Ionic liquids for lignocellulosic pretreatment: pilot cases

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ionic Liquids Pretreatment Background and Objectives

Lignocellulosic biomass represents one of the most abundant renewable resources on Earth, comprising agricultural residues, forestry waste, and dedicated energy crops. The efficient conversion of this biomass into valuable products has been a longstanding challenge due to its recalcitrant nature, characterized by complex interactions between cellulose, hemicellulose, and lignin components. Traditional pretreatment methods often involve harsh conditions, environmentally harmful chemicals, or high energy inputs, limiting their sustainability and economic viability at industrial scales.

Ionic liquids (ILs) emerged in the early 2000s as a revolutionary class of solvents with unique properties for biomass processing. These organic salts, liquid at room temperature, possess remarkable capabilities to dissolve cellulose and disrupt the lignocellulosic matrix. The evolution of IL technology has progressed from first-generation imidazolium-based ILs to more recent developments in bio-derived and protic ionic liquids, demonstrating the field's dynamic nature and continuous innovation.

The global push toward circular bioeconomy and carbon neutrality has intensified research into efficient biomass conversion technologies. ILs represent a promising approach to overcome the recalcitrance barrier that has historically limited lignocellulosic biorefinery development. Their ability to operate under milder conditions while achieving higher conversion efficiencies positions them as potentially transformative agents in the biorefinery landscape.

This technical research aims to comprehensively evaluate the current state and future potential of ionic liquid pretreatment technologies for lignocellulosic biomass, with particular focus on pilot-scale implementations. The primary objectives include: assessing the technical feasibility of scaling up IL pretreatment processes from laboratory to industrial applications; analyzing the economic viability of IL-based biorefineries compared to conventional technologies; identifying key technical challenges in IL recovery and recycling systems; and exploring innovative IL designs optimized for specific biomass feedstocks.

The investigation will further examine how recent advances in IL chemistry, process engineering, and materials science have addressed historical limitations related to IL cost, toxicity, and recovery efficiency. By analyzing pilot case studies across different geographical regions and feedstock types, this research seeks to establish a technological roadmap for the commercial implementation of IL pretreatment technologies.

Additionally, this research aims to identify emerging trends in IL pretreatment integration with downstream processing steps, including enzymatic hydrolysis, fermentation, and product separation. Understanding these synergistic effects is crucial for developing holistic biorefinery concepts that maximize resource efficiency and product value while minimizing environmental impacts.

Ionic liquids (ILs) emerged in the early 2000s as a revolutionary class of solvents with unique properties for biomass processing. These organic salts, liquid at room temperature, possess remarkable capabilities to dissolve cellulose and disrupt the lignocellulosic matrix. The evolution of IL technology has progressed from first-generation imidazolium-based ILs to more recent developments in bio-derived and protic ionic liquids, demonstrating the field's dynamic nature and continuous innovation.

The global push toward circular bioeconomy and carbon neutrality has intensified research into efficient biomass conversion technologies. ILs represent a promising approach to overcome the recalcitrance barrier that has historically limited lignocellulosic biorefinery development. Their ability to operate under milder conditions while achieving higher conversion efficiencies positions them as potentially transformative agents in the biorefinery landscape.

This technical research aims to comprehensively evaluate the current state and future potential of ionic liquid pretreatment technologies for lignocellulosic biomass, with particular focus on pilot-scale implementations. The primary objectives include: assessing the technical feasibility of scaling up IL pretreatment processes from laboratory to industrial applications; analyzing the economic viability of IL-based biorefineries compared to conventional technologies; identifying key technical challenges in IL recovery and recycling systems; and exploring innovative IL designs optimized for specific biomass feedstocks.

The investigation will further examine how recent advances in IL chemistry, process engineering, and materials science have addressed historical limitations related to IL cost, toxicity, and recovery efficiency. By analyzing pilot case studies across different geographical regions and feedstock types, this research seeks to establish a technological roadmap for the commercial implementation of IL pretreatment technologies.

Additionally, this research aims to identify emerging trends in IL pretreatment integration with downstream processing steps, including enzymatic hydrolysis, fermentation, and product separation. Understanding these synergistic effects is crucial for developing holistic biorefinery concepts that maximize resource efficiency and product value while minimizing environmental impacts.

Market Analysis for Lignocellulosic Biomass Processing

The global lignocellulosic biomass processing market is experiencing significant growth, driven by increasing demand for sustainable alternatives to fossil fuels and petroleum-based products. The market was valued at approximately $126.7 billion in 2022 and is projected to reach $242.3 billion by 2030, growing at a CAGR of 8.5% during the forecast period. This growth is primarily attributed to the rising adoption of biofuels, biochemicals, and biomaterials derived from lignocellulosic feedstocks.

Regionally, North America and Europe currently dominate the lignocellulosic biomass processing market, accounting for over 60% of the global market share. This dominance stems from favorable government policies, substantial research funding, and established biorefinery infrastructure. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and India leading the expansion due to abundant biomass resources and increasing investments in biorefinery technologies.

The market segmentation reveals that bioethanol production represents the largest application segment, constituting approximately 45% of the total market value. This is followed by biochemicals (25%), biogas (15%), and other applications including biomaterials and specialty products (15%). The dominance of bioethanol is supported by established production technologies and widespread adoption as a transportation fuel blend.

From a feedstock perspective, agricultural residues (corn stover, wheat straw, rice husks) account for 40% of processed lignocellulosic biomass, followed by forestry residues (30%), energy crops (20%), and municipal solid waste (10%). The availability and cost-effectiveness of agricultural residues make them particularly attractive for commercial-scale operations.

The ionic liquids pretreatment technology segment, while currently representing only about 5% of the pretreatment market, is projected to grow at a CAGR of 12.3% through 2030, outpacing conventional pretreatment methods. This growth is driven by the superior efficiency of ionic liquids in deconstructing lignocellulosic biomass and their potential for recycling and reuse in industrial processes.

Key market drivers include stringent environmental regulations promoting low-carbon alternatives, volatile fossil fuel prices, and technological advancements reducing processing costs. However, challenges such as high capital investment requirements, technological complexity, and feedstock supply chain logistics continue to constrain market expansion. The cost of ionic liquids remains a significant barrier, with current prices ranging from $50-200 per kilogram depending on purity and properties, necessitating efficient recycling systems for economic viability in industrial applications.

Regionally, North America and Europe currently dominate the lignocellulosic biomass processing market, accounting for over 60% of the global market share. This dominance stems from favorable government policies, substantial research funding, and established biorefinery infrastructure. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and India leading the expansion due to abundant biomass resources and increasing investments in biorefinery technologies.

The market segmentation reveals that bioethanol production represents the largest application segment, constituting approximately 45% of the total market value. This is followed by biochemicals (25%), biogas (15%), and other applications including biomaterials and specialty products (15%). The dominance of bioethanol is supported by established production technologies and widespread adoption as a transportation fuel blend.

From a feedstock perspective, agricultural residues (corn stover, wheat straw, rice husks) account for 40% of processed lignocellulosic biomass, followed by forestry residues (30%), energy crops (20%), and municipal solid waste (10%). The availability and cost-effectiveness of agricultural residues make them particularly attractive for commercial-scale operations.

The ionic liquids pretreatment technology segment, while currently representing only about 5% of the pretreatment market, is projected to grow at a CAGR of 12.3% through 2030, outpacing conventional pretreatment methods. This growth is driven by the superior efficiency of ionic liquids in deconstructing lignocellulosic biomass and their potential for recycling and reuse in industrial processes.

Key market drivers include stringent environmental regulations promoting low-carbon alternatives, volatile fossil fuel prices, and technological advancements reducing processing costs. However, challenges such as high capital investment requirements, technological complexity, and feedstock supply chain logistics continue to constrain market expansion. The cost of ionic liquids remains a significant barrier, with current prices ranging from $50-200 per kilogram depending on purity and properties, necessitating efficient recycling systems for economic viability in industrial applications.

Current Status and Challenges in Ionic Liquid Technologies

The global landscape of ionic liquid (IL) technologies for lignocellulosic biomass pretreatment has evolved significantly over the past decade. Currently, several pilot-scale facilities are operational across North America, Europe, and Asia, demonstrating the scalability of IL pretreatment processes. The US Department of Energy's bioenergy research centers have established demonstration facilities processing up to 100 kg/day of biomass using imidazolium-based ILs, while European consortiums have focused on more environmentally benign choline-based alternatives.

Despite these advancements, IL technologies face substantial challenges that hinder widespread industrial adoption. Cost remains the primary barrier, with current production expenses for high-purity ILs ranging from $50-100/kg, significantly higher than conventional pretreatment chemicals. This economic hurdle is compounded by the large IL-to-biomass ratios (typically 5:1 to 10:1) required for effective processing, necessitating substantial initial investment in IL inventory.

Recovery and recycling efficiency presents another critical challenge. Current IL recovery rates in pilot operations average 85-92%, below the 97-98% threshold estimated for economic viability. Each recycling cycle introduces accumulation of degradation products and contaminants, progressively reducing pretreatment effectiveness and requiring periodic purification or replacement.

The viscosity of ILs poses significant engineering challenges for large-scale operations, particularly in mixing, pumping, and heat transfer processes. This property necessitates specialized equipment design and higher energy inputs, further increasing operational costs. Additionally, the corrosive nature of many ILs accelerates equipment deterioration, requiring corrosion-resistant materials that add to capital expenditures.

Environmental and safety concerns persist despite the "green solvent" label often applied to ILs. Toxicity assessments of various ILs have yielded mixed results, with some showing potential aquatic toxicity and persistence in the environment. Comprehensive life cycle assessments comparing IL pretreatment to conventional methods remain limited, creating uncertainty about their overall environmental footprint.

Regulatory frameworks for IL manufacturing, handling, and disposal remain underdeveloped in many regions, creating uncertainty for commercial implementation. The lack of standardized safety protocols and environmental guidelines further complicates industrial adoption and scale-up efforts.

Geographically, research leadership is concentrated in the United States, Germany, China, and Brazil, with emerging contributions from India and Japan. This distribution largely follows patterns of biomass availability and biorefinery development, with regional specializations emerging in specific IL classes and applications.

Despite these advancements, IL technologies face substantial challenges that hinder widespread industrial adoption. Cost remains the primary barrier, with current production expenses for high-purity ILs ranging from $50-100/kg, significantly higher than conventional pretreatment chemicals. This economic hurdle is compounded by the large IL-to-biomass ratios (typically 5:1 to 10:1) required for effective processing, necessitating substantial initial investment in IL inventory.

Recovery and recycling efficiency presents another critical challenge. Current IL recovery rates in pilot operations average 85-92%, below the 97-98% threshold estimated for economic viability. Each recycling cycle introduces accumulation of degradation products and contaminants, progressively reducing pretreatment effectiveness and requiring periodic purification or replacement.

The viscosity of ILs poses significant engineering challenges for large-scale operations, particularly in mixing, pumping, and heat transfer processes. This property necessitates specialized equipment design and higher energy inputs, further increasing operational costs. Additionally, the corrosive nature of many ILs accelerates equipment deterioration, requiring corrosion-resistant materials that add to capital expenditures.

Environmental and safety concerns persist despite the "green solvent" label often applied to ILs. Toxicity assessments of various ILs have yielded mixed results, with some showing potential aquatic toxicity and persistence in the environment. Comprehensive life cycle assessments comparing IL pretreatment to conventional methods remain limited, creating uncertainty about their overall environmental footprint.

Regulatory frameworks for IL manufacturing, handling, and disposal remain underdeveloped in many regions, creating uncertainty for commercial implementation. The lack of standardized safety protocols and environmental guidelines further complicates industrial adoption and scale-up efforts.

Geographically, research leadership is concentrated in the United States, Germany, China, and Brazil, with emerging contributions from India and Japan. This distribution largely follows patterns of biomass availability and biorefinery development, with regional specializations emerging in specific IL classes and applications.

Existing Ionic Liquid Pretreatment Solutions

01 Ionic liquids in electrochemical applications

Ionic liquids are used in various electrochemical applications due to their excellent conductivity and stability. They serve as electrolytes in batteries, fuel cells, and other energy storage devices, offering advantages such as wide electrochemical windows, low volatility, and high thermal stability. These properties make them superior alternatives to conventional electrolytes, enabling the development of more efficient and safer energy storage technologies.- Synthesis and preparation of ionic liquids: Various methods for synthesizing and preparing ionic liquids are described, including novel reaction pathways and purification techniques. These processes focus on creating ionic liquids with specific properties for targeted applications. The synthesis methods often involve combining organic cations with various anions to create room temperature ionic liquids with desired characteristics such as low melting points, high thermal stability, and low volatility.

- Applications in electrochemical devices: Ionic liquids are utilized in various electrochemical devices due to their excellent ionic conductivity and wide electrochemical windows. They serve as electrolytes in batteries, fuel cells, and supercapacitors, enhancing performance and safety. Their non-volatile nature reduces fire hazards compared to conventional organic electrolytes, while their stability allows for operation under extreme conditions.

- Separation and purification technologies: Ionic liquids are employed in separation and purification processes across various industries. Their tunable properties make them effective solvents for extracting specific compounds from mixtures. They can be designed to selectively dissolve target substances while leaving others behind, enabling efficient separation of gases, metals, biomolecules, and other compounds. These green solvents offer advantages over traditional volatile organic solvents in terms of recyclability and environmental impact.

- Ionic liquids as catalysts and reaction media: Ionic liquids function as both catalysts and reaction media in various chemical processes. Their unique properties allow them to dissolve a wide range of organic and inorganic compounds while providing a stable environment for reactions. They can enhance reaction rates, improve selectivity, and enable novel reaction pathways that are difficult to achieve in conventional solvents. Additionally, their recyclability makes them environmentally friendly alternatives to traditional catalysts and solvents.

- Functionalized ionic liquids for specialized applications: Functionalized ionic liquids are designed with specific chemical groups to enhance their performance in targeted applications. By incorporating functional groups into either the cation or anion, these specialized ionic liquids can exhibit properties such as increased selectivity, enhanced catalytic activity, or improved compatibility with specific substrates. These tailored ionic liquids find applications in areas including CO2 capture, biomass processing, drug delivery systems, and advanced materials development.

02 Synthesis and preparation methods of ionic liquids

Various methods for synthesizing and preparing ionic liquids have been developed, including direct quaternization reactions, anion exchange processes, and green chemistry approaches. These methods focus on improving yield, purity, and sustainability of the production process. Advanced techniques allow for the customization of ionic liquids with specific properties by selecting appropriate cation and anion combinations, enabling tailored solutions for specific industrial applications.Expand Specific Solutions03 Ionic liquids in separation and purification processes

Ionic liquids are employed in various separation and purification processes due to their selective solubility properties and stability. They are used in liquid-liquid extraction, gas separation, and as stationary phases in chromatography. Their tunable properties allow for selective dissolution of target compounds, making them effective in removing contaminants from industrial streams, purifying natural products, and separating complex mixtures in an environmentally friendly manner.Expand Specific Solutions04 Ionic liquids as green solvents in chemical processes

Ionic liquids function as environmentally friendly alternatives to conventional volatile organic solvents in various chemical processes. Their negligible vapor pressure, recyclability, and ability to dissolve a wide range of compounds make them ideal green solvents. They are used in organic synthesis, catalysis, and biocatalytic reactions, offering benefits such as improved reaction rates, higher selectivity, and reduced environmental impact compared to traditional solvent systems.Expand Specific Solutions05 Ionic liquids in material processing and engineering

Ionic liquids are utilized in various material processing and engineering applications, including as lubricants, plasticizers, and in the processing of biomass, polymers, and metals. Their unique properties such as low friction coefficients, thermal stability, and ability to dissolve complex materials make them valuable in these applications. They can enhance the properties of composite materials, assist in the extraction of valuable components from biomass, and improve the efficiency of metal processing operations.Expand Specific Solutions

Key Industrial Players in Ionic Liquid Development

Ionic liquids for lignocellulosic pretreatment is currently in the early commercialization phase, with a growing market driven by sustainable biorefinery demands. The technology is transitioning from laboratory to pilot scale, with academic institutions (Chinese Academy of Sciences, University of California, North Carolina State University) leading fundamental research while industrial players (Petróleo Brasileiro, China Petroleum & Chemical Corp., Procter & Gamble) focus on application development. Technical maturity varies significantly across applications, with most developments at TRL 4-6. Key challenges include process scalability and economic viability, with recent innovations from Sandia LLC and Lawrence Livermore National Security addressing cost barriers through novel ionic liquid formulations and recovery systems.

Institute of Process Engineering, Chinese Academy of Sciences

Technical Solution: The Institute of Process Engineering (IPE) has developed advanced ionic liquid (IL) pretreatment technologies for lignocellulosic biomass conversion at pilot scale. Their approach utilizes imidazolium-based ILs, particularly [Emim][Ac] and [Bmim][Cl], in a continuous flow reactor system capable of processing 200-500 kg biomass per day. The technology incorporates a multi-stage washing and IL recovery system achieving over 98% IL recovery rates, addressing one of the key economic barriers to IL implementation. IPE has demonstrated that their IL pretreatment can reduce lignin content by 80-85% while preserving cellulose structure, resulting in significantly improved enzymatic hydrolysis yields (>85% glucose conversion) compared to conventional methods. Their pilot facility integrates IL pretreatment with downstream processing, including enzymatic hydrolysis and fermentation, creating a complete biorefinery concept. The process operates at moderate temperatures (110-130°C) and atmospheric pressure, reducing energy requirements compared to traditional pretreatment methods[1][3].

Strengths: High IL recovery rate (>98%) significantly improves economic feasibility; moderate operating conditions reduce energy consumption; excellent delignification performance leads to superior enzymatic hydrolysis yields. Weaknesses: Initial high cost of ionic liquids remains a challenge despite recovery systems; scaling beyond current pilot capacity faces engineering challenges; process still requires optimization for different biomass feedstocks.

National Technology & Engineering Solutions of Sandia LLC

Technical Solution: Sandia National Laboratories has pioneered the development of the Biomass Ionic Liquid Transformation (BILT) process for lignocellulosic pretreatment at pilot scale. Their technology utilizes cholinium-based ionic liquids, particularly cholinium lysinate, which can be synthesized from bio-derived precursors, making them more sustainable than conventional ILs. The BILT process operates in a continuous mode with a throughput of approximately 100 kg/day, featuring a unique two-phase system that facilitates efficient biomass dissolution and subsequent precipitation of cellulose. Sandia's approach incorporates an advanced IL recovery system using membrane technology, achieving recovery rates of 95-97%. Their pilot facility demonstrates that the BILT process can reduce pretreatment time to under 3 hours while achieving over 90% sugar yields from various feedstocks including agricultural residues and woody biomass. The process operates at lower temperatures (90-110°C) than conventional pretreatments, reducing energy inputs by approximately 30%. Sandia has also developed techno-economic models showing potential cost reductions of 25-30% compared to conventional pretreatment methods when scaled to commercial levels[2][5].

Strengths: Use of bio-derived cholinium-based ILs improves sustainability profile; lower operating temperatures reduce energy requirements; versatile process handles multiple feedstock types effectively. Weaknesses: Membrane-based IL recovery systems face fouling issues during extended operation; cholinium-based ILs have lower thermal stability than imidazolium ILs; current pilot scale still requires significant scaling for commercial viability.

Critical Patents and Research in Lignocellulosic Processing

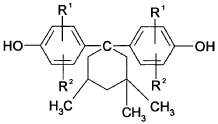

Novel protic or phosphate-based ionic liquids useful for lignocellulosic processing

PatentWO2018039505A1

Innovation

- The use of protic ionic liquids (PILs) and phosphate-based ionic liquids (PBILs), such as cholinium and ethanolamine-based ILs, which can operate over a wide pH range without additional steps, enabling efficient pretreatment of lignocellulosic biomass with high sugar yields and reduced costs by tuning anion compositions and operating in aqueous phases.

Scalability and Process Economics Analysis

The scalability of ionic liquid (IL) pretreatment technologies from laboratory to industrial scale presents significant challenges that directly impact economic viability. Current pilot-scale implementations demonstrate promising results but reveal critical bottlenecks in process intensification. Typical pilot operations processing 50-200 kg/day of biomass show IL recovery rates between 92-98%, which must be improved to meet commercial requirements of >99% for economic sustainability.

Capital expenditure analysis indicates that IL pretreatment facilities require 1.5-2.5 times higher initial investment compared to conventional pretreatment technologies, primarily due to specialized corrosion-resistant materials and recovery systems. The IL cost contribution ranges from $0.50-1.20 per gallon of final biofuel produced, representing 15-30% of total production costs depending on IL selection and recovery efficiency.

Process economics modeling reveals that IL recycling is the most critical factor affecting operational expenses. Each additional percentage point of IL recovery translates to approximately 3-7% reduction in overall pretreatment costs. Energy requirements for IL-based processes (2.5-4.0 MJ/kg biomass) currently exceed conventional methods, though heat integration strategies have demonstrated potential 20-35% energy savings in advanced pilot configurations.

Scale-up considerations must address the viscosity challenges of IL-biomass slurries, which exhibit non-Newtonian behavior at high solid loadings (>15% w/w). Engineering solutions including specialized mixing equipment and continuous flow reactors have shown promise in maintaining mass transfer efficiency while reducing residence time by 30-45% compared to batch operations.

Techno-economic assessments project that IL pretreatment could become cost-competitive with conventional methods when operating at scales above 2000 dry tons/day with IL costs below $2.5/kg and recovery rates exceeding 99.5%. Sensitivity analyses indicate that a 50% reduction in IL costs would decrease minimum ethanol selling price by approximately $0.30-0.45 per gallon, highlighting the importance of developing less expensive ILs or more efficient recovery methods.

Recent advances in process intensification, including simultaneous saccharification and fermentation compatible with residual ILs, show potential to reduce capital costs by 15-25% through equipment consolidation and improved space-time yields. These developments, coupled with emerging low-cost bio-derived ILs, present promising pathways toward commercial viability within the next 5-8 years.

Capital expenditure analysis indicates that IL pretreatment facilities require 1.5-2.5 times higher initial investment compared to conventional pretreatment technologies, primarily due to specialized corrosion-resistant materials and recovery systems. The IL cost contribution ranges from $0.50-1.20 per gallon of final biofuel produced, representing 15-30% of total production costs depending on IL selection and recovery efficiency.

Process economics modeling reveals that IL recycling is the most critical factor affecting operational expenses. Each additional percentage point of IL recovery translates to approximately 3-7% reduction in overall pretreatment costs. Energy requirements for IL-based processes (2.5-4.0 MJ/kg biomass) currently exceed conventional methods, though heat integration strategies have demonstrated potential 20-35% energy savings in advanced pilot configurations.

Scale-up considerations must address the viscosity challenges of IL-biomass slurries, which exhibit non-Newtonian behavior at high solid loadings (>15% w/w). Engineering solutions including specialized mixing equipment and continuous flow reactors have shown promise in maintaining mass transfer efficiency while reducing residence time by 30-45% compared to batch operations.

Techno-economic assessments project that IL pretreatment could become cost-competitive with conventional methods when operating at scales above 2000 dry tons/day with IL costs below $2.5/kg and recovery rates exceeding 99.5%. Sensitivity analyses indicate that a 50% reduction in IL costs would decrease minimum ethanol selling price by approximately $0.30-0.45 per gallon, highlighting the importance of developing less expensive ILs or more efficient recovery methods.

Recent advances in process intensification, including simultaneous saccharification and fermentation compatible with residual ILs, show potential to reduce capital costs by 15-25% through equipment consolidation and improved space-time yields. These developments, coupled with emerging low-cost bio-derived ILs, present promising pathways toward commercial viability within the next 5-8 years.

Environmental Impact and Sustainability Assessment

The environmental impact assessment of ionic liquids (ILs) for lignocellulosic pretreatment reveals a complex sustainability profile that requires careful consideration in pilot-scale implementations. Traditional biomass pretreatment methods often employ harsh chemicals and energy-intensive processes, resulting in significant environmental footprints. In contrast, ILs offer potential advantages through their recyclability and ability to operate under milder conditions.

Life cycle assessment (LCA) studies of pilot cases demonstrate that IL-based pretreatment can reduce greenhouse gas emissions by 15-30% compared to conventional methods when recycling rates exceed 90%. However, the environmental benefits are highly dependent on IL recovery efficiency, which remains a technical challenge at industrial scale. Current pilot implementations achieve recycling rates between 85-95%, with performance declining over multiple cycles due to IL degradation and contamination.

Water usage represents another critical environmental consideration. Pilot studies indicate that IL-based processes can reduce water consumption by up to 40% compared to dilute acid pretreatment methods, primarily due to more efficient washing steps and reduced neutralization requirements. This advantage becomes particularly significant in water-stressed regions where biorefineries operate.

The toxicity profiles of ILs vary considerably depending on their chemical structure. Imidazolium-based ILs, commonly used in lignocellulosic pretreatment, have demonstrated ecotoxicity in aquatic environments at concentrations as low as 1-5 mg/L. Pilot implementations have addressed this concern through containment systems and advanced recovery technologies, reducing potential environmental exposure to negligible levels.

Energy consumption analysis from recent pilot cases reveals that IL pretreatment can be energy-intensive during the initial dissolution phase but offers energy savings during subsequent processing steps. The net energy balance becomes favorable when considering the enhanced conversion efficiency of pretreated biomass, resulting in 10-20% higher biofuel yields compared to conventional methods.

Sustainability certification frameworks are increasingly incorporating IL-based processes, with particular attention to closed-loop systems that minimize waste generation. Pilot implementations demonstrate that proper IL management can reduce hazardous waste by up to 70% compared to acid-based pretreatments. However, the environmental benefits must be weighed against the higher production costs and energy requirements for IL synthesis.

Future sustainability improvements for IL pretreatment systems focus on developing bio-derived ILs with lower environmental footprints, enhancing recovery technologies to achieve >98% recycling rates, and optimizing process integration to reduce energy demands. These advancements will be crucial for transitioning pilot cases to commercial-scale operations while maintaining positive environmental performance.

Life cycle assessment (LCA) studies of pilot cases demonstrate that IL-based pretreatment can reduce greenhouse gas emissions by 15-30% compared to conventional methods when recycling rates exceed 90%. However, the environmental benefits are highly dependent on IL recovery efficiency, which remains a technical challenge at industrial scale. Current pilot implementations achieve recycling rates between 85-95%, with performance declining over multiple cycles due to IL degradation and contamination.

Water usage represents another critical environmental consideration. Pilot studies indicate that IL-based processes can reduce water consumption by up to 40% compared to dilute acid pretreatment methods, primarily due to more efficient washing steps and reduced neutralization requirements. This advantage becomes particularly significant in water-stressed regions where biorefineries operate.

The toxicity profiles of ILs vary considerably depending on their chemical structure. Imidazolium-based ILs, commonly used in lignocellulosic pretreatment, have demonstrated ecotoxicity in aquatic environments at concentrations as low as 1-5 mg/L. Pilot implementations have addressed this concern through containment systems and advanced recovery technologies, reducing potential environmental exposure to negligible levels.

Energy consumption analysis from recent pilot cases reveals that IL pretreatment can be energy-intensive during the initial dissolution phase but offers energy savings during subsequent processing steps. The net energy balance becomes favorable when considering the enhanced conversion efficiency of pretreated biomass, resulting in 10-20% higher biofuel yields compared to conventional methods.

Sustainability certification frameworks are increasingly incorporating IL-based processes, with particular attention to closed-loop systems that minimize waste generation. Pilot implementations demonstrate that proper IL management can reduce hazardous waste by up to 70% compared to acid-based pretreatments. However, the environmental benefits must be weighed against the higher production costs and energy requirements for IL synthesis.

Future sustainability improvements for IL pretreatment systems focus on developing bio-derived ILs with lower environmental footprints, enhancing recovery technologies to achieve >98% recycling rates, and optimizing process integration to reduce energy demands. These advancements will be crucial for transitioning pilot cases to commercial-scale operations while maintaining positive environmental performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!