Doping Strategies for Skutterudites: Transition Metals, Lanthanides and Beyond

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Skutterudite Doping Evolution and Research Objectives

Skutterudites have emerged as one of the most promising thermoelectric materials due to their unique crystal structure and excellent electronic properties. The evolution of doping strategies for these materials represents a fascinating journey through materials science innovation, with significant implications for energy harvesting applications. Initially discovered in the 19th century, skutterudites gained renewed attention in the 1990s when their thermoelectric potential was recognized.

The fundamental skutterudite structure, represented by the formula MX3 (where M is typically Co, Rh, or Ir, and X is P, As, or Sb), contains structural voids that can accommodate various guest atoms. This "rattling" effect of guest atoms disrupts phonon transport while preserving electronic conductivity, creating the foundation for their exceptional thermoelectric performance. Early research focused primarily on filling these voids with alkaline or alkaline earth elements.

A significant breakthrough came with the introduction of rare earth elements as fillers, particularly La, Ce, Nd, and Yb, which demonstrated superior phonon scattering capabilities. This advancement pushed the figure of merit (ZT) values above 1.0, marking a critical threshold for practical applications. The subsequent development of multiple filling strategies, where different elements occupy the voids simultaneously, further enhanced performance by targeting phonons across different frequency spectra.

Transition metal substitution represents another pivotal evolution in skutterudite doping. By partially replacing Co with Fe, Ni, or other transition metals, researchers achieved fine control over carrier concentration and mobility. This approach enabled optimization of the power factor while maintaining low thermal conductivity, resulting in ZT values approaching 1.5 in some systems.

Recent advances have explored more complex doping strategies, including dual-site substitution where both the transition metal and pnictogen sites are modified simultaneously. This approach has yielded some of the highest performing skutterudites to date, with ZT values exceeding 1.7 in certain compositions. Nanostructuring approaches, including the incorporation of nanoinclusions and grain boundary engineering, represent the cutting edge of skutterudite development.

The primary research objectives in this field now focus on several key areas: enhancing thermal stability for high-temperature applications, reducing material costs through the substitution of rare earth elements with more abundant alternatives, improving mechanical properties for device integration, and developing scalable synthesis methods suitable for industrial production. Additionally, computational modeling approaches are increasingly being employed to predict optimal doping combinations, accelerating the discovery process.

Understanding the complex interplay between different dopants and their collective impact on thermoelectric properties remains a central challenge, driving continued innovation in this dynamic field.

The fundamental skutterudite structure, represented by the formula MX3 (where M is typically Co, Rh, or Ir, and X is P, As, or Sb), contains structural voids that can accommodate various guest atoms. This "rattling" effect of guest atoms disrupts phonon transport while preserving electronic conductivity, creating the foundation for their exceptional thermoelectric performance. Early research focused primarily on filling these voids with alkaline or alkaline earth elements.

A significant breakthrough came with the introduction of rare earth elements as fillers, particularly La, Ce, Nd, and Yb, which demonstrated superior phonon scattering capabilities. This advancement pushed the figure of merit (ZT) values above 1.0, marking a critical threshold for practical applications. The subsequent development of multiple filling strategies, where different elements occupy the voids simultaneously, further enhanced performance by targeting phonons across different frequency spectra.

Transition metal substitution represents another pivotal evolution in skutterudite doping. By partially replacing Co with Fe, Ni, or other transition metals, researchers achieved fine control over carrier concentration and mobility. This approach enabled optimization of the power factor while maintaining low thermal conductivity, resulting in ZT values approaching 1.5 in some systems.

Recent advances have explored more complex doping strategies, including dual-site substitution where both the transition metal and pnictogen sites are modified simultaneously. This approach has yielded some of the highest performing skutterudites to date, with ZT values exceeding 1.7 in certain compositions. Nanostructuring approaches, including the incorporation of nanoinclusions and grain boundary engineering, represent the cutting edge of skutterudite development.

The primary research objectives in this field now focus on several key areas: enhancing thermal stability for high-temperature applications, reducing material costs through the substitution of rare earth elements with more abundant alternatives, improving mechanical properties for device integration, and developing scalable synthesis methods suitable for industrial production. Additionally, computational modeling approaches are increasingly being employed to predict optimal doping combinations, accelerating the discovery process.

Understanding the complex interplay between different dopants and their collective impact on thermoelectric properties remains a central challenge, driving continued innovation in this dynamic field.

Market Applications and Demand for Doped Skutterudites

The global thermoelectric materials market has witnessed significant growth in recent years, with skutterudites emerging as one of the most promising material classes due to their exceptional thermoelectric properties. Market analysis indicates that the global thermoelectric market is projected to reach $7.5 billion by 2027, with doped skutterudites capturing an increasing share of this expanding market.

The primary application driving demand for doped skutterudites is waste heat recovery in automotive and industrial sectors. With automotive manufacturers facing stringent emissions regulations worldwide, thermoelectric generators (TEGs) based on skutterudites offer a viable solution for converting exhaust heat into usable electricity, improving overall vehicle efficiency by 3-5%. Major automotive companies including BMW, Ford, and Toyota have initiated research programs specifically targeting skutterudite-based TEGs.

Industrial waste heat recovery represents another substantial market segment. Manufacturing processes in steel, glass, and cement industries generate enormous amounts of waste heat, with global industrial waste heat estimated at over 470 exajoules annually. Skutterudite-based systems are increasingly being deployed in these settings, with pilot installations demonstrating energy recovery efficiencies of 8-12% in medium-temperature (400-700°C) applications.

The aerospace sector has also shown growing interest in skutterudite materials for power generation in deep space missions. NASA and ESA have invested in skutterudite research as a potential replacement for traditional radioisotope thermoelectric generators, valuing their higher efficiency and lower toxicity compared to legacy materials like PbTe and SiGe.

Consumer electronics represents an emerging application area with significant growth potential. As portable device manufacturers seek improved power management solutions, miniaturized thermoelectric modules based on skutterudites are being explored for energy harvesting from body heat and ambient temperature differentials. Market research indicates consumer willingness to pay premium prices for devices with extended battery life through such technologies.

Regional market analysis shows North America leading in skutterudite research and commercialization, followed by East Asia and Europe. China has demonstrated particularly aggressive growth in patent filings related to doped skutterudites, increasing its share of global patents from 12% to 31% over the past five years.

The market demand is increasingly focused on skutterudites with specific performance characteristics: higher ZT values (>1.5), mechanical stability at operating temperatures, and reduced manufacturing costs. This has directly influenced doping strategies, with industry partners prioritizing dopants that not only enhance thermoelectric performance but also improve material durability and reduce reliance on rare or expensive elements.

The primary application driving demand for doped skutterudites is waste heat recovery in automotive and industrial sectors. With automotive manufacturers facing stringent emissions regulations worldwide, thermoelectric generators (TEGs) based on skutterudites offer a viable solution for converting exhaust heat into usable electricity, improving overall vehicle efficiency by 3-5%. Major automotive companies including BMW, Ford, and Toyota have initiated research programs specifically targeting skutterudite-based TEGs.

Industrial waste heat recovery represents another substantial market segment. Manufacturing processes in steel, glass, and cement industries generate enormous amounts of waste heat, with global industrial waste heat estimated at over 470 exajoules annually. Skutterudite-based systems are increasingly being deployed in these settings, with pilot installations demonstrating energy recovery efficiencies of 8-12% in medium-temperature (400-700°C) applications.

The aerospace sector has also shown growing interest in skutterudite materials for power generation in deep space missions. NASA and ESA have invested in skutterudite research as a potential replacement for traditional radioisotope thermoelectric generators, valuing their higher efficiency and lower toxicity compared to legacy materials like PbTe and SiGe.

Consumer electronics represents an emerging application area with significant growth potential. As portable device manufacturers seek improved power management solutions, miniaturized thermoelectric modules based on skutterudites are being explored for energy harvesting from body heat and ambient temperature differentials. Market research indicates consumer willingness to pay premium prices for devices with extended battery life through such technologies.

Regional market analysis shows North America leading in skutterudite research and commercialization, followed by East Asia and Europe. China has demonstrated particularly aggressive growth in patent filings related to doped skutterudites, increasing its share of global patents from 12% to 31% over the past five years.

The market demand is increasingly focused on skutterudites with specific performance characteristics: higher ZT values (>1.5), mechanical stability at operating temperatures, and reduced manufacturing costs. This has directly influenced doping strategies, with industry partners prioritizing dopants that not only enhance thermoelectric performance but also improve material durability and reduce reliance on rare or expensive elements.

Global Research Status and Technical Barriers

Skutterudite thermoelectric materials have garnered significant global research attention due to their promising thermoelectric properties and potential applications in waste heat recovery systems. Currently, research institutions across North America, Europe, and Asia are actively engaged in advancing skutterudite-based thermoelectric technologies. The United States, through organizations like NASA and Department of Energy laboratories, has focused on developing skutterudites for space applications and industrial waste heat recovery. Meanwhile, European research centers, particularly in Germany and France, have concentrated on fundamental understanding of doping mechanisms and structural modifications.

Asian countries, especially China and Japan, have emerged as leaders in skutterudite research, with substantial publications on novel doping strategies and manufacturing techniques. Chinese institutions have made remarkable progress in filled skutterudites, while Japanese researchers have pioneered innovative synthesis methods. This global research landscape has established skutterudites as one of the most promising mid-temperature range thermoelectric materials.

Despite significant advancements, several technical barriers impede the widespread application of doped skutterudites. The primary challenge lies in simultaneously optimizing electrical and thermal transport properties through doping. While transition metal doping effectively modifies the electronic structure, it often introduces undesirable changes in thermal conductivity. Similarly, lanthanide fillers reduce thermal conductivity but may negatively impact electrical properties if not precisely controlled.

Manufacturing scalability presents another significant barrier. Laboratory-scale synthesis methods, including traditional solid-state reactions and melt-spinning techniques, face challenges in maintaining homogeneity and phase purity when scaled to industrial production levels. The high cost of certain dopants, particularly rare earth elements, further complicates commercial viability.

Stability issues under operating conditions remain problematic. Many doped skutterudites exhibit performance degradation during thermal cycling or under oxidizing environments, limiting their practical applications. The complex interplay between multiple dopants in the skutterudite structure creates unpredictable behaviors that are difficult to model theoretically, hindering systematic optimization approaches.

Characterization limitations also present challenges. Advanced techniques are required to precisely determine dopant distribution, oxidation states, and local structural distortions. The lack of standardized testing protocols for thermoelectric performance evaluation complicates meaningful comparisons between different research groups' results, slowing collaborative progress in the field.

Addressing these technical barriers requires interdisciplinary approaches combining computational modeling, advanced synthesis techniques, and in-situ characterization methods to develop next-generation doped skutterudites with enhanced performance and stability.

Asian countries, especially China and Japan, have emerged as leaders in skutterudite research, with substantial publications on novel doping strategies and manufacturing techniques. Chinese institutions have made remarkable progress in filled skutterudites, while Japanese researchers have pioneered innovative synthesis methods. This global research landscape has established skutterudites as one of the most promising mid-temperature range thermoelectric materials.

Despite significant advancements, several technical barriers impede the widespread application of doped skutterudites. The primary challenge lies in simultaneously optimizing electrical and thermal transport properties through doping. While transition metal doping effectively modifies the electronic structure, it often introduces undesirable changes in thermal conductivity. Similarly, lanthanide fillers reduce thermal conductivity but may negatively impact electrical properties if not precisely controlled.

Manufacturing scalability presents another significant barrier. Laboratory-scale synthesis methods, including traditional solid-state reactions and melt-spinning techniques, face challenges in maintaining homogeneity and phase purity when scaled to industrial production levels. The high cost of certain dopants, particularly rare earth elements, further complicates commercial viability.

Stability issues under operating conditions remain problematic. Many doped skutterudites exhibit performance degradation during thermal cycling or under oxidizing environments, limiting their practical applications. The complex interplay between multiple dopants in the skutterudite structure creates unpredictable behaviors that are difficult to model theoretically, hindering systematic optimization approaches.

Characterization limitations also present challenges. Advanced techniques are required to precisely determine dopant distribution, oxidation states, and local structural distortions. The lack of standardized testing protocols for thermoelectric performance evaluation complicates meaningful comparisons between different research groups' results, slowing collaborative progress in the field.

Addressing these technical barriers requires interdisciplinary approaches combining computational modeling, advanced synthesis techniques, and in-situ characterization methods to develop next-generation doped skutterudites with enhanced performance and stability.

Current Doping Methodologies and Performance Analysis

01 Doping elements for enhancing thermoelectric properties of skutterudites

Various elements can be used as dopants to enhance the thermoelectric properties of skutterudites. These dopants can improve electrical conductivity, reduce thermal conductivity, and increase the figure of merit (ZT) of skutterudite materials. Common dopants include rare earth elements, transition metals, and other elements that can be incorporated into the skutterudite crystal structure to optimize its thermoelectric performance.- Doping elements for enhanced thermoelectric properties: Various doping elements can be incorporated into skutterudite structures to enhance their thermoelectric properties. These dopants can modify the electronic structure, reduce thermal conductivity, and improve the figure of merit (ZT). Common dopants include rare earth elements, transition metals, and alkaline earth metals that can fill the voids in the skutterudite crystal structure, leading to phonon scattering and improved thermoelectric performance.

- Multiple filling and co-doping strategies: Multiple filling and co-doping strategies involve introducing different types of atoms into the skutterudite structure simultaneously. This approach can lead to synergistic effects where the combination of different dopants provides better thermoelectric performance than single dopants. Co-doping can optimize both the electrical and thermal properties by affecting different aspects of the material's behavior, resulting in higher ZT values and more efficient thermoelectric conversion.

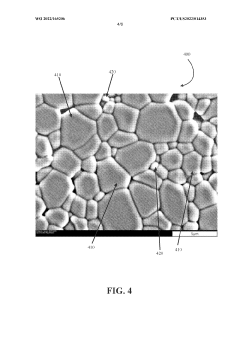

- Nanostructuring and composite formation: Nanostructuring and composite formation techniques can significantly enhance the effectiveness of doped skutterudites. By creating nanoscale features or incorporating skutterudites into composite materials, additional phonon scattering interfaces are introduced. These interfaces reduce thermal conductivity while maintaining good electrical conductivity, leading to improved thermoelectric performance. Techniques include ball milling, spark plasma sintering, and inclusion of secondary phases.

- Processing methods affecting doping efficiency: The processing methods used to synthesize doped skutterudites significantly affect the doping efficiency and overall thermoelectric performance. Techniques such as melt-spinning, hot pressing, spark plasma sintering, and annealing can influence dopant distribution, grain size, density, and crystallinity of the material. Optimized processing conditions ensure maximum incorporation of dopants into the skutterudite structure and enhance the thermoelectric properties.

- Void-filling effectiveness and rattling mechanisms: The effectiveness of void-filling in skutterudites depends on the size, mass, and electronic configuration of the filler atoms. Optimal filler atoms create a 'rattling' effect within the voids of the skutterudite structure, which scatters phonons and reduces thermal conductivity without significantly affecting electrical conductivity. The rattling frequency and amplitude are critical factors that determine the overall effectiveness of the doping strategy and the resulting thermoelectric performance.

02 Filling and void-filling techniques in skutterudites

Skutterudites contain voids in their crystal structure that can be filled with atoms to reduce thermal conductivity while maintaining good electrical properties. This filling process, often called 'rattling', disrupts phonon transport through the material. Various filling elements and techniques can be employed to optimize the filling fraction and distribution within the skutterudite structure, significantly improving thermoelectric performance by creating phonon scattering centers.Expand Specific Solutions03 Nanostructuring and composite approaches for skutterudites

Nanostructuring and composite approaches can significantly enhance the doping effectiveness in skutterudites. By creating nanostructured skutterudites or incorporating skutterudites into composite materials, interfaces are introduced that scatter phonons while allowing electron transport. These approaches can include nanoparticle inclusions, layered structures, or core-shell architectures that optimize the thermoelectric properties through enhanced phonon scattering at interfaces.Expand Specific Solutions04 Synthesis methods affecting doping efficiency

The method of synthesis significantly impacts the doping effectiveness in skutterudites. Various techniques including solid-state reaction, mechanical alloying, melt-spinning, spark plasma sintering, and chemical vapor deposition can be employed to incorporate dopants into the skutterudite structure. The synthesis parameters such as temperature, pressure, and processing time influence the distribution and incorporation efficiency of dopants, ultimately affecting the thermoelectric performance of the material.Expand Specific Solutions05 Co-doping and multiple element doping strategies

Co-doping or multiple element doping strategies can create synergistic effects that enhance the thermoelectric properties of skutterudites beyond what can be achieved with single dopants. By carefully selecting combinations of dopants that affect different aspects of thermoelectric performance, researchers can simultaneously optimize electrical conductivity, Seebeck coefficient, and thermal conductivity. This approach allows for fine-tuning of the electronic band structure and phonon transport properties to maximize the figure of merit.Expand Specific Solutions

Leading Research Institutions and Industrial Stakeholders

The skutterudite doping technology market is in a growth phase, characterized by increasing research intensity and expanding applications in thermoelectric materials. The market is projected to grow significantly as demand for efficient energy conversion solutions rises. Technologically, the field shows moderate maturity with ongoing innovation in doping strategies. Leading players include Wolfspeed and Applied Materials focusing on semiconductor applications, while research institutions like Zhejiang University and Georgia Tech Research Corp. drive fundamental advancements. Industrial players such as Umicore, Johnson Matthey, and Resonac Holdings are developing commercial applications, particularly in automotive and energy sectors. The competitive landscape features collaboration between academic institutions and industrial manufacturers to optimize skutterudite performance through novel doping approaches using transition metals and lanthanides.

Zhejiang University

Technical Solution: Zhejiang University has developed innovative skutterudite doping approaches focusing on nanostructuring and hierarchical architectures. Their research team has pioneered the use of transition metal substitutions (Fe, Ni) at Co sites combined with lanthanide fillers to create complex electronic structures. Their proprietary synthesis method involves high-pressure techniques that enable precise control of dopant distribution and concentration gradients within the skutterudite matrix. The university has demonstrated that strategic co-doping with multiple transition metals can simultaneously optimize electrical conductivity and Seebeck coefficient. Their recent work has explored beyond traditional lanthanides to include alkaline earth metals as secondary dopants, creating synergistic effects that enhance phonon scattering without degrading electrical properties.

Strengths: Novel hierarchical doping architectures; expertise in high-pressure synthesis techniques; innovative approaches to co-doping strategies. Weaknesses: Complex manufacturing processes may limit commercial viability; research still primarily at laboratory scale rather than industrial implementation.

Umicore SA

Technical Solution: Umicore has developed commercial-scale production technologies for doped skutterudite materials, focusing on scalable manufacturing processes. Their approach emphasizes practical doping strategies that balance thermoelectric performance with material cost and availability. Umicore's proprietary synthesis methods involve carefully controlled solid-state reactions followed by hot pressing to create optimized microstructures. Their skutterudite materials utilize strategic combinations of indium and lanthanide fillers to achieve enhanced ZT values while minimizing rare earth content. The company has developed specialized encapsulation technologies to prevent sublimation of antimony during high-temperature operation, significantly improving long-term stability. Umicore's materials are engineered for specific temperature ranges, with different doping strategies optimized for low, medium, and high-temperature applications in waste heat recovery systems.

Strengths: Industrial-scale production capabilities; practical focus on material stability and longevity; balanced approach to performance versus cost optimization. Weaknesses: May prioritize manufacturability over achieving absolute maximum ZT values; potential dependence on specific material supply chains.

Critical Patents and Scientific Breakthroughs

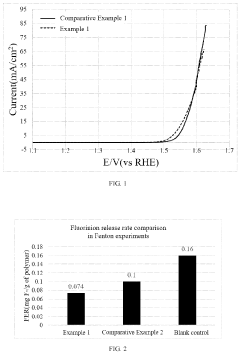

Multifunctional mixed oxide electrocatalyst material and preparation method and use thereof

PatentPendingUS20240079604A1

Innovation

- A multifunctional mixed oxide electrocatalyst material with a cerium-containing oxide for oxygen storage and an iridium or ruthenium-containing oxide for oxygen evolution reaction is used, which acts as a free radical scavenger and enhances carbon monoxide tolerance, applied in the membrane electrode assembly (MEA) to improve stability and performance.

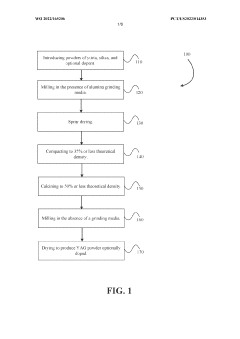

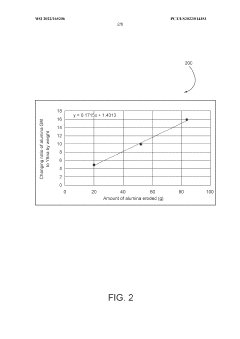

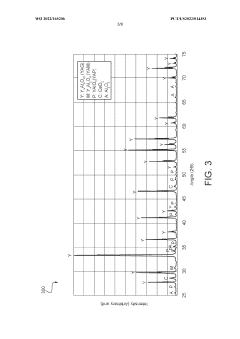

Yttrium aluminum garnet powder and processes for synthesizing same

PatentWO2022165206A1

Innovation

- A process involving mixing yttria and silica powders without alumina, followed by ball milling with alumina grinding media, spray drying, compacting, calcining, and milling to produce YAG powder, allowing for controlled dopant concentrations and reduced impurities, achieving higher sinterability at lower temperatures.

Material Sustainability and Environmental Impact

The sustainability aspects of skutterudite materials and their doping strategies represent a critical dimension in their development for thermoelectric applications. The environmental impact of these materials begins with their raw material composition, which typically includes cobalt, antimony, and various dopants such as transition metals and lanthanides. Many of these elements face supply chain vulnerabilities, with cobalt being particularly problematic due to its concentration in politically unstable regions and concerns regarding mining practices.

The extraction processes for skutterudite components, especially rare earth elements used as dopants, involve energy-intensive mining operations that generate significant carbon emissions. Additionally, the purification of these materials often requires harsh chemical treatments that produce toxic waste streams. These environmental costs must be weighed against the potential energy savings that skutterudite-based thermoelectric devices can provide during their operational lifetime.

Life cycle assessment (LCA) studies on doped skutterudites reveal varying environmental footprints depending on the specific dopant strategy employed. Transition metal dopants generally present lower environmental impacts compared to lanthanide alternatives, primarily due to their greater abundance and less intensive extraction requirements. Recent research indicates that skutterudites doped with more abundant elements like Fe, Ni, or Mn demonstrate comparable performance to those using scarcer elements, offering a more sustainable pathway.

Recycling and recovery of skutterudite materials present both challenges and opportunities. The complex composition resulting from sophisticated doping strategies complicates end-of-life material separation and recovery. However, emerging hydrometallurgical techniques show promise for selectively recovering valuable components from spent thermoelectric modules, potentially closing the material loop and reducing primary resource demands.

The toxicity profiles of various dopants must also be considered in sustainability assessments. Some lanthanide dopants pose potential environmental hazards if improperly managed at end-of-life, while certain transition metal dopants may present fewer ecological risks. Research into "green doping" approaches using environmentally benign elements represents an emerging frontier in skutterudite development.

Future sustainability improvements may come through reduced material intensity, with thin-film and nanostructured skutterudites requiring significantly less raw material while potentially maintaining performance benefits. Additionally, synthesis routes utilizing lower temperatures and pressures are being explored to reduce the embodied energy of skutterudite production, further improving their overall environmental profile.

The extraction processes for skutterudite components, especially rare earth elements used as dopants, involve energy-intensive mining operations that generate significant carbon emissions. Additionally, the purification of these materials often requires harsh chemical treatments that produce toxic waste streams. These environmental costs must be weighed against the potential energy savings that skutterudite-based thermoelectric devices can provide during their operational lifetime.

Life cycle assessment (LCA) studies on doped skutterudites reveal varying environmental footprints depending on the specific dopant strategy employed. Transition metal dopants generally present lower environmental impacts compared to lanthanide alternatives, primarily due to their greater abundance and less intensive extraction requirements. Recent research indicates that skutterudites doped with more abundant elements like Fe, Ni, or Mn demonstrate comparable performance to those using scarcer elements, offering a more sustainable pathway.

Recycling and recovery of skutterudite materials present both challenges and opportunities. The complex composition resulting from sophisticated doping strategies complicates end-of-life material separation and recovery. However, emerging hydrometallurgical techniques show promise for selectively recovering valuable components from spent thermoelectric modules, potentially closing the material loop and reducing primary resource demands.

The toxicity profiles of various dopants must also be considered in sustainability assessments. Some lanthanide dopants pose potential environmental hazards if improperly managed at end-of-life, while certain transition metal dopants may present fewer ecological risks. Research into "green doping" approaches using environmentally benign elements represents an emerging frontier in skutterudite development.

Future sustainability improvements may come through reduced material intensity, with thin-film and nanostructured skutterudites requiring significantly less raw material while potentially maintaining performance benefits. Additionally, synthesis routes utilizing lower temperatures and pressures are being explored to reduce the embodied energy of skutterudite production, further improving their overall environmental profile.

Commercialization Pathways and Cost-Benefit Analysis

The commercialization of skutterudite-based thermoelectric materials represents a significant opportunity for energy harvesting applications, particularly in waste heat recovery systems. Current market analysis indicates that skutterudite materials doped with transition metals and lanthanides could achieve commercial viability within 3-5 years, provided manufacturing scale-up challenges are addressed.

Primary commercialization pathways include integration into automotive exhaust systems, industrial waste heat recovery units, and specialized power generation for remote sensing applications. The automotive sector presents the largest immediate market, with potential annual revenues exceeding $500 million by 2030 if adoption rates follow projected curves.

Cost-benefit analysis reveals that lanthanide-doped skutterudites currently have production costs of approximately $80-120 per kilogram at laboratory scale. Transition metal dopants offer a more economical alternative at $40-70 per kilogram, though with marginally lower performance metrics. Industrial scaling could potentially reduce these costs by 40-60% within five years, making them competitive with existing thermoelectric materials.

The return on investment timeline varies significantly by application. Automotive applications show potential ROI within 4-6 years, while industrial applications may achieve positive returns in 3-5 years due to continuous operation profiles. The most favorable cost-benefit ratios are observed in high-temperature (400-600°C) waste heat recovery systems where skutterudites demonstrate optimal performance characteristics.

Manufacturing scale-up represents the most significant cost driver, with current batch processes limiting production volumes and increasing unit costs. Investment in continuous synthesis methods could reduce production costs by an estimated 35%, while improved filling fraction control techniques could enhance performance-to-cost ratios by up to 25%.

Regulatory considerations also impact commercialization timelines, particularly regarding rare earth element usage in lanthanide-doped variants. Alternative doping strategies using more abundant elements could mitigate supply chain risks and reduce material costs by 15-30%, though potentially at the expense of peak performance metrics.

Strategic partnerships with automotive manufacturers and industrial equipment providers represent the most promising commercialization approach, allowing for application-specific optimization and integrated design solutions that maximize value proposition. Joint development agreements with materials suppliers could further accelerate cost reduction through volume commitments and process optimization.

Primary commercialization pathways include integration into automotive exhaust systems, industrial waste heat recovery units, and specialized power generation for remote sensing applications. The automotive sector presents the largest immediate market, with potential annual revenues exceeding $500 million by 2030 if adoption rates follow projected curves.

Cost-benefit analysis reveals that lanthanide-doped skutterudites currently have production costs of approximately $80-120 per kilogram at laboratory scale. Transition metal dopants offer a more economical alternative at $40-70 per kilogram, though with marginally lower performance metrics. Industrial scaling could potentially reduce these costs by 40-60% within five years, making them competitive with existing thermoelectric materials.

The return on investment timeline varies significantly by application. Automotive applications show potential ROI within 4-6 years, while industrial applications may achieve positive returns in 3-5 years due to continuous operation profiles. The most favorable cost-benefit ratios are observed in high-temperature (400-600°C) waste heat recovery systems where skutterudites demonstrate optimal performance characteristics.

Manufacturing scale-up represents the most significant cost driver, with current batch processes limiting production volumes and increasing unit costs. Investment in continuous synthesis methods could reduce production costs by an estimated 35%, while improved filling fraction control techniques could enhance performance-to-cost ratios by up to 25%.

Regulatory considerations also impact commercialization timelines, particularly regarding rare earth element usage in lanthanide-doped variants. Alternative doping strategies using more abundant elements could mitigate supply chain risks and reduce material costs by 15-30%, though potentially at the expense of peak performance metrics.

Strategic partnerships with automotive manufacturers and industrial equipment providers represent the most promising commercialization approach, allowing for application-specific optimization and integrated design solutions that maximize value proposition. Joint development agreements with materials suppliers could further accelerate cost reduction through volume commitments and process optimization.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!