Deep Eutectic Solvents In Biomass Pretreatment: Lignin Dissolution, Cellulose Integrity And Recovery

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DES Technology Background and Objectives

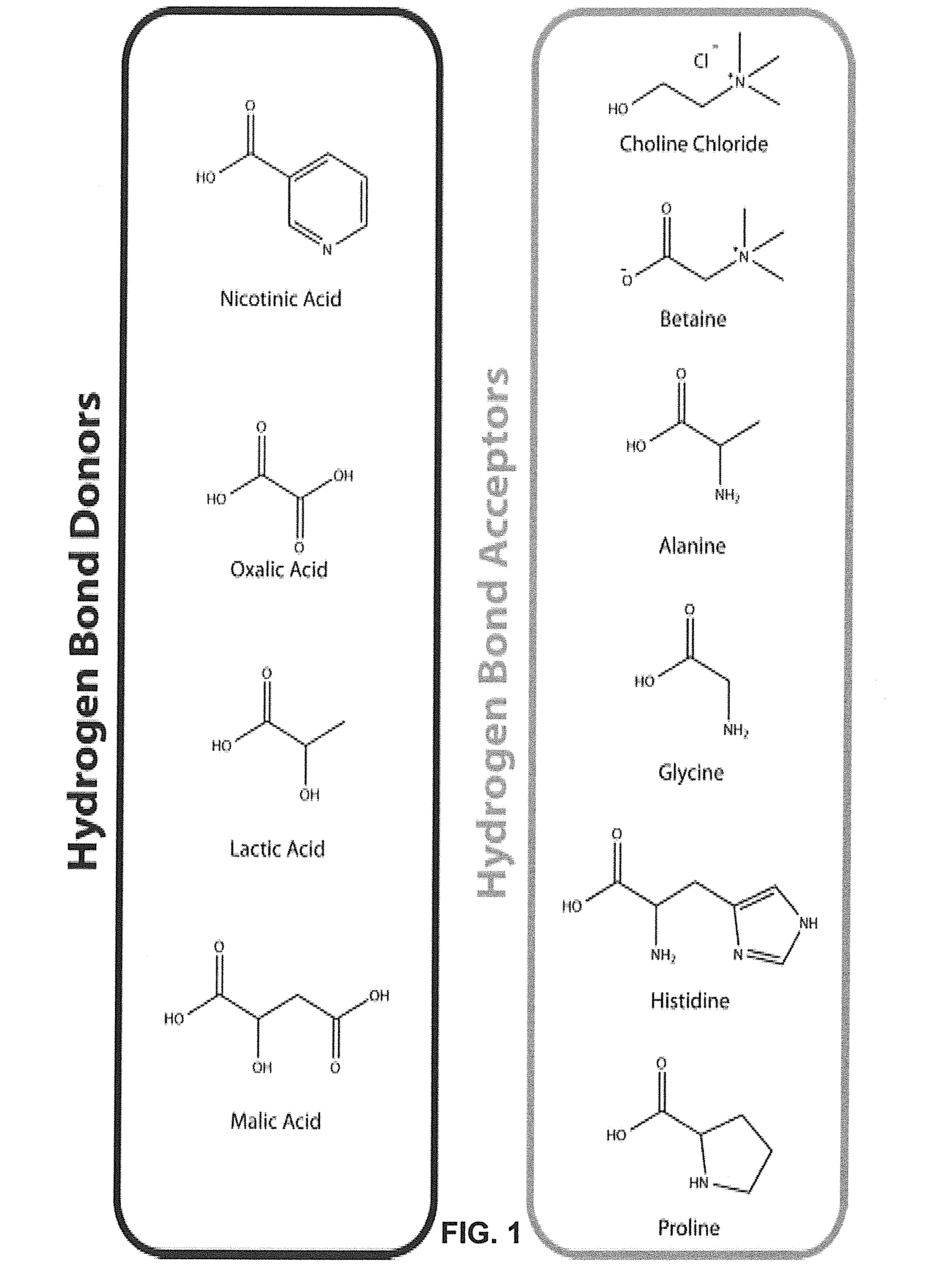

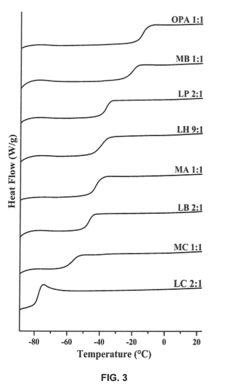

Deep Eutectic Solvents (DES) represent a revolutionary class of green solvents that have emerged as a promising alternative to conventional pretreatment methods for biomass processing. The concept of DES was first introduced in the early 2000s, but their application in biomass pretreatment has gained significant momentum only in the past decade. These solvents are formed by complexation between hydrogen bond acceptors (HBAs) and hydrogen bond donors (HBDs), resulting in a eutectic mixture with a melting point significantly lower than either of the individual components.

The evolution of biomass pretreatment technologies has traversed from harsh chemical methods using concentrated acids or bases to more environmentally benign approaches. Traditional pretreatment methods often suffer from drawbacks including high energy consumption, equipment corrosion, environmental pollution, and degradation of valuable biomass components. DES technology represents a paradigm shift in this domain, offering a more sustainable approach to biomass fractionation.

The fundamental principle behind DES application in biomass processing lies in their ability to selectively dissolve lignin while preserving cellulose integrity. This selective dissolution is attributed to the unique hydrogen bonding network within DES systems that can effectively disrupt the recalcitrant lignin-carbohydrate complexes in lignocellulosic biomass. The technology has evolved from simple choline chloride-based DES to more sophisticated formulations tailored for specific biomass types.

Recent technological trends indicate a growing interest in developing DES systems with enhanced selectivity, recyclability, and efficiency. Research has expanded to include various combinations of HBAs and HBDs, optimization of pretreatment conditions, and integration with other processing technologies. The field is witnessing a transition from laboratory-scale investigations to pilot-scale demonstrations, signaling the maturation of this technology.

The primary technical objectives for DES in biomass pretreatment encompass several dimensions: maximizing lignin dissolution efficiency, maintaining cellulose structural integrity, facilitating high recovery rates of both lignin and cellulose, minimizing energy requirements, and ensuring environmental sustainability. Additionally, there is a growing emphasis on developing DES formulations that can be easily recycled and reused, thereby enhancing the economic viability of the process.

Looking forward, the technology aims to address the scalability challenges and establish standardized protocols for different biomass feedstocks. The ultimate goal is to position DES as a cornerstone technology in biorefinery operations, enabling the efficient conversion of lignocellulosic biomass into high-value products while adhering to the principles of green chemistry and circular economy.

The evolution of biomass pretreatment technologies has traversed from harsh chemical methods using concentrated acids or bases to more environmentally benign approaches. Traditional pretreatment methods often suffer from drawbacks including high energy consumption, equipment corrosion, environmental pollution, and degradation of valuable biomass components. DES technology represents a paradigm shift in this domain, offering a more sustainable approach to biomass fractionation.

The fundamental principle behind DES application in biomass processing lies in their ability to selectively dissolve lignin while preserving cellulose integrity. This selective dissolution is attributed to the unique hydrogen bonding network within DES systems that can effectively disrupt the recalcitrant lignin-carbohydrate complexes in lignocellulosic biomass. The technology has evolved from simple choline chloride-based DES to more sophisticated formulations tailored for specific biomass types.

Recent technological trends indicate a growing interest in developing DES systems with enhanced selectivity, recyclability, and efficiency. Research has expanded to include various combinations of HBAs and HBDs, optimization of pretreatment conditions, and integration with other processing technologies. The field is witnessing a transition from laboratory-scale investigations to pilot-scale demonstrations, signaling the maturation of this technology.

The primary technical objectives for DES in biomass pretreatment encompass several dimensions: maximizing lignin dissolution efficiency, maintaining cellulose structural integrity, facilitating high recovery rates of both lignin and cellulose, minimizing energy requirements, and ensuring environmental sustainability. Additionally, there is a growing emphasis on developing DES formulations that can be easily recycled and reused, thereby enhancing the economic viability of the process.

Looking forward, the technology aims to address the scalability challenges and establish standardized protocols for different biomass feedstocks. The ultimate goal is to position DES as a cornerstone technology in biorefinery operations, enabling the efficient conversion of lignocellulosic biomass into high-value products while adhering to the principles of green chemistry and circular economy.

Market Analysis for Biomass Pretreatment Solutions

The global biomass pretreatment solutions market is experiencing significant growth, driven by increasing demand for sustainable alternatives to fossil fuels and petroleum-based products. The market was valued at approximately $1.5 billion in 2022 and is projected to reach $2.8 billion by 2030, growing at a compound annual growth rate of around 8.2% during the forecast period.

Biomass pretreatment technologies are essential for converting lignocellulosic biomass into valuable products such as biofuels, biochemicals, and biomaterials. Traditional pretreatment methods including dilute acid, alkaline, and steam explosion treatments have dominated the market. However, these conventional approaches face significant challenges related to environmental concerns, high energy consumption, and degradation of valuable biomass components.

Deep Eutectic Solvents (DES) represent an emerging segment within the biomass pretreatment market, offering significant advantages over conventional methods. The DES-based pretreatment solutions segment is currently small but growing rapidly at over 12% annually, outpacing the overall market growth rate. This acceleration is primarily driven by the superior performance of DES in lignin dissolution while maintaining cellulose integrity.

Geographically, North America and Europe lead the biomass pretreatment market, accounting for approximately 60% of the global market share. This dominance stems from stringent environmental regulations, substantial research funding, and strong commitment to reducing carbon emissions. The Asia-Pacific region, particularly China and India, represents the fastest-growing market due to rapid industrialization, increasing energy demands, and government initiatives promoting bioeconomy development.

By application, the biofuel sector currently consumes the largest share of biomass pretreatment solutions, accounting for approximately 45% of the market. However, high-value applications in biochemicals and biomaterials are growing more rapidly, with projected annual growth rates exceeding 10%. This shift reflects the industry's movement toward higher-margin products and integrated biorefinery concepts.

Customer segments for biomass pretreatment solutions include biorefinery operators, pulp and paper industries, biofuel producers, and specialty chemical manufacturers. Large-scale biorefineries represent the primary customer base, but small and medium-sized enterprises are increasingly adopting these technologies as they become more accessible and cost-effective.

Market barriers include high initial capital investment requirements, technological complexity, and competition from established fossil-based industries. However, favorable government policies, increasing environmental awareness, and technological advancements are expected to overcome these challenges, driving continued market expansion for innovative biomass pretreatment solutions like DES.

Biomass pretreatment technologies are essential for converting lignocellulosic biomass into valuable products such as biofuels, biochemicals, and biomaterials. Traditional pretreatment methods including dilute acid, alkaline, and steam explosion treatments have dominated the market. However, these conventional approaches face significant challenges related to environmental concerns, high energy consumption, and degradation of valuable biomass components.

Deep Eutectic Solvents (DES) represent an emerging segment within the biomass pretreatment market, offering significant advantages over conventional methods. The DES-based pretreatment solutions segment is currently small but growing rapidly at over 12% annually, outpacing the overall market growth rate. This acceleration is primarily driven by the superior performance of DES in lignin dissolution while maintaining cellulose integrity.

Geographically, North America and Europe lead the biomass pretreatment market, accounting for approximately 60% of the global market share. This dominance stems from stringent environmental regulations, substantial research funding, and strong commitment to reducing carbon emissions. The Asia-Pacific region, particularly China and India, represents the fastest-growing market due to rapid industrialization, increasing energy demands, and government initiatives promoting bioeconomy development.

By application, the biofuel sector currently consumes the largest share of biomass pretreatment solutions, accounting for approximately 45% of the market. However, high-value applications in biochemicals and biomaterials are growing more rapidly, with projected annual growth rates exceeding 10%. This shift reflects the industry's movement toward higher-margin products and integrated biorefinery concepts.

Customer segments for biomass pretreatment solutions include biorefinery operators, pulp and paper industries, biofuel producers, and specialty chemical manufacturers. Large-scale biorefineries represent the primary customer base, but small and medium-sized enterprises are increasingly adopting these technologies as they become more accessible and cost-effective.

Market barriers include high initial capital investment requirements, technological complexity, and competition from established fossil-based industries. However, favorable government policies, increasing environmental awareness, and technological advancements are expected to overcome these challenges, driving continued market expansion for innovative biomass pretreatment solutions like DES.

Current Challenges in DES Biomass Processing

Despite the promising potential of Deep Eutectic Solvents (DES) in biomass pretreatment, several significant challenges currently impede their widespread industrial adoption. The primary obstacle remains the high viscosity of most DES systems, particularly at ambient temperatures, which substantially hinders mass transfer efficiency during biomass processing. This characteristic necessitates either operation at elevated temperatures or the addition of co-solvents, both of which introduce additional process complexities and energy requirements.

The recovery and recycling of DES components present another formidable challenge. Current separation methods often fail to achieve complete recovery of the hydrogen bond donor and acceptor constituents, leading to gradual degradation of solvent performance over multiple cycles. This issue is exacerbated by the strong interactions between DES components and dissolved biomass fractions, particularly lignin, which complicates separation processes.

Scalability concerns persist as most successful DES applications have been demonstrated only at laboratory scale. The transition to industrial-scale operations faces hurdles related to process design, equipment compatibility, and maintaining consistent performance across larger volumes. Additionally, the economic viability of DES-based processes remains questionable when factoring in the costs of DES preparation, energy requirements for processing, and component recovery expenses.

From a fundamental science perspective, the mechanisms governing lignin dissolution and cellulose preservation in various DES systems are not fully elucidated. This knowledge gap hampers the rational design of optimized DES formulations for specific biomass feedstocks. The complex and heterogeneous nature of biomass further complicates this challenge, as DES performance varies significantly across different plant species and tissue types.

Environmental and safety considerations also present ongoing challenges. While DES are generally considered greener alternatives to conventional solvents, comprehensive life cycle assessments and toxicity studies remain limited. Some DES components, particularly certain hydrogen bond donors, may pose toxicity concerns that require thorough evaluation before large-scale implementation.

Process integration represents another significant hurdle, as incorporating DES pretreatment into existing biorefinery configurations requires substantial process modifications. The compatibility of DES-treated biomass with downstream enzymatic hydrolysis and fermentation processes needs further optimization to ensure seamless integration and maximum product yields.

The recovery and recycling of DES components present another formidable challenge. Current separation methods often fail to achieve complete recovery of the hydrogen bond donor and acceptor constituents, leading to gradual degradation of solvent performance over multiple cycles. This issue is exacerbated by the strong interactions between DES components and dissolved biomass fractions, particularly lignin, which complicates separation processes.

Scalability concerns persist as most successful DES applications have been demonstrated only at laboratory scale. The transition to industrial-scale operations faces hurdles related to process design, equipment compatibility, and maintaining consistent performance across larger volumes. Additionally, the economic viability of DES-based processes remains questionable when factoring in the costs of DES preparation, energy requirements for processing, and component recovery expenses.

From a fundamental science perspective, the mechanisms governing lignin dissolution and cellulose preservation in various DES systems are not fully elucidated. This knowledge gap hampers the rational design of optimized DES formulations for specific biomass feedstocks. The complex and heterogeneous nature of biomass further complicates this challenge, as DES performance varies significantly across different plant species and tissue types.

Environmental and safety considerations also present ongoing challenges. While DES are generally considered greener alternatives to conventional solvents, comprehensive life cycle assessments and toxicity studies remain limited. Some DES components, particularly certain hydrogen bond donors, may pose toxicity concerns that require thorough evaluation before large-scale implementation.

Process integration represents another significant hurdle, as incorporating DES pretreatment into existing biorefinery configurations requires substantial process modifications. The compatibility of DES-treated biomass with downstream enzymatic hydrolysis and fermentation processes needs further optimization to ensure seamless integration and maximum product yields.

Current DES Formulations for Lignin Extraction

01 DES composition for lignin dissolution

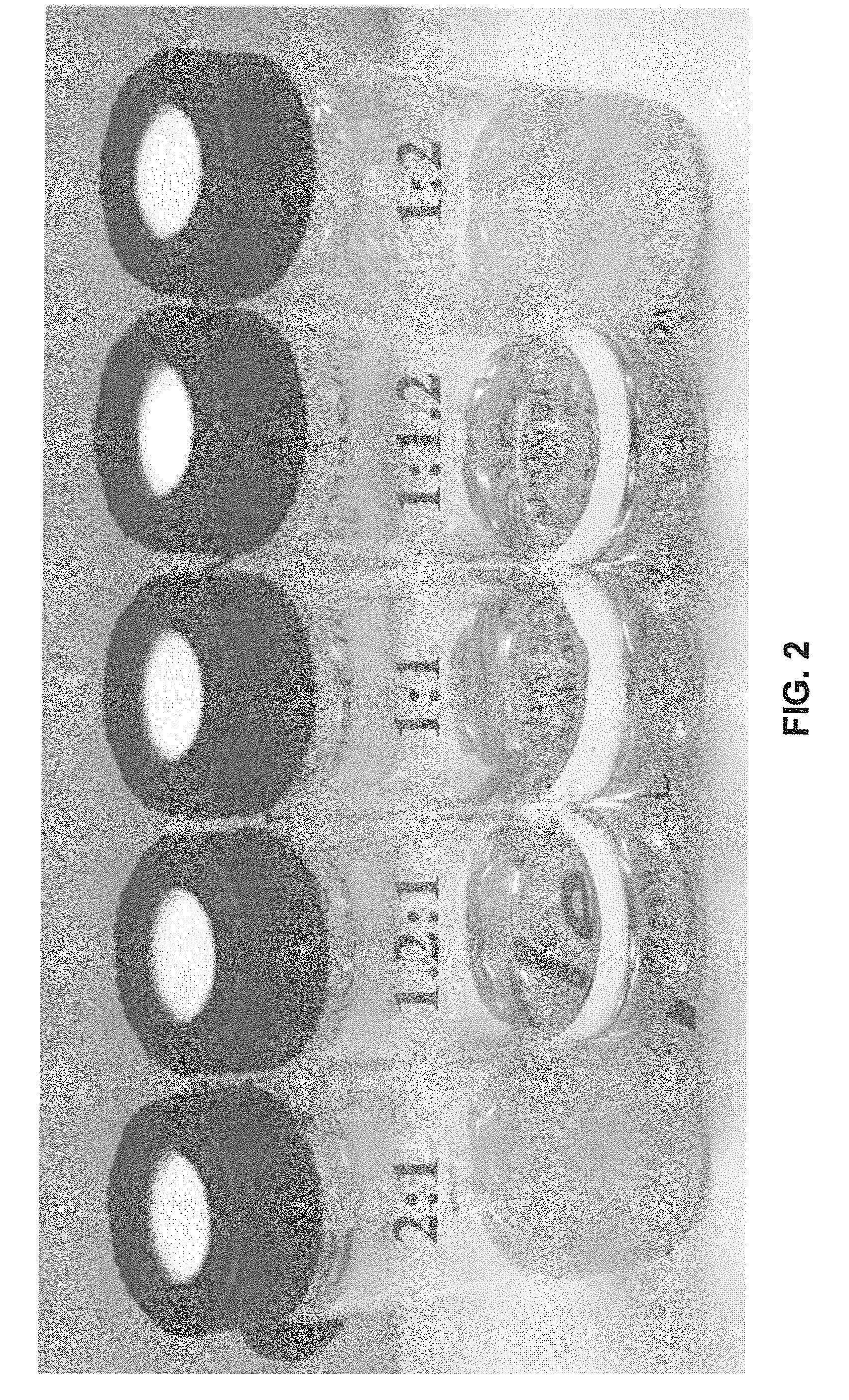

Deep Eutectic Solvents (DES) can be formulated with specific components to effectively dissolve lignin while maintaining cellulose integrity. These compositions typically include hydrogen bond donors (like organic acids or alcohols) and hydrogen bond acceptors (such as choline chloride or quaternary ammonium salts). The molar ratio and selection of components significantly affect the dissolution efficiency and selectivity toward lignin, allowing for effective biomass fractionation while preserving cellulosic structures.- DES composition for lignin dissolution: Deep Eutectic Solvents (DES) with specific compositions can effectively dissolve lignin while maintaining cellulose integrity. These DES typically consist of hydrogen bond donors (like organic acids) and hydrogen bond acceptors (like choline chloride) in specific molar ratios. The composition can be optimized to selectively dissolve lignin from lignocellulosic biomass while preserving the cellulose structure, which is crucial for subsequent processing steps.

- Process conditions for DES-based lignin extraction: The efficiency of lignin dissolution using DES depends on process conditions such as temperature, time, and solid-to-liquid ratio. Optimal conditions typically involve moderate temperatures (80-120°C) and treatment times of 2-6 hours. These conditions allow for effective lignin removal while minimizing cellulose degradation. The process can be further enhanced by mechanical agitation or ultrasonic assistance to improve mass transfer and dissolution kinetics.

- Recovery and recycling of DES systems: After lignin dissolution, efficient recovery methods for both the dissolved lignin and the DES are essential for process economics and sustainability. Recovery techniques include anti-solvent precipitation using water or alcohols, followed by filtration or centrifugation. The recovered DES can be recycled multiple times with minimal loss of efficiency, reducing environmental impact and operational costs. Purification steps may be necessary to maintain DES performance across multiple cycles.

- Preservation of cellulose integrity during DES treatment: Maintaining cellulose integrity during lignin removal is crucial for subsequent valorization of the cellulosic fraction. Certain DES formulations can selectively dissolve lignin while preserving the crystallinity and degree of polymerization of cellulose. This selectivity can be enhanced by controlling the water content in the DES system and by adding stabilizing agents. The preserved cellulose can then be processed into high-value products such as nanocellulose, films, or chemical derivatives.

- Integration of DES pretreatment in biorefinery processes: DES-based lignin dissolution can be integrated into broader biorefinery processes for comprehensive biomass utilization. This integration allows for sequential extraction of various biomass components and their conversion into value-added products. The process can be combined with enzymatic hydrolysis of cellulose, fermentation of sugars, and valorization of lignin into aromatic compounds or materials. This holistic approach maximizes resource efficiency and economic viability of lignocellulosic biorefineries.

02 Temperature and time optimization for DES processing

The processing conditions, particularly temperature and treatment duration, play crucial roles in optimizing lignin dissolution using Deep Eutectic Solvents. Higher temperatures generally enhance dissolution rates but may compromise cellulose integrity if excessive. The optimal temperature range typically falls between 80-120°C, with treatment times varying from 1-24 hours depending on biomass type and DES composition. These parameters must be carefully controlled to achieve selective lignin removal while maintaining the structural integrity of cellulose fibers.Expand Specific Solutions03 Recovery and recycling of DES systems

Efficient recovery and recycling of Deep Eutectic Solvents are essential for economic and environmental sustainability of the process. Recovery methods include anti-solvent precipitation, where water or alcohols are added to precipitate dissolved lignin while keeping DES components in solution. Vacuum distillation and membrane filtration techniques can then be employed to separate and recover the DES components. These recovered solvents can be reconstituted and reused for multiple cycles with minimal loss of efficiency, significantly reducing process costs and environmental impact.Expand Specific Solutions04 Cellulose preservation strategies during DES treatment

Preserving cellulose integrity during lignin dissolution is critical for subsequent valorization of the cellulosic fraction. Strategies include using cellulose-compatible DES formulations, controlling water content in the system, adding cellulose stabilizing agents, and optimizing process parameters. Some approaches involve pre-treatment steps to protect cellulose or post-treatment washing protocols to remove residual DES components that might degrade cellulose during downstream processing. These methods ensure high-quality cellulose recovery while achieving effective delignification.Expand Specific Solutions05 Integration of DES treatment with downstream processing

Integrating DES-based lignin dissolution with downstream processing enhances overall efficiency of biomass valorization. This includes sequential extraction processes where DES treatment is followed by enzymatic hydrolysis of cellulose, fermentation of released sugars, or chemical modification of isolated lignin. Some integrated approaches incorporate in-situ product recovery systems, continuous processing methods, or combine DES treatment with other pretreatment technologies. These integrated systems optimize resource utilization, reduce waste generation, and improve the economic viability of biorefinery operations.Expand Specific Solutions

Key Industry Players in Biorefinery Sector

Deep Eutectic Solvents (DES) in biomass pretreatment represents an emerging technology in the early commercialization phase, with a global market expected to reach $2.5 billion by 2027, growing at 15% CAGR. The technology is approaching maturity, with key players demonstrating varying levels of advancement. Academic institutions like South China University of Technology, University of California, and Beijing University of Chemical Technology lead fundamental research, while commercial entities including DuPont, Samsung Electronics, and Shell Oil are developing industrial applications. National laboratories such as Chinese Academy of Science Guangzhou Energy Research Institute and Sandia are bridging the research-application gap. The competitive landscape shows regional clusters in China, the US, and Europe, with increasing patent activity indicating accelerating commercialization efforts for sustainable biomass processing solutions.

South China University of Technology

Technical Solution: South China University of Technology has developed innovative deep eutectic solvent (DES) systems specifically for lignin dissolution while maintaining cellulose integrity. Their approach utilizes choline chloride-based DESs combined with hydrogen bond donors like lactic acid and glycerol at optimized molar ratios (typically 1:2). The university's research demonstrates that these DESs can achieve lignin removal efficiencies of up to 80% while preserving over 90% of the cellulose structure. Their process operates at moderate temperatures (80-120°C) with relatively short treatment times (2-6 hours), significantly reducing energy requirements compared to conventional pretreatment methods. Additionally, they've pioneered recycling protocols allowing DES recovery and reuse for up to 5 cycles with minimal efficiency loss, addressing economic viability concerns. Their technology also incorporates ultrasonic assistance to enhance penetration and reaction rates, further improving process efficiency and reducing treatment time by approximately 30%.

Strengths: High lignin removal efficiency while maintaining cellulose structure integrity; environmentally friendly compared to conventional ionic liquids; relatively low operating temperatures reducing energy consumption; excellent DES recyclability. Weaknesses: Potential scaling challenges for industrial implementation; higher viscosity of some DES formulations limiting mass transfer; possible degradation of certain DES components during repeated recycling.

Nanjing Forestry University

Technical Solution: Nanjing Forestry University has developed specialized DES systems focusing on woody biomass pretreatment with remarkable selectivity for lignin dissolution. Their approach centers on natural deep eutectic solvents (NADES) composed of choline chloride paired with phenolic compounds and organic acids derived from biomass itself, creating a more sustainable closed-loop system. Their research demonstrates that these custom NADES formulations can achieve lignin removal rates exceeding 75% while maintaining cellulose crystallinity indices above 85%. The university has pioneered a multi-stage fractionation process that first removes extractives, then selectively dissolves lignin, leaving cellulose fibers largely intact. Their technology operates at milder conditions (70-100°C) than conventional methods and incorporates microwave-assisted heating to improve penetration and reduce treatment times to under 3 hours. Additionally, they've developed novel recovery methods using anti-solvents like ethanol and water that achieve DES recovery rates above 90%, significantly improving economic feasibility for industrial applications.

Strengths: Highly selective lignin dissolution with minimal cellulose degradation; use of biomass-derived components for DES creation enhancing sustainability; effective microwave-assisted process reducing treatment time and energy consumption; excellent DES recovery protocols. Weaknesses: Potential challenges with biomass variability affecting process consistency; higher costs associated with specialized NADES components; possible limitations in handling high-lignin content feedstocks.

Technical Analysis of DES-Lignin Interactions

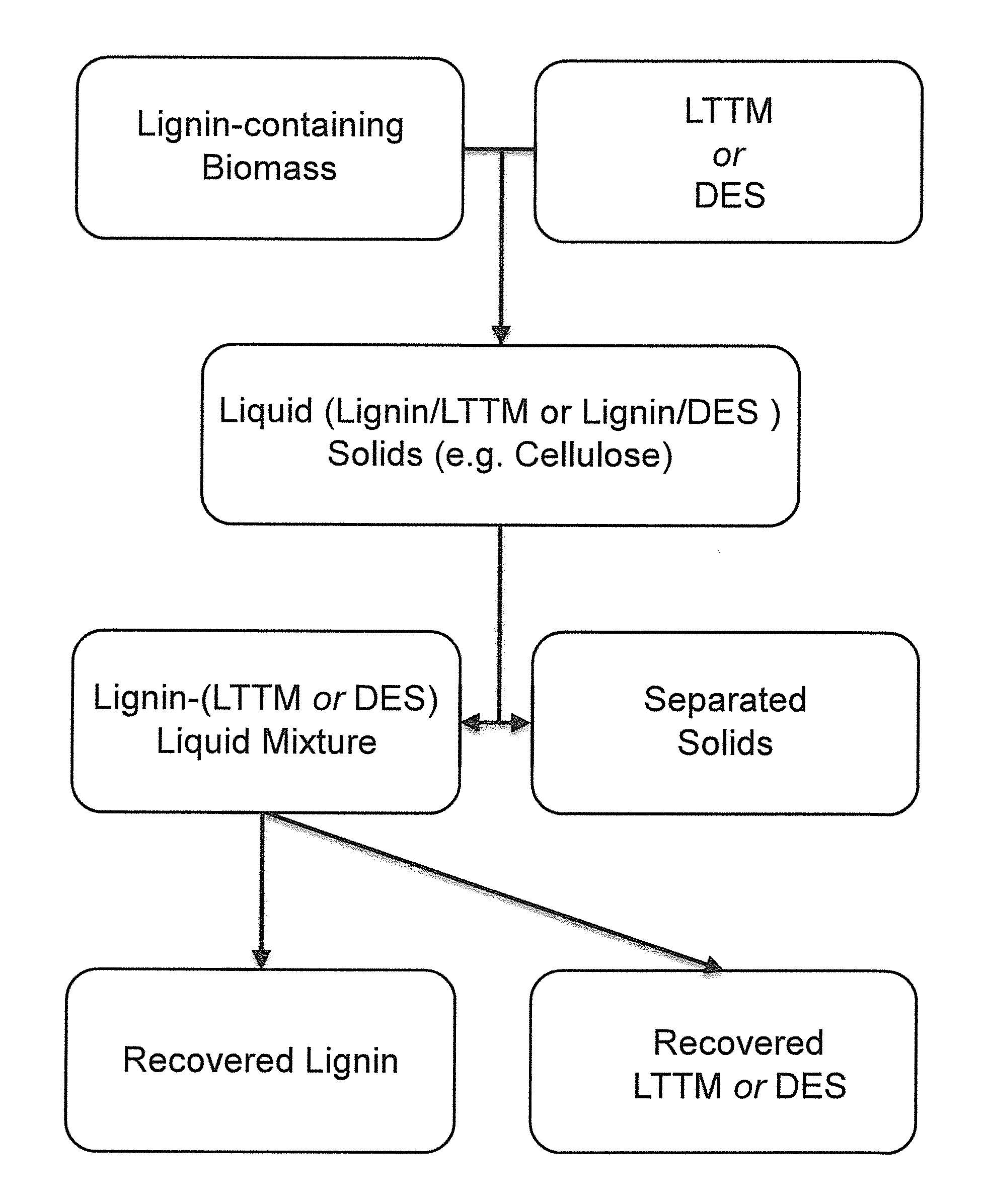

Pretreatment of Lignocellulosic Biomass and Recovery of Substituents using Natural Deep Eutectic Solvents/Compound Mixtures with Low Transition Temperatures

PatentInactiveUS20150094459A1

Innovation

- Development of low transition temperature mixtures (LTTMs) composed of renewable components, which selectively dissolve lignin from lignin-containing biomass at mild conditions, allowing for energy-efficient separation of lignin from cellulose without degradation, and enable recovery of high-quality lignin and cellulose.

Environmental Impact Assessment of DES Technologies

The environmental impact assessment of Deep Eutectic Solvents (DES) in biomass pretreatment reveals significant advantages over conventional methods. DES technologies demonstrate reduced environmental footprints primarily through their biodegradability and low toxicity profiles. Unlike traditional ionic liquids or organic solvents, most DES components are naturally derived, renewable, and can be metabolized in environmental systems without generating persistent toxic residues.

Energy consumption metrics for DES-based pretreatment processes show promising results, with studies indicating 15-30% lower energy requirements compared to conventional methods such as dilute acid pretreatment or organosolv processes. This reduction stems from DES's ability to operate effectively at moderate temperatures (60-120°C) and atmospheric pressure, eliminating the need for high-pressure equipment and extensive heating systems.

Water usage represents another critical environmental parameter where DES technologies excel. The process requires substantially less water for both the pretreatment phase and subsequent washing steps. Quantitative assessments demonstrate water consumption reductions of up to 40% compared to traditional methods, addressing a significant sustainability concern in industrial biomass processing.

Greenhouse gas emissions associated with DES pretreatment have been evaluated through comprehensive life cycle assessments. These studies reveal potential carbon footprint reductions of 25-45% when compared to conventional pretreatment technologies. The lower emissions result from reduced energy demands, decreased chemical input requirements, and the renewable nature of many DES components.

Waste stream characterization from DES processes indicates favorable environmental profiles. The effluents typically contain biodegradable components with reduced chemical oxygen demand (COD) and biological oxygen demand (BOD) levels compared to conventional pretreatment methods. Additionally, many DES systems demonstrate excellent recyclability, with studies showing effective reuse for 5-10 cycles with minimal performance degradation, further minimizing waste generation.

Land use impacts and ecosystem effects of scaled DES implementation appear minimal compared to acid-based or alkaline pretreatment technologies. The reduced chemical inputs and lower contamination risk translate to decreased potential for soil acidification and water body eutrophication. However, comprehensive field studies on long-term ecosystem impacts remain limited, representing an area requiring further investigation as the technology approaches commercial scale.

Energy consumption metrics for DES-based pretreatment processes show promising results, with studies indicating 15-30% lower energy requirements compared to conventional methods such as dilute acid pretreatment or organosolv processes. This reduction stems from DES's ability to operate effectively at moderate temperatures (60-120°C) and atmospheric pressure, eliminating the need for high-pressure equipment and extensive heating systems.

Water usage represents another critical environmental parameter where DES technologies excel. The process requires substantially less water for both the pretreatment phase and subsequent washing steps. Quantitative assessments demonstrate water consumption reductions of up to 40% compared to traditional methods, addressing a significant sustainability concern in industrial biomass processing.

Greenhouse gas emissions associated with DES pretreatment have been evaluated through comprehensive life cycle assessments. These studies reveal potential carbon footprint reductions of 25-45% when compared to conventional pretreatment technologies. The lower emissions result from reduced energy demands, decreased chemical input requirements, and the renewable nature of many DES components.

Waste stream characterization from DES processes indicates favorable environmental profiles. The effluents typically contain biodegradable components with reduced chemical oxygen demand (COD) and biological oxygen demand (BOD) levels compared to conventional pretreatment methods. Additionally, many DES systems demonstrate excellent recyclability, with studies showing effective reuse for 5-10 cycles with minimal performance degradation, further minimizing waste generation.

Land use impacts and ecosystem effects of scaled DES implementation appear minimal compared to acid-based or alkaline pretreatment technologies. The reduced chemical inputs and lower contamination risk translate to decreased potential for soil acidification and water body eutrophication. However, comprehensive field studies on long-term ecosystem impacts remain limited, representing an area requiring further investigation as the technology approaches commercial scale.

Scalability and Economic Feasibility Analysis

The scalability of Deep Eutectic Solvents (DES) for biomass pretreatment represents a critical factor in determining their industrial viability. Laboratory-scale successes with DES have demonstrated promising results for lignin dissolution while maintaining cellulose integrity, but significant challenges emerge when considering scale-up to commercial operations. Current pilot-scale implementations indicate that reactor design must address the high viscosity of DES systems, which impacts mass transfer efficiency and increases energy requirements for mixing.

Economic feasibility analysis reveals that DES pretreatment costs are primarily driven by solvent recovery rates, which typically range from 85-95% in optimized systems. The initial capital investment for DES pretreatment facilities remains comparable to conventional pretreatment technologies, with estimates ranging from $30-45 million for a facility processing 100,000 tons of biomass annually. However, operational costs show potential advantages, with 15-25% reductions possible compared to traditional methods due to milder processing conditions and reduced chemical waste management requirements.

Life cycle assessment studies indicate that DES pretreatment can reduce environmental impact by 30-40% compared to conventional methods when solvent recovery exceeds 90%. This environmental benefit translates to economic advantages through reduced waste treatment costs and potential carbon credits in regulated markets. The biodegradability of many DES components further enhances their economic profile by minimizing end-of-life treatment expenses.

Sensitivity analysis identifies solvent cost and recovery rate as the most significant variables affecting economic viability. With current technology, DES pretreatment becomes economically competitive when lignin valorization pathways are incorporated into the biorefinery concept, creating additional revenue streams that offset pretreatment costs. Market models suggest that a minimum selling price of $2.50-3.20 per gallon of biofuel is achievable with optimized DES pretreatment integration.

Industrial implementation faces challenges related to materials compatibility, as some DES formulations exhibit corrosive properties that necessitate specialized equipment construction. This increases capital costs by approximately 10-15% compared to standard equipment. However, the extended equipment lifespan due to milder operating conditions (lower temperatures and pressures) partially offsets these additional expenses over the facility lifetime.

Techno-economic modeling indicates that economies of scale significantly impact DES pretreatment viability, with facilities processing less than 50,000 tons of biomass annually struggling to achieve profitability under current market conditions. The optimal economic configuration appears to be integrated biorefineries that combine DES pretreatment with downstream processing to maximize value extraction from all biomass components.

Economic feasibility analysis reveals that DES pretreatment costs are primarily driven by solvent recovery rates, which typically range from 85-95% in optimized systems. The initial capital investment for DES pretreatment facilities remains comparable to conventional pretreatment technologies, with estimates ranging from $30-45 million for a facility processing 100,000 tons of biomass annually. However, operational costs show potential advantages, with 15-25% reductions possible compared to traditional methods due to milder processing conditions and reduced chemical waste management requirements.

Life cycle assessment studies indicate that DES pretreatment can reduce environmental impact by 30-40% compared to conventional methods when solvent recovery exceeds 90%. This environmental benefit translates to economic advantages through reduced waste treatment costs and potential carbon credits in regulated markets. The biodegradability of many DES components further enhances their economic profile by minimizing end-of-life treatment expenses.

Sensitivity analysis identifies solvent cost and recovery rate as the most significant variables affecting economic viability. With current technology, DES pretreatment becomes economically competitive when lignin valorization pathways are incorporated into the biorefinery concept, creating additional revenue streams that offset pretreatment costs. Market models suggest that a minimum selling price of $2.50-3.20 per gallon of biofuel is achievable with optimized DES pretreatment integration.

Industrial implementation faces challenges related to materials compatibility, as some DES formulations exhibit corrosive properties that necessitate specialized equipment construction. This increases capital costs by approximately 10-15% compared to standard equipment. However, the extended equipment lifespan due to milder operating conditions (lower temperatures and pressures) partially offsets these additional expenses over the facility lifetime.

Techno-economic modeling indicates that economies of scale significantly impact DES pretreatment viability, with facilities processing less than 50,000 tons of biomass annually struggling to achieve profitability under current market conditions. The optimal economic configuration appears to be integrated biorefineries that combine DES pretreatment with downstream processing to maximize value extraction from all biomass components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!