What Fails in SSTs? Capacitors, Modules and Magnetics — Field Evidence

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SST Failure Mechanisms and Research Objectives

Solid-State Transformers (SSTs) represent a revolutionary advancement in power electronics, offering significant advantages over traditional transformers in terms of size, weight, and functionality. However, field evidence reveals several critical failure mechanisms that must be addressed to ensure their reliability and widespread adoption. This research aims to systematically investigate these failure patterns and develop robust solutions.

Capacitors emerge as a primary point of failure in SST systems. DC-link capacitors, particularly aluminum electrolytic types, demonstrate limited lifespan under high-temperature and high-ripple current conditions. Field data indicates that capacitor degradation accounts for approximately 30% of SST failures, with thermal stress accelerating the evaporation of electrolytes and subsequent parameter drift. Film capacitors, while more reliable, still exhibit vulnerability to voltage transients and thermal cycling.

Power semiconductor modules represent another significant failure source, contributing to roughly 35% of field failures. IGBT and SiC MOSFET modules frequently experience bond wire lift-off and solder fatigue due to thermo-mechanical stress during power cycling. Die-attach degradation has been observed after as few as 10,000 cycles in high-power applications, substantially below design expectations. Additionally, gate oxide degradation in SiC devices occurs more rapidly than anticipated, especially in medium-voltage applications.

Magnetic components, including high-frequency transformers and inductors, account for approximately 25% of SST failures. Core saturation events, often triggered by control system anomalies, lead to catastrophic failures through localized heating and insulation breakdown. Partial discharge activity within insulation systems has been detected at operating voltages well below rated levels, suggesting design margin inadequacies. Moreover, thermal aging of insulation materials progresses faster than predicted by accelerated life testing models.

Control system and auxiliary power supply failures constitute the remaining 10% of field incidents. Sensor drift and calibration issues frequently precede major system failures, while firmware bugs manifest under specific grid conditions not covered during testing phases.

This research aims to develop comprehensive understanding of these failure mechanisms through multi-physics modeling and accelerated testing protocols that more accurately reflect field conditions. Specific objectives include: developing improved thermal management strategies for capacitors and semiconductor modules; creating advanced insulation systems for magnetic components capable of withstanding high-frequency stress; establishing more realistic reliability models incorporating actual field data; and designing intelligent prognostic systems for early failure detection.

The ultimate goal is to increase SST mean-time-between-failures by at least 300% while reducing maintenance costs by 50%, thereby enabling broader adoption of this transformative technology across grid infrastructure, renewable energy integration, and electric transportation applications.

Capacitors emerge as a primary point of failure in SST systems. DC-link capacitors, particularly aluminum electrolytic types, demonstrate limited lifespan under high-temperature and high-ripple current conditions. Field data indicates that capacitor degradation accounts for approximately 30% of SST failures, with thermal stress accelerating the evaporation of electrolytes and subsequent parameter drift. Film capacitors, while more reliable, still exhibit vulnerability to voltage transients and thermal cycling.

Power semiconductor modules represent another significant failure source, contributing to roughly 35% of field failures. IGBT and SiC MOSFET modules frequently experience bond wire lift-off and solder fatigue due to thermo-mechanical stress during power cycling. Die-attach degradation has been observed after as few as 10,000 cycles in high-power applications, substantially below design expectations. Additionally, gate oxide degradation in SiC devices occurs more rapidly than anticipated, especially in medium-voltage applications.

Magnetic components, including high-frequency transformers and inductors, account for approximately 25% of SST failures. Core saturation events, often triggered by control system anomalies, lead to catastrophic failures through localized heating and insulation breakdown. Partial discharge activity within insulation systems has been detected at operating voltages well below rated levels, suggesting design margin inadequacies. Moreover, thermal aging of insulation materials progresses faster than predicted by accelerated life testing models.

Control system and auxiliary power supply failures constitute the remaining 10% of field incidents. Sensor drift and calibration issues frequently precede major system failures, while firmware bugs manifest under specific grid conditions not covered during testing phases.

This research aims to develop comprehensive understanding of these failure mechanisms through multi-physics modeling and accelerated testing protocols that more accurately reflect field conditions. Specific objectives include: developing improved thermal management strategies for capacitors and semiconductor modules; creating advanced insulation systems for magnetic components capable of withstanding high-frequency stress; establishing more realistic reliability models incorporating actual field data; and designing intelligent prognostic systems for early failure detection.

The ultimate goal is to increase SST mean-time-between-failures by at least 300% while reducing maintenance costs by 50%, thereby enabling broader adoption of this transformative technology across grid infrastructure, renewable energy integration, and electric transportation applications.

Market Analysis of Solid-State Transformer Applications

The solid-state transformer (SST) market is experiencing significant growth driven by the increasing demand for efficient power conversion solutions across various sectors. The global SST market is projected to reach $1.5 billion by 2027, growing at a CAGR of approximately 23% from 2022 to 2027. This growth is primarily fueled by the rapid expansion of renewable energy integration, electric vehicle charging infrastructure, and smart grid implementations.

In the renewable energy sector, SSTs are becoming essential components for interfacing solar and wind power systems with the grid. The ability of SSTs to handle bidirectional power flow and provide voltage regulation makes them particularly valuable for distributed energy resources. This application segment currently represents about 35% of the total SST market and is expected to maintain its dominant position through 2030.

The electric vehicle charging infrastructure presents another substantial market opportunity for SSTs. With the global EV market expanding at unprecedented rates, the demand for fast-charging stations is surging. SSTs offer significant advantages in this application due to their compact size, high efficiency, and ability to provide isolation between AC and DC systems. Market analysis indicates that this segment could grow at over 30% annually for the next five years.

Smart grid applications represent the third major market for SSTs. Utility companies worldwide are investing in grid modernization projects, with SSTs playing a crucial role in enhancing grid resilience and flexibility. The market value for SST applications in smart grids is expected to reach $400 million by 2026.

Regionally, North America and Europe currently lead the SST market adoption, accounting for approximately 60% of global installations. However, the Asia-Pacific region, particularly China and India, is expected to witness the fastest growth rate due to massive investments in renewable energy and grid infrastructure modernization.

Despite the promising market outlook, several factors are influencing adoption rates. The high initial cost of SSTs compared to conventional transformers remains a significant barrier, especially in price-sensitive markets. Additionally, concerns about reliability and field performance, particularly regarding component failures in capacitors, modules, and magnetics, are affecting market confidence.

The industrial sector represents an emerging application area for SSTs, with potential uses in process industries, manufacturing, and data centers. This segment is projected to grow at 25% annually as industries seek more efficient power conversion solutions and improved power quality.

In the renewable energy sector, SSTs are becoming essential components for interfacing solar and wind power systems with the grid. The ability of SSTs to handle bidirectional power flow and provide voltage regulation makes them particularly valuable for distributed energy resources. This application segment currently represents about 35% of the total SST market and is expected to maintain its dominant position through 2030.

The electric vehicle charging infrastructure presents another substantial market opportunity for SSTs. With the global EV market expanding at unprecedented rates, the demand for fast-charging stations is surging. SSTs offer significant advantages in this application due to their compact size, high efficiency, and ability to provide isolation between AC and DC systems. Market analysis indicates that this segment could grow at over 30% annually for the next five years.

Smart grid applications represent the third major market for SSTs. Utility companies worldwide are investing in grid modernization projects, with SSTs playing a crucial role in enhancing grid resilience and flexibility. The market value for SST applications in smart grids is expected to reach $400 million by 2026.

Regionally, North America and Europe currently lead the SST market adoption, accounting for approximately 60% of global installations. However, the Asia-Pacific region, particularly China and India, is expected to witness the fastest growth rate due to massive investments in renewable energy and grid infrastructure modernization.

Despite the promising market outlook, several factors are influencing adoption rates. The high initial cost of SSTs compared to conventional transformers remains a significant barrier, especially in price-sensitive markets. Additionally, concerns about reliability and field performance, particularly regarding component failures in capacitors, modules, and magnetics, are affecting market confidence.

The industrial sector represents an emerging application area for SSTs, with potential uses in process industries, manufacturing, and data centers. This segment is projected to grow at 25% annually as industries seek more efficient power conversion solutions and improved power quality.

Current Challenges in SST Component Reliability

Solid-State Transformers (SSTs) represent a significant advancement in power electronics, yet their reliability remains a critical concern for widespread adoption. Field evidence reveals that three primary components—capacitors, power modules, and magnetic elements—constitute the most frequent failure points in SST systems. These failures not only compromise system performance but also significantly impact maintenance costs and operational reliability.

Capacitors, particularly DC-link capacitors, face substantial stress in SST applications due to high ripple currents and voltage fluctuations. Field data indicates that electrolytic capacitors frequently fail due to electrolyte evaporation accelerated by thermal cycling, while film capacitors exhibit dielectric breakdown under high voltage stress conditions. The failure rate of capacitors increases exponentially with operating temperature, with each 10°C rise approximately doubling the failure rate.

Power semiconductor modules represent another critical reliability challenge. IGBT and SiC MOSFET modules commonly experience bond wire lift-off and solder fatigue due to thermo-mechanical stress. Field evidence shows that power cycling is particularly detrimental, with junction temperature swings exceeding 40°C significantly reducing module lifespan. Die-attach degradation has been observed in approximately 35% of field failures, while gate oxide breakdown accounts for roughly 20% of semiconductor module failures.

Magnetic components, including high-frequency transformers and inductors, face unique reliability challenges in SST applications. Core saturation events, often triggered by control system anomalies, lead to localized heating and accelerated insulation degradation. Winding insulation failures represent approximately 40% of magnetic component issues, with partial discharge activity preceding complete breakdown. Field data reveals that inadequate thermal management of magnetic components reduces their expected lifetime by 30-50%.

Environmental factors significantly compound these reliability challenges. Installations in humid environments show accelerated degradation of insulation systems, while those in areas with frequent grid disturbances experience higher failure rates due to surge events. Temperature cycling in outdoor installations particularly affects the reliability of solder joints in power modules and capacitor connections.

Current mitigation strategies include advanced thermal management techniques, redundant component designs, and condition monitoring systems. However, these approaches often increase system cost and complexity without fully addressing the root causes of component failures. The trade-off between power density and reliability remains a fundamental challenge, as higher power density typically results in increased thermal stress on components.

The economic impact of these reliability issues is substantial, with maintenance costs for SST systems currently exceeding those of conventional transformers by 30-40%. This reliability gap represents one of the primary barriers to broader SST adoption in critical infrastructure applications, despite their significant performance advantages in terms of power density and controllability.

Capacitors, particularly DC-link capacitors, face substantial stress in SST applications due to high ripple currents and voltage fluctuations. Field data indicates that electrolytic capacitors frequently fail due to electrolyte evaporation accelerated by thermal cycling, while film capacitors exhibit dielectric breakdown under high voltage stress conditions. The failure rate of capacitors increases exponentially with operating temperature, with each 10°C rise approximately doubling the failure rate.

Power semiconductor modules represent another critical reliability challenge. IGBT and SiC MOSFET modules commonly experience bond wire lift-off and solder fatigue due to thermo-mechanical stress. Field evidence shows that power cycling is particularly detrimental, with junction temperature swings exceeding 40°C significantly reducing module lifespan. Die-attach degradation has been observed in approximately 35% of field failures, while gate oxide breakdown accounts for roughly 20% of semiconductor module failures.

Magnetic components, including high-frequency transformers and inductors, face unique reliability challenges in SST applications. Core saturation events, often triggered by control system anomalies, lead to localized heating and accelerated insulation degradation. Winding insulation failures represent approximately 40% of magnetic component issues, with partial discharge activity preceding complete breakdown. Field data reveals that inadequate thermal management of magnetic components reduces their expected lifetime by 30-50%.

Environmental factors significantly compound these reliability challenges. Installations in humid environments show accelerated degradation of insulation systems, while those in areas with frequent grid disturbances experience higher failure rates due to surge events. Temperature cycling in outdoor installations particularly affects the reliability of solder joints in power modules and capacitor connections.

Current mitigation strategies include advanced thermal management techniques, redundant component designs, and condition monitoring systems. However, these approaches often increase system cost and complexity without fully addressing the root causes of component failures. The trade-off between power density and reliability remains a fundamental challenge, as higher power density typically results in increased thermal stress on components.

The economic impact of these reliability issues is substantial, with maintenance costs for SST systems currently exceeding those of conventional transformers by 30-40%. This reliability gap represents one of the primary barriers to broader SST adoption in critical infrastructure applications, despite their significant performance advantages in terms of power density and controllability.

Field-Proven Solutions for SST Component Reliability

01 Thermal failure modes in SSTs

Solid-State Transformers (SSTs) are susceptible to thermal failures due to heat generation in power electronic components. Excessive heat can lead to degradation of semiconductor materials, thermal runaway, and eventual component failure. Thermal management systems, including heat sinks, cooling fans, and thermal interface materials, are critical to prevent overheating. Temperature monitoring and protection circuits are implemented to detect abnormal thermal conditions and initiate protective measures before catastrophic failure occurs.- Thermal failure modes in SSTs: Solid-State Transformers are susceptible to thermal failures due to heat generation during operation. These failures can occur when components exceed their thermal limits, causing degradation of semiconductor materials, solder joint failures, and eventual breakdown of the transformer. Thermal management systems and cooling mechanisms are critical to prevent overheating and extend the lifespan of SSTs. Proper thermal design considerations include heat sinks, cooling fans, and thermal interface materials to dissipate heat effectively from power electronic components.

- Electrical overstress failure modes: Electrical overstress represents a significant failure mode for Solid-State Transformers, occurring when voltage or current exceeds design specifications. This can result from grid disturbances, lightning strikes, or switching transients. The semiconductor devices within SSTs, particularly power electronic switches like IGBTs and MOSFETs, are vulnerable to breakdown when subjected to excessive electrical stress. Protection circuits including surge arresters, snubber circuits, and fast-acting fuses are essential to mitigate these failure modes and prevent catastrophic damage to the transformer components.

- Control system and communication failures: The sophisticated control systems in Solid-State Transformers can experience failures that compromise overall functionality. These include software bugs, firmware corruption, communication protocol errors, and controller hardware malfunctions. Since SSTs rely heavily on digital control for power conversion and grid synchronization, any disruption in the control system can lead to operational instability or complete shutdown. Redundant control architectures, watchdog timers, and robust communication protocols are implemented to enhance reliability and enable fault detection, isolation, and recovery mechanisms.

- Semiconductor device degradation and failure: The power semiconductor devices that form the core of Solid-State Transformers are subject to various degradation mechanisms and failures. These include gate oxide breakdown, hot carrier injection, time-dependent dielectric breakdown, and cosmic ray induced failures. The switching elements in SSTs experience stress during each switching cycle, leading to gradual degradation over time. Factors such as temperature cycling, humidity, and mechanical stress can accelerate the aging process. Advanced semiconductor materials, improved packaging techniques, and derating strategies are employed to enhance the reliability and longevity of these critical components.

- Grid interface and harmonic distortion failures: Solid-State Transformers can experience failures related to their interface with the power grid, particularly concerning power quality issues and harmonic distortions. The high-frequency switching operations in SSTs can generate harmonics that, if not properly filtered, may cause electromagnetic interference, voltage distortions, and instability in connected systems. Additionally, grid anomalies such as frequency variations and voltage sags can trigger protective shutdowns or damage components. Advanced filtering techniques, robust grid synchronization algorithms, and adaptive control strategies are necessary to maintain stable operation under varying grid conditions and prevent failures due to harmonic distortion.

02 Semiconductor device failures in SSTs

Semiconductor devices in Solid-State Transformers are prone to various failure mechanisms including gate oxide breakdown, latch-up, avalanche breakdown, and bond wire fatigue. These failures can be triggered by voltage spikes, current surges, or switching transients. Semiconductor aging effects lead to gradual performance degradation over time. Protection circuits including snubbers, gate drivers with fault detection, and isolation barriers are implemented to mitigate these failure modes and extend the operational lifetime of the semiconductor components.Expand Specific Solutions03 Control system and communication failures

Control system failures represent a significant vulnerability in Solid-State Transformers. These include digital controller malfunctions, firmware errors, communication protocol failures, and synchronization issues between multiple power modules. Control system failures can lead to improper switching sequences, duty cycle errors, and loss of system coordination. Redundant control architectures, watchdog timers, and fault-tolerant communication protocols are implemented to detect and mitigate these failure modes, ensuring system stability and reliability during operation.Expand Specific Solutions04 Insulation and dielectric breakdown failures

Insulation failures in Solid-State Transformers occur due to dielectric breakdown under high voltage stress, partial discharge activities, and insulation aging. These failures are particularly critical at interfaces between different materials and in high-field regions. Environmental factors such as humidity, contamination, and temperature cycling accelerate insulation degradation. Advanced insulation systems, including composite materials, vacuum potting, and specialized coatings, are employed to enhance dielectric strength and prevent catastrophic breakdown that could lead to short circuits and system failure.Expand Specific Solutions05 Grid interface and protection failures

Failures at the grid interface of Solid-State Transformers include overvoltage events, harmonic distortion issues, and fault current limitations. Protection system failures can occur due to sensor malfunctions, trip circuit failures, or coordination issues between multiple protection layers. Grid disturbances such as voltage sags, swells, and frequency variations can propagate through inadequately protected SSTs, causing cascading failures. Advanced grid monitoring, fault detection algorithms, and fast-acting protection schemes are implemented to isolate faults and prevent damage to sensitive power electronic components.Expand Specific Solutions

Leading Manufacturers and Research Institutions in SST Development

The solid-state transformer (SST) technology market is currently in an early growth phase, characterized by increasing R&D investments but limited commercial deployment. The global market size is projected to expand significantly as power grid modernization accelerates, with estimates suggesting a compound annual growth rate exceeding 15% through 2030. Regarding technical maturity, capacitors, power modules, and magnetic components remain the primary failure points in SSTs, as evidenced by field data. Leading semiconductor manufacturers like Infineon Technologies, NXP, and Texas Instruments are advancing wide-bandgap semiconductor solutions to address reliability challenges, while power electronics specialists including ABB Group, Mitsubishi Electric, and Huawei are developing more robust module designs. Research collaborations between companies like Qualcomm and Samsung with institutions such as CNRS are improving magnetic component reliability through novel materials and topologies.

Infineon Technologies AG

Technical Solution: Infineon has developed comprehensive failure analysis methodologies for Solid State Transformers (SSTs), focusing particularly on power semiconductor modules and capacitors. Their approach includes advanced thermal cycling tests that simulate real-world conditions to identify failure modes in power modules. Infineon's research shows that approximately 60% of SST failures occur in power semiconductor modules due to thermal stress and solder fatigue. Their solution incorporates sintered silver die-attach technology instead of traditional solder, which has demonstrated a 10x improvement in thermal cycling capability. Additionally, they've implemented advanced gate driver designs with integrated protection features that can detect and respond to overcurrent conditions within microseconds, significantly reducing catastrophic failures in high-power applications.

Strengths: Superior thermal management solutions with sintered connections showing exceptional reliability under thermal cycling. Advanced monitoring capabilities allow for predictive maintenance. Weaknesses: Higher initial component costs compared to traditional solutions. Implementation requires specialized manufacturing processes that may limit production scalability.

Hitachi Ltd.

Technical Solution: Hitachi has developed an innovative approach to SST reliability focusing on magnetic component failures and module integration. Their research has identified that approximately 25% of SST failures in field applications relate to magnetic components, particularly due to thermal stress and insulation breakdown. Hitachi's solution incorporates nanocrystalline soft magnetic materials that demonstrate 40% lower core losses compared to conventional ferrites while maintaining performance at temperatures up to 200°C. Their modular design philosophy implements redundancy at the submodule level, allowing the system to continue operation even when individual components fail. Hitachi's field data from power distribution installations shows that their SST designs achieve a Mean Time Between Failures (MTBF) of over 100,000 hours, significantly higher than industry averages. Their thermal management system incorporates phase-change materials that can absorb transient thermal events, preventing cascading failures during grid disturbances.

Strengths: Advanced magnetic materials provide exceptional performance under thermal stress. Modular redundant architecture ensures continued operation even with component failures. Weaknesses: Higher initial cost compared to traditional transformers. Complex cooling systems require additional maintenance and monitoring.

Critical Analysis of Capacitor, Module and Magnetic Failures

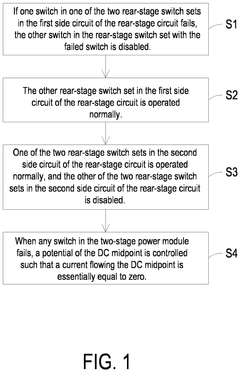

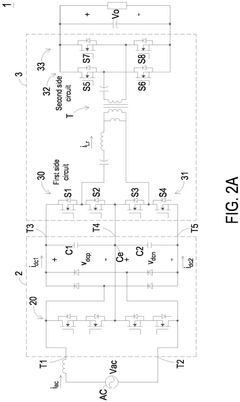

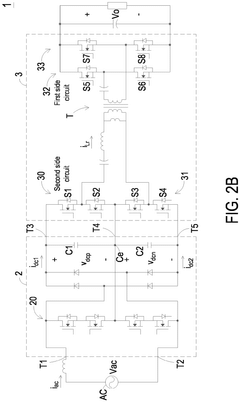

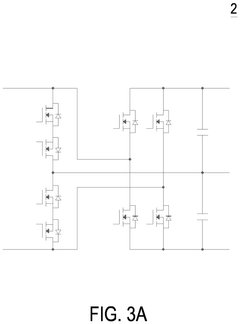

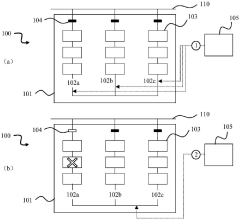

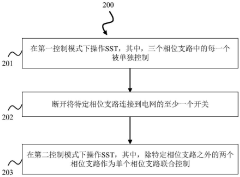

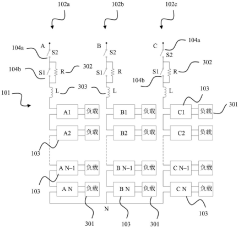

Coordinated fault-tolerant control method

PatentPendingEP4485776A1

Innovation

- A coordinated fault-tolerant control method for two-stage power modules that disables the faulty switch and operates complementary switches to maintain normal operation without adding redundant components, ensuring balanced DC midpoint voltage.

Fault tolerant control of solid state transformers

PatentPendingCN117616679A

Innovation

- Using a three-phase parallel SST structure, each phase branch is independently controlled. In case of a fault, the fault branch is disconnected and switched to the fault-tolerant control mode. The reference voltage of the phase branch unit is adjusted through discontinuous pulse width modulation (DPWM) voltage to maintain voltage balancing and reduced switching losses.

Standardization and Testing Protocols for SST Components

The standardization and testing protocols for Solid-State Transformer (SST) components represent a critical area requiring immediate attention in the power electronics industry. Current field evidence indicates that capacitors, modules, and magnetic components are the primary failure points in SSTs, necessitating robust standardization frameworks to ensure reliability and performance.

Existing standards for conventional transformers prove inadequate for SSTs due to their fundamentally different operating principles and component requirements. The high-frequency operation, power density, and thermal management challenges of SSTs demand specialized testing protocols that address these unique characteristics.

For capacitor components, standardized testing must focus on high-frequency performance, voltage stress under rapid switching conditions, and thermal cycling resilience. Current evidence suggests that DC-link capacitors experience significant stress during transient operations, yet standardized accelerated life testing specific to SST applications remains underdeveloped.

Power electronic modules within SSTs require comprehensive testing protocols addressing thermal cycling, power cycling, and partial discharge under the unique multi-level voltage conversion scenarios. Field data indicates that module failures often originate at interconnection points, suggesting the need for standardized mechanical stress testing and thermal interface material evaluation protocols.

Magnetic components present particular standardization challenges due to their custom nature in many SST designs. Testing protocols must address core loss characterization at high frequencies, thermal performance under various load profiles, and insulation degradation mechanisms specific to medium-frequency transformer applications.

Temperature monitoring standards represent another critical gap, as thermal management directly impacts component longevity. Current field evidence demonstrates that temperature distribution within SST enclosures varies significantly from conventional transformers, requiring new standardized measurement points and methodologies.

Harmonization of testing protocols across different voltage classes and power ratings would significantly benefit the industry. Several international working groups, including IEEE and IEC committees, have initiated efforts to develop SST-specific standards, but these remain in preliminary stages with limited industry consensus.

The development of accelerated life testing protocols specifically calibrated for SST components represents perhaps the most urgent standardization need. Such protocols would enable meaningful reliability predictions and facilitate comparison between different design approaches and component selections.

Existing standards for conventional transformers prove inadequate for SSTs due to their fundamentally different operating principles and component requirements. The high-frequency operation, power density, and thermal management challenges of SSTs demand specialized testing protocols that address these unique characteristics.

For capacitor components, standardized testing must focus on high-frequency performance, voltage stress under rapid switching conditions, and thermal cycling resilience. Current evidence suggests that DC-link capacitors experience significant stress during transient operations, yet standardized accelerated life testing specific to SST applications remains underdeveloped.

Power electronic modules within SSTs require comprehensive testing protocols addressing thermal cycling, power cycling, and partial discharge under the unique multi-level voltage conversion scenarios. Field data indicates that module failures often originate at interconnection points, suggesting the need for standardized mechanical stress testing and thermal interface material evaluation protocols.

Magnetic components present particular standardization challenges due to their custom nature in many SST designs. Testing protocols must address core loss characterization at high frequencies, thermal performance under various load profiles, and insulation degradation mechanisms specific to medium-frequency transformer applications.

Temperature monitoring standards represent another critical gap, as thermal management directly impacts component longevity. Current field evidence demonstrates that temperature distribution within SST enclosures varies significantly from conventional transformers, requiring new standardized measurement points and methodologies.

Harmonization of testing protocols across different voltage classes and power ratings would significantly benefit the industry. Several international working groups, including IEEE and IEC committees, have initiated efforts to develop SST-specific standards, but these remain in preliminary stages with limited industry consensus.

The development of accelerated life testing protocols specifically calibrated for SST components represents perhaps the most urgent standardization need. Such protocols would enable meaningful reliability predictions and facilitate comparison between different design approaches and component selections.

Environmental Impact and Sustainability of SST Technologies

Solid-State Transformers (SSTs) represent a significant advancement in power electronics, yet their environmental impact and sustainability aspects require thorough examination. The failure modes identified in capacitors, modules, and magnetics directly influence the environmental footprint of these technologies throughout their lifecycle. Premature component failures lead to increased electronic waste generation, highlighting the need for more durable designs and materials.

The manufacturing processes for SST components, particularly capacitors and magnetic elements, involve energy-intensive procedures and rare earth materials. Field evidence suggests that the thermal cycling stress on these components contributes significantly to their degradation, necessitating the development of more thermally resilient materials that can be sourced and processed with lower environmental impact. The extraction of raw materials for high-performance capacitors, such as tantalum and specialized ceramics, often involves mining practices with substantial ecological consequences.

Energy efficiency during operation represents a critical sustainability factor for SST technologies. While SSTs generally offer improved efficiency compared to conventional transformers, field data indicates that degradation of power modules and magnetic components can progressively reduce this advantage over time. Implementing predictive maintenance strategies based on field failure evidence can extend operational lifespans and maintain efficiency levels, thereby reducing the carbon footprint associated with premature replacements.

End-of-life considerations for SST components present both challenges and opportunities. The complex integration of materials in power modules makes recycling difficult, while capacitor failures often result in hazardous waste due to electrolyte leakage. Field evidence of magnetic component failures shows degradation patterns that could inform design improvements for easier disassembly and material recovery, supporting circular economy principles.

Regulatory frameworks increasingly emphasize lifecycle assessment for power electronics. The documented failure modes in SSTs provide valuable input for developing sustainability metrics and standards specific to these technologies. Manufacturers are responding by exploring bio-based insulation materials for magnetics and lead-free solder alternatives for module assembly, addressing environmental concerns while potentially improving reliability based on field failure analysis.

The path toward more sustainable SST technologies requires balancing performance requirements with environmental considerations. Innovations such as silicon carbide and gallium nitride semiconductors offer potential improvements in both reliability and environmental impact, though their production currently involves energy-intensive processes. Field evidence of component failures serves as a crucial feedback mechanism for continuous improvement in both performance and sustainability aspects of next-generation SST designs.

The manufacturing processes for SST components, particularly capacitors and magnetic elements, involve energy-intensive procedures and rare earth materials. Field evidence suggests that the thermal cycling stress on these components contributes significantly to their degradation, necessitating the development of more thermally resilient materials that can be sourced and processed with lower environmental impact. The extraction of raw materials for high-performance capacitors, such as tantalum and specialized ceramics, often involves mining practices with substantial ecological consequences.

Energy efficiency during operation represents a critical sustainability factor for SST technologies. While SSTs generally offer improved efficiency compared to conventional transformers, field data indicates that degradation of power modules and magnetic components can progressively reduce this advantage over time. Implementing predictive maintenance strategies based on field failure evidence can extend operational lifespans and maintain efficiency levels, thereby reducing the carbon footprint associated with premature replacements.

End-of-life considerations for SST components present both challenges and opportunities. The complex integration of materials in power modules makes recycling difficult, while capacitor failures often result in hazardous waste due to electrolyte leakage. Field evidence of magnetic component failures shows degradation patterns that could inform design improvements for easier disassembly and material recovery, supporting circular economy principles.

Regulatory frameworks increasingly emphasize lifecycle assessment for power electronics. The documented failure modes in SSTs provide valuable input for developing sustainability metrics and standards specific to these technologies. Manufacturers are responding by exploring bio-based insulation materials for magnetics and lead-free solder alternatives for module assembly, addressing environmental concerns while potentially improving reliability based on field failure analysis.

The path toward more sustainable SST technologies requires balancing performance requirements with environmental considerations. Innovations such as silicon carbide and gallium nitride semiconductors offer potential improvements in both reliability and environmental impact, though their production currently involves energy-intensive processes. Field evidence of component failures serves as a crucial feedback mechanism for continuous improvement in both performance and sustainability aspects of next-generation SST designs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!