Deep Eutectic Solvents Qualification: Purity Specs, Water Limits And Acceptance Tests

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DES Technology Background and Objectives

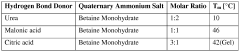

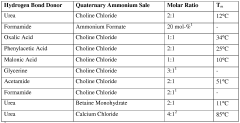

Deep Eutectic Solvents (DES) have emerged as a revolutionary class of green solvents over the past two decades, representing a significant advancement in sustainable chemistry. First conceptualized in 2003 by Abbott and colleagues, these systems consist of a hydrogen bond acceptor (typically a quaternary ammonium salt) and a hydrogen bond donor that form a eutectic mixture with a melting point substantially lower than either individual component. This unique property has positioned DES as an environmentally friendly alternative to conventional organic solvents and ionic liquids.

The evolution of DES technology has progressed through several distinct phases. Initially, research focused primarily on choline chloride-based systems, particularly the widely studied choline chloride-urea mixture. Subsequently, the field expanded to explore various hydrogen bond donors including polyols, carboxylic acids, and amides, significantly broadening the application spectrum of these solvents.

A critical turning point in DES development occurred with the recognition of their potential in industrial applications, prompting increased attention to quality control parameters. The inherent variability in DES preparation methods, component purity, and water content has highlighted the urgent need for standardized qualification protocols to ensure consistent performance across applications.

Current technological objectives in the DES qualification domain center on establishing rigorous purity specifications, determining appropriate water content limits, and developing reliable acceptance tests. These objectives are driven by the understanding that even minor variations in composition can significantly impact DES physicochemical properties, including viscosity, conductivity, and solvation capacity, which directly affect their performance in target applications.

The water content in DES presents a particularly complex challenge, as it can act both as a beneficial co-solvent in some applications and as a detrimental contaminant in others. Establishing scientifically sound upper and lower limits for water content based on application requirements represents a key technological goal in this field.

The broader objective of DES qualification research extends beyond immediate quality control concerns to enabling wider industrial adoption. By developing robust, standardized qualification methodologies, researchers aim to facilitate the transition of DES from laboratory curiosities to commercially viable alternatives in sectors including pharmaceuticals, electrochemistry, catalysis, and extraction processes.

Recent technological trends indicate a shift toward automated, high-throughput qualification methods capable of rapidly assessing multiple quality parameters simultaneously. This evolution aligns with the growing industrial interest in DES and the need for efficient quality assurance protocols suitable for large-scale production environments.

The evolution of DES technology has progressed through several distinct phases. Initially, research focused primarily on choline chloride-based systems, particularly the widely studied choline chloride-urea mixture. Subsequently, the field expanded to explore various hydrogen bond donors including polyols, carboxylic acids, and amides, significantly broadening the application spectrum of these solvents.

A critical turning point in DES development occurred with the recognition of their potential in industrial applications, prompting increased attention to quality control parameters. The inherent variability in DES preparation methods, component purity, and water content has highlighted the urgent need for standardized qualification protocols to ensure consistent performance across applications.

Current technological objectives in the DES qualification domain center on establishing rigorous purity specifications, determining appropriate water content limits, and developing reliable acceptance tests. These objectives are driven by the understanding that even minor variations in composition can significantly impact DES physicochemical properties, including viscosity, conductivity, and solvation capacity, which directly affect their performance in target applications.

The water content in DES presents a particularly complex challenge, as it can act both as a beneficial co-solvent in some applications and as a detrimental contaminant in others. Establishing scientifically sound upper and lower limits for water content based on application requirements represents a key technological goal in this field.

The broader objective of DES qualification research extends beyond immediate quality control concerns to enabling wider industrial adoption. By developing robust, standardized qualification methodologies, researchers aim to facilitate the transition of DES from laboratory curiosities to commercially viable alternatives in sectors including pharmaceuticals, electrochemistry, catalysis, and extraction processes.

Recent technological trends indicate a shift toward automated, high-throughput qualification methods capable of rapidly assessing multiple quality parameters simultaneously. This evolution aligns with the growing industrial interest in DES and the need for efficient quality assurance protocols suitable for large-scale production environments.

Market Demand Analysis for DES Applications

The global market for Deep Eutectic Solvents (DES) is experiencing significant growth driven by increasing demand for environmentally friendly alternatives to traditional solvents. The market value for green solvents, including DES, is projected to reach several billion dollars by 2028, with a compound annual growth rate exceeding 6%. This growth trajectory underscores the urgent need for standardized qualification methods, particularly regarding purity specifications, water limits, and acceptance tests.

Industrial sectors including pharmaceuticals, cosmetics, and chemical manufacturing represent the primary demand drivers for DES applications. The pharmaceutical industry, valued at over $1.4 trillion globally, is actively seeking greener extraction and synthesis methods, with DES offering significant advantages over conventional organic solvents. Similarly, the cosmetics industry, with its market size exceeding $500 billion, is increasingly adopting DES for natural ingredient extraction and formulation.

Consumer preferences are shifting dramatically toward environmentally sustainable products, creating market pull for green chemistry solutions. Recent market surveys indicate that over 70% of consumers across major markets prefer products manufactured using environmentally friendly processes. This consumer-driven demand is compelling manufacturers to adopt greener solvent technologies like DES, further accelerating market growth.

Regulatory pressures represent another significant market driver. Stringent environmental regulations in Europe, North America, and increasingly in Asia are restricting the use of volatile organic compounds (VOCs) and other hazardous solvents. The European Union's REACH regulation and similar frameworks worldwide are creating regulatory environments that favor DES adoption across multiple industries.

The electroplating and metal processing industries present emerging high-growth application areas for DES. With the global metal finishing market exceeding $90 billion, the potential for DES to replace toxic traditional electrolytes represents a substantial market opportunity. However, this industrial adoption is contingent upon establishing reliable purity specifications and acceptance tests.

A critical market need identified through industry consultations is the establishment of standardized purity specifications and water content limits for DES. Current market feedback indicates that inconsistent quality and variable water content in commercially available DES products are significant barriers to wider industrial adoption. Manufacturing processes requiring precise solvent properties demand reliable quality control measures that current DES supply chains often cannot guarantee.

The development of rapid, cost-effective analytical methods for DES qualification represents a significant market opportunity. Industry stakeholders report willingness to pay premium prices for DES products with certified purity levels and well-defined water content specifications, highlighting the commercial value of advanced qualification methodologies.

Industrial sectors including pharmaceuticals, cosmetics, and chemical manufacturing represent the primary demand drivers for DES applications. The pharmaceutical industry, valued at over $1.4 trillion globally, is actively seeking greener extraction and synthesis methods, with DES offering significant advantages over conventional organic solvents. Similarly, the cosmetics industry, with its market size exceeding $500 billion, is increasingly adopting DES for natural ingredient extraction and formulation.

Consumer preferences are shifting dramatically toward environmentally sustainable products, creating market pull for green chemistry solutions. Recent market surveys indicate that over 70% of consumers across major markets prefer products manufactured using environmentally friendly processes. This consumer-driven demand is compelling manufacturers to adopt greener solvent technologies like DES, further accelerating market growth.

Regulatory pressures represent another significant market driver. Stringent environmental regulations in Europe, North America, and increasingly in Asia are restricting the use of volatile organic compounds (VOCs) and other hazardous solvents. The European Union's REACH regulation and similar frameworks worldwide are creating regulatory environments that favor DES adoption across multiple industries.

The electroplating and metal processing industries present emerging high-growth application areas for DES. With the global metal finishing market exceeding $90 billion, the potential for DES to replace toxic traditional electrolytes represents a substantial market opportunity. However, this industrial adoption is contingent upon establishing reliable purity specifications and acceptance tests.

A critical market need identified through industry consultations is the establishment of standardized purity specifications and water content limits for DES. Current market feedback indicates that inconsistent quality and variable water content in commercially available DES products are significant barriers to wider industrial adoption. Manufacturing processes requiring precise solvent properties demand reliable quality control measures that current DES supply chains often cannot guarantee.

The development of rapid, cost-effective analytical methods for DES qualification represents a significant market opportunity. Industry stakeholders report willingness to pay premium prices for DES products with certified purity levels and well-defined water content specifications, highlighting the commercial value of advanced qualification methodologies.

Current Challenges in DES Qualification

Despite significant advancements in Deep Eutectic Solvents (DES) research, the qualification and standardization of these promising green solvents remain challenging. The absence of universally accepted purity specifications creates inconsistencies in research outcomes and hinders industrial adoption. Current analytical methods often struggle to accurately quantify individual components within complex DES matrices, particularly when dealing with hydrogen bond donors and acceptors that may undergo chemical equilibria.

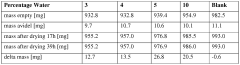

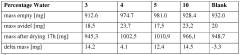

Water content management presents a particularly significant challenge in DES qualification. Unlike conventional solvents, many DES systems are hygroscopic and can absorb atmospheric moisture rapidly, altering their physicochemical properties. The acceptable water threshold varies dramatically between different DES compositions, with some applications requiring ultra-dry conditions while others maintain functionality with moderate water content. This variability complicates the establishment of standardized water limits.

The development of reliable acceptance tests is further complicated by the diverse nature of DES applications across industries. Pharmaceutical applications demand stringent purity profiles and residual solvent limits, while industrial chemical processes may prioritize thermal stability and recyclability. This diversity of requirements makes creating unified qualification protocols exceptionally difficult, resulting in fragmented standards across different sectors.

Current analytical techniques also face limitations when applied to DES qualification. Traditional methods like Karl Fischer titration for water determination require careful optimization for DES matrices to avoid interference from hydrogen bonding components. Similarly, chromatographic techniques for purity assessment often require extensive method development to achieve adequate separation and quantification of DES constituents.

Regulatory frameworks present another layer of complexity. Most existing solvent regulations were developed for conventional organic solvents and do not adequately address the unique properties of DES systems. This regulatory gap creates uncertainty for manufacturers and end-users regarding compliance requirements, further impeding commercial adoption.

The stability and shelf-life determination of DES presents additional qualification challenges. Many DES systems exhibit time-dependent property changes, particularly when exposed to varying environmental conditions. Current accelerated stability testing protocols may not accurately predict long-term behavior of these complex systems, creating uncertainty in product specifications and expiration dating.

Batch-to-batch consistency represents a critical industrial challenge, as slight variations in starting material purity or preparation conditions can significantly impact DES properties. The development of robust quality control parameters that can effectively capture these variations remains an ongoing challenge for large-scale DES production and application.

Water content management presents a particularly significant challenge in DES qualification. Unlike conventional solvents, many DES systems are hygroscopic and can absorb atmospheric moisture rapidly, altering their physicochemical properties. The acceptable water threshold varies dramatically between different DES compositions, with some applications requiring ultra-dry conditions while others maintain functionality with moderate water content. This variability complicates the establishment of standardized water limits.

The development of reliable acceptance tests is further complicated by the diverse nature of DES applications across industries. Pharmaceutical applications demand stringent purity profiles and residual solvent limits, while industrial chemical processes may prioritize thermal stability and recyclability. This diversity of requirements makes creating unified qualification protocols exceptionally difficult, resulting in fragmented standards across different sectors.

Current analytical techniques also face limitations when applied to DES qualification. Traditional methods like Karl Fischer titration for water determination require careful optimization for DES matrices to avoid interference from hydrogen bonding components. Similarly, chromatographic techniques for purity assessment often require extensive method development to achieve adequate separation and quantification of DES constituents.

Regulatory frameworks present another layer of complexity. Most existing solvent regulations were developed for conventional organic solvents and do not adequately address the unique properties of DES systems. This regulatory gap creates uncertainty for manufacturers and end-users regarding compliance requirements, further impeding commercial adoption.

The stability and shelf-life determination of DES presents additional qualification challenges. Many DES systems exhibit time-dependent property changes, particularly when exposed to varying environmental conditions. Current accelerated stability testing protocols may not accurately predict long-term behavior of these complex systems, creating uncertainty in product specifications and expiration dating.

Batch-to-batch consistency represents a critical industrial challenge, as slight variations in starting material purity or preparation conditions can significantly impact DES properties. The development of robust quality control parameters that can effectively capture these variations remains an ongoing challenge for large-scale DES production and application.

Current DES Qualification Methodologies

01 Methods for purification of deep eutectic solvents

Various techniques are employed to purify deep eutectic solvents (DES) and remove impurities. These methods include vacuum distillation, crystallization, and adsorption processes using activated carbon or molecular sieves. Purification steps are critical to ensure the DES meets required specifications for industrial applications, as impurities can significantly affect the physical properties and performance of the solvent system.- Methods for purification of deep eutectic solvents: Various techniques are employed to purify deep eutectic solvents (DES) and remove impurities. These methods include vacuum distillation, molecular sieves, and chromatographic techniques. Purification processes are critical as impurities can significantly affect the physical properties and performance of DES in various applications. Effective purification methods can achieve high purity levels, which is essential for industrial and research applications.

- Water content measurement and control in DES: Water content in deep eutectic solvents significantly impacts their properties and applications. Various analytical techniques are used to measure water content, including Karl Fischer titration, thermogravimetric analysis, and spectroscopic methods. Controlling water content is crucial as it affects viscosity, conductivity, and solvent properties of DES. Some applications require anhydrous conditions while others benefit from specific water content levels to optimize performance.

- Effect of water on DES stability and functionality: Water content significantly influences the stability and functionality of deep eutectic solvents. Research shows that controlled amounts of water can enhance certain properties like decreased viscosity and increased conductivity, while excessive water can dilute the eutectic effect and alter the fundamental characteristics of the DES. Understanding the relationship between water content and DES performance is essential for optimizing applications in catalysis, extraction, and electrochemistry.

- DES preparation methods for high purity applications: Specialized preparation methods have been developed to create high-purity deep eutectic solvents for sensitive applications. These include vacuum drying techniques, controlled synthesis under inert atmospheres, and precise component ratio control. For applications in pharmaceuticals, electronics, and catalysis, high-purity DES with minimal water content is critical. These preparation methods focus on eliminating contaminants and achieving consistent composition for reproducible performance.

- Industrial applications requiring specific DES purity levels: Different industrial applications demand specific purity levels and water content in deep eutectic solvents. For example, electrochemical applications often require low water content to maximize conductivity and electrochemical window, while certain extraction processes may benefit from controlled water content. Industries such as pharmaceuticals, metal processing, and CO2 capture have established purity specifications for DES to ensure optimal performance. Understanding these requirements is essential for successful implementation of DES technology in industrial settings.

02 Water content measurement and control in DES

Water content in deep eutectic solvents is typically measured using Karl Fischer titration or other analytical techniques. Controlling water content is crucial as it affects the physical properties of DES including viscosity, conductivity, and solvation capabilities. Specific water content thresholds are established for different applications, with some processes requiring anhydrous conditions while others can tolerate or even benefit from controlled amounts of water.Expand Specific Solutions03 Impact of water on DES properties and performance

Water content significantly influences the physicochemical properties of deep eutectic solvents. Small amounts of water can decrease viscosity and increase conductivity, which may be beneficial for certain applications. However, excessive water can disrupt the hydrogen bonding network that characterizes DES, potentially leading to phase separation or reduced efficacy. Understanding this relationship is essential for optimizing DES formulations for specific applications.Expand Specific Solutions04 Drying techniques for water removal from DES

Various drying techniques are employed to reduce water content in deep eutectic solvents to desired levels. These include vacuum drying at elevated temperatures, use of desiccants such as molecular sieves or anhydrous salts, azeotropic distillation, and freeze-drying methods. The selection of an appropriate drying technique depends on the thermal stability of the DES components and the target water content specification.Expand Specific Solutions05 Quality control and standardization of DES purity

Quality control protocols for deep eutectic solvents involve standardized testing methods to ensure consistent purity levels. These include spectroscopic techniques (NMR, FTIR), chromatographic methods (HPLC, GC), thermal analysis (DSC, TGA), and specific tests for water content and other impurities. Establishing industry standards for DES purity is important for reproducible results in research and industrial applications, with specifications varying based on the intended use.Expand Specific Solutions

Key Industry Players in DES Development

Deep Eutectic Solvents (DES) qualification is currently in an emerging growth phase, with the market expected to expand significantly due to increasing applications in pharmaceuticals, chemical processing, and sustainable manufacturing. The global DES market is projected to reach substantial value by 2030, driven by growing demand for green solvents. Technologically, the field is advancing rapidly with companies like Nippon Shokubai, F. Hoffmann-La Roche, and Saudi Aramco leading industrial applications, while academic institutions including University of Manchester, King Abdullah University of Science & Technology, and University of Minho are pioneering fundamental research. The development of standardized purity specifications, water content limits, and acceptance tests represents a critical maturation point for this technology, enabling broader commercial adoption across multiple industries.

University of Minho

Technical Solution: University of Minho has developed comprehensive analytical protocols for Deep Eutectic Solvents (DES) qualification focusing on purity assessment through multi-technique characterization. Their approach combines Nuclear Magnetic Resonance (NMR) spectroscopy for structural verification and impurity detection with Fourier Transform Infrared (FTIR) spectroscopy to identify functional groups and confirm component interactions. The university employs Karl Fischer titration specifically calibrated for DES matrices to determine water content with precision down to 50 ppm, addressing the hygroscopic nature of many DES components. Their qualification framework includes thermal analysis (DSC/TGA) to establish phase transition temperatures and thermal stability profiles as critical quality attributes. Additionally, they've pioneered standardized viscosity and conductivity measurements as functional performance indicators, with established acceptance criteria based on statistical process control methods across multiple batches.

Strengths: Comprehensive multi-analytical approach provides robust characterization; established statistical process control methods ensure reproducibility across batches. Weaknesses: Academic approach may require industrial adaptation; methods may be time-consuming and resource-intensive for routine quality control in production environments.

Université du Littoral Côte d'Opale

Technical Solution: Université du Littoral Côte d'Opale has developed a green chemistry-focused qualification approach for Deep Eutectic Solvents that emphasizes both analytical characterization and functional performance testing. Their methodology employs capillary electrophoresis coupled with conductivity detection to verify component ratios and detect ionic impurities with high sensitivity. For water content determination, they utilize a two-step approach combining Karl Fischer titration with thermogravimetric analysis to establish both absolute water content and water binding characteristics within the DES matrix. The university has pioneered the use of in-situ Raman spectroscopy for real-time monitoring of DES formation and stability, enabling process analytical technology approaches to quality assurance. Their qualification protocol includes solvatochromic parameter determination (Kamlet-Taft parameters) as functional acceptance criteria, ensuring consistent solvent properties across batches. Additionally, they've established ecotoxicity testing protocols specifically adapted for DES systems to ensure environmental safety profiles meet green chemistry standards.

Strengths: Integration of functional performance testing with analytical characterization ensures practical quality control; green chemistry focus addresses sustainability concerns. Weaknesses: Specialized spectroscopic techniques may require dedicated instrumentation; ecotoxicity testing adds time and complexity to qualification process.

Critical Analytical Techniques for DES Purity

Deep eutectic solvent systems and methods

PatentWO2012145522A2

Innovation

- Development of deep eutectic solvent systems comprising betaine monohydrate as a replacement for choline chloride, combined with hydrogen bond donors like urea or acids, which significantly lower melting points and reduce viscosity, enabling the dissolution of cellulose and other insoluble materials.

Deep eutectic solvents and applications

PatentInactiveUS20110207633A1

Innovation

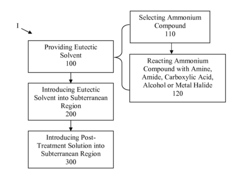

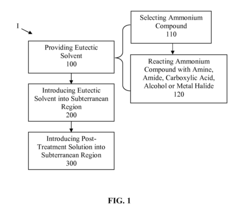

- The use of deep eutectic solvents, specifically formed by reacting quaternary ammonium compounds with hydrogen bond donors such as amides, carboxylic acids, and alcohols, to solubilize up to 30 wt% cellulosic material, allowing for their removal from subterranean regions, and these solvents are introduced as additives in drilling or fracturing fluids.

Regulatory Framework for DES Implementation

The implementation of Deep Eutectic Solvents (DES) in industrial applications necessitates a comprehensive regulatory framework that addresses their unique properties and potential environmental impacts. Currently, DES exist in a regulatory gray area, as they are neither fully covered by existing solvent regulations nor specifically addressed in most chemical control frameworks.

At the international level, organizations such as the Organization for Economic Co-operation and Development (OECD) and the International Organization for Standardization (ISO) are beginning to develop guidelines for green solvents, which may eventually encompass DES. The European Chemicals Agency (ECHA) under REACH regulation requires registration of chemical substances manufactured or imported in quantities of one tonne or more per year, potentially affecting commercial DES applications.

In the United States, the Environmental Protection Agency (EPA) oversees chemical substances through the Toxic Substances Control Act (TSCA), which would apply to novel DES formulations. The FDA's regulatory framework becomes relevant when DES are used in pharmaceutical applications, requiring compliance with Good Manufacturing Practices (GMP) and appropriate toxicological assessments.

Specific to DES qualification, emerging regulatory considerations focus on three key areas: purity specifications, water content limitations, and standardized acceptance testing protocols. Purity requirements vary by application sector, with pharmaceutical applications typically demanding 99.5% purity or higher, while industrial applications may accept 95-98% purity levels depending on the specific use case.

Water content regulation is particularly critical for DES, as excessive moisture can significantly alter their physicochemical properties and functionality. Current industry practices suggest water content limitations between 0.01-1.0% depending on the specific DES composition and intended application, though these have not yet been formalized in regulatory standards.

Acceptance testing protocols remain largely industry-specific without standardized regulatory requirements. Common analytical methods include Karl Fischer titration for water content determination, gas chromatography for purity assessment, and various spectroscopic techniques for compositional verification. The lack of harmonized testing standards presents challenges for cross-border trade and technology transfer.

Regulatory gaps specifically related to DES qualification include the absence of established impurity profiles, limited toxicological data for novel DES compositions, and insufficient environmental impact assessments for large-scale implementation. Industry stakeholders and regulatory bodies are increasingly recognizing the need for DES-specific frameworks that balance innovation potential with appropriate safety and environmental safeguards.

At the international level, organizations such as the Organization for Economic Co-operation and Development (OECD) and the International Organization for Standardization (ISO) are beginning to develop guidelines for green solvents, which may eventually encompass DES. The European Chemicals Agency (ECHA) under REACH regulation requires registration of chemical substances manufactured or imported in quantities of one tonne or more per year, potentially affecting commercial DES applications.

In the United States, the Environmental Protection Agency (EPA) oversees chemical substances through the Toxic Substances Control Act (TSCA), which would apply to novel DES formulations. The FDA's regulatory framework becomes relevant when DES are used in pharmaceutical applications, requiring compliance with Good Manufacturing Practices (GMP) and appropriate toxicological assessments.

Specific to DES qualification, emerging regulatory considerations focus on three key areas: purity specifications, water content limitations, and standardized acceptance testing protocols. Purity requirements vary by application sector, with pharmaceutical applications typically demanding 99.5% purity or higher, while industrial applications may accept 95-98% purity levels depending on the specific use case.

Water content regulation is particularly critical for DES, as excessive moisture can significantly alter their physicochemical properties and functionality. Current industry practices suggest water content limitations between 0.01-1.0% depending on the specific DES composition and intended application, though these have not yet been formalized in regulatory standards.

Acceptance testing protocols remain largely industry-specific without standardized regulatory requirements. Common analytical methods include Karl Fischer titration for water content determination, gas chromatography for purity assessment, and various spectroscopic techniques for compositional verification. The lack of harmonized testing standards presents challenges for cross-border trade and technology transfer.

Regulatory gaps specifically related to DES qualification include the absence of established impurity profiles, limited toxicological data for novel DES compositions, and insufficient environmental impact assessments for large-scale implementation. Industry stakeholders and regulatory bodies are increasingly recognizing the need for DES-specific frameworks that balance innovation potential with appropriate safety and environmental safeguards.

Environmental Impact Assessment of DES

The environmental impact assessment of Deep Eutectic Solvents (DES) reveals significant advantages over conventional organic solvents. DES systems demonstrate lower toxicity profiles and reduced environmental persistence due to their biodegradable components, typically comprising natural substances like choline chloride paired with hydrogen bond donors such as urea or glycerol. This composition results in minimal bioaccumulation potential and reduced ecological risk compared to traditional petroleum-derived solvents.

Water content in DES formulations plays a critical role in their environmental footprint. Higher water content generally reduces viscosity and enhances biodegradability, but may simultaneously diminish the unique solvent properties that make DES environmentally advantageous. Establishing optimal water limits is therefore essential for balancing performance requirements with environmental considerations.

Life cycle assessment (LCA) studies indicate that DES production typically generates lower carbon emissions than conventional solvent manufacturing processes. The renewable nature of many DES components contributes to reduced resource depletion and smaller carbon footprints. However, comprehensive LCA data remains limited, particularly regarding scaled industrial applications and end-of-life management scenarios.

Waste management considerations for DES are generally favorable, with most systems being amenable to biological treatment processes. The biodegradability of DES varies significantly based on their specific composition, with those derived from natural components showing superior degradation profiles. Purity specifications directly impact environmental outcomes, as contaminants may introduce unexpected toxicity or persistence characteristics.

Regulatory frameworks for DES environmental assessment are still evolving. Current approaches often apply existing chemical assessment methodologies, which may not fully capture the unique properties of these eutectic systems. The development of DES-specific environmental testing protocols would enhance regulatory certainty and facilitate wider industrial adoption.

Acceptance tests for environmental compliance should include aquatic toxicity assessments, biodegradation studies, and bioaccumulation potential evaluations. These parameters provide critical insights into the environmental safety profile of specific DES formulations and help establish appropriate handling and disposal guidelines.

Future research directions should focus on standardizing environmental impact metrics for DES qualification, developing predictive models for environmental fate based on composition, and establishing industry-wide purity specifications that incorporate environmental performance criteria alongside functional requirements.

Water content in DES formulations plays a critical role in their environmental footprint. Higher water content generally reduces viscosity and enhances biodegradability, but may simultaneously diminish the unique solvent properties that make DES environmentally advantageous. Establishing optimal water limits is therefore essential for balancing performance requirements with environmental considerations.

Life cycle assessment (LCA) studies indicate that DES production typically generates lower carbon emissions than conventional solvent manufacturing processes. The renewable nature of many DES components contributes to reduced resource depletion and smaller carbon footprints. However, comprehensive LCA data remains limited, particularly regarding scaled industrial applications and end-of-life management scenarios.

Waste management considerations for DES are generally favorable, with most systems being amenable to biological treatment processes. The biodegradability of DES varies significantly based on their specific composition, with those derived from natural components showing superior degradation profiles. Purity specifications directly impact environmental outcomes, as contaminants may introduce unexpected toxicity or persistence characteristics.

Regulatory frameworks for DES environmental assessment are still evolving. Current approaches often apply existing chemical assessment methodologies, which may not fully capture the unique properties of these eutectic systems. The development of DES-specific environmental testing protocols would enhance regulatory certainty and facilitate wider industrial adoption.

Acceptance tests for environmental compliance should include aquatic toxicity assessments, biodegradation studies, and bioaccumulation potential evaluations. These parameters provide critical insights into the environmental safety profile of specific DES formulations and help establish appropriate handling and disposal guidelines.

Future research directions should focus on standardizing environmental impact metrics for DES qualification, developing predictive models for environmental fate based on composition, and establishing industry-wide purity specifications that incorporate environmental performance criteria alongside functional requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!