Deep Eutectic Solvents For Nanomaterials: Size Control, Surface Passivation And Purification

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DES Nanomaterial Technology Background and Objectives

Deep Eutectic Solvents (DES) have emerged as a revolutionary class of green solvents that offer significant advantages over conventional ionic liquids and organic solvents in nanomaterial synthesis. The development of DES technology can be traced back to the early 2000s, when researchers began exploring alternatives to traditional solvents that presented environmental concerns and processing limitations. Since then, DES have gained substantial attention due to their biodegradability, low toxicity, cost-effectiveness, and tunable physicochemical properties.

The evolution of DES in nanomaterial applications has progressed through several key phases. Initially, these solvents were primarily investigated as reaction media for chemical processes. By the 2010s, researchers recognized their potential in nanomaterial synthesis, particularly for metal nanoparticles. Recent years have witnessed an expansion into more complex nanomaterials including quantum dots, metal oxides, and carbon-based nanomaterials, with increasing focus on precise size control, surface functionalization, and purification processes.

Current technological trends indicate a growing emphasis on developing DES systems specifically optimized for nanomaterial applications. This includes the design of DES compositions that can simultaneously act as solvents, reducing agents, and stabilizers in one-pot synthesis approaches. Additionally, there is increasing interest in understanding the fundamental interactions between DES components and nanomaterial surfaces, which govern critical aspects such as size distribution, morphology, and colloidal stability.

The primary technical objectives in this field include developing reproducible methodologies for precise size control of nanomaterials using DES, which remains challenging due to the complex interplay of multiple parameters. Another critical goal is establishing effective surface passivation strategies that leverage the unique chemical environment provided by DES to enhance nanomaterial stability and functionality. Furthermore, researchers aim to develop efficient purification protocols that maintain the integrity of nanomaterials while removing excess reagents and byproducts.

Long-term technological goals include the integration of DES-based nanomaterial synthesis into continuous flow processes for industrial-scale production, the development of predictive models for nanomaterial behavior in various DES environments, and the creation of standardized protocols that ensure consistent quality across different batches and production facilities. These advancements would significantly impact multiple sectors including electronics, energy storage, catalysis, and biomedical applications.

The intersection of DES technology with nanomaterial science represents a promising frontier with potential to address key sustainability challenges in advanced materials manufacturing while enabling novel material properties through precise structural control at the nanoscale.

The evolution of DES in nanomaterial applications has progressed through several key phases. Initially, these solvents were primarily investigated as reaction media for chemical processes. By the 2010s, researchers recognized their potential in nanomaterial synthesis, particularly for metal nanoparticles. Recent years have witnessed an expansion into more complex nanomaterials including quantum dots, metal oxides, and carbon-based nanomaterials, with increasing focus on precise size control, surface functionalization, and purification processes.

Current technological trends indicate a growing emphasis on developing DES systems specifically optimized for nanomaterial applications. This includes the design of DES compositions that can simultaneously act as solvents, reducing agents, and stabilizers in one-pot synthesis approaches. Additionally, there is increasing interest in understanding the fundamental interactions between DES components and nanomaterial surfaces, which govern critical aspects such as size distribution, morphology, and colloidal stability.

The primary technical objectives in this field include developing reproducible methodologies for precise size control of nanomaterials using DES, which remains challenging due to the complex interplay of multiple parameters. Another critical goal is establishing effective surface passivation strategies that leverage the unique chemical environment provided by DES to enhance nanomaterial stability and functionality. Furthermore, researchers aim to develop efficient purification protocols that maintain the integrity of nanomaterials while removing excess reagents and byproducts.

Long-term technological goals include the integration of DES-based nanomaterial synthesis into continuous flow processes for industrial-scale production, the development of predictive models for nanomaterial behavior in various DES environments, and the creation of standardized protocols that ensure consistent quality across different batches and production facilities. These advancements would significantly impact multiple sectors including electronics, energy storage, catalysis, and biomedical applications.

The intersection of DES technology with nanomaterial science represents a promising frontier with potential to address key sustainability challenges in advanced materials manufacturing while enabling novel material properties through precise structural control at the nanoscale.

Market Analysis for DES in Nanomaterial Processing

The global market for Deep Eutectic Solvents (DES) in nanomaterial processing is experiencing significant growth, driven by increasing demand for sustainable and efficient methods in nanomaterial synthesis. Current market valuation stands at approximately $1.2 billion, with projections indicating a compound annual growth rate of 8.7% through 2028, potentially reaching $1.8 billion by that time.

The electronics and semiconductor industry represents the largest market segment, accounting for nearly 35% of DES applications in nanomaterial processing. This dominance stems from the critical need for precise size control and high purity in nanomaterials used for advanced electronic components. The ability of DES to facilitate controlled synthesis of quantum dots and other semiconductor nanoparticles has positioned it as a preferred method among manufacturers seeking to enhance product performance.

Pharmaceutical and biomedical applications constitute the second-largest market segment at 28%, where DES-processed nanomaterials are increasingly utilized in drug delivery systems, diagnostic tools, and therapeutic applications. The biocompatibility of many DES formulations has accelerated adoption in this sector, particularly for applications requiring surface-passivated nanoparticles with specific biological interactions.

Regional analysis reveals that North America currently leads the market with a 38% share, followed by Europe (32%) and Asia-Pacific (25%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 10.3% annually, primarily driven by expanding manufacturing capabilities in China, South Korea, and India, coupled with increasing government investments in nanotechnology research.

Market penetration analysis indicates that DES technology has achieved approximately 15% adoption among potential end-users, suggesting substantial room for growth. The primary barriers to wider adoption include limited awareness of DES capabilities among potential users, initial investment costs for transitioning from conventional solvents, and the need for specialized expertise in DES formulation optimization.

Customer segmentation reveals three distinct market tiers: large-scale industrial manufacturers seeking cost-effective and environmentally friendly processing methods; research institutions and specialty manufacturers requiring precise control over nanomaterial properties; and emerging startups focused on innovative nanomaterial applications. Each segment presents unique requirements and growth opportunities for DES technology providers.

Competitive landscape assessment identifies increasing competition from alternative green solvents and processing methods, including supercritical fluids and ionic liquids. However, DES maintains competitive advantages in terms of cost-effectiveness, ease of preparation, and versatility across different nanomaterial types, particularly for applications requiring specific size control and surface functionalization capabilities.

The electronics and semiconductor industry represents the largest market segment, accounting for nearly 35% of DES applications in nanomaterial processing. This dominance stems from the critical need for precise size control and high purity in nanomaterials used for advanced electronic components. The ability of DES to facilitate controlled synthesis of quantum dots and other semiconductor nanoparticles has positioned it as a preferred method among manufacturers seeking to enhance product performance.

Pharmaceutical and biomedical applications constitute the second-largest market segment at 28%, where DES-processed nanomaterials are increasingly utilized in drug delivery systems, diagnostic tools, and therapeutic applications. The biocompatibility of many DES formulations has accelerated adoption in this sector, particularly for applications requiring surface-passivated nanoparticles with specific biological interactions.

Regional analysis reveals that North America currently leads the market with a 38% share, followed by Europe (32%) and Asia-Pacific (25%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 10.3% annually, primarily driven by expanding manufacturing capabilities in China, South Korea, and India, coupled with increasing government investments in nanotechnology research.

Market penetration analysis indicates that DES technology has achieved approximately 15% adoption among potential end-users, suggesting substantial room for growth. The primary barriers to wider adoption include limited awareness of DES capabilities among potential users, initial investment costs for transitioning from conventional solvents, and the need for specialized expertise in DES formulation optimization.

Customer segmentation reveals three distinct market tiers: large-scale industrial manufacturers seeking cost-effective and environmentally friendly processing methods; research institutions and specialty manufacturers requiring precise control over nanomaterial properties; and emerging startups focused on innovative nanomaterial applications. Each segment presents unique requirements and growth opportunities for DES technology providers.

Competitive landscape assessment identifies increasing competition from alternative green solvents and processing methods, including supercritical fluids and ionic liquids. However, DES maintains competitive advantages in terms of cost-effectiveness, ease of preparation, and versatility across different nanomaterial types, particularly for applications requiring specific size control and surface functionalization capabilities.

Current Challenges in DES Nanomaterial Synthesis

Despite the promising potential of Deep Eutectic Solvents (DES) in nanomaterial synthesis, several significant challenges currently impede their widespread industrial adoption and optimization. The primary challenge lies in achieving precise size control during nanomaterial synthesis. While DES environments offer unique solvation properties, maintaining consistent particle size distributions remains difficult due to the complex interplay between DES components, precursors, and reaction conditions. Temperature fluctuations within DES systems can dramatically alter viscosity profiles, leading to unpredictable nucleation and growth kinetics.

Surface passivation presents another substantial hurdle in DES-based nanomaterial production. The interaction between DES components and nanomaterial surfaces often results in unpredictable surface chemistry, affecting stability and functional properties. Current passivation techniques developed for conventional solvents frequently prove ineffective or require significant modification when applied to DES environments, necessitating novel approaches specifically tailored to these unique solvent systems.

Purification processes for DES-synthesized nanomaterials remain underdeveloped compared to traditional methods. The high viscosity of many DES formulations complicates conventional separation techniques such as centrifugation and filtration. Additionally, the strong interactions between DES components and nanomaterial surfaces often result in residual solvent contamination that proves difficult to remove without compromising nanomaterial integrity or morphology.

Scalability represents a critical limitation in current DES nanomaterial synthesis approaches. Laboratory-scale processes often fail to translate effectively to industrial production volumes due to heat transfer limitations, mixing inefficiencies, and challenges in maintaining homogeneous reaction conditions throughout larger reaction vessels. These scaling issues directly impact product consistency and economic viability.

Characterization methodologies for nanomaterials within DES environments remain inadequate. Traditional analytical techniques frequently require sample preparation steps that alter the native state of nanomaterials in DES media, potentially leading to misleading results. In-situ characterization tools specifically designed for DES systems are largely absent from the current technological landscape.

Reproducibility concerns persist across different DES formulations and synthesis protocols. The sensitivity of nanomaterial outcomes to subtle variations in DES composition, water content, and preparation methods creates significant barriers to standardization. This variability hampers both fundamental research progress and commercial implementation efforts.

Environmental and toxicological assessments of DES-nanomaterial systems remain incomplete, creating uncertainty regarding their long-term sustainability and safety profiles. While DES are often promoted as "green" alternatives, comprehensive lifecycle analyses and toxicity studies for specific DES-nanomaterial combinations are still lacking in the scientific literature.

Surface passivation presents another substantial hurdle in DES-based nanomaterial production. The interaction between DES components and nanomaterial surfaces often results in unpredictable surface chemistry, affecting stability and functional properties. Current passivation techniques developed for conventional solvents frequently prove ineffective or require significant modification when applied to DES environments, necessitating novel approaches specifically tailored to these unique solvent systems.

Purification processes for DES-synthesized nanomaterials remain underdeveloped compared to traditional methods. The high viscosity of many DES formulations complicates conventional separation techniques such as centrifugation and filtration. Additionally, the strong interactions between DES components and nanomaterial surfaces often result in residual solvent contamination that proves difficult to remove without compromising nanomaterial integrity or morphology.

Scalability represents a critical limitation in current DES nanomaterial synthesis approaches. Laboratory-scale processes often fail to translate effectively to industrial production volumes due to heat transfer limitations, mixing inefficiencies, and challenges in maintaining homogeneous reaction conditions throughout larger reaction vessels. These scaling issues directly impact product consistency and economic viability.

Characterization methodologies for nanomaterials within DES environments remain inadequate. Traditional analytical techniques frequently require sample preparation steps that alter the native state of nanomaterials in DES media, potentially leading to misleading results. In-situ characterization tools specifically designed for DES systems are largely absent from the current technological landscape.

Reproducibility concerns persist across different DES formulations and synthesis protocols. The sensitivity of nanomaterial outcomes to subtle variations in DES composition, water content, and preparation methods creates significant barriers to standardization. This variability hampers both fundamental research progress and commercial implementation efforts.

Environmental and toxicological assessments of DES-nanomaterial systems remain incomplete, creating uncertainty regarding their long-term sustainability and safety profiles. While DES are often promoted as "green" alternatives, comprehensive lifecycle analyses and toxicity studies for specific DES-nanomaterial combinations are still lacking in the scientific literature.

Current DES Methods for Size Control and Purification

01 DES for nanomaterial size control

Deep Eutectic Solvents (DES) can be effectively used to control the size of nanomaterials during synthesis. The unique properties of DES, including their tunable viscosity and polarity, allow for precise manipulation of nucleation and growth processes. By adjusting the composition and ratio of DES components, researchers can achieve nanomaterials with uniform size distribution and desired dimensions. This approach offers advantages over conventional solvents in terms of reproducibility and fine control over particle morphology.- DES for nanomaterial size control: Deep Eutectic Solvents (DES) can be effectively used to control the size of nanomaterials during synthesis. The unique properties of DES, including their tunable viscosity and polarity, allow for precise manipulation of nucleation and growth processes. By adjusting the composition and ratio of DES components, researchers can achieve nanomaterials with uniform size distribution and desired dimensions. This approach offers advantages over conventional solvents in terms of reproducibility and fine control over particle morphology.

- Surface passivation of nanomaterials using DES: Deep Eutectic Solvents serve as effective media for surface passivation of nanomaterials, which is crucial for preventing agglomeration and enhancing stability. The hydrogen bonding network in DES can interact with the surface of nanomaterials, creating a protective layer that prevents oxidation and unwanted reactions. This passivation technique improves the optical, electronic, and catalytic properties of nanomaterials while extending their shelf life. The environmentally friendly nature of DES makes this approach particularly attractive for sustainable nanomaterial production.

- DES-based purification methods for nanomaterials: Deep Eutectic Solvents offer innovative approaches for the purification of nanomaterials, effectively removing impurities and byproducts from synthesis processes. The selective solubility properties of DES enable separation of nanomaterials from reaction mixtures through processes such as extraction, precipitation, or phase separation. This purification technique can be performed under mild conditions, preserving the structural integrity and properties of the nanomaterials. The recyclability of DES further enhances the sustainability of these purification methods.

- Novel DES compositions for nanomaterial processing: Innovative Deep Eutectic Solvent compositions have been developed specifically for nanomaterial processing applications. These novel DES formulations combine hydrogen bond donors and acceptors in optimal ratios to achieve desired physicochemical properties such as conductivity, viscosity, and thermal stability. Some compositions incorporate additives that enhance specific interactions with nanomaterial surfaces or precursors. These tailored DES systems enable more efficient synthesis, functionalization, and processing of nanomaterials while reducing environmental impact compared to conventional organic solvents.

- Green synthesis of nanomaterials using DES: Deep Eutectic Solvents enable environmentally friendly synthesis routes for nanomaterials, aligning with green chemistry principles. These solvents can act as both reaction media and templating agents, facilitating the formation of nanomaterials with controlled properties. The biodegradability and low toxicity of many DES components reduce environmental concerns associated with nanomaterial production. Additionally, DES-based synthesis often operates at moderate temperatures and pressures, reducing energy consumption. This approach represents a sustainable alternative to conventional methods that rely on hazardous solvents and harsh reaction conditions.

02 Surface passivation of nanomaterials using DES

Deep Eutectic Solvents serve as effective media for surface passivation of nanomaterials, preventing agglomeration and enhancing stability. The hydrogen bonding network in DES can interact with the surface of nanomaterials, creating a protective layer that reduces surface energy and prevents undesired reactions. This passivation technique improves the optical, electronic, and catalytic properties of nanomaterials by eliminating surface defects and dangling bonds. The environmentally friendly nature of DES makes this approach particularly attractive for sustainable nanomaterial production.Expand Specific Solutions03 DES-based purification methods for nanomaterials

Deep Eutectic Solvents offer innovative approaches for the purification of nanomaterials, providing alternatives to conventional solvent-based methods. The selective solubility properties of DES enable efficient separation of nanomaterials from reaction byproducts and impurities. This purification technique can be performed under mild conditions, preserving the structural integrity and properties of the nanomaterials. Additionally, the recyclability of DES contributes to the development of sustainable purification processes with reduced environmental impact.Expand Specific Solutions04 Green synthesis of nanomaterials using DES

Deep Eutectic Solvents provide an environmentally friendly platform for the green synthesis of nanomaterials. As alternatives to toxic organic solvents, DES can act as both reaction media and stabilizing agents in nanomaterial synthesis. Their biodegradability, low volatility, and non-toxicity align with sustainable chemistry principles. The synthesis processes using DES typically require lower energy inputs and generate fewer hazardous byproducts. Furthermore, the biocompatibility of many DES compositions makes the resulting nanomaterials suitable for biomedical applications.Expand Specific Solutions05 Functionalization of nanomaterials in DES systems

Deep Eutectic Solvents facilitate the functionalization of nanomaterials with various organic and inorganic moieties, enhancing their application-specific properties. The unique solvation environment provided by DES enables efficient surface modification reactions under mild conditions. This approach allows for the introduction of functional groups that can improve the dispersibility, biocompatibility, or catalytic activity of nanomaterials. The versatility of DES compositions permits tailored functionalization strategies for different types of nanomaterials, including metal nanoparticles, quantum dots, and carbon-based nanomaterials.Expand Specific Solutions

Key Industry Players in DES Nanomaterial Development

The Deep Eutectic Solvents (DES) for nanomaterials market is in an early growth phase, characterized by increasing research activities but limited commercial applications. The global market size is estimated to be relatively small but growing rapidly as nanomaterial applications expand across industries. Technologically, DES applications for nanomaterial synthesis are still developing, with academic institutions leading research efforts. Key players include research-focused organizations like Université du Littoral Côte d'Opale, VTT, and King Abdullah University of Science & Technology, alongside commercial entities such as Saudi Aramco, LG Chem, and Givaudan that are exploring industrial applications. The technology shows promise but requires further development for size control, surface passivation, and purification processes to achieve widespread commercial adoption in nanomaterial manufacturing.

Teknologian Tutkimuskeskus VTT Oy

Technical Solution: Teknologian Tutkimuskeskus VTT Oy has developed an innovative DES-based platform for industrial-scale nanomaterial production. Their approach utilizes renewable-sourced DES components derived from forest industry byproducts combined with choline-based ionic compounds to create sustainable reaction media. VTT researchers have demonstrated precise control over metal oxide nanoparticle size (10-100 nm) by manipulating DES viscosity and hydrogen bonding networks. Their technology employs continuous flow reactors with in-situ monitoring capabilities to ensure consistent nanomaterial quality during scaled production. For surface passivation, VTT has developed bio-based DES formulations containing polyphenolic compounds that form stable protective layers on nanomaterial surfaces, enhancing colloidal stability while providing antioxidant properties. Their purification strategy utilizes membrane filtration techniques optimized for DES media, achieving efficient separation of nanomaterials from reaction byproducts while enabling DES recycling for subsequent synthesis cycles, with recovery rates exceeding 90%.

Strengths: Highly sustainable approach using bio-based DES components; excellent scalability potential for industrial applications; integrated recycling protocols for minimal environmental impact. Weaknesses: Some bio-based DES systems show batch-to-batch variability; potential challenges in achieving ultra-small nanoparticle sizes (<5 nm); limited compatibility with certain noble metal nanomaterials.

University of Minho

Technical Solution: University of Minho has developed specialized DES systems for nanomaterial synthesis and processing with a focus on biocompatible applications. Their approach utilizes natural deep eutectic solvents (NADES) derived from primary metabolites like organic acids, sugars, and amino acids to create environmentally benign reaction media. University researchers have demonstrated precise control over gold and silver nanoparticle size (5-50 nm) through manipulation of NADES composition and reaction kinetics. Their technology employs ultrasonic-assisted synthesis in NADES media to enhance nucleation control and reduce reaction times. For surface passivation, they've pioneered biomolecule-containing NADES that form biocompatible coatings on nanomaterial surfaces, enhancing stability while enabling targeted biological interactions. Their purification methodology utilizes selective precipitation combined with bioaffinity techniques in NADES media, achieving separation efficiencies exceeding 95% while maintaining biocompatibility of the final nanomaterial products.

Strengths: Exceptional biocompatibility of both the synthesis process and resulting nanomaterials; highly sustainable approach using renewable resources; excellent stability of nanomaterials in biological media. Weaknesses: Some NADES systems show limited thermal stability; potential challenges in achieving precise size control for certain semiconductor nanomaterials; higher production costs compared to conventional synthetic methods.

Core Patents in DES-Nanomaterial Interface Engineering

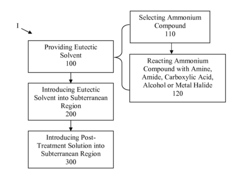

Deep eutectic solvents and applications

PatentInactiveUS20110207633A1

Innovation

- The use of deep eutectic solvents, specifically formed by reacting quaternary ammonium compounds with hydrogen bond donors such as amides, carboxylic acids, and alcohols, to solubilize up to 30 wt% cellulosic material, allowing for their removal from subterranean regions, and these solvents are introduced as additives in drilling or fracturing fluids.

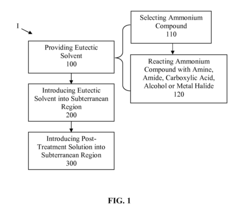

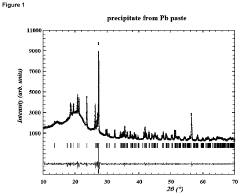

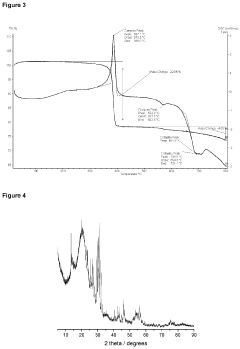

Recycling of lead- and tin-based materials

PatentActiveUS20210317001A1

Innovation

- A low-energy and low-pollution chemical method using a deep eutectic solvent and a compound with a carboxylic acid moiety to precipitate lead and tin carboxylates from lead- and tin-based materials, allowing for the extraction and recycling of lead and tin with reduced environmental impact.

Environmental Impact and Green Chemistry Aspects

Deep Eutectic Solvents (DES) represent a significant advancement in green chemistry principles when applied to nanomaterial synthesis and processing. These solvents offer substantial environmental benefits compared to conventional organic solvents, primarily due to their biodegradability, low toxicity, and minimal vapor pressure. The environmental footprint of DES-based nanomaterial production is markedly reduced, as these solvents can be derived from renewable, bio-based sources rather than petroleum-based feedstocks.

The life cycle assessment of DES in nanomaterial applications demonstrates considerable advantages in terms of reduced carbon emissions and energy consumption. Studies indicate that DES-mediated synthesis routes can decrease energy requirements by 30-45% compared to traditional solvent-based methods, particularly in the size control and purification stages of nanomaterial production.

Water consumption represents another critical environmental parameter where DES excel. The high solvation capacity of DES often eliminates or significantly reduces the need for additional water in purification processes. This aspect is particularly valuable in regions facing water scarcity challenges, where sustainable manufacturing practices are increasingly prioritized.

The principles of green chemistry are fundamentally embedded in DES applications for nanomaterials. These solvents address several of the twelve principles of green chemistry, including waste prevention, atom economy, and safer solvent selection. The ability of DES to function effectively at ambient temperatures further reduces energy demands, aligning with the energy efficiency principle of green chemistry.

Regulatory frameworks worldwide are increasingly recognizing DES as preferred alternatives in sustainable chemical processes. The European Union's REACH regulation and similar initiatives in North America and Asia have begun incorporating provisions that favor green solvents like DES, potentially accelerating their industrial adoption for nanomaterial applications.

The recyclability of DES presents another significant environmental advantage. Research demonstrates that many DES systems can be recovered and reused multiple times without significant loss of efficacy in nanomaterial synthesis and purification processes. This characteristic substantially reduces waste generation and resource consumption in industrial applications.

Biodegradation studies of DES components after their use in nanomaterial processing show promising results, with many common DES systems exhibiting complete degradation under environmental conditions within acceptable timeframes. This biodegradability ensures that any potential environmental release poses minimal long-term ecological risk compared to persistent conventional solvents.

The life cycle assessment of DES in nanomaterial applications demonstrates considerable advantages in terms of reduced carbon emissions and energy consumption. Studies indicate that DES-mediated synthesis routes can decrease energy requirements by 30-45% compared to traditional solvent-based methods, particularly in the size control and purification stages of nanomaterial production.

Water consumption represents another critical environmental parameter where DES excel. The high solvation capacity of DES often eliminates or significantly reduces the need for additional water in purification processes. This aspect is particularly valuable in regions facing water scarcity challenges, where sustainable manufacturing practices are increasingly prioritized.

The principles of green chemistry are fundamentally embedded in DES applications for nanomaterials. These solvents address several of the twelve principles of green chemistry, including waste prevention, atom economy, and safer solvent selection. The ability of DES to function effectively at ambient temperatures further reduces energy demands, aligning with the energy efficiency principle of green chemistry.

Regulatory frameworks worldwide are increasingly recognizing DES as preferred alternatives in sustainable chemical processes. The European Union's REACH regulation and similar initiatives in North America and Asia have begun incorporating provisions that favor green solvents like DES, potentially accelerating their industrial adoption for nanomaterial applications.

The recyclability of DES presents another significant environmental advantage. Research demonstrates that many DES systems can be recovered and reused multiple times without significant loss of efficacy in nanomaterial synthesis and purification processes. This characteristic substantially reduces waste generation and resource consumption in industrial applications.

Biodegradation studies of DES components after their use in nanomaterial processing show promising results, with many common DES systems exhibiting complete degradation under environmental conditions within acceptable timeframes. This biodegradability ensures that any potential environmental release poses minimal long-term ecological risk compared to persistent conventional solvents.

Scalability and Industrial Implementation Pathways

The scalability of Deep Eutectic Solvents (DES) for nanomaterial production represents a critical consideration for transitioning from laboratory-scale synthesis to industrial implementation. Current laboratory protocols typically produce nanomaterials in milligram to gram quantities, whereas industrial applications demand kilogram to ton-scale production. The inherent advantages of DES systems—including low volatility, thermal stability, and recyclability—position them favorably for large-scale operations compared to conventional solvents.

Several engineering approaches have emerged to facilitate industrial scaling of DES-based nanomaterial synthesis. Continuous flow reactors offer significant promise by enabling consistent reaction conditions and reducing batch-to-batch variations. These systems allow for precise control over residence time, temperature gradients, and mixing parameters—all crucial factors for maintaining nanomaterial size uniformity during scale-up. Preliminary studies demonstrate that flow chemistry approaches can increase production rates by 10-15 times while maintaining quality parameters.

Microreactor technology represents another viable implementation pathway, particularly for nanomaterials requiring precise size control. These systems leverage enhanced mass and heat transfer characteristics to maintain reaction homogeneity at larger scales. Industrial partners have reported successful scale-up factors of 50-100x using microreactor arrays while preserving nanomaterial quality metrics.

Economic considerations also drive implementation strategies. Cost analyses indicate that DES recycling efficiency significantly impacts overall process economics. Current recovery rates of 85-95% for most DES systems suggest favorable economics compared to conventional solvent-based processes. Additionally, the ambient pressure operation of many DES systems reduces capital equipment requirements, further enhancing economic viability.

Regulatory pathways for industrial implementation must address both environmental and safety considerations. The biodegradability of many DES components presents advantages for waste management compliance. However, comprehensive toxicological profiles remain incomplete for newer DES formulations, potentially creating regulatory hurdles for certain applications. Industry-academic partnerships are actively developing standardized safety protocols to address these gaps.

Technology transfer considerations include process robustness and operator training requirements. The relative simplicity of many DES-based syntheses compared to high-pressure or high-temperature alternatives facilitates knowledge transfer. However, quality control methodologies for DES-produced nanomaterials require standardization to ensure consistent implementation across manufacturing facilities.

Several engineering approaches have emerged to facilitate industrial scaling of DES-based nanomaterial synthesis. Continuous flow reactors offer significant promise by enabling consistent reaction conditions and reducing batch-to-batch variations. These systems allow for precise control over residence time, temperature gradients, and mixing parameters—all crucial factors for maintaining nanomaterial size uniformity during scale-up. Preliminary studies demonstrate that flow chemistry approaches can increase production rates by 10-15 times while maintaining quality parameters.

Microreactor technology represents another viable implementation pathway, particularly for nanomaterials requiring precise size control. These systems leverage enhanced mass and heat transfer characteristics to maintain reaction homogeneity at larger scales. Industrial partners have reported successful scale-up factors of 50-100x using microreactor arrays while preserving nanomaterial quality metrics.

Economic considerations also drive implementation strategies. Cost analyses indicate that DES recycling efficiency significantly impacts overall process economics. Current recovery rates of 85-95% for most DES systems suggest favorable economics compared to conventional solvent-based processes. Additionally, the ambient pressure operation of many DES systems reduces capital equipment requirements, further enhancing economic viability.

Regulatory pathways for industrial implementation must address both environmental and safety considerations. The biodegradability of many DES components presents advantages for waste management compliance. However, comprehensive toxicological profiles remain incomplete for newer DES formulations, potentially creating regulatory hurdles for certain applications. Industry-academic partnerships are actively developing standardized safety protocols to address these gaps.

Technology transfer considerations include process robustness and operator training requirements. The relative simplicity of many DES-based syntheses compared to high-pressure or high-temperature alternatives facilitates knowledge transfer. However, quality control methodologies for DES-produced nanomaterials require standardization to ensure consistent implementation across manufacturing facilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!