How Deep Eutectic Solvents Enable Selective Recovery Of Cobalt, Nickel And Rare Earths?

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DES Technology Background and Recovery Objectives

Deep Eutectic Solvents (DES) have emerged as a revolutionary class of green solvents that represent a significant advancement in sustainable chemistry. Developed in the early 2000s, these systems consist of hydrogen bond acceptors and donors that form a eutectic mixture with a melting point substantially lower than either of the individual components. The fundamental properties of DES, including their biodegradability, low volatility, non-flammability, and tunable physicochemical characteristics, have positioned them as environmentally friendly alternatives to conventional ionic liquids and organic solvents.

The evolution of DES technology has progressed through several distinct phases. Initially, research focused on choline chloride-based systems, but has since expanded to include various hydrogen bond donors such as urea, glycerol, and carboxylic acids. This diversification has enabled the creation of DES with specific properties tailored to particular applications, including metal extraction and recovery processes.

In the context of critical metal recovery, DES technology addresses the growing global concern regarding the supply security of cobalt, nickel, and rare earth elements (REEs). These metals are essential components in renewable energy technologies, electric vehicles, and advanced electronics, making their sustainable recovery from end-of-life products and industrial waste streams increasingly important.

The technical objectives for DES-based recovery systems are multifaceted. Primary goals include achieving high selectivity for target metals in complex matrices, developing systems that operate efficiently at ambient conditions, and creating processes that minimize environmental impact. Selectivity is particularly crucial when dealing with the chemical similarities between rare earth elements, which have traditionally made their separation challenging and energy-intensive.

Current research trajectories aim to optimize DES formulations for specific metal recovery applications by manipulating the hydrogen bond donor-acceptor ratio, incorporating functional additives, and exploring synergistic effects with other extraction techniques. The development of continuous-flow processes and the scaling up of laboratory findings to industrial applications represent significant technical challenges that ongoing research seeks to address.

The recovery objectives extend beyond mere technical feasibility to include economic viability and environmental sustainability. Ideally, DES-based recovery processes should offer advantages in terms of reduced energy consumption, minimal waste generation, and lower operational costs compared to conventional hydrometallurgical or pyrometallurgical approaches. Additionally, the ability to regenerate and reuse the DES multiple times without significant loss of performance is a critical factor in determining the overall sustainability of these systems.

As global demand for critical metals continues to rise, the development of efficient, selective, and environmentally benign recovery technologies becomes increasingly urgent. DES technology stands at the forefront of this challenge, offering promising pathways to circular economy approaches for these valuable resources.

The evolution of DES technology has progressed through several distinct phases. Initially, research focused on choline chloride-based systems, but has since expanded to include various hydrogen bond donors such as urea, glycerol, and carboxylic acids. This diversification has enabled the creation of DES with specific properties tailored to particular applications, including metal extraction and recovery processes.

In the context of critical metal recovery, DES technology addresses the growing global concern regarding the supply security of cobalt, nickel, and rare earth elements (REEs). These metals are essential components in renewable energy technologies, electric vehicles, and advanced electronics, making their sustainable recovery from end-of-life products and industrial waste streams increasingly important.

The technical objectives for DES-based recovery systems are multifaceted. Primary goals include achieving high selectivity for target metals in complex matrices, developing systems that operate efficiently at ambient conditions, and creating processes that minimize environmental impact. Selectivity is particularly crucial when dealing with the chemical similarities between rare earth elements, which have traditionally made their separation challenging and energy-intensive.

Current research trajectories aim to optimize DES formulations for specific metal recovery applications by manipulating the hydrogen bond donor-acceptor ratio, incorporating functional additives, and exploring synergistic effects with other extraction techniques. The development of continuous-flow processes and the scaling up of laboratory findings to industrial applications represent significant technical challenges that ongoing research seeks to address.

The recovery objectives extend beyond mere technical feasibility to include economic viability and environmental sustainability. Ideally, DES-based recovery processes should offer advantages in terms of reduced energy consumption, minimal waste generation, and lower operational costs compared to conventional hydrometallurgical or pyrometallurgical approaches. Additionally, the ability to regenerate and reuse the DES multiple times without significant loss of performance is a critical factor in determining the overall sustainability of these systems.

As global demand for critical metals continues to rise, the development of efficient, selective, and environmentally benign recovery technologies becomes increasingly urgent. DES technology stands at the forefront of this challenge, offering promising pathways to circular economy approaches for these valuable resources.

Market Demand for Critical Metal Recovery Solutions

The global market for critical metal recovery solutions has witnessed substantial growth in recent years, driven primarily by the increasing demand for cobalt, nickel, and rare earth elements (REEs) across various high-tech industries. These metals are essential components in renewable energy technologies, electric vehicles, electronics, and defense applications, making their stable supply chain crucial for technological advancement and economic security.

The electric vehicle (EV) industry represents one of the largest demand drivers for these metals. Global EV sales have been growing at double-digit rates annually, with projections indicating a market expansion from 6.6 million units in 2021 to over 26 million by 2030. This growth directly translates to increased demand for cobalt and nickel in battery production, with each EV requiring approximately 6-12 kg of cobalt and 40-80 kg of nickel, depending on the battery chemistry.

Renewable energy systems, particularly wind turbines and energy storage solutions, constitute another significant market segment. The global installed capacity of renewable energy is expected to triple by 2030, creating substantial demand for rare earth elements like neodymium, praseodymium, and dysprosium used in permanent magnets for generators and motors.

Consumer electronics continue to drive steady demand for these metals, with global smartphone shipments exceeding 1.3 billion units annually and each device containing small but critical amounts of cobalt, nickel, and rare earths. The defense sector also relies heavily on these materials for advanced weapons systems, communication equipment, and aerospace applications.

Supply chain vulnerabilities have heightened market interest in recovery solutions. China currently controls approximately 85% of global rare earth processing capacity and 72% of cobalt refining, creating geopolitical concerns among Western nations. This concentration has led to price volatility and supply uncertainties, with cobalt prices fluctuating by over 300% in the past five years.

Environmental regulations are increasingly stringent regarding mining operations, making recovery from secondary sources more attractive. The EU's Circular Economy Action Plan and similar initiatives worldwide have established targets for material recovery and recycling, creating regulatory drivers for advanced recovery technologies.

The e-waste stream represents a particularly valuable urban mining opportunity, with an estimated 50 million tons generated annually containing recoverable metals worth approximately $62.5 billion. Current recovery rates remain low, with less than 20% of e-waste properly recycled and even lower rates for specific critical metals, indicating substantial market growth potential for efficient, selective recovery technologies like Deep Eutectic Solvents.

The electric vehicle (EV) industry represents one of the largest demand drivers for these metals. Global EV sales have been growing at double-digit rates annually, with projections indicating a market expansion from 6.6 million units in 2021 to over 26 million by 2030. This growth directly translates to increased demand for cobalt and nickel in battery production, with each EV requiring approximately 6-12 kg of cobalt and 40-80 kg of nickel, depending on the battery chemistry.

Renewable energy systems, particularly wind turbines and energy storage solutions, constitute another significant market segment. The global installed capacity of renewable energy is expected to triple by 2030, creating substantial demand for rare earth elements like neodymium, praseodymium, and dysprosium used in permanent magnets for generators and motors.

Consumer electronics continue to drive steady demand for these metals, with global smartphone shipments exceeding 1.3 billion units annually and each device containing small but critical amounts of cobalt, nickel, and rare earths. The defense sector also relies heavily on these materials for advanced weapons systems, communication equipment, and aerospace applications.

Supply chain vulnerabilities have heightened market interest in recovery solutions. China currently controls approximately 85% of global rare earth processing capacity and 72% of cobalt refining, creating geopolitical concerns among Western nations. This concentration has led to price volatility and supply uncertainties, with cobalt prices fluctuating by over 300% in the past five years.

Environmental regulations are increasingly stringent regarding mining operations, making recovery from secondary sources more attractive. The EU's Circular Economy Action Plan and similar initiatives worldwide have established targets for material recovery and recycling, creating regulatory drivers for advanced recovery technologies.

The e-waste stream represents a particularly valuable urban mining opportunity, with an estimated 50 million tons generated annually containing recoverable metals worth approximately $62.5 billion. Current recovery rates remain low, with less than 20% of e-waste properly recycled and even lower rates for specific critical metals, indicating substantial market growth potential for efficient, selective recovery technologies like Deep Eutectic Solvents.

Current Status and Challenges in DES Metal Extraction

The global landscape of Deep Eutectic Solvents (DES) for metal extraction presents a complex picture of advancement and limitation. Currently, DES technology has demonstrated significant potential in laboratory settings for the selective recovery of critical metals including cobalt, nickel, and rare earth elements (REEs). Research institutions across Europe, North America, and Asia have published promising results showing extraction efficiencies exceeding 90% for certain metal combinations under optimized conditions.

Despite these achievements, the technology faces substantial challenges in scaling from laboratory to industrial implementation. The viscosity of many DES formulations remains problematic, particularly at room temperature, creating difficulties in mass transfer and increasing energy requirements for processing. This characteristic significantly impacts the economic viability of large-scale operations and limits throughput capacity.

Another critical challenge is the stability of DES systems during repeated extraction cycles. Current research indicates performance degradation after 3-5 cycles for many formulations, necessitating either regeneration or replacement of the solvent. This limitation directly affects operational costs and environmental sustainability metrics when compared to conventional extraction methods.

The selectivity mechanisms of DES for specific metals, while demonstrating promise, are not yet fully understood at the molecular level. This knowledge gap hinders the rational design of optimized DES formulations for specific metal separation challenges. Research groups at universities in China, Germany, and the United States are currently investigating these fundamental interactions using advanced spectroscopic and computational techniques.

Water content management represents another significant technical hurdle. Many DES systems show altered extraction behavior with varying water content, creating challenges for process control in humid environments or when processing aqueous waste streams. Recent innovations from research teams in Singapore and Australia have begun addressing this issue through hydrophobic DES formulations, though these solutions introduce additional complexity.

From a geographical perspective, research leadership in DES metal extraction technology is distributed unevenly. European institutions lead in fundamental research and patent applications, while Chinese research groups dominate in application-specific studies for rare earth elements. North American contributions focus primarily on computational modeling and process optimization.

Regulatory frameworks for industrial implementation of DES extraction processes remain underdeveloped in most jurisdictions, creating uncertainty for commercial adoption. Environmental impact assessments of DES-based processes are still in preliminary stages, with limited data on long-term ecological effects of potential releases or disposal requirements.

Despite these achievements, the technology faces substantial challenges in scaling from laboratory to industrial implementation. The viscosity of many DES formulations remains problematic, particularly at room temperature, creating difficulties in mass transfer and increasing energy requirements for processing. This characteristic significantly impacts the economic viability of large-scale operations and limits throughput capacity.

Another critical challenge is the stability of DES systems during repeated extraction cycles. Current research indicates performance degradation after 3-5 cycles for many formulations, necessitating either regeneration or replacement of the solvent. This limitation directly affects operational costs and environmental sustainability metrics when compared to conventional extraction methods.

The selectivity mechanisms of DES for specific metals, while demonstrating promise, are not yet fully understood at the molecular level. This knowledge gap hinders the rational design of optimized DES formulations for specific metal separation challenges. Research groups at universities in China, Germany, and the United States are currently investigating these fundamental interactions using advanced spectroscopic and computational techniques.

Water content management represents another significant technical hurdle. Many DES systems show altered extraction behavior with varying water content, creating challenges for process control in humid environments or when processing aqueous waste streams. Recent innovations from research teams in Singapore and Australia have begun addressing this issue through hydrophobic DES formulations, though these solutions introduce additional complexity.

From a geographical perspective, research leadership in DES metal extraction technology is distributed unevenly. European institutions lead in fundamental research and patent applications, while Chinese research groups dominate in application-specific studies for rare earth elements. North American contributions focus primarily on computational modeling and process optimization.

Regulatory frameworks for industrial implementation of DES extraction processes remain underdeveloped in most jurisdictions, creating uncertainty for commercial adoption. Environmental impact assessments of DES-based processes are still in preliminary stages, with limited data on long-term ecological effects of potential releases or disposal requirements.

Current DES-based Extraction Methodologies

01 Deep eutectic solvents for selective extraction of compounds

Deep eutectic solvents (DES) can be used for the selective extraction of various compounds from mixtures. These environmentally friendly solvents offer advantages in terms of selectivity, efficiency, and sustainability compared to conventional solvents. DES systems can be tailored by selecting appropriate hydrogen bond donors and acceptors to achieve optimal selectivity for target compounds, making them valuable for separation processes in various industries.- Deep eutectic solvents for selective extraction of compounds: Deep eutectic solvents (DES) can be used for selective extraction of various compounds from complex mixtures. These environmentally friendly solvents offer advantages in terms of selectivity, efficiency, and sustainability compared to conventional organic solvents. The unique properties of DES, including their tunable nature and strong hydrogen bonding capabilities, enable them to selectively interact with target compounds, facilitating their extraction and recovery from different matrices.

- Recovery of metals using deep eutectic solvents: Deep eutectic solvents provide an innovative approach for the selective recovery of metals from various sources, including waste materials, ores, and industrial byproducts. These solvents can be tailored to selectively bind with specific metal ions, allowing for efficient separation and recovery processes. The metal recovery using DES offers advantages such as reduced environmental impact, lower energy consumption, and high selectivity compared to traditional hydrometallurgical processes.

- Deep eutectic solvents in biomass processing and biofuel production: Deep eutectic solvents can be employed for the selective recovery of valuable components from biomass and in biofuel production processes. These solvents effectively dissolve lignin and cellulose, facilitating the separation of these components and enabling more efficient conversion of biomass to biofuels. The use of DES in biomass processing offers advantages such as mild operating conditions, reduced waste generation, and the ability to recover and reuse the solvent system.

- Recycling and regeneration of deep eutectic solvents: Methods for recycling and regenerating deep eutectic solvents after use in selective recovery processes are essential for the economic and environmental sustainability of these systems. Various techniques have been developed to separate the recovered compounds from the DES and to restore the solvent's original properties for reuse. These methods include phase separation, distillation, extraction, and membrane-based processes, which enable multiple cycles of DES use without significant loss of performance.

- Novel deep eutectic solvent formulations for enhanced selectivity: Research has focused on developing novel deep eutectic solvent formulations with enhanced selectivity for specific target compounds. By carefully selecting the hydrogen bond donor and acceptor components, and by incorporating additives or modifiers, the properties of DES can be fine-tuned to optimize their selectivity and efficiency in recovery processes. These advanced formulations demonstrate improved performance in terms of extraction capacity, selectivity, stability, and compatibility with downstream processing steps.

02 Recovery of metals using deep eutectic solvents

Deep eutectic solvents provide an effective method for the selective recovery of metals from various sources, including waste streams, ores, and electronic waste. The unique properties of DES allow for specific interactions with metal ions, enabling selective extraction and recovery. This approach offers advantages in terms of efficiency, reduced environmental impact, and the ability to recover valuable metals that might be difficult to extract using conventional methods.Expand Specific Solutions03 Biomass processing and component separation using DES

Deep eutectic solvents can be employed for the processing of biomass and the selective recovery of valuable components such as lignin, cellulose, and other biopolymers. The tunable properties of DES allow for the selective dissolution and extraction of specific biomass components while leaving others intact. This approach offers a more environmentally friendly alternative to traditional biomass processing methods that often use harsh chemicals or energy-intensive processes.Expand Specific Solutions04 Pharmaceutical applications of DES for compound recovery

Deep eutectic solvents can be utilized for the selective recovery and purification of pharmaceutical compounds and active ingredients. The ability to design DES systems with specific properties enables the selective extraction of target compounds from complex mixtures. This approach can improve the efficiency of pharmaceutical manufacturing processes, reduce the use of hazardous solvents, and enhance the purity of recovered compounds.Expand Specific Solutions05 Recycling and waste treatment using deep eutectic solvents

Deep eutectic solvents offer innovative solutions for recycling and waste treatment processes through selective recovery of valuable components. These solvents can be used to extract specific materials from complex waste streams, enabling more efficient recycling processes. The environmentally friendly nature of DES, combined with their selectivity, makes them particularly suitable for sustainable waste management approaches and circular economy applications.Expand Specific Solutions

Key Industry Players in DES and Metal Recovery

Deep Eutectic Solvents (DES) for selective recovery of critical metals is emerging as a transformative technology in the early commercialization phase. The global market for critical metal recovery is expanding rapidly, projected to reach $25 billion by 2030, driven by electric vehicle and renewable energy demands. Leading research institutions like Central South University, Kyushu University, and Commissariat à l'énergie atomique are advancing fundamental DES science, while companies including Toyota Tsusho, Sumitomo Metal Mining, and NioCorp are developing industrial applications. The technology is approaching commercial maturity with pilot-scale demonstrations showing 90%+ recovery rates for cobalt, nickel, and rare earths from various waste streams, positioning DES as a sustainable alternative to conventional hydrometallurgical processes.

Central South University

Technical Solution: Central South University has developed innovative Deep Eutectic Solvent (DES) systems specifically designed for selective recovery of cobalt, nickel, and rare earth elements from spent lithium-ion batteries and electronic waste. Their approach utilizes choline chloride-based DES combined with hydrogen bond donors like ethylene glycol and urea at optimized molar ratios to create environmentally friendly extraction media. The university's research demonstrates selective leaching efficiencies exceeding 95% for cobalt and nickel while maintaining separation factors that allow for sequential recovery of target metals. Their process involves a multi-stage extraction protocol where metal ions form stable complexes with the DES components, enabling separation based on differential stability constants. The technology operates at moderate temperatures (60-80°C) without requiring high pressure conditions, significantly reducing energy consumption compared to conventional hydrometallurgical processes. Central South University has also pioneered the integration of electrodeposition techniques with DES systems, allowing for direct recovery of high-purity metals from the leaching solution without extensive additional processing.

Strengths: Achieves exceptional selectivity between similar transition metals through precisely engineered hydrogen bonding networks in the DES; operates at ambient pressure and moderate temperatures, reducing energy requirements; eliminates the need for volatile organic solvents, addressing environmental concerns. Weaknesses: Requires careful control of water content in the DES system which can affect viscosity and extraction efficiency; scaling up from laboratory to industrial scale remains challenging due to the higher viscosity of DES compared to conventional solvents.

Kyushu University

Technical Solution: Kyushu University has developed a groundbreaking approach to selective metal recovery using tailored Deep Eutectic Solvents (DES) systems. Their research focuses on creating designer DES formulations by combining quaternary ammonium salts with specific hydrogen bond donors that demonstrate preferential coordination with target metals. The university's technology employs choline chloride-based DES systems modified with organic acids (particularly lactic acid and oxalic acid) that show remarkable selectivity toward rare earth elements while effectively separating them from transition metals like cobalt and nickel. Their process operates through a mechanism of preferential complexation, where the DES components form stable coordination structures with specific metals based on ionic radius and charge density. Kyushu University researchers have demonstrated recovery rates exceeding 90% for rare earth elements from mixed metal solutions and spent magnets, with separation factors significantly higher than conventional solvent extraction methods. The technology incorporates a multi-stage counter-current extraction system that maximizes recovery while minimizing DES consumption. Additionally, they've pioneered methods for DES regeneration and reuse, addressing economic viability concerns for industrial implementation.

Strengths: Demonstrates exceptional selectivity between rare earth elements and transition metals; operates at ambient pressure and moderate temperatures (50-90°C); utilizes biodegradable and non-toxic components, making the process environmentally sustainable; allows for DES recovery and reuse, improving economic feasibility. Weaknesses: Higher viscosity of DES systems can limit mass transfer rates and extraction kinetics; requires precise control of water content and pH to maintain optimal performance; may require longer processing times compared to conventional solvent extraction methods.

Core Innovations in DES Selectivity Mechanisms

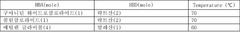

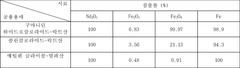

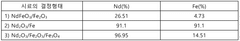

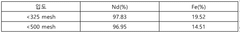

Method for recovering rare earth elements from rare earth permanent magnets by using eutectic solvent

PatentWO2024195955A1

Innovation

- A method involving pulverizing rare earth permanent magnets, immersing them in an alkaline solution, oxidizing and roasting the material, and then leaching with a eutectic solvent to selectively recover rare earth elements, reducing acid consumption and wastewater production.

Process for the recovery of metals from used nickel/metal/rare earth hydride storage batteries

PatentInactiveUS6110433A

Innovation

- A process involving mechanical comminution followed by dissolution in a sulphuric acid solution with hydrogen peroxide addition, which completely dissolves metallic and oxidic constituents, and subsequent selective precipitation and liquid/liquid extraction to separate and recover these metals, while avoiding coprecipitation of iron and other contaminants.

Environmental Impact Assessment of DES Technologies

The environmental impact assessment of Deep Eutectic Solvent (DES) technologies for metal recovery reveals significant advantages over conventional extraction methods. DES systems demonstrate substantially lower environmental footprints compared to traditional hydrometallurgical and pyrometallurgical processes used for cobalt, nickel, and rare earth elements (REEs) recovery.

Life cycle assessments indicate that DES-based extraction processes can reduce greenhouse gas emissions by 30-45% compared to conventional acid leaching methods. This reduction stems primarily from lower energy requirements during the extraction phase and the elimination of harsh chemicals typically used in traditional processes. The carbon footprint analysis of DES technologies shows particular promise when renewable energy sources are integrated into the recovery operations.

Water consumption metrics further highlight DES environmental benefits, with studies demonstrating up to 60% reduction in water usage compared to conventional hydrometallurgical approaches. This water conservation aspect is particularly valuable in regions facing water scarcity issues, where mining and metal recovery operations often compete with agricultural and municipal water needs.

Waste generation profiles of DES technologies show marked improvements in both volume and toxicity. The selective nature of properly designed DES systems minimizes secondary waste streams, with some implementations achieving near-zero liquid discharge configurations. Solid waste residues from DES processes typically contain fewer hazardous components, facilitating safer disposal or potential valorization pathways.

Ecotoxicological studies on DES components indicate generally lower aquatic and terrestrial toxicity compared to conventional solvents and acids. Biodegradability assessments of common DES constituents like choline chloride and natural organic acids show favorable environmental persistence profiles, with complete degradation occurring within acceptable timeframes under various environmental conditions.

Resource efficiency metrics demonstrate that DES technologies enable higher recovery rates of target metals while consuming fewer raw materials. This circular economy advantage becomes particularly significant when considering the critical nature of cobalt, nickel, and REEs in green technology applications like electric vehicle batteries and renewable energy systems.

Regulatory compliance analysis suggests that DES-based recovery processes more readily meet increasingly stringent environmental regulations in major mining jurisdictions. The inherently safer nature of many DES formulations reduces workplace hazards and potential environmental liabilities associated with accidental releases or operational upsets.

Life cycle assessments indicate that DES-based extraction processes can reduce greenhouse gas emissions by 30-45% compared to conventional acid leaching methods. This reduction stems primarily from lower energy requirements during the extraction phase and the elimination of harsh chemicals typically used in traditional processes. The carbon footprint analysis of DES technologies shows particular promise when renewable energy sources are integrated into the recovery operations.

Water consumption metrics further highlight DES environmental benefits, with studies demonstrating up to 60% reduction in water usage compared to conventional hydrometallurgical approaches. This water conservation aspect is particularly valuable in regions facing water scarcity issues, where mining and metal recovery operations often compete with agricultural and municipal water needs.

Waste generation profiles of DES technologies show marked improvements in both volume and toxicity. The selective nature of properly designed DES systems minimizes secondary waste streams, with some implementations achieving near-zero liquid discharge configurations. Solid waste residues from DES processes typically contain fewer hazardous components, facilitating safer disposal or potential valorization pathways.

Ecotoxicological studies on DES components indicate generally lower aquatic and terrestrial toxicity compared to conventional solvents and acids. Biodegradability assessments of common DES constituents like choline chloride and natural organic acids show favorable environmental persistence profiles, with complete degradation occurring within acceptable timeframes under various environmental conditions.

Resource efficiency metrics demonstrate that DES technologies enable higher recovery rates of target metals while consuming fewer raw materials. This circular economy advantage becomes particularly significant when considering the critical nature of cobalt, nickel, and REEs in green technology applications like electric vehicle batteries and renewable energy systems.

Regulatory compliance analysis suggests that DES-based recovery processes more readily meet increasingly stringent environmental regulations in major mining jurisdictions. The inherently safer nature of many DES formulations reduces workplace hazards and potential environmental liabilities associated with accidental releases or operational upsets.

Supply Chain Security Implications for Critical Metals

The global supply chain for critical metals such as cobalt, nickel, and rare earth elements faces significant vulnerabilities that directly impact national security, economic stability, and technological advancement. These metals are essential components in renewable energy technologies, electric vehicles, defense systems, and consumer electronics, making their secure supply a strategic imperative for industrialized nations.

China currently dominates the supply chain for rare earth elements, controlling approximately 85% of global processing capacity. This concentration creates substantial geopolitical risks, as evidenced by past export restrictions that caused price volatility and supply uncertainties. Similarly, cobalt production is heavily concentrated in the Democratic Republic of Congo, which accounts for over 70% of global supply, often under questionable labor and environmental conditions.

The development of Deep Eutectic Solvents (DES) for selective recovery of these critical metals represents a transformative opportunity to address these supply chain vulnerabilities. By enabling more efficient extraction from primary ores, processing of low-grade deposits, and recovery from end-of-life products, DES technology can diversify supply sources and reduce dependence on geopolitically sensitive regions.

DES-based recovery methods offer particular promise for establishing domestic recycling capabilities within consuming nations. This circular economy approach could significantly reduce import reliance while mitigating environmental impacts associated with primary mining. For instance, the selective recovery of cobalt and nickel from spent lithium-ion batteries could recapture up to 30% of demand for these metals in advanced economies.

The security implications extend beyond simple resource availability to include environmental security and ethical sourcing considerations. Traditional extraction and processing methods for these metals often involve toxic chemicals and generate hazardous waste. DES technologies offer substantially reduced environmental footprints, potentially alleviating community opposition to processing facilities in developed nations.

From a policy perspective, investment in DES technologies aligns with broader strategic initiatives to secure critical material supply chains. Several nations, including the United States, European Union members, and Japan, have already designated rare earths, cobalt, and nickel as critical materials requiring supply chain diversification strategies. The development of DES-based recovery processes represents a technological pathway to achieve these strategic objectives.

The timeline for implementing DES technologies at commercial scale will significantly impact supply chain security planning. Current projections suggest that industrial-scale applications could be realized within 3-5 years, potentially coinciding with projected supply shortfalls for several critical metals needed for the clean energy transition.

China currently dominates the supply chain for rare earth elements, controlling approximately 85% of global processing capacity. This concentration creates substantial geopolitical risks, as evidenced by past export restrictions that caused price volatility and supply uncertainties. Similarly, cobalt production is heavily concentrated in the Democratic Republic of Congo, which accounts for over 70% of global supply, often under questionable labor and environmental conditions.

The development of Deep Eutectic Solvents (DES) for selective recovery of these critical metals represents a transformative opportunity to address these supply chain vulnerabilities. By enabling more efficient extraction from primary ores, processing of low-grade deposits, and recovery from end-of-life products, DES technology can diversify supply sources and reduce dependence on geopolitically sensitive regions.

DES-based recovery methods offer particular promise for establishing domestic recycling capabilities within consuming nations. This circular economy approach could significantly reduce import reliance while mitigating environmental impacts associated with primary mining. For instance, the selective recovery of cobalt and nickel from spent lithium-ion batteries could recapture up to 30% of demand for these metals in advanced economies.

The security implications extend beyond simple resource availability to include environmental security and ethical sourcing considerations. Traditional extraction and processing methods for these metals often involve toxic chemicals and generate hazardous waste. DES technologies offer substantially reduced environmental footprints, potentially alleviating community opposition to processing facilities in developed nations.

From a policy perspective, investment in DES technologies aligns with broader strategic initiatives to secure critical material supply chains. Several nations, including the United States, European Union members, and Japan, have already designated rare earths, cobalt, and nickel as critical materials requiring supply chain diversification strategies. The development of DES-based recovery processes represents a technological pathway to achieve these strategic objectives.

The timeline for implementing DES technologies at commercial scale will significantly impact supply chain security planning. Current projections suggest that industrial-scale applications could be realized within 3-5 years, potentially coinciding with projected supply shortfalls for several critical metals needed for the clean energy transition.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!