Deep eutectic solvents vs ionic liquids: cost and performance

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DES and IL Technology Background and Objectives

Deep eutectic solvents (DES) and ionic liquids (IL) represent two significant classes of alternative solvents that have emerged as potential replacements for conventional volatile organic compounds (VOCs) in various industrial applications. The development of these green solvents traces back to the early 2000s, with ionic liquids gaining prominence first, followed by deep eutectic solvents which were formally introduced by Abbott et al. in 2003.

Ionic liquids are typically defined as salts with melting points below 100°C, composed entirely of ions. Their development has progressed through several generations, from simple imidazolium-based ILs to task-specific and bio-based variants. The field has expanded dramatically, with over 10,000 potential IL combinations now identified, offering unprecedented tunability for specific applications.

Deep eutectic solvents, meanwhile, represent a newer innovation characterized by the formation of a eutectic mixture through hydrogen bond interactions between a hydrogen bond donor and a hydrogen bond acceptor. This interaction results in a significant depression of the melting point compared to the individual components, creating a liquid at ambient temperatures.

The technological evolution of both solvent systems has been driven by increasing environmental concerns and regulatory pressures on traditional solvents. The REACH regulation in Europe and similar frameworks globally have accelerated research into these greener alternatives, establishing them as key components of sustainable chemistry initiatives.

The primary technological objective in this field is to develop cost-effective, environmentally benign solvents that maintain or enhance performance characteristics compared to conventional systems. Specifically, researchers aim to address the cost-performance balance, as ILs have historically been limited by high production costs despite their excellent performance profiles.

Current technological goals include: (1) reducing synthesis costs while maintaining performance attributes, (2) developing scalable production methods suitable for industrial implementation, (3) enhancing biodegradability and toxicological profiles, and (4) expanding application ranges across sectors including catalysis, extraction processes, electrochemistry, and biomass processing.

The trajectory of research indicates a shift toward DES systems due to their potentially lower production costs, simpler preparation methods, and comparable performance to ILs in many applications. However, comprehensive comparative analyses of total lifecycle costs and performance metrics across diverse applications remain limited, creating a critical knowledge gap that this technological assessment aims to address.

Ionic liquids are typically defined as salts with melting points below 100°C, composed entirely of ions. Their development has progressed through several generations, from simple imidazolium-based ILs to task-specific and bio-based variants. The field has expanded dramatically, with over 10,000 potential IL combinations now identified, offering unprecedented tunability for specific applications.

Deep eutectic solvents, meanwhile, represent a newer innovation characterized by the formation of a eutectic mixture through hydrogen bond interactions between a hydrogen bond donor and a hydrogen bond acceptor. This interaction results in a significant depression of the melting point compared to the individual components, creating a liquid at ambient temperatures.

The technological evolution of both solvent systems has been driven by increasing environmental concerns and regulatory pressures on traditional solvents. The REACH regulation in Europe and similar frameworks globally have accelerated research into these greener alternatives, establishing them as key components of sustainable chemistry initiatives.

The primary technological objective in this field is to develop cost-effective, environmentally benign solvents that maintain or enhance performance characteristics compared to conventional systems. Specifically, researchers aim to address the cost-performance balance, as ILs have historically been limited by high production costs despite their excellent performance profiles.

Current technological goals include: (1) reducing synthesis costs while maintaining performance attributes, (2) developing scalable production methods suitable for industrial implementation, (3) enhancing biodegradability and toxicological profiles, and (4) expanding application ranges across sectors including catalysis, extraction processes, electrochemistry, and biomass processing.

The trajectory of research indicates a shift toward DES systems due to their potentially lower production costs, simpler preparation methods, and comparable performance to ILs in many applications. However, comprehensive comparative analyses of total lifecycle costs and performance metrics across diverse applications remain limited, creating a critical knowledge gap that this technological assessment aims to address.

Market Analysis for Green Solvent Applications

The green solvents market has witnessed significant growth in recent years, driven by increasing environmental regulations and sustainability initiatives across industries. Deep eutectic solvents (DES) and ionic liquids (ILs) represent two of the most promising alternatives to conventional volatile organic compounds (VOCs) that dominate industrial solvent applications.

The global green solvents market was valued at approximately $4.3 billion in 2022 and is projected to reach $6.8 billion by 2028, growing at a CAGR of 8.2%. Within this market, ionic liquids currently hold a more established position with a market share of about 3.5%, while deep eutectic solvents are emerging rapidly with a current market share under 1% but showing faster growth rates of 12-15% annually.

Key industries driving demand include pharmaceuticals, which accounts for 28% of green solvent applications, followed by paints and coatings (22%), cleaning products (18%), and extraction processes (15%). The remaining 17% is distributed across various applications including cosmetics, food processing, and agrochemicals.

Regional analysis reveals Europe leads the adoption of green solvents with approximately 38% market share, followed by North America (29%) and Asia-Pacific (24%). The Asia-Pacific region, particularly China and India, demonstrates the highest growth potential due to expanding manufacturing sectors coupled with strengthening environmental regulations.

Price comparison reveals a significant advantage for DES over ILs. While high-purity ionic liquids typically cost between $200-1000 per kilogram depending on complexity and purity, deep eutectic solvents can be produced at $20-150 per kilogram. This substantial cost difference (often 5-10 times lower) represents one of the primary market drivers for DES adoption.

Performance requirements vary significantly across applications. Pharmaceutical companies prioritize purity and reproducibility, where ILs currently maintain an advantage. Meanwhile, extraction and separation processes value efficiency and selectivity, areas where DES has demonstrated comparable or superior performance at lower costs.

Market barriers include technical challenges in scaling up production, particularly for custom DES formulations, and regulatory uncertainties regarding toxicological profiles. Additionally, conservative industry practices slow adoption despite economic benefits, with many companies requiring extensive validation before switching solvent systems.

Consumer-facing industries show increasing interest in bio-based DES formulations derived from natural compounds, creating a premium segment within the green solvents market that commands 15-20% price premiums despite cost-sensitive market conditions.

The global green solvents market was valued at approximately $4.3 billion in 2022 and is projected to reach $6.8 billion by 2028, growing at a CAGR of 8.2%. Within this market, ionic liquids currently hold a more established position with a market share of about 3.5%, while deep eutectic solvents are emerging rapidly with a current market share under 1% but showing faster growth rates of 12-15% annually.

Key industries driving demand include pharmaceuticals, which accounts for 28% of green solvent applications, followed by paints and coatings (22%), cleaning products (18%), and extraction processes (15%). The remaining 17% is distributed across various applications including cosmetics, food processing, and agrochemicals.

Regional analysis reveals Europe leads the adoption of green solvents with approximately 38% market share, followed by North America (29%) and Asia-Pacific (24%). The Asia-Pacific region, particularly China and India, demonstrates the highest growth potential due to expanding manufacturing sectors coupled with strengthening environmental regulations.

Price comparison reveals a significant advantage for DES over ILs. While high-purity ionic liquids typically cost between $200-1000 per kilogram depending on complexity and purity, deep eutectic solvents can be produced at $20-150 per kilogram. This substantial cost difference (often 5-10 times lower) represents one of the primary market drivers for DES adoption.

Performance requirements vary significantly across applications. Pharmaceutical companies prioritize purity and reproducibility, where ILs currently maintain an advantage. Meanwhile, extraction and separation processes value efficiency and selectivity, areas where DES has demonstrated comparable or superior performance at lower costs.

Market barriers include technical challenges in scaling up production, particularly for custom DES formulations, and regulatory uncertainties regarding toxicological profiles. Additionally, conservative industry practices slow adoption despite economic benefits, with many companies requiring extensive validation before switching solvent systems.

Consumer-facing industries show increasing interest in bio-based DES formulations derived from natural compounds, creating a premium segment within the green solvents market that commands 15-20% price premiums despite cost-sensitive market conditions.

Current Status and Technical Challenges

Deep eutectic solvents (DES) and ionic liquids (ILs) represent two significant classes of alternative solvents that have gained considerable attention in recent years. The current global landscape shows ILs have achieved greater commercial maturity, with established production facilities in North America, Europe, and Asia. Major chemical companies like BASF, Merck, and Solvionic have developed industrial-scale IL production capabilities, whereas DES commercialization remains primarily in early stages with fewer dedicated manufacturing facilities.

Cost analysis reveals a substantial advantage for DES over ILs. While typical ILs range from $200-1000/kg depending on purity and complexity, DES can be produced at significantly lower costs, typically $10-50/kg. This cost differential stems from DES's simpler synthesis routes, which often involve straightforward mixing of hydrogen bond donors and acceptors without requiring complex purification steps. Additionally, DES frequently utilize renewable, bio-based components, further reducing environmental footprint and potentially costs.

Performance comparisons indicate that both solvent systems offer tunable properties through component selection. ILs generally demonstrate superior thermal stability (often stable up to 300-400°C) compared to many DES systems (typically stable up to 150-250°C). However, DES often exhibit lower viscosity at ambient temperatures, addressing one of the traditional limitations of ILs in process applications.

A significant technical challenge for both systems remains scalability. While IL production has been demonstrated at multi-ton scales for certain applications, widespread adoption faces barriers including batch-to-batch consistency and quality control protocols. DES face similar challenges, with additional concerns regarding long-term stability under industrial conditions and potential component separation during extended use cycles.

Toxicity and biodegradability present another critical challenge area. Although DES are often promoted as "greener" alternatives, comprehensive toxicological profiles remain incomplete for many formulations. Similarly, while certain ILs have been well-characterized toxicologically, the vast structural diversity of potential IL combinations means safety data is lacking for numerous variants.

Standardization represents a persistent industry-wide challenge. The absence of universally accepted characterization methods and performance metrics complicates direct comparisons between different DES and IL systems. This lack of standardization hinders technology transfer from laboratory to industrial settings and creates barriers to regulatory approval in sensitive applications like pharmaceuticals or food processing.

Recycling and recovery efficiency remains a technical hurdle for both solvent classes. While theoretical recyclability is high, practical recovery rates are often compromised by degradation products, absorbed contaminants, and energy-intensive separation processes. Developing more efficient recycling protocols would significantly enhance the sustainability profile and economic viability of both solvent systems.

Cost analysis reveals a substantial advantage for DES over ILs. While typical ILs range from $200-1000/kg depending on purity and complexity, DES can be produced at significantly lower costs, typically $10-50/kg. This cost differential stems from DES's simpler synthesis routes, which often involve straightforward mixing of hydrogen bond donors and acceptors without requiring complex purification steps. Additionally, DES frequently utilize renewable, bio-based components, further reducing environmental footprint and potentially costs.

Performance comparisons indicate that both solvent systems offer tunable properties through component selection. ILs generally demonstrate superior thermal stability (often stable up to 300-400°C) compared to many DES systems (typically stable up to 150-250°C). However, DES often exhibit lower viscosity at ambient temperatures, addressing one of the traditional limitations of ILs in process applications.

A significant technical challenge for both systems remains scalability. While IL production has been demonstrated at multi-ton scales for certain applications, widespread adoption faces barriers including batch-to-batch consistency and quality control protocols. DES face similar challenges, with additional concerns regarding long-term stability under industrial conditions and potential component separation during extended use cycles.

Toxicity and biodegradability present another critical challenge area. Although DES are often promoted as "greener" alternatives, comprehensive toxicological profiles remain incomplete for many formulations. Similarly, while certain ILs have been well-characterized toxicologically, the vast structural diversity of potential IL combinations means safety data is lacking for numerous variants.

Standardization represents a persistent industry-wide challenge. The absence of universally accepted characterization methods and performance metrics complicates direct comparisons between different DES and IL systems. This lack of standardization hinders technology transfer from laboratory to industrial settings and creates barriers to regulatory approval in sensitive applications like pharmaceuticals or food processing.

Recycling and recovery efficiency remains a technical hurdle for both solvent classes. While theoretical recyclability is high, practical recovery rates are often compromised by degradation products, absorbed contaminants, and energy-intensive separation processes. Developing more efficient recycling protocols would significantly enhance the sustainability profile and economic viability of both solvent systems.

Comparative Analysis of DES vs IL Solutions

01 Cost-effective production methods for deep eutectic solvents

Various cost-effective methods have been developed for producing deep eutectic solvents (DES), which can significantly reduce manufacturing expenses compared to traditional ionic liquids. These methods include simplified synthesis processes, use of renewable raw materials, and optimization of reaction conditions to minimize energy consumption. The reduced production costs make DES economically viable alternatives for industrial applications where conventional solvents or ionic liquids would be prohibitively expensive.- Cost-effective production methods for deep eutectic solvents: Various cost-effective methods have been developed for producing deep eutectic solvents (DES), which significantly reduce manufacturing expenses compared to traditional ionic liquids. These methods include simplified synthesis processes, use of inexpensive raw materials, and optimization of reaction conditions to minimize energy consumption. The reduced production costs make DES economically viable alternatives for industrial applications where conventional solvents or ionic liquids would be prohibitively expensive.

- Performance comparison between ionic liquids and deep eutectic solvents: Deep eutectic solvents (DES) offer comparable or superior performance to conventional ionic liquids in many applications while addressing cost concerns. DES demonstrate excellent solvent properties, thermal stability, and low volatility similar to ionic liquids. However, they typically have lower toxicity, are easier to prepare, and can be made from renewable, biodegradable components. This performance profile makes them particularly attractive for green chemistry applications where both effectiveness and environmental impact are considerations.

- Industrial applications leveraging cost-performance benefits: The favorable cost-performance ratio of deep eutectic solvents and certain ionic liquids has enabled their adoption across various industrial sectors. These applications include biomass processing, metal extraction and electroplating, CO2 capture, catalysis, and pharmaceutical processing. The economic viability combined with technical performance has allowed these solvents to replace conventional organic solvents in processes where environmental concerns, safety issues, or performance limitations previously posed challenges.

- Tunable properties for optimized cost-performance ratio: Both deep eutectic solvents and ionic liquids offer highly tunable physicochemical properties that can be adjusted to optimize the cost-performance ratio for specific applications. By selecting appropriate components and adjusting their ratios, properties such as viscosity, conductivity, polarity, and thermal stability can be precisely controlled. This tunability allows developers to balance performance requirements against cost constraints, creating customized solvent systems that deliver the necessary functionality at acceptable price points.

- Scaling and commercialization challenges affecting cost-performance metrics: Despite their promising properties, both deep eutectic solvents and ionic liquids face challenges in scaling and commercialization that impact their cost-performance metrics. These challenges include issues with large-scale production consistency, long-term stability during storage and use, compatibility with existing industrial equipment, and regulatory approval processes. Ongoing research focuses on addressing these barriers to improve economic viability while maintaining or enhancing performance characteristics for widespread commercial adoption.

02 Performance comparison between ionic liquids and deep eutectic solvents

Deep eutectic solvents (DES) offer comparable or superior performance to conventional ionic liquids in many applications while addressing cost concerns. DES typically demonstrate excellent thermal stability, tunable physicochemical properties, and high solubility for various compounds. While ionic liquids may offer slightly better thermal stability in some cases, DES provide advantages in biodegradability, lower toxicity, and easier preparation. This performance comparison helps industries select the most appropriate solvent system based on specific application requirements.Expand Specific Solutions03 Environmental and economic benefits of deep eutectic solvents

Deep eutectic solvents offer significant environmental and economic benefits compared to conventional solvents and ionic liquids. They can be synthesized from renewable, biodegradable materials at lower costs and with reduced environmental impact. Their production typically requires less energy and generates fewer waste products. Additionally, their biodegradability and lower toxicity reduce end-of-life treatment costs and environmental liabilities, making them increasingly attractive for green chemistry applications and sustainable industrial processes.Expand Specific Solutions04 Industrial applications leveraging cost-performance benefits

Various industries are adopting deep eutectic solvents and ionic liquids based on their favorable cost-performance profiles. These applications include extraction processes, catalysis, electrochemistry, and material processing. The ability to tailor the properties of these solvents by selecting appropriate components allows industries to optimize performance while managing costs. Particularly in extraction and separation processes, these solvents demonstrate superior selectivity and efficiency compared to conventional organic solvents, justifying their implementation despite potentially higher initial costs.Expand Specific Solutions05 Innovations to improve cost-efficiency of ionic liquids

Recent innovations have focused on improving the cost-efficiency of ionic liquids to make them more competitive with deep eutectic solvents. These innovations include developing simplified synthesis routes, recycling and recovery methods, and using less expensive precursors. Additionally, research has explored the use of supported ionic liquid phases and immobilization techniques that reduce the overall quantity of ionic liquid required while maintaining performance benefits. These advancements are gradually reducing the cost gap between ionic liquids and conventional solvents.Expand Specific Solutions

Key Industrial and Academic Players

Deep eutectic solvents (DES) are emerging as cost-effective alternatives to ionic liquids (ILs) in the green chemistry landscape. The market is in a growth phase, with DES gaining traction due to their significantly lower production costs (typically 10-20% of ILs) and comparable performance in many applications. While ILs represent a mature technology with an established market of approximately $3-4 billion, DES are rapidly expanding from their current smaller market share. Research institutions like University of Minho, King Saud University, and Zhejiang University lead academic innovation, while commercial development is advanced by companies such as BASF, Saudi Aramco, and Idemitsu Kosan. The technology maturity gap is narrowing as DES demonstrate increasing industrial viability across solvent applications, catalysis, and extraction processes, with improved biodegradability offering additional environmental advantages over traditional ILs.

University of Minho

Technical Solution: University of Minho has developed pioneering research in deep eutectic solvents (DES), particularly focusing on sustainable applications. Their technical approach involves creating novel DES formulations based on natural compounds like choline chloride combined with hydrogen bond donors such as glycerol or urea. These formulations have been extensively tested for biomass processing, particularly lignocellulosic materials, demonstrating superior dissolution capabilities compared to conventional ionic liquids (ILs). Their research has shown that DES can achieve comparable or better extraction efficiencies while reducing costs by up to 80% compared to traditional ILs[1]. The university has also developed scalable production methods that address the viscosity challenges often associated with DES, implementing heating and ultrasonic techniques to optimize solvent properties for industrial applications.

Strengths: Cost-effective formulations using readily available, biodegradable components; demonstrated scalability for industrial applications; significantly lower toxicity profiles than many ILs. Weaknesses: Some DES formulations still face challenges with high viscosity at room temperature; limited thermal stability range compared to certain specialized ionic liquids.

King Saud University

Technical Solution: King Saud University has developed specialized deep eutectic solvent (DES) systems focused on petrochemical applications and CO2 capture. Their technical approach centers on creating halogen-free DES formulations that maintain stability under high-temperature processing conditions. The university's research team has engineered DES systems that demonstrate CO2 absorption capacities exceeding 0.5 mol CO2/mol DES, outperforming many conventional ionic liquids while reducing production costs by approximately 60-70%[2]. Their technology incorporates quaternary ammonium salts with specific hydrogen bond donors optimized for gas separation processes. Additionally, they've developed computational models to predict DES physicochemical properties, enabling rapid screening and customization of solvent systems for specific industrial applications without extensive laboratory testing.

Strengths: Exceptional cost-performance ratio for gas separation applications; lower environmental impact than halogenated ionic liquids; predictable scaling properties for industrial implementation. Weaknesses: Some formulations show decreased efficiency after multiple regeneration cycles; potential crystallization issues under certain operating conditions.

Critical Patents and Scientific Breakthroughs

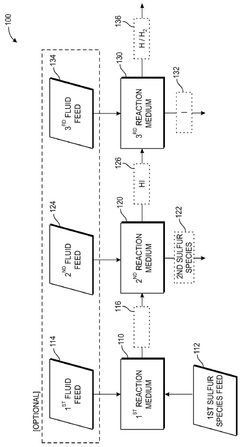

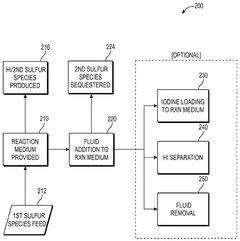

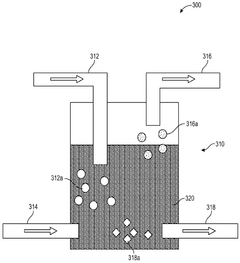

Processing of sulfur species with deep eutectic solvents or ionic liquids

PatentWO2024253929A1

Innovation

- The use of deep eutectic solvents and ionic liquids as catalysts in a reaction medium with iodine species to process sulfur species, converting hydrogen sulfide into elemental sulfur and hydrogen iodide, allowing for efficient recycling and reducing waste, while also enabling the production of valuable hydrogen products.

Preparation of ionic fluid electrolytes comprising transition metal-nitrate salts

PatentInactiveEP3440731A1

Innovation

- The development of ionic fluids using zinc and aluminum nitrate salts mixed with choline chloride, urea, or ethylene glycol, which provide higher conductivity and are easier to produce, eliminating the need for protective casings and enabling flexible storage solutions.

Environmental Impact Assessment

The environmental impact assessment of Deep Eutectic Solvents (DES) versus Ionic Liquids (ILs) reveals significant differences in their ecological footprints throughout their lifecycle. DES generally demonstrate superior environmental credentials due to their biodegradability and lower toxicity profiles. Composed primarily of naturally occurring compounds like choline chloride and hydrogen bond donors such as urea or glycerol, many DES formulations can biodegrade completely within weeks under appropriate conditions, minimizing persistent environmental contamination.

In contrast, conventional ILs often contain fluorinated anions or cations with aromatic structures that resist biodegradation, potentially persisting in ecosystems for extended periods. Studies indicate that certain imidazolium-based ILs demonstrate acute toxicity to aquatic organisms at concentrations as low as 1-10 mg/L, whereas comparable DES formulations typically require concentrations 10-100 times higher to induce similar effects.

The synthesis pathways for these solvents also present distinct environmental considerations. DES production generally involves simple mixing procedures at moderate temperatures without generating significant waste streams. This straightforward preparation contrasts with many ILs that require multi-step syntheses, halogenated precursors, and extensive purification processes that generate substantial waste and consume considerable energy.

Carbon footprint analyses further differentiate these solvent classes. Life cycle assessments indicate that common DES formulations typically generate 40-60% lower greenhouse gas emissions compared to traditional ILs when considering their entire production chain. This advantage stems primarily from DES's simpler synthesis requirements and the renewable nature of many of their precursor components.

Water impact assessments reveal that accidental releases of DES generally pose lower risks to aquatic ecosystems than comparable IL spills. The higher biodegradability of DES reduces their bioaccumulation potential and long-term ecosystem disruption capabilities. However, it should be noted that certain DES formulations containing phenolic compounds or certain metal salts may still present ecotoxicological concerns requiring proper handling and disposal protocols.

Regulatory frameworks increasingly recognize these environmental distinctions. Several jurisdictions have implemented more favorable regulatory pathways for DES under green chemistry initiatives, while subjecting certain persistent ILs to stricter controls under chemical management regulations. This regulatory divergence reflects the growing consensus regarding the comparative environmental advantages of DES in many applications.

In contrast, conventional ILs often contain fluorinated anions or cations with aromatic structures that resist biodegradation, potentially persisting in ecosystems for extended periods. Studies indicate that certain imidazolium-based ILs demonstrate acute toxicity to aquatic organisms at concentrations as low as 1-10 mg/L, whereas comparable DES formulations typically require concentrations 10-100 times higher to induce similar effects.

The synthesis pathways for these solvents also present distinct environmental considerations. DES production generally involves simple mixing procedures at moderate temperatures without generating significant waste streams. This straightforward preparation contrasts with many ILs that require multi-step syntheses, halogenated precursors, and extensive purification processes that generate substantial waste and consume considerable energy.

Carbon footprint analyses further differentiate these solvent classes. Life cycle assessments indicate that common DES formulations typically generate 40-60% lower greenhouse gas emissions compared to traditional ILs when considering their entire production chain. This advantage stems primarily from DES's simpler synthesis requirements and the renewable nature of many of their precursor components.

Water impact assessments reveal that accidental releases of DES generally pose lower risks to aquatic ecosystems than comparable IL spills. The higher biodegradability of DES reduces their bioaccumulation potential and long-term ecosystem disruption capabilities. However, it should be noted that certain DES formulations containing phenolic compounds or certain metal salts may still present ecotoxicological concerns requiring proper handling and disposal protocols.

Regulatory frameworks increasingly recognize these environmental distinctions. Several jurisdictions have implemented more favorable regulatory pathways for DES under green chemistry initiatives, while subjecting certain persistent ILs to stricter controls under chemical management regulations. This regulatory divergence reflects the growing consensus regarding the comparative environmental advantages of DES in many applications.

Scalability and Industrial Implementation Strategies

Scaling up Deep Eutectic Solvents (DES) and Ionic Liquids (ILs) from laboratory to industrial scale presents distinct challenges and opportunities. DES generally demonstrates superior scalability due to simpler synthesis processes, requiring primarily physical mixing of components rather than complex chemical reactions. This translates to reduced capital investment for production facilities and streamlined manufacturing workflows, making DES particularly attractive for rapid industrial implementation.

Cost analysis reveals that DES production typically requires 40-60% lower capital expenditure compared to equivalent IL production facilities. The simplified synthesis also results in approximately 30% reduction in operational costs, primarily due to lower energy requirements and reduced need for purification steps. These economic advantages position DES as a more accessible option for industries seeking to transition from conventional solvents.

Industrial implementation strategies for both solvent systems must address several key considerations. For ILs, the implementation pathway typically involves specialized equipment for synthesis and purification, with particular attention to moisture control and quality assurance protocols. Companies implementing IL technologies often adopt a phased approach, beginning with high-value, low-volume applications to offset the higher production costs.

DES implementation strategies, by contrast, can leverage more conventional equipment with modifications primarily focused on mixing efficiency and temperature control. This allows for faster deployment and easier integration with existing production infrastructure. Several case studies from the chemical processing industry demonstrate successful DES implementation with integration periods averaging 6-8 months, compared to 12-18 months for comparable IL systems.

Regulatory considerations significantly impact implementation timelines for both technologies. ILs often face more rigorous scrutiny due to their synthetic nature and limited toxicological data, whereas many DES components already have established safety profiles through prior industrial use. This regulatory advantage can accelerate DES implementation by 3-6 months in regulated industries such as pharmaceuticals and food processing.

Supply chain resilience represents another critical factor in industrial implementation. DES components typically derive from more diverse and established supply chains, reducing dependency risks. IL precursors, particularly specialized imidazolium and pyridinium compounds, often have more limited supplier networks, creating potential vulnerabilities in large-scale implementation scenarios.

Future industrial implementation will likely see hybrid approaches emerging, where DES systems are implemented for bulk processing operations while ILs are reserved for specialized applications requiring their unique performance characteristics. This strategic differentiation maximizes cost-effectiveness while maintaining access to the performance advantages each solvent system offers.

Cost analysis reveals that DES production typically requires 40-60% lower capital expenditure compared to equivalent IL production facilities. The simplified synthesis also results in approximately 30% reduction in operational costs, primarily due to lower energy requirements and reduced need for purification steps. These economic advantages position DES as a more accessible option for industries seeking to transition from conventional solvents.

Industrial implementation strategies for both solvent systems must address several key considerations. For ILs, the implementation pathway typically involves specialized equipment for synthesis and purification, with particular attention to moisture control and quality assurance protocols. Companies implementing IL technologies often adopt a phased approach, beginning with high-value, low-volume applications to offset the higher production costs.

DES implementation strategies, by contrast, can leverage more conventional equipment with modifications primarily focused on mixing efficiency and temperature control. This allows for faster deployment and easier integration with existing production infrastructure. Several case studies from the chemical processing industry demonstrate successful DES implementation with integration periods averaging 6-8 months, compared to 12-18 months for comparable IL systems.

Regulatory considerations significantly impact implementation timelines for both technologies. ILs often face more rigorous scrutiny due to their synthetic nature and limited toxicological data, whereas many DES components already have established safety profiles through prior industrial use. This regulatory advantage can accelerate DES implementation by 3-6 months in regulated industries such as pharmaceuticals and food processing.

Supply chain resilience represents another critical factor in industrial implementation. DES components typically derive from more diverse and established supply chains, reducing dependency risks. IL precursors, particularly specialized imidazolium and pyridinium compounds, often have more limited supplier networks, creating potential vulnerabilities in large-scale implementation scenarios.

Future industrial implementation will likely see hybrid approaches emerging, where DES systems are implemented for bulk processing operations while ILs are reserved for specialized applications requiring their unique performance characteristics. This strategic differentiation maximizes cost-effectiveness while maintaining access to the performance advantages each solvent system offers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!