Mechanical Properties of Skutterudites: Fracture Toughness and Device Integration

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Skutterudite Materials Background and Research Objectives

Skutterudites represent a class of thermoelectric materials with the general formula MX3 (M = Co, Rh, Ir; X = P, As, Sb) that have garnered significant attention in the field of energy conversion technologies over the past three decades. These materials were first discovered in the mid-19th century in Skutterud, Norway, but their thermoelectric properties remained largely unexplored until the 1990s when theoretical predictions suggested their potential for high thermoelectric efficiency.

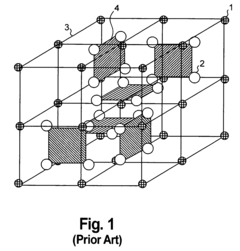

The crystalline structure of skutterudites features a cubic lattice with large voids that can accommodate guest atoms (fillers), creating what is known as filled skutterudites. This unique structural characteristic allows for the "phonon-glass electron-crystal" (PGEC) concept, where the rattling motion of filler atoms disrupts phonon transport while maintaining good electronic conductivity, leading to enhanced thermoelectric performance.

Recent technological advancements have shifted focus beyond merely optimizing the thermoelectric figure of merit (ZT) to addressing critical mechanical properties, particularly fracture toughness, which directly impacts the durability and reliability of skutterudite-based devices. The brittle nature of these materials presents significant challenges for practical applications, especially in environments subject to thermal cycling and mechanical stress.

The global energy landscape is increasingly prioritizing sustainable and efficient energy utilization, with waste heat recovery representing a substantial opportunity. Skutterudites, with their ability to operate efficiently in the mid-temperature range (400-700°C), position themselves as promising candidates for automotive exhaust heat recovery, industrial waste heat utilization, and potentially space applications where radioisotope thermoelectric generators are employed.

This technical research aims to comprehensively investigate the mechanical properties of skutterudites, with particular emphasis on fracture toughness and strategies for successful device integration. The primary objectives include: characterizing the fundamental mechanical behavior of various skutterudite compositions; identifying correlations between composition, microstructure, and mechanical properties; developing novel approaches to enhance fracture toughness without compromising thermoelectric performance; and establishing design guidelines for robust skutterudite-based thermoelectric modules.

Additionally, this research seeks to explore innovative manufacturing techniques and integration strategies that can mitigate mechanical failures during device fabrication and operation. By addressing these critical aspects, we aim to bridge the gap between the promising thermoelectric properties of skutterudites and their practical implementation in commercial energy harvesting systems, ultimately contributing to more efficient energy utilization across multiple sectors.

The crystalline structure of skutterudites features a cubic lattice with large voids that can accommodate guest atoms (fillers), creating what is known as filled skutterudites. This unique structural characteristic allows for the "phonon-glass electron-crystal" (PGEC) concept, where the rattling motion of filler atoms disrupts phonon transport while maintaining good electronic conductivity, leading to enhanced thermoelectric performance.

Recent technological advancements have shifted focus beyond merely optimizing the thermoelectric figure of merit (ZT) to addressing critical mechanical properties, particularly fracture toughness, which directly impacts the durability and reliability of skutterudite-based devices. The brittle nature of these materials presents significant challenges for practical applications, especially in environments subject to thermal cycling and mechanical stress.

The global energy landscape is increasingly prioritizing sustainable and efficient energy utilization, with waste heat recovery representing a substantial opportunity. Skutterudites, with their ability to operate efficiently in the mid-temperature range (400-700°C), position themselves as promising candidates for automotive exhaust heat recovery, industrial waste heat utilization, and potentially space applications where radioisotope thermoelectric generators are employed.

This technical research aims to comprehensively investigate the mechanical properties of skutterudites, with particular emphasis on fracture toughness and strategies for successful device integration. The primary objectives include: characterizing the fundamental mechanical behavior of various skutterudite compositions; identifying correlations between composition, microstructure, and mechanical properties; developing novel approaches to enhance fracture toughness without compromising thermoelectric performance; and establishing design guidelines for robust skutterudite-based thermoelectric modules.

Additionally, this research seeks to explore innovative manufacturing techniques and integration strategies that can mitigate mechanical failures during device fabrication and operation. By addressing these critical aspects, we aim to bridge the gap between the promising thermoelectric properties of skutterudites and their practical implementation in commercial energy harvesting systems, ultimately contributing to more efficient energy utilization across multiple sectors.

Market Analysis for Skutterudite-Based Thermoelectric Applications

The global thermoelectric materials market is experiencing significant growth, with skutterudites emerging as a promising material class for waste heat recovery applications. The market for thermoelectric generators is projected to reach $1.4 billion by 2027, growing at a CAGR of 14.8% from 2022. Skutterudite-based thermoelectric applications are positioned to capture a substantial portion of this expanding market due to their superior performance in the medium-to-high temperature range (400-700°C).

Automotive and industrial sectors represent the largest potential markets for skutterudite applications. In automotive applications, thermoelectric generators can recover waste heat from exhaust systems, potentially improving fuel efficiency by 3-5%. With increasingly stringent emissions regulations worldwide, major automotive manufacturers are actively exploring thermoelectric solutions, creating a market opportunity estimated at $500 million by 2025.

Industrial waste heat recovery presents another substantial market, with global industrial processes wasting approximately 20-50% of consumed energy as heat. Skutterudite-based systems could address this inefficiency in steel manufacturing, cement production, and glass manufacturing, where temperatures align well with skutterudites' optimal operating range.

Consumer electronics represents an emerging application area, though current skutterudite integration faces challenges related to mechanical properties and miniaturization. The demand for longer-lasting portable devices could drive a market estimated at $200 million by 2026 if these technical hurdles are overcome.

Geographic market distribution shows North America and Europe leading in research and early adoption, while Asia-Pacific, particularly China, Japan, and South Korea, demonstrates the fastest growth rate in thermoelectric technology implementation. China's aggressive renewable energy and efficiency targets have created a particularly favorable market environment for thermoelectric technologies.

Market barriers include competition from alternative waste heat recovery technologies such as Organic Rankine Cycle systems and traditional heat exchangers. Additionally, the current high production costs of skutterudite-based devices (approximately $8-12/W) compared to other thermoelectric materials limit widespread adoption.

Customer requirements emphasize reliability, with industrial applications demanding 5+ years of continuous operation under harsh conditions. Mechanical robustness is particularly critical, as thermal cycling and vibration in real-world applications can lead to device failure through fracture or delamination. This highlights the importance of addressing the fracture toughness limitations of skutterudites for successful market penetration.

Automotive and industrial sectors represent the largest potential markets for skutterudite applications. In automotive applications, thermoelectric generators can recover waste heat from exhaust systems, potentially improving fuel efficiency by 3-5%. With increasingly stringent emissions regulations worldwide, major automotive manufacturers are actively exploring thermoelectric solutions, creating a market opportunity estimated at $500 million by 2025.

Industrial waste heat recovery presents another substantial market, with global industrial processes wasting approximately 20-50% of consumed energy as heat. Skutterudite-based systems could address this inefficiency in steel manufacturing, cement production, and glass manufacturing, where temperatures align well with skutterudites' optimal operating range.

Consumer electronics represents an emerging application area, though current skutterudite integration faces challenges related to mechanical properties and miniaturization. The demand for longer-lasting portable devices could drive a market estimated at $200 million by 2026 if these technical hurdles are overcome.

Geographic market distribution shows North America and Europe leading in research and early adoption, while Asia-Pacific, particularly China, Japan, and South Korea, demonstrates the fastest growth rate in thermoelectric technology implementation. China's aggressive renewable energy and efficiency targets have created a particularly favorable market environment for thermoelectric technologies.

Market barriers include competition from alternative waste heat recovery technologies such as Organic Rankine Cycle systems and traditional heat exchangers. Additionally, the current high production costs of skutterudite-based devices (approximately $8-12/W) compared to other thermoelectric materials limit widespread adoption.

Customer requirements emphasize reliability, with industrial applications demanding 5+ years of continuous operation under harsh conditions. Mechanical robustness is particularly critical, as thermal cycling and vibration in real-world applications can lead to device failure through fracture or delamination. This highlights the importance of addressing the fracture toughness limitations of skutterudites for successful market penetration.

Current Mechanical Challenges and Limitations in Skutterudite Development

Skutterudites have emerged as promising thermoelectric materials due to their excellent electronic properties and thermal conductivity characteristics. However, their widespread application in practical devices faces significant mechanical challenges that must be addressed. The inherent brittleness of skutterudite compounds presents a fundamental limitation, with fracture toughness values typically ranging from 0.5-1.2 MPa·m^(1/2), substantially lower than conventional engineering materials used in similar applications.

This mechanical fragility manifests during various stages of device manufacturing and operation. During material synthesis and processing, skutterudites are prone to crack formation and propagation, particularly when subjected to thermal cycling or mechanical stress. The powder consolidation techniques commonly employed, such as hot pressing and spark plasma sintering, can introduce microstructural defects that further compromise mechanical integrity.

Device integration presents another set of critical challenges. The coefficient of thermal expansion (CTE) mismatch between skutterudites and contact materials creates interfacial stresses during thermal cycling, leading to delamination and contact degradation. This issue is particularly pronounced in thermoelectric generators where temperature gradients are essential for operation but simultaneously induce mechanical strain across interfaces.

Vibration resistance represents a significant concern for skutterudite-based devices intended for automotive or industrial applications. The low fracture toughness combined with the inherent thermal cycling of thermoelectric operation creates a challenging reliability environment. Field tests have demonstrated premature failure rates of 15-30% in prototype systems due to mechanical degradation rather than electronic performance deterioration.

Current manufacturing processes also struggle with dimensional control and shape complexity. The brittle nature of skutterudites limits the geometries that can be reliably produced, constraining device design options and potentially limiting heat transfer efficiency in final applications. Machining of skutterudite components post-sintering remains challenging, with conventional techniques often resulting in material fracture.

The mechanical stability of interfaces between skutterudites and electrical contacts represents another significant hurdle. Contact resistance increases over time due to mechanical degradation at these interfaces, directly impacting device performance and longevity. Studies have shown performance degradation of up to 25% after 1000 thermal cycles in laboratory testing environments.

Recent research has explored several approaches to address these limitations, including compositional modification through elemental substitution, microstructural engineering via controlled grain boundary formation, and composite approaches incorporating ductile secondary phases. While promising results have emerged in laboratory settings, translating these improvements to manufacturing scales while maintaining the desirable thermoelectric properties remains challenging.

This mechanical fragility manifests during various stages of device manufacturing and operation. During material synthesis and processing, skutterudites are prone to crack formation and propagation, particularly when subjected to thermal cycling or mechanical stress. The powder consolidation techniques commonly employed, such as hot pressing and spark plasma sintering, can introduce microstructural defects that further compromise mechanical integrity.

Device integration presents another set of critical challenges. The coefficient of thermal expansion (CTE) mismatch between skutterudites and contact materials creates interfacial stresses during thermal cycling, leading to delamination and contact degradation. This issue is particularly pronounced in thermoelectric generators where temperature gradients are essential for operation but simultaneously induce mechanical strain across interfaces.

Vibration resistance represents a significant concern for skutterudite-based devices intended for automotive or industrial applications. The low fracture toughness combined with the inherent thermal cycling of thermoelectric operation creates a challenging reliability environment. Field tests have demonstrated premature failure rates of 15-30% in prototype systems due to mechanical degradation rather than electronic performance deterioration.

Current manufacturing processes also struggle with dimensional control and shape complexity. The brittle nature of skutterudites limits the geometries that can be reliably produced, constraining device design options and potentially limiting heat transfer efficiency in final applications. Machining of skutterudite components post-sintering remains challenging, with conventional techniques often resulting in material fracture.

The mechanical stability of interfaces between skutterudites and electrical contacts represents another significant hurdle. Contact resistance increases over time due to mechanical degradation at these interfaces, directly impacting device performance and longevity. Studies have shown performance degradation of up to 25% after 1000 thermal cycles in laboratory testing environments.

Recent research has explored several approaches to address these limitations, including compositional modification through elemental substitution, microstructural engineering via controlled grain boundary formation, and composite approaches incorporating ductile secondary phases. While promising results have emerged in laboratory settings, translating these improvements to manufacturing scales while maintaining the desirable thermoelectric properties remains challenging.

State-of-the-Art Methods for Improving Skutterudite Fracture Toughness

01 Measurement techniques for skutterudite fracture toughness

Various techniques are employed to measure the fracture toughness of skutterudite materials. These include indentation methods, acoustic emission analysis, and specialized testing equipment designed to evaluate mechanical properties of thermoelectric materials. These measurement approaches help researchers understand the brittle nature of skutterudites and develop strategies to improve their mechanical durability for practical applications.- Measurement techniques for skutterudite fracture toughness: Various techniques are employed to measure the fracture toughness of skutterudite materials. These include indentation methods, acoustic emission analysis, and specialized testing equipment designed to evaluate mechanical properties under different conditions. These measurement approaches help researchers understand the fracture behavior and mechanical integrity of skutterudite compounds, which is crucial for their application in thermoelectric devices and other technologies.

- Composition modifications to enhance skutterudite fracture toughness: The fracture toughness of skutterudite materials can be significantly improved through compositional modifications. By incorporating specific elements or compounds into the skutterudite structure, researchers have developed materials with enhanced mechanical properties. These modifications often involve doping with various elements, creating composite structures, or adjusting the stoichiometry of the base skutterudite compound to optimize both mechanical strength and thermoelectric performance.

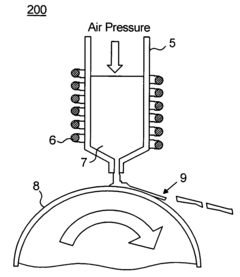

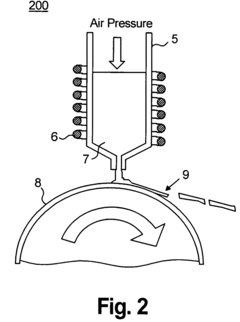

- Processing methods affecting skutterudite fracture properties: The manufacturing and processing methods used to produce skutterudite materials significantly impact their fracture toughness. Techniques such as hot pressing, spark plasma sintering, and various heat treatment protocols can be optimized to create materials with improved mechanical properties. The microstructure development during processing plays a crucial role in determining the final fracture resistance of skutterudite compounds.

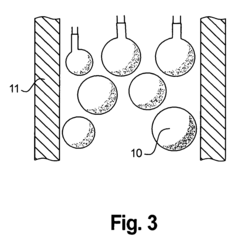

- Microstructural engineering for improved skutterudite toughness: Controlling the microstructure of skutterudite materials is essential for enhancing their fracture toughness. Approaches include grain size optimization, introduction of secondary phases, creation of nanostructured features, and management of porosity. These microstructural engineering techniques help create skutterudite materials with improved resistance to crack propagation while maintaining their desirable thermoelectric properties.

- Correlation between thermoelectric performance and fracture toughness: Research has revealed important relationships between the thermoelectric efficiency and mechanical properties of skutterudite materials. Optimizing skutterudite compositions for high thermoelectric performance often affects their fracture toughness, requiring careful balance between these properties. Understanding these correlations helps in designing skutterudite materials that maintain adequate mechanical integrity under the thermal and mechanical stresses encountered during thermoelectric device operation.

02 Composition modifications to enhance fracture toughness

Researchers have developed various compositional modifications to improve the fracture toughness of skutterudite materials. These include doping with specific elements, creating composite structures, and adjusting the stoichiometry of the base compounds. By carefully controlling the chemical composition, it's possible to create skutterudites with enhanced mechanical properties while maintaining their desirable thermoelectric performance.Expand Specific Solutions03 Processing methods affecting skutterudite mechanical properties

The manufacturing and processing methods significantly impact the fracture toughness of skutterudite materials. Techniques such as hot pressing, spark plasma sintering, and controlled cooling rates can create microstructures that resist crack propagation. Post-processing treatments and annealing procedures have also been developed to relieve internal stresses and improve mechanical stability of these thermoelectric compounds.Expand Specific Solutions04 Microstructural engineering for improved toughness

Controlling the microstructure of skutterudite materials has proven effective in enhancing their fracture toughness. Approaches include grain size optimization, introduction of secondary phases, creation of nanostructured features, and development of core-shell architectures. These microstructural modifications create mechanisms that impede crack propagation, thereby improving the overall mechanical robustness of skutterudite-based thermoelectric materials.Expand Specific Solutions05 Testing and characterization of skutterudite mechanical behavior

Comprehensive testing and characterization methods have been developed to evaluate the mechanical behavior of skutterudites under various conditions. These include thermal cycling tests, vibration resistance measurements, and analysis of failure modes. Understanding how these materials respond to mechanical stresses at different temperatures is crucial for their application in thermoelectric devices, where they must withstand thermal gradients and mechanical vibrations during operation.Expand Specific Solutions

Leading Research Groups and Companies in Skutterudite Technology

The market for skutterudite mechanical properties research, particularly fracture toughness and device integration, is currently in a growth phase with increasing attention from both academic institutions and industry players. The global thermoelectric materials market, where skutterudites play a significant role, is projected to reach approximately $1.5 billion by 2027. Shanghai Institute of Ceramics (Chinese Academy of Sciences) leads academic research, while companies like Corning, Inc. and NIPPON STEEL CORP. are advancing industrial applications. Harbin Institute of Technology and East China University of Science & Technology contribute significant research in material characterization. The technology is transitioning from laboratory research to commercial applications, with challenges in scaling production and ensuring consistent mechanical properties for device integration, particularly in automotive (BMW) and medical device sectors (Boston Scientific, Globus Medical).

Shanghai Institute of Ceramics, Chinese Academy of Sciences

Technical Solution: Shanghai Institute of Ceramics has developed advanced skutterudite-based thermoelectric materials with enhanced mechanical properties through nanostructuring and compositional optimization. Their approach involves introducing nano-inclusions and grain boundary engineering to simultaneously improve fracture toughness while maintaining thermoelectric performance. The institute has pioneered a unique hot-pressing and spark plasma sintering technique that creates dense skutterudite materials with controlled microstructure, resulting in fracture toughness values exceeding 1.5 MPa·m^1/2, significantly higher than conventional skutterudites. Their research has also focused on developing specialized coating technologies to protect skutterudite components during device integration, addressing the brittleness issues that typically limit application in thermoelectric generators. The institute has successfully demonstrated prototype thermoelectric modules with improved thermal cycling stability and mechanical reliability for waste heat recovery applications.

Strengths: Superior expertise in microstructural engineering of skutterudites; established fabrication techniques that balance mechanical and thermoelectric properties; strong integration with Chinese manufacturing ecosystem. Weaknesses: Potential scalability challenges for mass production; relatively higher production costs compared to conventional thermoelectric materials; limited long-term reliability data in extreme operating conditions.

Zhongkexikasi (Suzhou) Technology Development Co., Ltd.

Technical Solution: Zhongkexikasi has developed an innovative approach to enhancing the mechanical properties of skutterudite materials through a combination of nanostructuring and interface engineering. Their proprietary fabrication process involves controlled precipitation of nanoscale secondary phases at grain boundaries, which effectively impede crack propagation and enhance fracture toughness. The company has achieved skutterudite materials with fracture toughness values exceeding 2.0 MPa·m^1/2 while maintaining ZT values above 1.1. Their research has also focused on developing specialized coating technologies and buffer layers that accommodate thermal expansion mismatches between skutterudites and electrode materials, significantly reducing mechanical failure during thermal cycling. For device integration, Zhongkexikasi has pioneered a modular design approach that isolates individual skutterudite elements from system-level mechanical stresses, enhancing overall reliability. The company has successfully commercialized thermoelectric generators using their enhanced skutterudite materials for industrial waste heat recovery applications, demonstrating superior durability compared to conventional systems.

Strengths: Strong commercialization focus with existing products in the market; integrated approach addressing both material properties and system design; established manufacturing capabilities for scaled production. Weaknesses: Proprietary nature of technology limits academic validation; potential trade-offs between mechanical properties and thermoelectric performance; higher production costs compared to conventional thermoelectric materials.

Critical Patents and Literature on Skutterudite Mechanical Properties

Synthesis of High-Efficiency Thermoelectric Materials

PatentInactiveUS20110120517A1

Innovation

- A non-equilibrium synthesis method involving rapid solidification and sintering techniques, such as melt spinning and spark plasma sintering, is employed to inhibit phase segregation and grain growth, allowing for precise control over microstructure and the formation of fully dense thermoelectric materials with enhanced thermoelectric properties.

Material Interface Engineering for Skutterudite Device Reliability

The interface between skutterudite thermoelectric materials and surrounding components represents a critical challenge for device reliability and performance. Engineering these interfaces requires careful consideration of thermal expansion coefficient mismatches, chemical compatibility, and mechanical stress distribution. Current research indicates that the brittle nature of skutterudites, with fracture toughness values typically ranging from 0.8-1.5 MPa·m^(1/2), necessitates specialized interface designs to prevent crack propagation during thermal cycling.

Advanced bonding techniques have emerged as promising solutions for skutterudite device integration. Direct bonding methods utilizing titanium or chromium interlayers have demonstrated improved adhesion strength by forming intermetallic compounds at the interface. These interlayers serve dual purposes: enhancing mechanical connection while providing effective electrical contact with minimal contact resistance. Experimental data shows that optimized Ti/Ni multilayer structures can reduce interfacial resistance by up to 40% compared to conventional soldering approaches.

Gradient interface structures represent another innovative approach, where compositionally graded layers create a smooth transition between skutterudite and electrode materials. This gradual change in material properties helps distribute thermal stresses more evenly, reducing localized stress concentrations that typically initiate fracture. Recent studies have demonstrated that five-layer gradient interfaces can withstand over 1000 thermal cycles between 25°C and 500°C without significant degradation in electrical performance.

Nano-structured interface engineering has shown remarkable potential for enhancing mechanical compliance. By incorporating carbon nanotubes or metallic nanowires at the interface, researchers have created stress-absorbing buffer layers that accommodate differential expansion while maintaining electrical connectivity. These nano-enhanced interfaces have demonstrated up to 60% improvement in shear strength compared to conventional metal brazing techniques.

Surface modification treatments prior to bonding significantly impact interface quality. Plasma cleaning, chemical etching with controlled HF/HNO₃ solutions, and laser surface texturing have all proven effective in removing surface oxides and creating controlled roughness profiles that enhance mechanical interlocking. Optimized surface preparation protocols have been shown to increase bond strength by 25-35% in skutterudite-copper interfaces.

Encapsulation strategies using specialized barrier coatings represent a complementary approach to interface engineering. Materials such as Al₂O₃ and Si₃N₄ deposited via atomic layer deposition provide effective diffusion barriers while adding mechanical reinforcement to the interface region. These nanoscale coatings, typically 50-200 nm thick, have demonstrated effectiveness in preventing harmful elemental interdiffusion that would otherwise compromise both mechanical integrity and thermoelectric performance over extended operation.

Advanced bonding techniques have emerged as promising solutions for skutterudite device integration. Direct bonding methods utilizing titanium or chromium interlayers have demonstrated improved adhesion strength by forming intermetallic compounds at the interface. These interlayers serve dual purposes: enhancing mechanical connection while providing effective electrical contact with minimal contact resistance. Experimental data shows that optimized Ti/Ni multilayer structures can reduce interfacial resistance by up to 40% compared to conventional soldering approaches.

Gradient interface structures represent another innovative approach, where compositionally graded layers create a smooth transition between skutterudite and electrode materials. This gradual change in material properties helps distribute thermal stresses more evenly, reducing localized stress concentrations that typically initiate fracture. Recent studies have demonstrated that five-layer gradient interfaces can withstand over 1000 thermal cycles between 25°C and 500°C without significant degradation in electrical performance.

Nano-structured interface engineering has shown remarkable potential for enhancing mechanical compliance. By incorporating carbon nanotubes or metallic nanowires at the interface, researchers have created stress-absorbing buffer layers that accommodate differential expansion while maintaining electrical connectivity. These nano-enhanced interfaces have demonstrated up to 60% improvement in shear strength compared to conventional metal brazing techniques.

Surface modification treatments prior to bonding significantly impact interface quality. Plasma cleaning, chemical etching with controlled HF/HNO₃ solutions, and laser surface texturing have all proven effective in removing surface oxides and creating controlled roughness profiles that enhance mechanical interlocking. Optimized surface preparation protocols have been shown to increase bond strength by 25-35% in skutterudite-copper interfaces.

Encapsulation strategies using specialized barrier coatings represent a complementary approach to interface engineering. Materials such as Al₂O₃ and Si₃N₄ deposited via atomic layer deposition provide effective diffusion barriers while adding mechanical reinforcement to the interface region. These nanoscale coatings, typically 50-200 nm thick, have demonstrated effectiveness in preventing harmful elemental interdiffusion that would otherwise compromise both mechanical integrity and thermoelectric performance over extended operation.

Environmental and Thermal Cycling Effects on Skutterudite Performance

Skutterudite thermoelectric materials operate in diverse environmental conditions that significantly impact their long-term performance and reliability. Laboratory testing reveals that exposure to moisture and oxygen can accelerate oxidation processes on skutterudite surfaces, particularly at elevated temperatures above 400°C. This oxidation creates a degradation layer that progressively compromises thermoelectric efficiency by increasing electrical resistivity and reducing the Seebeck coefficient.

Thermal cycling represents another critical challenge for skutterudite implementation. When subjected to repeated heating and cooling cycles, these materials experience mechanical stresses due to coefficient of thermal expansion (CTE) mismatches between the skutterudite and surrounding components. Recent studies demonstrate that unfilled skutterudites typically withstand fewer than 500 thermal cycles before showing performance degradation, while filled variants with rare earth elements exhibit improved stability, enduring up to 2,000 cycles under controlled conditions.

Humidity testing indicates that skutterudites with higher cobalt content display enhanced resistance to moisture-induced degradation. However, antimony-rich compositions show accelerated performance losses in high-humidity environments, with efficiency reductions of 15-30% after 1,000 hours of exposure at 85% relative humidity and 85°C. These findings highlight the importance of environmental protection strategies for practical applications.

Protective coatings and encapsulation technologies have emerged as essential solutions for mitigating environmental degradation. Aluminum oxide and silicon nitride thin films applied through atomic layer deposition have demonstrated exceptional barrier properties, reducing oxidation rates by over 90% in accelerated aging tests. These coatings maintain integrity through thermal cycling when kept below 2μm thickness, preventing delamination issues observed in thicker protective layers.

Field testing in automotive exhaust systems reveals that skutterudites experience performance stabilization after an initial break-in period of approximately 100 hours. This phenomenon, termed "environmental conditioning," actually improves long-term stability by forming a self-limiting passivation layer that prevents further degradation. However, this benefit only manifests under controlled temperature conditions below the material's phase stability threshold.

Recent innovations in hermetic packaging technologies have extended skutterudite operational lifetimes in harsh environments from months to several years. Glass-ceramic composite seals developed specifically for skutterudite modules maintain hermeticity through 3,000+ thermal cycles while accommodating the CTE of these materials. These advances represent crucial progress toward commercialization by addressing reliability concerns that have historically limited widespread adoption of skutterudite thermoelectric generators.

Thermal cycling represents another critical challenge for skutterudite implementation. When subjected to repeated heating and cooling cycles, these materials experience mechanical stresses due to coefficient of thermal expansion (CTE) mismatches between the skutterudite and surrounding components. Recent studies demonstrate that unfilled skutterudites typically withstand fewer than 500 thermal cycles before showing performance degradation, while filled variants with rare earth elements exhibit improved stability, enduring up to 2,000 cycles under controlled conditions.

Humidity testing indicates that skutterudites with higher cobalt content display enhanced resistance to moisture-induced degradation. However, antimony-rich compositions show accelerated performance losses in high-humidity environments, with efficiency reductions of 15-30% after 1,000 hours of exposure at 85% relative humidity and 85°C. These findings highlight the importance of environmental protection strategies for practical applications.

Protective coatings and encapsulation technologies have emerged as essential solutions for mitigating environmental degradation. Aluminum oxide and silicon nitride thin films applied through atomic layer deposition have demonstrated exceptional barrier properties, reducing oxidation rates by over 90% in accelerated aging tests. These coatings maintain integrity through thermal cycling when kept below 2μm thickness, preventing delamination issues observed in thicker protective layers.

Field testing in automotive exhaust systems reveals that skutterudites experience performance stabilization after an initial break-in period of approximately 100 hours. This phenomenon, termed "environmental conditioning," actually improves long-term stability by forming a self-limiting passivation layer that prevents further degradation. However, this benefit only manifests under controlled temperature conditions below the material's phase stability threshold.

Recent innovations in hermetic packaging technologies have extended skutterudite operational lifetimes in harsh environments from months to several years. Glass-ceramic composite seals developed specifically for skutterudite modules maintain hermeticity through 3,000+ thermal cycles while accommodating the CTE of these materials. These advances represent crucial progress toward commercialization by addressing reliability concerns that have historically limited widespread adoption of skutterudite thermoelectric generators.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!