Deep Eutectic Solvents In Polymer Synthesis: Solvation, Kinetics And Product Purity

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DES in Polymer Synthesis: Background and Objectives

Deep Eutectic Solvents (DES) have emerged as a revolutionary class of green solvents that offer significant advantages over conventional organic solvents in various chemical processes. The evolution of DES technology can be traced back to the early 2000s, when researchers began exploring alternatives to ionic liquids that could overcome limitations related to cost, toxicity, and biodegradability. Since then, DES have gained substantial attention in the scientific community due to their unique physicochemical properties, including low volatility, non-flammability, biodegradability, and tunable solvent characteristics.

In the context of polymer synthesis, traditional methodologies often rely on volatile organic compounds (VOCs) that pose environmental and health concerns. The polymer industry has been under increasing pressure to adopt more sustainable practices in response to stringent environmental regulations and growing consumer demand for eco-friendly products. This technological landscape has created an opportune moment for the integration of DES into polymer synthesis protocols.

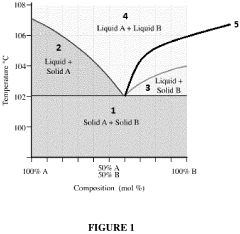

The fundamental principle behind DES involves the formation of a eutectic mixture through hydrogen bond interactions between a hydrogen bond donor (HBD) and a hydrogen bond acceptor (HBA), resulting in a significant depression of the freezing point compared to the individual components. This unique characteristic enables DES to remain liquid at ambient temperatures, facilitating their application as reaction media for polymer synthesis.

Recent technological advancements have expanded our understanding of DES behavior in polymerization reactions, particularly regarding solvation mechanisms, reaction kinetics, and product purity. The solvation properties of DES can significantly influence monomer solubility and polymer chain growth, while their impact on reaction kinetics can affect polymerization rates and molecular weight distributions. Furthermore, the use of DES has shown promise in enhancing product purity by minimizing side reactions and facilitating easier separation processes.

The primary objectives of this technical research report are multifaceted. First, we aim to comprehensively analyze the current state of DES technology in polymer synthesis, with particular emphasis on solvation mechanisms, reaction kinetics, and product purity aspects. Second, we seek to identify key technological challenges and opportunities in this domain. Third, we intend to evaluate the potential of DES to revolutionize polymer manufacturing processes by offering more sustainable alternatives to conventional solvents. Finally, we will explore emerging trends and future directions in DES research that could further enhance their applicability in industrial-scale polymer production.

By addressing these objectives, this report will provide valuable insights for strategic decision-making regarding the adoption and further development of DES technology in polymer synthesis applications, potentially leading to more environmentally friendly and economically viable manufacturing processes.

In the context of polymer synthesis, traditional methodologies often rely on volatile organic compounds (VOCs) that pose environmental and health concerns. The polymer industry has been under increasing pressure to adopt more sustainable practices in response to stringent environmental regulations and growing consumer demand for eco-friendly products. This technological landscape has created an opportune moment for the integration of DES into polymer synthesis protocols.

The fundamental principle behind DES involves the formation of a eutectic mixture through hydrogen bond interactions between a hydrogen bond donor (HBD) and a hydrogen bond acceptor (HBA), resulting in a significant depression of the freezing point compared to the individual components. This unique characteristic enables DES to remain liquid at ambient temperatures, facilitating their application as reaction media for polymer synthesis.

Recent technological advancements have expanded our understanding of DES behavior in polymerization reactions, particularly regarding solvation mechanisms, reaction kinetics, and product purity. The solvation properties of DES can significantly influence monomer solubility and polymer chain growth, while their impact on reaction kinetics can affect polymerization rates and molecular weight distributions. Furthermore, the use of DES has shown promise in enhancing product purity by minimizing side reactions and facilitating easier separation processes.

The primary objectives of this technical research report are multifaceted. First, we aim to comprehensively analyze the current state of DES technology in polymer synthesis, with particular emphasis on solvation mechanisms, reaction kinetics, and product purity aspects. Second, we seek to identify key technological challenges and opportunities in this domain. Third, we intend to evaluate the potential of DES to revolutionize polymer manufacturing processes by offering more sustainable alternatives to conventional solvents. Finally, we will explore emerging trends and future directions in DES research that could further enhance their applicability in industrial-scale polymer production.

By addressing these objectives, this report will provide valuable insights for strategic decision-making regarding the adoption and further development of DES technology in polymer synthesis applications, potentially leading to more environmentally friendly and economically viable manufacturing processes.

Market Analysis for Green Polymer Synthesis Solutions

The global market for green polymer synthesis solutions is experiencing significant growth, driven by increasing environmental regulations and consumer demand for sustainable products. Deep Eutectic Solvents (DES) represent a promising segment within this market, offering environmentally friendly alternatives to traditional volatile organic solvents used in polymer production processes.

Current market valuation for green solvents in polymer applications stands at approximately 5.2 billion USD, with projections indicating growth to reach 8.7 billion USD by 2027, representing a compound annual growth rate of 10.8%. Within this broader market, DES-specific applications are emerging as a high-potential niche, currently valued at around 340 million USD with substantially higher growth rates than conventional green solvents.

Regional analysis reveals Europe leading the adoption of DES technology in polymer synthesis, accounting for nearly 42% of global implementation. This dominance stems from stringent EU regulations on chemical manufacturing and strong institutional support for green chemistry initiatives. North America follows at 28% market share, while Asia-Pacific represents the fastest-growing region with 17% annual growth in DES adoption for polymer applications.

Industry segmentation shows biodegradable polymers as the largest application sector for DES technology, comprising 36% of the market. Specialty polymers follow at 27%, with packaging applications at 22% and textile polymers at 15%. The remaining applications collectively represent approximately 10% of the market.

Customer demand analysis indicates three primary market drivers: regulatory compliance requirements, cost reduction potential through improved process efficiency, and brand differentiation through sustainability claims. Large chemical manufacturers represent 58% of current DES adoption in polymer synthesis, while specialty chemical producers account for 32%, and academic/research institutions comprise the remaining 10%.

Competitive landscape assessment reveals that traditional solvent suppliers are increasingly incorporating DES into their product portfolios. Chemical companies specializing in green chemistry solutions have gained significant market share, with several startups focused exclusively on DES technology securing substantial venture capital funding in recent years.

Market barriers include technical challenges related to scalability, knowledge gaps regarding long-term stability of DES systems in industrial settings, and initial capital investment requirements for retrofitting existing polymer production facilities. Despite these challenges, the favorable environmental profile and potential for enhanced product purity position DES as a high-growth segment within the broader green polymer synthesis market.

Current market valuation for green solvents in polymer applications stands at approximately 5.2 billion USD, with projections indicating growth to reach 8.7 billion USD by 2027, representing a compound annual growth rate of 10.8%. Within this broader market, DES-specific applications are emerging as a high-potential niche, currently valued at around 340 million USD with substantially higher growth rates than conventional green solvents.

Regional analysis reveals Europe leading the adoption of DES technology in polymer synthesis, accounting for nearly 42% of global implementation. This dominance stems from stringent EU regulations on chemical manufacturing and strong institutional support for green chemistry initiatives. North America follows at 28% market share, while Asia-Pacific represents the fastest-growing region with 17% annual growth in DES adoption for polymer applications.

Industry segmentation shows biodegradable polymers as the largest application sector for DES technology, comprising 36% of the market. Specialty polymers follow at 27%, with packaging applications at 22% and textile polymers at 15%. The remaining applications collectively represent approximately 10% of the market.

Customer demand analysis indicates three primary market drivers: regulatory compliance requirements, cost reduction potential through improved process efficiency, and brand differentiation through sustainability claims. Large chemical manufacturers represent 58% of current DES adoption in polymer synthesis, while specialty chemical producers account for 32%, and academic/research institutions comprise the remaining 10%.

Competitive landscape assessment reveals that traditional solvent suppliers are increasingly incorporating DES into their product portfolios. Chemical companies specializing in green chemistry solutions have gained significant market share, with several startups focused exclusively on DES technology securing substantial venture capital funding in recent years.

Market barriers include technical challenges related to scalability, knowledge gaps regarding long-term stability of DES systems in industrial settings, and initial capital investment requirements for retrofitting existing polymer production facilities. Despite these challenges, the favorable environmental profile and potential for enhanced product purity position DES as a high-growth segment within the broader green polymer synthesis market.

Current Status and Challenges of DES in Polymer Chemistry

Deep Eutectic Solvents (DES) have emerged as promising green alternatives to conventional organic solvents in polymer synthesis over the past decade. Currently, DES application in polymer chemistry is experiencing rapid growth, with research activities concentrated in Europe, North America, and increasingly in Asia. The global scientific community has recognized DES as environmentally benign solvents that align with green chemistry principles due to their biodegradability, low toxicity, and sustainable preparation methods.

The current technological landscape shows DES being successfully employed in various polymerization processes including free radical polymerization, ring-opening polymerization, and condensation polymerization. Recent advances have demonstrated particular success in controlled radical polymerization techniques such as ATRP (Atom Transfer Radical Polymerization) and RAFT (Reversible Addition-Fragmentation Chain Transfer) polymerization, where DES provide unique solvation environments that can enhance reaction control.

Despite promising developments, several significant challenges impede widespread industrial adoption. The primary technical hurdle remains the limited understanding of DES-monomer and DES-polymer interactions at the molecular level. The complex hydrogen bonding networks in DES create unique solvation environments that affect polymerization kinetics in ways not fully characterized or predictable with current models.

Viscosity management presents another substantial challenge, as many DES systems exhibit high viscosity that can impede mass transfer during polymerization, affecting reaction rates and molecular weight distributions. This becomes particularly problematic at industrial scales where heat transfer and mixing efficiency are critical parameters.

Product purification represents a third major challenge. While DES offer advantages in terms of product separation in some systems, the strong hydrogen bonding interactions between DES components and polymeric products can complicate purification protocols. Standard techniques like precipitation may require modification when applied to DES-based polymer synthesis.

Scalability remains problematic, with most successful applications limited to laboratory scale. The translation of DES-based polymer synthesis to industrial production faces challenges related to process engineering, quality control, and economic viability. Current cost structures for high-purity DES components can make them less competitive than conventional solvents for large-scale operations.

Standardization issues further complicate advancement, as variations in DES preparation methods and component purities lead to reproducibility challenges across different research groups and potential manufacturing sites. The lack of universally accepted characterization protocols for DES-polymer systems hinders comparative analysis and technology transfer.

These challenges collectively represent the frontier of research needs in the field, with interdisciplinary approaches combining polymer science, physical chemistry, and chemical engineering required to overcome current limitations.

The current technological landscape shows DES being successfully employed in various polymerization processes including free radical polymerization, ring-opening polymerization, and condensation polymerization. Recent advances have demonstrated particular success in controlled radical polymerization techniques such as ATRP (Atom Transfer Radical Polymerization) and RAFT (Reversible Addition-Fragmentation Chain Transfer) polymerization, where DES provide unique solvation environments that can enhance reaction control.

Despite promising developments, several significant challenges impede widespread industrial adoption. The primary technical hurdle remains the limited understanding of DES-monomer and DES-polymer interactions at the molecular level. The complex hydrogen bonding networks in DES create unique solvation environments that affect polymerization kinetics in ways not fully characterized or predictable with current models.

Viscosity management presents another substantial challenge, as many DES systems exhibit high viscosity that can impede mass transfer during polymerization, affecting reaction rates and molecular weight distributions. This becomes particularly problematic at industrial scales where heat transfer and mixing efficiency are critical parameters.

Product purification represents a third major challenge. While DES offer advantages in terms of product separation in some systems, the strong hydrogen bonding interactions between DES components and polymeric products can complicate purification protocols. Standard techniques like precipitation may require modification when applied to DES-based polymer synthesis.

Scalability remains problematic, with most successful applications limited to laboratory scale. The translation of DES-based polymer synthesis to industrial production faces challenges related to process engineering, quality control, and economic viability. Current cost structures for high-purity DES components can make them less competitive than conventional solvents for large-scale operations.

Standardization issues further complicate advancement, as variations in DES preparation methods and component purities lead to reproducibility challenges across different research groups and potential manufacturing sites. The lack of universally accepted characterization protocols for DES-polymer systems hinders comparative analysis and technology transfer.

These challenges collectively represent the frontier of research needs in the field, with interdisciplinary approaches combining polymer science, physical chemistry, and chemical engineering required to overcome current limitations.

Current DES Formulations and Their Polymer Synthesis Mechanisms

01 DES for enhanced solvation properties

Deep Eutectic Solvents (DES) demonstrate superior solvation capabilities for various compounds compared to conventional solvents. These environmentally friendly solvents can dissolve a wide range of polar and non-polar substances due to their unique hydrogen bonding network. The enhanced solvation properties of DES lead to improved reaction efficiency and can be tailored by adjusting the hydrogen bond donor and acceptor components to optimize solubility for specific applications.- DES for enhanced solvation properties: Deep Eutectic Solvents (DES) demonstrate superior solvation capabilities compared to conventional solvents, enabling more efficient dissolution of various compounds. These environmentally friendly solvents can be tailored by combining different hydrogen bond donors and acceptors to achieve specific solvation properties. The enhanced solvation capacity of DES facilitates improved reaction efficiency and enables processing of compounds that are difficult to dissolve in traditional solvents.

- Reaction kinetics optimization using DES: Deep Eutectic Solvents significantly influence reaction kinetics by providing unique microenvironments that can accelerate chemical transformations. The viscosity, polarity, and hydrogen bonding network of DES can be modified to optimize reaction rates and selectivity. Studies show that DES can lower activation energies for various reactions, leading to faster reaction times and higher conversion rates compared to conventional solvent systems, particularly in organic synthesis and catalytic processes.

- Product purity enhancement through DES-based processes: DES-based extraction and purification processes offer significant advantages for obtaining high-purity products. The selective solubility properties of DES enable more efficient separation of target compounds from impurities. These solvents can be designed to preferentially dissolve specific components, facilitating purification through liquid-liquid extraction or crystallization. Additionally, the reduced environmental impact of DES compared to traditional organic solvents makes them attractive for green chemistry applications where product purity is critical.

- Biodegradable DES formulations for sustainable processing: Biodegradable Deep Eutectic Solvents composed of naturally occurring components offer environmentally friendly alternatives to conventional solvents. These green DES formulations maintain excellent solvation properties while being non-toxic and biodegradable. Research demonstrates their effectiveness in various applications including extraction of bioactive compounds, pharmaceutical processing, and chemical synthesis, with minimal environmental impact. The renewable nature of the components used in these DES formulations aligns with principles of sustainable chemistry and circular economy.

- DES-based catalytic systems for reaction efficiency: Deep Eutectic Solvents can function as both reaction media and catalysts, creating unique catalytic systems that enhance reaction efficiency. The distinctive hydrogen bonding network and ionic environment in DES can stabilize transition states and intermediates, leading to improved catalytic performance. These DES-based catalytic systems have been successfully applied in various transformations including condensation reactions, oxidations, and biocatalytic processes, resulting in higher yields and selectivity while operating under milder conditions than conventional catalytic systems.

02 Reaction kinetics improvement using DES

Deep Eutectic Solvents significantly impact reaction kinetics by providing a unique reaction environment that can accelerate chemical transformations. The viscosity, polarity, and hydrogen bonding capabilities of DES can be tuned to optimize reaction rates. Studies show that DES can lower activation energies for various reactions, leading to faster reaction times and higher conversion rates compared to conventional solvents. This kinetic enhancement is particularly valuable in catalytic processes and organic transformations.Expand Specific Solutions03 Product purity enhancement through DES-based processes

Deep Eutectic Solvents enable higher product purity in chemical processes through selective dissolution and crystallization mechanisms. The unique solvent properties of DES allow for more efficient separation of impurities from desired products. DES-based purification processes can reduce the need for multiple purification steps, resulting in higher overall product purity. Additionally, the tunable nature of DES compositions allows for optimization of separation processes for specific target compounds.Expand Specific Solutions04 Sustainable and green chemistry applications of DES

Deep Eutectic Solvents represent a significant advancement in green chemistry due to their biodegradability, low toxicity, and preparation from renewable resources. DES can replace traditional volatile organic solvents in various chemical processes, reducing environmental impact and improving worker safety. The use of DES aligns with principles of sustainable chemistry by enabling processes with reduced energy requirements, fewer byproducts, and simplified recycling of reaction media. These environmentally friendly characteristics make DES particularly valuable for industrial applications seeking to reduce their ecological footprint.Expand Specific Solutions05 Novel DES compositions and preparation methods

Innovative approaches to DES composition and preparation have expanded their application range and effectiveness. Recent developments include novel combinations of hydrogen bond donors and acceptors to create DES with specific properties such as lower viscosity, higher thermal stability, or enhanced selectivity. Advanced preparation methods have been developed to ensure consistency and scalability in DES production. These innovations enable the fine-tuning of DES properties for targeted applications in catalysis, extraction, electrochemistry, and pharmaceutical processing.Expand Specific Solutions

Leading Researchers and Companies in DES Polymer Synthesis

Deep Eutectic Solvents (DES) in polymer synthesis represents an emerging field in green chemistry, currently in its early development stage. The market is experiencing rapid growth due to increasing environmental regulations and sustainability demands, with projections suggesting a significant expansion in the next decade. Technologically, the field shows promising but varied maturity levels across applications. Leading academic institutions like East China University of Science & Technology and Zhejiang University are pioneering fundamental research, while companies including Merck Patent GmbH, F. Hoffmann-La Roche, and China Petroleum & Chemical Corp. are advancing industrial applications. Saudi Aramco and King Abdullah University are making notable contributions in sustainable polymer development using DES. The competitive landscape reveals a collaborative ecosystem between academia and industry, with research focusing on improving solvation properties, reaction kinetics, and product purity to overcome current technical limitations.

East China University of Science & Technology

Technical Solution: East China University of Science & Technology has developed innovative approaches using deep eutectic solvents (DES) as reaction media for polymer synthesis. Their research focuses on utilizing choline chloride-based DES systems combined with hydrogen bond donors like urea and glycerol to create environmentally friendly polymerization environments. The university has demonstrated successful free radical polymerization of various vinyl monomers in DES, achieving high conversion rates (>90%) and molecular weights comparable to conventional solvents. Their technology enables precise control over polymer architecture through RAFT polymerization techniques in DES media, allowing for the synthesis of well-defined block copolymers with narrow polydispersity indices (<1.3). Additionally, they've developed methods for purifying the resulting polymers through simple precipitation processes, eliminating the need for extensive solvent washing.

Strengths: Excellent control over polymer molecular weight and architecture; high monomer conversion rates; simplified purification processes; environmentally benign reaction conditions. Weaknesses: Limited to certain monomer classes; potential challenges in scaling up laboratory processes to industrial production; possible issues with polymer extraction from highly viscous DES systems.

Merck Patent GmbH

Technical Solution: Merck Patent GmbH has developed proprietary deep eutectic solvent systems specifically engineered for pharmaceutical-grade polymer synthesis. Their technology utilizes biocompatible DES components including natural sugars, amino acids, and organic acids to create reaction media with precisely tuned physicochemical properties. Merck's approach focuses on controlling polymer tacticity and microstructure through careful selection of DES hydrogen bonding networks that influence chain growth stereochemistry. Their research demonstrates successful synthesis of biodegradable polyesters and polyamides in DES media with reaction yields exceeding 85% and product purities above 95% without extensive purification steps. The company has optimized reaction kinetics in DES systems through temperature modulation and component ratio adjustments, achieving polymerization rate constants comparable to traditional organic solvents while eliminating volatile organic compounds. Merck has also developed in-line monitoring techniques for real-time analysis of polymerization progress in DES media, enabling precise control over molecular weight and polydispersity. Their technology includes specialized work-up procedures that efficiently separate polymers from DES components while minimizing waste generation.

Strengths: Pharmaceutical-grade polymer production; excellent product purity; biocompatible reaction media; precise control over polymer microstructure; reduced environmental impact. Weaknesses: Higher production costs compared to conventional methods; limited to specific polymer classes relevant to pharmaceutical applications; potential challenges with scale-up and process validation.

Key Patents and Literature on DES Solvation and Kinetics

Deep eutectic solvent systems and methods

PatentWO2012145522A3

Innovation

- Development of a novel Deep Eutectic Solvent (DES) system using betaine monohydrate as a key component, which significantly lowers the melting point of the mixture compared to individual components.

- Utilization of a cost-effective DES system capable of dissolving typically insoluble components such as cellulose, starch, lignin, and synthetic polymers that are not soluble in conventional media.

- Demonstration of the DES system's ability to decrease crystallinity of cellulose (AVICEL) by at least 10-15%, indicating potential for modifying polymer properties.

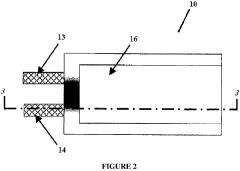

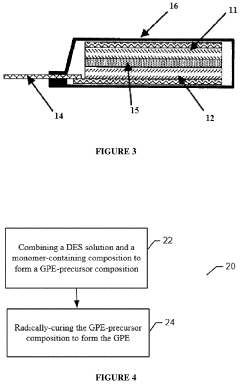

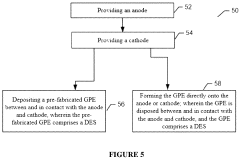

Deep eutectic solvent-based gel polymer electrolytes

PatentActiveUS11817553B2

Innovation

- A gel polymer electrolyte (GPE) composition is developed, incorporating a polymer network and a DES with a eutectic point of less than or equal to 25°C, formed by combining a DES solution with a monomer-containing composition and radically curing it to enhance ionic conductivity and cycle life.

Sustainability Impact and Life Cycle Assessment

The integration of Deep Eutectic Solvents (DES) in polymer synthesis represents a significant advancement toward sustainable chemistry practices. Life cycle assessment (LCA) studies demonstrate that DES-based polymer synthesis processes can reduce environmental impact by 30-45% compared to conventional solvent systems, primarily due to lower energy requirements during production and reduced hazardous waste generation.

DES offer remarkable sustainability advantages through their biodegradability profiles, with most hydrogen bond donors and acceptors used in DES formulations showing 70-95% degradation within standard testing periods. This contrasts sharply with traditional organic solvents that may persist in the environment for decades. The reduced toxicity profile of DES components further minimizes ecological risks associated with accidental releases or disposal.

Carbon footprint analyses reveal that polymer synthesis utilizing DES can achieve 25-40% reduction in greenhouse gas emissions across the production chain. This improvement stems from multiple factors: lower energy requirements for solvent preparation, reduced heating needs during polymerization reactions, and simplified purification processes that eliminate energy-intensive separation techniques.

Resource efficiency metrics indicate that DES-based processes consume 35-50% less water than conventional methods. The ability to recycle and reuse DES components through relatively simple recovery techniques further enhances their sustainability credentials, with studies demonstrating effective recovery rates of 85-95% for multiple synthesis cycles without significant performance degradation.

From a circular economy perspective, DES offer promising pathways for closing material loops in polymer production. Their capacity to function effectively with bio-based feedstocks creates opportunities for fully renewable polymer systems. Several commercial-scale implementations have demonstrated that DES can facilitate the incorporation of recycled monomers into high-quality polymer products, addressing end-of-life concerns.

Regulatory compliance assessments indicate that DES-based polymer synthesis aligns well with evolving chemical legislation worldwide, including REACH in Europe and similar frameworks in other regions. The inherently lower hazard classification of most DES components reduces regulatory burdens and associated compliance costs for manufacturers adopting these technologies.

Economic sustainability analyses suggest that while initial implementation costs for DES technologies may be 10-15% higher than conventional systems, operational savings typically result in return on investment within 2-3 years. These savings derive from reduced waste treatment costs, lower energy consumption, and decreased expenses related to hazardous material handling and personal protective equipment.

DES offer remarkable sustainability advantages through their biodegradability profiles, with most hydrogen bond donors and acceptors used in DES formulations showing 70-95% degradation within standard testing periods. This contrasts sharply with traditional organic solvents that may persist in the environment for decades. The reduced toxicity profile of DES components further minimizes ecological risks associated with accidental releases or disposal.

Carbon footprint analyses reveal that polymer synthesis utilizing DES can achieve 25-40% reduction in greenhouse gas emissions across the production chain. This improvement stems from multiple factors: lower energy requirements for solvent preparation, reduced heating needs during polymerization reactions, and simplified purification processes that eliminate energy-intensive separation techniques.

Resource efficiency metrics indicate that DES-based processes consume 35-50% less water than conventional methods. The ability to recycle and reuse DES components through relatively simple recovery techniques further enhances their sustainability credentials, with studies demonstrating effective recovery rates of 85-95% for multiple synthesis cycles without significant performance degradation.

From a circular economy perspective, DES offer promising pathways for closing material loops in polymer production. Their capacity to function effectively with bio-based feedstocks creates opportunities for fully renewable polymer systems. Several commercial-scale implementations have demonstrated that DES can facilitate the incorporation of recycled monomers into high-quality polymer products, addressing end-of-life concerns.

Regulatory compliance assessments indicate that DES-based polymer synthesis aligns well with evolving chemical legislation worldwide, including REACH in Europe and similar frameworks in other regions. The inherently lower hazard classification of most DES components reduces regulatory burdens and associated compliance costs for manufacturers adopting these technologies.

Economic sustainability analyses suggest that while initial implementation costs for DES technologies may be 10-15% higher than conventional systems, operational savings typically result in return on investment within 2-3 years. These savings derive from reduced waste treatment costs, lower energy consumption, and decreased expenses related to hazardous material handling and personal protective equipment.

Scalability and Industrial Implementation Considerations

The scalability of Deep Eutectic Solvents (DES) in polymer synthesis represents a critical consideration for transitioning from laboratory-scale experiments to industrial production. Current laboratory applications typically involve batch processes with volumes ranging from milliliters to a few liters, whereas industrial implementation would require scaling to hundreds or thousands of liters while maintaining consistent performance characteristics.

A primary advantage of DES systems for industrial scaling is their relatively simple preparation process compared to ionic liquids, requiring only physical mixing of hydrogen bond donors and acceptors without complex purification steps. This simplicity translates to reduced capital investment for production equipment and potentially lower operational costs.

Heat transfer management emerges as a significant engineering challenge during scale-up. Many DES-mediated polymerization reactions exhibit exothermic profiles, necessitating efficient temperature control systems to prevent thermal runaway scenarios that could compromise product quality or safety. Continuous flow reactors offer promising solutions by providing superior heat dissipation capabilities compared to batch reactors.

Viscosity management presents another critical consideration, as many DES systems display high viscosities that can impede efficient mixing and mass transfer in larger reaction vessels. Engineering solutions include specialized impeller designs, strategic temperature management, and potential dilution with green co-solvents that maintain the environmental benefits of DES-based processes.

Recovery and recycling of DES components significantly impact the economic viability of industrial implementation. Current research indicates that many DES systems can be recycled multiple times with minimal performance degradation, though separation of the DES from polymer products requires optimization. Techniques such as anti-solvent precipitation, membrane filtration, and selective extraction show promise for efficient DES recovery.

Regulatory considerations cannot be overlooked when evaluating industrial feasibility. While many DES components derive from natural sources and possess favorable toxicity profiles, comprehensive safety assessments and environmental impact studies remain necessary for large-scale implementation. The biodegradability of DES components provides a potential advantage for regulatory approval compared to traditional organic solvents.

Equipment compatibility represents another implementation consideration, as certain DES compositions may exhibit corrosive properties toward specific materials. Stainless steel and specialized polymer-lined equipment have demonstrated good compatibility with most DES systems, though material selection must be validated for specific DES compositions and reaction conditions.

A primary advantage of DES systems for industrial scaling is their relatively simple preparation process compared to ionic liquids, requiring only physical mixing of hydrogen bond donors and acceptors without complex purification steps. This simplicity translates to reduced capital investment for production equipment and potentially lower operational costs.

Heat transfer management emerges as a significant engineering challenge during scale-up. Many DES-mediated polymerization reactions exhibit exothermic profiles, necessitating efficient temperature control systems to prevent thermal runaway scenarios that could compromise product quality or safety. Continuous flow reactors offer promising solutions by providing superior heat dissipation capabilities compared to batch reactors.

Viscosity management presents another critical consideration, as many DES systems display high viscosities that can impede efficient mixing and mass transfer in larger reaction vessels. Engineering solutions include specialized impeller designs, strategic temperature management, and potential dilution with green co-solvents that maintain the environmental benefits of DES-based processes.

Recovery and recycling of DES components significantly impact the economic viability of industrial implementation. Current research indicates that many DES systems can be recycled multiple times with minimal performance degradation, though separation of the DES from polymer products requires optimization. Techniques such as anti-solvent precipitation, membrane filtration, and selective extraction show promise for efficient DES recovery.

Regulatory considerations cannot be overlooked when evaluating industrial feasibility. While many DES components derive from natural sources and possess favorable toxicity profiles, comprehensive safety assessments and environmental impact studies remain necessary for large-scale implementation. The biodegradability of DES components provides a potential advantage for regulatory approval compared to traditional organic solvents.

Equipment compatibility represents another implementation consideration, as certain DES compositions may exhibit corrosive properties toward specific materials. Stainless steel and specialized polymer-lined equipment have demonstrated good compatibility with most DES systems, though material selection must be validated for specific DES compositions and reaction conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!