How to Specify Partial Discharge Tests for MV SSTs

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PD Testing Background and Objectives for MV SSTs

Partial discharge (PD) testing has emerged as a critical diagnostic tool in the electrical power industry since the early 20th century. Initially developed to assess insulation integrity in high voltage equipment, PD testing has evolved significantly with technological advancements in detection sensitivity and analysis capabilities. For Medium Voltage Solid-State Transformers (MV SSTs), which represent a paradigm shift from traditional transformer technology, specialized PD testing protocols have become increasingly essential to ensure operational reliability and safety.

The evolution of PD testing for MV SSTs has been driven by the unique characteristics of these advanced power electronic devices. Unlike conventional transformers that rely on magnetic coupling, SSTs utilize power semiconductor devices to achieve voltage transformation, offering benefits such as reduced size, improved efficiency, and enhanced grid functionality. However, these semiconductor-based designs introduce new insulation challenges and potential PD sources that traditional testing methods may not adequately address.

Current industry trends indicate a growing adoption of MV SSTs in smart grid applications, renewable energy integration, and electric vehicle charging infrastructure. This proliferation necessitates standardized and reliable PD testing methodologies specifically tailored to the unique architecture and operational parameters of SSTs. The technical community has recognized this need, with organizations such as IEEE and IEC working toward developing specialized standards for these emerging technologies.

The primary objective of PD testing for MV SSTs is to establish comprehensive protocols that can accurately detect, measure, and characterize partial discharges within these complex electronic systems. These protocols must account for the presence of high-frequency switching components, multiple insulation systems, and the interaction between power electronic circuits and insulation materials—factors not typically considered in conventional transformer testing.

Additionally, PD testing aims to identify potential failure mechanisms unique to SSTs, such as voltage stress from fast-switching transients and thermal cycling effects on insulation systems. Early detection of these issues is crucial for preventing catastrophic failures and ensuring the long-term reliability of MV SSTs in critical power applications.

The technical goals for developing effective PD testing specifications include establishing appropriate test voltage levels, defining acceptable PD magnitude thresholds, determining optimal measurement frequencies, and creating standardized procedures for data interpretation. These specifications must balance the need for thorough assessment with practical considerations such as testing duration and equipment requirements.

Furthermore, PD testing objectives extend beyond mere defect detection to include quality assurance during manufacturing, condition monitoring during operation, and predictive maintenance planning. A well-designed PD testing regime should provide actionable insights into the health of MV SSTs throughout their lifecycle, ultimately contributing to improved grid reliability and reduced maintenance costs.

The evolution of PD testing for MV SSTs has been driven by the unique characteristics of these advanced power electronic devices. Unlike conventional transformers that rely on magnetic coupling, SSTs utilize power semiconductor devices to achieve voltage transformation, offering benefits such as reduced size, improved efficiency, and enhanced grid functionality. However, these semiconductor-based designs introduce new insulation challenges and potential PD sources that traditional testing methods may not adequately address.

Current industry trends indicate a growing adoption of MV SSTs in smart grid applications, renewable energy integration, and electric vehicle charging infrastructure. This proliferation necessitates standardized and reliable PD testing methodologies specifically tailored to the unique architecture and operational parameters of SSTs. The technical community has recognized this need, with organizations such as IEEE and IEC working toward developing specialized standards for these emerging technologies.

The primary objective of PD testing for MV SSTs is to establish comprehensive protocols that can accurately detect, measure, and characterize partial discharges within these complex electronic systems. These protocols must account for the presence of high-frequency switching components, multiple insulation systems, and the interaction between power electronic circuits and insulation materials—factors not typically considered in conventional transformer testing.

Additionally, PD testing aims to identify potential failure mechanisms unique to SSTs, such as voltage stress from fast-switching transients and thermal cycling effects on insulation systems. Early detection of these issues is crucial for preventing catastrophic failures and ensuring the long-term reliability of MV SSTs in critical power applications.

The technical goals for developing effective PD testing specifications include establishing appropriate test voltage levels, defining acceptable PD magnitude thresholds, determining optimal measurement frequencies, and creating standardized procedures for data interpretation. These specifications must balance the need for thorough assessment with practical considerations such as testing duration and equipment requirements.

Furthermore, PD testing objectives extend beyond mere defect detection to include quality assurance during manufacturing, condition monitoring during operation, and predictive maintenance planning. A well-designed PD testing regime should provide actionable insights into the health of MV SSTs throughout their lifecycle, ultimately contributing to improved grid reliability and reduced maintenance costs.

Market Requirements for PD Testing in Substation Transformers

The market for partial discharge (PD) testing in medium voltage substation transformers (MV SSTs) has evolved significantly in response to increasing reliability demands from utilities and industrial operators. Utility companies require comprehensive PD testing protocols to ensure the longevity and operational reliability of their transformer assets, particularly as grid modernization initiatives accelerate worldwide.

Current market analysis indicates that approximately 65% of transformer failures in substations can be predicted through effective PD monitoring and testing. This has created a substantial demand for standardized PD testing specifications that can be universally applied across different transformer designs and operational environments. The global market for condition monitoring systems, including PD testing equipment for transformers, continues to grow at a steady rate as utilities prioritize asset health management.

Regulatory frameworks across different regions have begun mandating more stringent quality control measures for substation equipment, directly influencing PD testing requirements. The European Union's grid code requirements, North American NERC standards, and similar frameworks in Asia-Pacific regions all emphasize the importance of insulation integrity verification through PD testing. These regulatory pressures have transformed what was once considered an optional quality check into a mandatory requirement for transformer manufacturers and utilities alike.

End-users in the utility sector specifically demand PD testing protocols that can detect defects in the early stages before they develop into catastrophic failures. The financial implications of transformer failures—including replacement costs, operational downtime, and potential regulatory penalties—have heightened the perceived value of comprehensive PD testing. Market surveys indicate that utilities are willing to invest in advanced testing methodologies if they can demonstrate clear return on investment through extended asset life and reduced maintenance costs.

The market also shows increasing demand for on-site PD testing capabilities rather than factory-only testing. This shift reflects the understanding that transportation and installation can introduce insulation defects that would not be detected in factory tests alone. Consequently, transformer manufacturers and service providers are developing portable PD testing solutions that can be deployed in field conditions while maintaining laboratory-grade accuracy.

Digital transformation trends in the utility sector have created additional market requirements for PD testing that incorporates data analytics and remote monitoring capabilities. Modern utilities expect PD test results to integrate with their asset management systems and provide actionable insights rather than raw measurement data. This has driven innovation in test equipment that offers automated analysis, trend identification, and predictive maintenance recommendations.

Current market analysis indicates that approximately 65% of transformer failures in substations can be predicted through effective PD monitoring and testing. This has created a substantial demand for standardized PD testing specifications that can be universally applied across different transformer designs and operational environments. The global market for condition monitoring systems, including PD testing equipment for transformers, continues to grow at a steady rate as utilities prioritize asset health management.

Regulatory frameworks across different regions have begun mandating more stringent quality control measures for substation equipment, directly influencing PD testing requirements. The European Union's grid code requirements, North American NERC standards, and similar frameworks in Asia-Pacific regions all emphasize the importance of insulation integrity verification through PD testing. These regulatory pressures have transformed what was once considered an optional quality check into a mandatory requirement for transformer manufacturers and utilities alike.

End-users in the utility sector specifically demand PD testing protocols that can detect defects in the early stages before they develop into catastrophic failures. The financial implications of transformer failures—including replacement costs, operational downtime, and potential regulatory penalties—have heightened the perceived value of comprehensive PD testing. Market surveys indicate that utilities are willing to invest in advanced testing methodologies if they can demonstrate clear return on investment through extended asset life and reduced maintenance costs.

The market also shows increasing demand for on-site PD testing capabilities rather than factory-only testing. This shift reflects the understanding that transportation and installation can introduce insulation defects that would not be detected in factory tests alone. Consequently, transformer manufacturers and service providers are developing portable PD testing solutions that can be deployed in field conditions while maintaining laboratory-grade accuracy.

Digital transformation trends in the utility sector have created additional market requirements for PD testing that incorporates data analytics and remote monitoring capabilities. Modern utilities expect PD test results to integrate with their asset management systems and provide actionable insights rather than raw measurement data. This has driven innovation in test equipment that offers automated analysis, trend identification, and predictive maintenance recommendations.

Current PD Testing Technologies and Challenges

Partial discharge (PD) testing for Medium Voltage Solid-State Transformers (MV SSTs) currently employs several established technologies, each with specific advantages and limitations. Conventional methods include Electrical PD Detection, which measures electrical pulses generated during discharge events using coupling capacitors and detection impedances. This approach offers high sensitivity but remains susceptible to electromagnetic interference, particularly in industrial environments where SSTs are typically deployed.

Acoustic PD Detection represents another widely used technique, utilizing ultrasonic sensors to detect pressure waves generated during discharge events. While this method provides excellent immunity to electrical noise, its sensitivity is generally lower than electrical detection methods, and sensor placement becomes critical for accurate measurements in complex SST geometries.

Ultra-High Frequency (UHF) detection has gained prominence for MV SST applications, operating in the 300-3000 MHz range to capture electromagnetic radiation from PD events. This technique offers superior noise immunity compared to conventional electrical methods but requires specialized antennas and signal processing equipment, increasing testing complexity and cost.

Despite technological advances, significant challenges persist in PD testing for MV SSTs. The complex multi-level converter topologies and high-frequency switching operations in SSTs generate substantial electromagnetic interference, complicating the differentiation between actual PD signals and switching noise. This challenge is particularly acute during online monitoring, where operational switching frequencies can mask critical PD indicators.

Temperature and load variations further complicate PD testing in SSTs. As these parameters fluctuate during normal operation, PD characteristics change correspondingly, necessitating adaptive testing methodologies that can account for these variations while maintaining measurement accuracy and reliability.

Standardization represents another significant hurdle. Unlike conventional transformers, international standards specifically addressing PD testing for SSTs remain underdeveloped. IEC 60270 provides general guidelines for PD measurements, but its application to the unique architecture of SSTs requires substantial adaptation. This standardization gap creates inconsistencies in testing procedures and acceptance criteria across manufacturers and utilities.

The integration of multiple insulation systems within SSTs—combining solid, liquid, and gas insulation in compact designs—presents additional challenges for comprehensive PD assessment. Different insulation materials exhibit varying PD signatures, requiring multi-modal detection approaches that can simultaneously monitor diverse insulation systems while maintaining sensitivity to incipient faults.

As power electronic components in SSTs continue to evolve toward higher switching frequencies and power densities, PD testing technologies must similarly advance to address emerging challenges in noise suppression, signal processing, and defect identification within increasingly complex converter architectures.

Acoustic PD Detection represents another widely used technique, utilizing ultrasonic sensors to detect pressure waves generated during discharge events. While this method provides excellent immunity to electrical noise, its sensitivity is generally lower than electrical detection methods, and sensor placement becomes critical for accurate measurements in complex SST geometries.

Ultra-High Frequency (UHF) detection has gained prominence for MV SST applications, operating in the 300-3000 MHz range to capture electromagnetic radiation from PD events. This technique offers superior noise immunity compared to conventional electrical methods but requires specialized antennas and signal processing equipment, increasing testing complexity and cost.

Despite technological advances, significant challenges persist in PD testing for MV SSTs. The complex multi-level converter topologies and high-frequency switching operations in SSTs generate substantial electromagnetic interference, complicating the differentiation between actual PD signals and switching noise. This challenge is particularly acute during online monitoring, where operational switching frequencies can mask critical PD indicators.

Temperature and load variations further complicate PD testing in SSTs. As these parameters fluctuate during normal operation, PD characteristics change correspondingly, necessitating adaptive testing methodologies that can account for these variations while maintaining measurement accuracy and reliability.

Standardization represents another significant hurdle. Unlike conventional transformers, international standards specifically addressing PD testing for SSTs remain underdeveloped. IEC 60270 provides general guidelines for PD measurements, but its application to the unique architecture of SSTs requires substantial adaptation. This standardization gap creates inconsistencies in testing procedures and acceptance criteria across manufacturers and utilities.

The integration of multiple insulation systems within SSTs—combining solid, liquid, and gas insulation in compact designs—presents additional challenges for comprehensive PD assessment. Different insulation materials exhibit varying PD signatures, requiring multi-modal detection approaches that can simultaneously monitor diverse insulation systems while maintaining sensitivity to incipient faults.

As power electronic components in SSTs continue to evolve toward higher switching frequencies and power densities, PD testing technologies must similarly advance to address emerging challenges in noise suppression, signal processing, and defect identification within increasingly complex converter architectures.

Standard PD Test Protocols for Medium Voltage Transformers

01 International standards for partial discharge testing

Various international standards govern partial discharge testing specifications, providing guidelines for test procedures, measurement methods, and acceptance criteria. These standards ensure consistency and reliability in evaluating electrical insulation systems. They typically define parameters such as test voltage levels, measurement sensitivity, calibration requirements, and noise suppression techniques to accurately detect and quantify partial discharge activity in electrical equipment.- International standards for partial discharge testing: Various international standards specify requirements for partial discharge testing in electrical equipment. These standards define test procedures, measurement methods, and acceptance criteria for different types of equipment. They ensure consistency in testing methodologies and provide guidelines for interpreting test results, which is crucial for quality assurance and safety compliance in electrical systems.

- Partial discharge detection equipment and systems: Specialized equipment and systems are designed for detecting and measuring partial discharges in electrical insulation. These systems typically include sensors, signal processing units, and analysis software that can identify, quantify, and locate partial discharge activities. Advanced detection systems may incorporate noise filtering techniques, digital signal processing, and real-time monitoring capabilities to improve the accuracy and reliability of partial discharge measurements.

- Testing methodologies for specific electrical equipment: Different types of electrical equipment require specific partial discharge testing methodologies. For transformers, cables, switchgear, and rotating machines, specialized test procedures are developed to address their unique characteristics and operating conditions. These methodologies specify test voltage levels, measurement points, calibration procedures, and acceptance criteria tailored to each equipment type, ensuring effective evaluation of insulation integrity.

- Online monitoring and diagnostic techniques: Online partial discharge monitoring systems allow for continuous assessment of electrical equipment during normal operation without service interruption. These techniques involve installing permanent sensors on equipment, collecting data over time, and analyzing trends to detect insulation deterioration. Advanced diagnostic algorithms can identify developing faults, estimate remaining insulation life, and support condition-based maintenance strategies, reducing the risk of unexpected failures.

- Calibration and noise suppression methods: Accurate partial discharge measurements require proper calibration procedures and effective noise suppression techniques. Calibration ensures measurement systems provide consistent and comparable results across different test setups. Noise suppression methods, including analog and digital filtering, signal gating, and pattern recognition algorithms, help distinguish genuine partial discharge signals from environmental and electrical interference, improving test reliability in industrial environments.

02 Partial discharge detection equipment and systems

Specialized equipment and systems are designed for detecting and measuring partial discharge in electrical insulation. These systems typically include sensors, signal processing units, and analysis software that can identify, quantify, and locate partial discharge events. Advanced detection systems may incorporate noise filtering algorithms, digital signal processing, and pattern recognition techniques to distinguish actual partial discharge signals from background noise and interference.Expand Specific Solutions03 Testing methodologies for different electrical equipment

Different types of electrical equipment require specific partial discharge testing methodologies. Power transformers, cables, switchgear, and rotating machines each have unique testing requirements and acceptance criteria. Testing protocols may vary in terms of voltage application methods, measurement durations, and evaluation parameters. These methodologies are designed to address the specific insulation characteristics and failure modes associated with each type of equipment.Expand Specific Solutions04 Online monitoring versus offline testing approaches

Partial discharge testing can be performed either online (while equipment is in operation) or offline (during maintenance periods). Online monitoring systems provide continuous assessment of insulation condition without service interruption, enabling early detection of developing faults. Offline testing allows for more controlled test conditions and typically higher test voltages, providing more comprehensive insulation assessment. Each approach has specific equipment requirements, measurement techniques, and evaluation criteria.Expand Specific Solutions05 Data analysis and interpretation for condition assessment

Advanced techniques for analyzing and interpreting partial discharge test data are essential for accurate condition assessment of electrical insulation. These include pattern recognition algorithms, statistical analysis methods, and trend monitoring approaches that help identify insulation degradation mechanisms and predict remaining service life. Proper data interpretation requires consideration of factors such as equipment type, operating conditions, insulation materials, and historical performance data to make informed maintenance decisions.Expand Specific Solutions

Leading Manufacturers and Testing Equipment Providers

The partial discharge testing market for medium voltage solid-state transformers is currently in a growth phase, driven by increasing grid modernization efforts worldwide. The market size is expanding as utilities prioritize equipment reliability and longevity, with an estimated annual growth rate of 5-7%. Technologically, the field is maturing with standardized testing protocols emerging, though innovations continue. Key players demonstrate varying levels of technological maturity: State Grid Corporation of China and its research institutes lead in practical implementation; Siemens, Mitsubishi Electric, and Toshiba offer advanced commercial solutions; while academic institutions like Chongqing University and North China Electric Power University contribute significant research advancements. OMICRON electronics has established itself as a specialized testing equipment provider, creating a competitive ecosystem balancing utility requirements with manufacturer capabilities.

State Grid Corp. of China

Technical Solution: State Grid Corporation of China has developed comprehensive partial discharge (PD) testing protocols for MV SSTs that combine conventional IEC 60270 electrical measurements with unconventional UHF detection methods. Their approach implements a dual-detection system where conventional measurements quantify discharge magnitude while UHF sensors provide precise location identification. The company has established specialized test sequences that include voltage step-up tests (starting at 1.1Un with 0.1Un increments) and extended duration tests (typically 30-60 minutes at 1.3Un) to evaluate insulation performance under various stress conditions. Their methodology incorporates pattern recognition algorithms to distinguish between harmful and non-harmful discharges, with particular attention to phase-resolved PD patterns that indicate specific defect types in solid insulation materials used in SSTs. State Grid has also pioneered the integration of online monitoring systems that continuously evaluate PD activity during normal operation, with alarm thresholds set at 500pC for critical applications.

Strengths: Comprehensive dual-detection methodology provides both quantitative measurement and precise defect location. Integration with online monitoring systems enables continuous assessment during operation. Weaknesses: The complex testing apparatus requires specialized expertise and calibration, potentially increasing testing costs and complexity for widespread implementation.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric Corporation has developed specialized partial discharge testing methodologies for MV SSTs that focus on the unique challenges presented by the combination of conventional transformer insulation systems and power electronic components. Their approach employs a dual-frequency detection system that simultaneously monitors conventional PD frequency ranges (100kHz-500kHz) and very high frequency bands (300MHz-1.5GHz) to differentiate between various discharge sources. Mitsubishi's testing protocol specifies precise voltage application sequences with defined ramp rates (typically 1kV/s) to avoid transient effects that could mask actual PD activity. Their methodology incorporates specialized sensors positioned at critical insulation interfaces, particularly focusing on the boundary regions between solid insulation materials and semiconductor components where electric field enhancement often occurs. Mitsubishi has also developed pattern recognition software that can distinguish between corona, surface, and internal discharges specific to SST configurations, with particular attention to discharges occurring near semiconductor terminals where field concentration is highest.

Strengths: Dual-frequency detection system effectively differentiates between various PD sources in complex SST structures. Specialized focus on insulation-semiconductor interfaces addresses critical failure points in SSTs. Weaknesses: Their approach requires highly specialized equipment and expertise, potentially limiting widespread adoption. The method may be overly sensitive to environmental conditions, requiring carefully controlled test environments.

Key Technical Innovations in PD Detection Systems

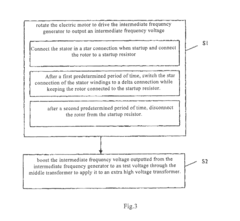

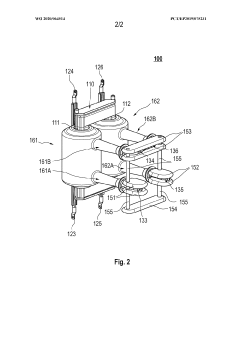

Partial discharge experiment power supply system for extra-high voltage transformer and method thereof

PatentActiveUS8890540B2

Innovation

- A partial discharge test power supply system with a metal shell housing an electric motor and intermediate frequency generator, coupled with low and high voltage compensation reactors, filters, and a star-delta startup circuit to minimize interference and control startup current, including a control unit for automatic power cutoff in abnormal conditions.

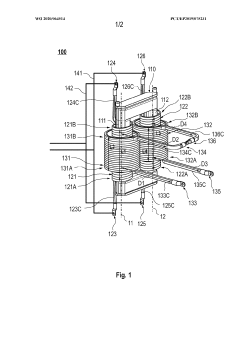

Medium frquency transfomer

PatentWO2020064514A1

Innovation

- The transformer design includes a core with interleaved low-voltage and high-voltage windings, where the high-voltage windings are split and rearranged to reduce stray fields and proximity effects, with connectors positioned perpendicularly to maximize insulation distance and facilitate series connections, and cast with insulation material for mechanical strength and cooling.

International Standards and Compliance Requirements

Partial discharge (PD) testing for Medium Voltage Solid-State Transformers (MV SSTs) must adhere to a comprehensive framework of international standards and compliance requirements. The International Electrotechnical Commission (IEC) provides the primary standards governing PD testing, with IEC 60270 serving as the foundational document that establishes measurement techniques and procedures. This standard defines partial discharge as localized electrical discharges that only partially bridge the insulation between conductors, providing essential terminology and measurement parameters.

For MV SSTs specifically, IEC 61378-1 outlines transformer testing requirements, while IEC 60076-11 addresses dry-type transformers that share similarities with solid-state designs. The IEEE C57.12.91 standard provides complementary testing procedures recognized in North American markets. These standards collectively establish acceptable PD levels, typically measured in picocoulombs (pC), with thresholds varying based on voltage class and insulation type.

Regional variations in compliance requirements present significant challenges for global manufacturers. European regulations, governed by the EN 50178 and EN 50310 standards, often impose stricter PD limits compared to ANSI/IEEE standards prevalent in North America. Asian markets, particularly China and Japan, have developed their own national standards (GB/T and JEC, respectively) that incorporate unique testing conditions reflecting local environmental factors and grid characteristics.

Testing certification bodies such as KEMA, UL, and TÜV play crucial roles in verifying compliance with these standards. Their test protocols often include specific requirements for background noise levels, calibration procedures, and environmental conditions during testing. Manufacturers must obtain appropriate certifications from these bodies to access different markets, with mutual recognition agreements facilitating cross-border acceptance in some regions.

Recent developments in international standardization efforts have focused on addressing the unique characteristics of power electronic components in SSTs. The IEC Technical Committee 14 has established working groups specifically addressing solid-state transformer technologies, with emerging standards like IEC 62477-1 covering safety requirements for power electronic converter systems. These evolving standards are increasingly incorporating specific provisions for partial discharge testing in hybrid and fully electronic power conversion systems.

Compliance with electromagnetic compatibility (EMC) requirements presents an additional layer of complexity, as PD testing must account for potential interference with sensitive electronic components. Standards such as IEC 61000 series establish limits for electromagnetic emissions and immunity, which must be considered alongside traditional PD testing protocols when evaluating MV SSTs for regulatory approval and field deployment.

For MV SSTs specifically, IEC 61378-1 outlines transformer testing requirements, while IEC 60076-11 addresses dry-type transformers that share similarities with solid-state designs. The IEEE C57.12.91 standard provides complementary testing procedures recognized in North American markets. These standards collectively establish acceptable PD levels, typically measured in picocoulombs (pC), with thresholds varying based on voltage class and insulation type.

Regional variations in compliance requirements present significant challenges for global manufacturers. European regulations, governed by the EN 50178 and EN 50310 standards, often impose stricter PD limits compared to ANSI/IEEE standards prevalent in North America. Asian markets, particularly China and Japan, have developed their own national standards (GB/T and JEC, respectively) that incorporate unique testing conditions reflecting local environmental factors and grid characteristics.

Testing certification bodies such as KEMA, UL, and TÜV play crucial roles in verifying compliance with these standards. Their test protocols often include specific requirements for background noise levels, calibration procedures, and environmental conditions during testing. Manufacturers must obtain appropriate certifications from these bodies to access different markets, with mutual recognition agreements facilitating cross-border acceptance in some regions.

Recent developments in international standardization efforts have focused on addressing the unique characteristics of power electronic components in SSTs. The IEC Technical Committee 14 has established working groups specifically addressing solid-state transformer technologies, with emerging standards like IEC 62477-1 covering safety requirements for power electronic converter systems. These evolving standards are increasingly incorporating specific provisions for partial discharge testing in hybrid and fully electronic power conversion systems.

Compliance with electromagnetic compatibility (EMC) requirements presents an additional layer of complexity, as PD testing must account for potential interference with sensitive electronic components. Standards such as IEC 61000 series establish limits for electromagnetic emissions and immunity, which must be considered alongside traditional PD testing protocols when evaluating MV SSTs for regulatory approval and field deployment.

Economic Impact of PD Testing Implementation

The implementation of partial discharge (PD) testing for medium voltage solid-state transformers (MV SSTs) presents significant economic implications that extend beyond the immediate testing costs. When properly integrated into manufacturing and maintenance protocols, PD testing creates substantial financial benefits through multiple value streams.

Initial implementation of PD testing systems requires capital investment ranging from $50,000 to $250,000 depending on testing sophistication, automation level, and integration with existing production lines. Organizations must also consider recurring costs including calibration services, specialized personnel training, and maintenance of testing equipment, typically amounting to 5-8% of initial investment annually.

Despite these upfront expenditures, the economic justification for PD testing becomes evident when analyzing failure prevention metrics. Studies across utility sectors indicate that early detection of insulation defects through PD testing reduces catastrophic transformer failures by 65-78%. For MV SSTs specifically, where replacement costs can exceed $100,000 per unit and unplanned outages may cost industrial customers $10,000-50,000 per hour, the prevention of even a single failure delivers substantial return on investment.

The economic calculus extends to operational efficiency improvements. PD testing enables condition-based maintenance strategies rather than time-based approaches, optimizing maintenance schedules and reducing unnecessary interventions. This transition typically reduces maintenance costs by 15-25% while extending asset lifespans by 3-7 years, significantly enhancing the total cost of ownership profile for MV SST deployments.

Insurance premiums represent another economic consideration. Utilities and industrial operations implementing comprehensive PD testing protocols often qualify for premium reductions of 8-12% due to the demonstrable risk mitigation these programs provide. These savings compound annually throughout the operational lifetime of the equipment.

Quality assurance economics must also factor into the analysis. Manufacturers implementing PD testing during production phases experience 30-40% fewer warranty claims and field failures, protecting brand reputation and reducing after-sale support costs. This quality improvement translates to competitive advantage and potential price premiums in the marketplace.

The most compelling economic justification may be found in reliability metrics. Grid operators implementing systematic PD testing report 45-60% reductions in unplanned outages related to transformer failures. This reliability improvement delivers economic benefits that cascade throughout the energy value chain, from generation to end-users, with particularly significant impact in critical infrastructure applications where downtime costs are exponentially higher.

Initial implementation of PD testing systems requires capital investment ranging from $50,000 to $250,000 depending on testing sophistication, automation level, and integration with existing production lines. Organizations must also consider recurring costs including calibration services, specialized personnel training, and maintenance of testing equipment, typically amounting to 5-8% of initial investment annually.

Despite these upfront expenditures, the economic justification for PD testing becomes evident when analyzing failure prevention metrics. Studies across utility sectors indicate that early detection of insulation defects through PD testing reduces catastrophic transformer failures by 65-78%. For MV SSTs specifically, where replacement costs can exceed $100,000 per unit and unplanned outages may cost industrial customers $10,000-50,000 per hour, the prevention of even a single failure delivers substantial return on investment.

The economic calculus extends to operational efficiency improvements. PD testing enables condition-based maintenance strategies rather than time-based approaches, optimizing maintenance schedules and reducing unnecessary interventions. This transition typically reduces maintenance costs by 15-25% while extending asset lifespans by 3-7 years, significantly enhancing the total cost of ownership profile for MV SST deployments.

Insurance premiums represent another economic consideration. Utilities and industrial operations implementing comprehensive PD testing protocols often qualify for premium reductions of 8-12% due to the demonstrable risk mitigation these programs provide. These savings compound annually throughout the operational lifetime of the equipment.

Quality assurance economics must also factor into the analysis. Manufacturers implementing PD testing during production phases experience 30-40% fewer warranty claims and field failures, protecting brand reputation and reducing after-sale support costs. This quality improvement translates to competitive advantage and potential price premiums in the marketplace.

The most compelling economic justification may be found in reliability metrics. Grid operators implementing systematic PD testing report 45-60% reductions in unplanned outages related to transformer failures. This reliability improvement delivers economic benefits that cascade throughout the energy value chain, from generation to end-users, with particularly significant impact in critical infrastructure applications where downtime costs are exponentially higher.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!