benchmarks or reliability data.

Finally, the accelerated aging mechanisms in SSTs differ significantly from conventional transformers. The combination of high-frequency voltage stress, thermal cycling, and compact design creates unique degradation patterns that are not well captured by existing lifetime models. This makes it challenging to validate whether a clearance distance that appears adequate during initial testing will maintain its insulation integrity throughout the expected service life of the device.

Current Validation Methodologies for MV Insulation Requirements

01 Design considerations for SST clearance and creepage distances

Solid State Transformers require specific clearance and creepage distances to ensure electrical isolation and safety. These design considerations include proper spacing between conductive parts, selection of appropriate insulation materials, and adherence to electrical safety standards. The physical layout must account for voltage levels, environmental conditions, and operational requirements to prevent electrical breakdown and ensure long-term reliability.- Design considerations for SST clearance and creepage distances: Solid State Transformers require specific clearance and creepage distances to ensure electrical isolation and safety. These design considerations include proper spacing between conductive parts, selection of appropriate insulation materials, and adherence to electrical safety standards. The physical layout must account for voltage levels, environmental conditions, and operational requirements to prevent electrical breakdown and ensure long-term reliability.

- Insulation techniques for high-voltage SST applications: Advanced insulation techniques are essential for high-voltage Solid State Transformers to maintain proper clearance and creepage distances. These include the use of specialized insulation materials, potting compounds, conformal coatings, and barrier insulators. Such techniques help manage electric field distribution, prevent partial discharges, and ensure compliance with safety standards while enabling compact designs for high-voltage applications.

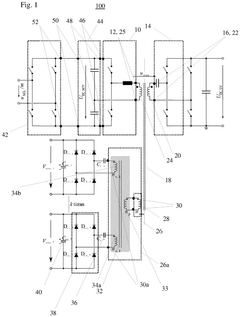

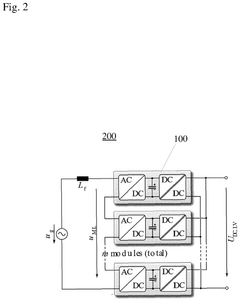

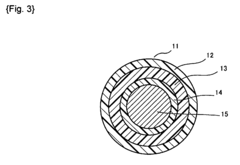

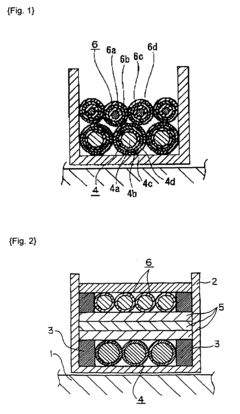

- Modular SST designs with optimized clearance requirements: Modular approaches to Solid State Transformer design allow for optimized clearance and creepage distances while maintaining compact form factors. These designs feature separate modules for different voltage stages, strategic component placement, and integrated cooling systems. The modular architecture enables better isolation between high and low voltage sections, simplified maintenance, and scalability while ensuring compliance with electrical safety standards.

- Environmental considerations affecting SST clearance requirements: Environmental factors significantly impact clearance and creepage requirements for Solid State Transformers. Factors such as humidity, pollution, altitude, temperature variations, and condensation can reduce the effectiveness of insulation. SST designs must account for these environmental conditions by incorporating appropriate pollution degree ratings, applying conformal coatings, implementing controlled environments, or using sealed enclosures to maintain electrical safety under various operating conditions.

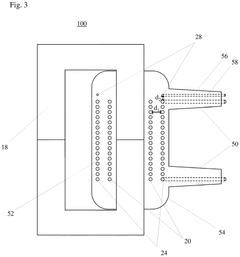

- Innovative packaging solutions for SST clearance optimization: Advanced packaging technologies help optimize clearance and creepage distances in Solid State Transformers while reducing overall size. These innovations include 3D packaging techniques, integrated cooling structures, advanced ceramic substrates, and specialized encapsulation methods. Such approaches enable higher power density while maintaining required isolation distances, managing thermal issues, and ensuring compliance with safety standards for various applications.

02 Insulation techniques for high-voltage SST applications

Advanced insulation techniques are essential for high-voltage SST applications to maintain proper clearance and creepage distances. These techniques include using specialized insulating materials, potting compounds, and barrier designs that can withstand high electric field strengths. Proper insulation ensures the safe operation of SSTs in high-voltage environments while minimizing the risk of partial discharge and electrical breakdown.Expand Specific Solutions03 Modular SST designs with optimized clearance requirements

Modular approaches to SST design can help optimize clearance and creepage requirements. By compartmentalizing high-voltage and low-voltage sections, these designs create natural isolation barriers that enhance safety while potentially reducing overall size. Modular designs also facilitate maintenance and replacement of components without compromising the electrical isolation integrity of the entire system.Expand Specific Solutions04 Thermal management considerations for SST clearance design

Thermal management plays a crucial role in SST clearance design as heat can affect insulation properties and long-term reliability. Proper thermal design ensures that temperature rises do not compromise clearance and creepage distances or degrade insulation materials. Cooling systems, heat dissipation techniques, and temperature monitoring are integrated into SST designs to maintain safe operating temperatures and preserve electrical isolation integrity.Expand Specific Solutions05 Standards and testing methods for SST clearance and creepage compliance

Specific standards and testing methodologies are employed to verify that SSTs meet required clearance and creepage specifications. These include partial discharge testing, high-potential testing, and impulse voltage testing to validate insulation performance. Compliance with international standards such as IEC and IEEE ensures that SSTs maintain appropriate electrical isolation under various operating conditions and environmental factors, including pollution, humidity, and altitude.Expand Specific Solutions

Key Industry Players in Solid State Transformer Development

Solid State Transformer (SST) technology is currently in the early growth phase, with the market expected to expand significantly due to increasing demand for efficient power conversion solutions. The global SST market is projected to reach approximately $1.5 billion by 2027, driven by smart grid implementations and renewable energy integration. Regarding MV clearance/creepage validation in compact SSTs, the technical maturity varies across key players. State Grid Corp. of China and ABB Group lead with advanced research and commercial implementations, while Hitachi Energy and Murata Manufacturing demonstrate strong capabilities in miniaturization techniques. Furukawa Electric and JFE Steel contribute specialized materials expertise, with universities like Freiburg and Beijing Science & Technology providing theoretical frameworks for clearance optimization in compact designs.

State Grid Corp. of China

Technical Solution: State Grid Corporation of China has developed a multi-tiered validation framework for MV clearance/creepage in compact solid state transformers, particularly focused on grid integration applications. Their approach combines theoretical modeling with extensive field testing across diverse environmental conditions found throughout China's varied geography. State Grid's methodology incorporates pollution mapping to determine appropriate creepage requirements based on installation location, allowing for optimization in less contaminated environments. They've implemented a comprehensive testing protocol that includes impulse voltage testing, partial discharge monitoring, and thermal cycling to validate insulation coordination in compact designs. Their validation process incorporates China's national standards (GB/T) alongside international standards like IEC 60664, with modifications to address specific challenges in compact SST designs. State Grid has also developed specialized monitoring systems that continuously validate clearance/creepage adequacy during operation through real-time partial discharge detection and insulation resistance measurement.

Strengths: Extensive real-world validation data from diverse operating environments; strong integration with grid-level systems; comprehensive testing facilities capable of validating full-scale equipment. Weaknesses: Some methodologies may be specifically tailored to Chinese grid requirements and environmental conditions; documentation may not be widely available in English.

ABB Group

Technical Solution: ABB Group has developed comprehensive validation methodologies for MV clearance and creepage in compact solid state transformers (SSTs) based on IEC 60664 and IEC 61800-5-1 standards. Their approach incorporates advanced 3D electric field simulation techniques to analyze potential weak points in insulation systems. ABB's validation process includes partial discharge measurements under various environmental conditions (temperature, humidity, altitude) to ensure reliability. They've implemented a multi-layer insulation system with specialized materials that maintain dielectric strength while minimizing physical dimensions. Their testing protocols include accelerated aging tests with combined electrical and thermal stress to validate long-term performance of clearance and creepage distances in compact designs. ABB has also developed specialized coating materials with high comparative tracking index (CTI) values exceeding 600V to reduce required creepage distances while maintaining safety margins.

Strengths: Industry-leading expertise in power electronics with extensive testing facilities; proprietary insulation materials optimized for compact designs; comprehensive validation methodology covering multiple environmental factors. Weaknesses: Their solutions may be more costly than competitors; some proprietary technologies may limit interoperability with third-party components.

Critical Technical Standards and Testing Protocols

Medium-frequency transformer-based double-isolated auxiliary supply for medium-voltage DC/DC converters

PatentPendingEP4529013A1

Innovation

- A converter design incorporating a magnetic core with LV and MV windings, an auxiliary winding, and galvanic insulation to withstand Basic Insulation Levels (BIL) of up to 250 kV, along with MV bushings and a configuration that allows for efficient power transfer while minimizing the size and cost of auxiliary power components.

Multilayer insulated wire and transformer using same

PatentInactiveEP2474984A1

Innovation

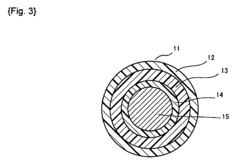

- A multilayer insulated electric wire with at least three extruded insulating layers, where the outermost layer is composed of a polyamide resin with a thickness of 25 µm or less, and the inner layer consists of a crystalline resin with a melting point of 225°C or more, or an amorphous resin with a glass transition temperature of 200°C or more, incorporating resin mixtures such as thermoplastic linear polyester, ethylene-based copolymers, and epoxy group-containing resins for enhanced voltage resistance and heat resistance.

Safety Compliance Framework for MV Power Electronics

The safety compliance framework for medium voltage (MV) power electronics represents a critical foundation for ensuring the reliable and safe operation of solid-state transformers (SSTs) in compact designs. This framework must address the unique challenges posed by the integration of high-voltage components in confined spaces while maintaining strict adherence to international safety standards. Current regulatory frameworks such as IEC 61800-5-1, IEC 60664-1, and UL 61800-5-1 provide baseline requirements, but their application to novel SST topologies requires careful interpretation.

The framework necessitates a multi-layered approach to safety validation, beginning with the establishment of appropriate clearance and creepage distances based on pollution degree, overvoltage category, and operating altitude. For MV applications typically operating between 1.5kV and 36kV, these distances become particularly critical as they directly impact the physical dimensions of the transformer design while ensuring protection against electrical breakdown and surface tracking.

Insulation coordination represents another essential element of the framework, requiring systematic classification of insulation systems as functional, basic, supplementary, reinforced, or double insulation. This classification determines the testing protocols and safety margins required for each insulation barrier within the SST. The framework must incorporate partial discharge testing methodologies with clearly defined inception and extinction voltage thresholds appropriate for the compact nature of modern SSTs.

Thermal management considerations must be integrated into the safety compliance framework, as elevated temperatures can significantly reduce insulation performance and accelerate aging. The framework should establish temperature monitoring requirements at critical points and define derating factors for clearance and creepage distances under various thermal conditions.

Verification methodologies constitute a fundamental component of the framework, encompassing both design validation through simulation tools like finite element analysis (FEA) and physical testing protocols. These methodologies must account for the three-dimensional nature of electric field distribution in compact designs, where traditional two-dimensional approximations may prove inadequate.

The framework should also address environmental factors that influence insulation performance, including humidity, condensation, and altitude corrections. For global deployment of SST technology, the framework must incorporate regional variations in safety standards while maintaining a consistent approach to validation across different markets and applications.

The framework necessitates a multi-layered approach to safety validation, beginning with the establishment of appropriate clearance and creepage distances based on pollution degree, overvoltage category, and operating altitude. For MV applications typically operating between 1.5kV and 36kV, these distances become particularly critical as they directly impact the physical dimensions of the transformer design while ensuring protection against electrical breakdown and surface tracking.

Insulation coordination represents another essential element of the framework, requiring systematic classification of insulation systems as functional, basic, supplementary, reinforced, or double insulation. This classification determines the testing protocols and safety margins required for each insulation barrier within the SST. The framework must incorporate partial discharge testing methodologies with clearly defined inception and extinction voltage thresholds appropriate for the compact nature of modern SSTs.

Thermal management considerations must be integrated into the safety compliance framework, as elevated temperatures can significantly reduce insulation performance and accelerate aging. The framework should establish temperature monitoring requirements at critical points and define derating factors for clearance and creepage distances under various thermal conditions.

Verification methodologies constitute a fundamental component of the framework, encompassing both design validation through simulation tools like finite element analysis (FEA) and physical testing protocols. These methodologies must account for the three-dimensional nature of electric field distribution in compact designs, where traditional two-dimensional approximations may prove inadequate.

The framework should also address environmental factors that influence insulation performance, including humidity, condensation, and altitude corrections. For global deployment of SST technology, the framework must incorporate regional variations in safety standards while maintaining a consistent approach to validation across different markets and applications.

Environmental Impact of Insulation Materials in SSTs

The environmental impact of insulation materials used in Solid State Transformers (SSTs) represents a critical consideration in the sustainable development of modern power electronics. Traditional transformer insulation materials often contain environmentally harmful substances such as mineral oils, which pose significant risks of soil and water contamination when leakage occurs. In contrast, SSTs utilize various alternative insulation materials that offer improved environmental profiles while maintaining the necessary electrical clearance and creepage requirements for medium voltage applications.

Epoxy resins, commonly employed in SST insulation systems, demonstrate superior environmental performance compared to traditional oil-based insulations. These materials are non-toxic, non-flammable, and do not contribute to water or soil pollution in case of failure. However, the manufacturing process of epoxy resins involves energy-intensive procedures and chemical compounds that may generate greenhouse gas emissions, requiring careful lifecycle assessment.

Silicone-based insulation materials present another environmentally conscious option for SST applications. These materials offer excellent thermal stability and electrical insulation properties while being chemically inert and resistant to environmental degradation. The extended lifespan of silicone insulations reduces replacement frequency, thereby minimizing waste generation and resource consumption over the operational lifetime of SSTs.

Biodegradable insulation materials represent an emerging trend in SST design, with research focusing on plant-based oils and natural esters as potential replacements for conventional synthetic insulations. These materials offer reduced environmental impact at end-of-life disposal while maintaining competitive dielectric strength and thermal performance necessary for MV clearance requirements in compact SST designs.

The recyclability of insulation materials significantly influences the overall environmental footprint of SSTs. Materials such as certain ceramics and glass-reinforced composites used for insulation in SSTs can be recovered and repurposed at end-of-life, reducing landfill waste and conserving valuable resources. This circular economy approach aligns with global sustainability initiatives and regulatory frameworks promoting responsible electronic waste management.

Energy efficiency during operation represents another environmental dimension of insulation material selection. Advanced insulation systems with superior thermal management properties enable SSTs to operate at higher efficiencies, reducing energy losses and associated carbon emissions throughout the operational lifespan. This operational efficiency must be balanced against manufacturing impacts when assessing overall environmental performance.

Epoxy resins, commonly employed in SST insulation systems, demonstrate superior environmental performance compared to traditional oil-based insulations. These materials are non-toxic, non-flammable, and do not contribute to water or soil pollution in case of failure. However, the manufacturing process of epoxy resins involves energy-intensive procedures and chemical compounds that may generate greenhouse gas emissions, requiring careful lifecycle assessment.

Silicone-based insulation materials present another environmentally conscious option for SST applications. These materials offer excellent thermal stability and electrical insulation properties while being chemically inert and resistant to environmental degradation. The extended lifespan of silicone insulations reduces replacement frequency, thereby minimizing waste generation and resource consumption over the operational lifetime of SSTs.

Biodegradable insulation materials represent an emerging trend in SST design, with research focusing on plant-based oils and natural esters as potential replacements for conventional synthetic insulations. These materials offer reduced environmental impact at end-of-life disposal while maintaining competitive dielectric strength and thermal performance necessary for MV clearance requirements in compact SST designs.

The recyclability of insulation materials significantly influences the overall environmental footprint of SSTs. Materials such as certain ceramics and glass-reinforced composites used for insulation in SSTs can be recovered and repurposed at end-of-life, reducing landfill waste and conserving valuable resources. This circular economy approach aligns with global sustainability initiatives and regulatory frameworks promoting responsible electronic waste management.

Energy efficiency during operation represents another environmental dimension of insulation material selection. Advanced insulation systems with superior thermal management properties enable SSTs to operate at higher efficiencies, reducing energy losses and associated carbon emissions throughout the operational lifespan. This operational efficiency must be balanced against manufacturing impacts when assessing overall environmental performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!