Nanostructuring Approaches to Reduce Lattice Thermal Conductivity in Skutterudites

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Skutterudite Nanostructuring Background and Objectives

Skutterudites represent a class of thermoelectric materials that have garnered significant attention over the past three decades due to their promising thermoelectric properties. These materials, with the general formula MX3 (where M is typically Co, Rh, or Ir, and X is P, As, or Sb), were first discovered in the mid-19th century but only gained prominence in thermoelectric research during the 1990s. The evolution of skutterudite research has been characterized by continuous efforts to optimize their thermoelectric efficiency, particularly through reducing their lattice thermal conductivity while maintaining favorable electrical properties.

The fundamental challenge in thermoelectric materials lies in the interdependence of thermal conductivity, electrical conductivity, and Seebeck coefficient. Skutterudites naturally possess good electrical properties but suffer from relatively high thermal conductivity, which limits their thermoelectric figure of merit (ZT). The concept of phonon-glass electron-crystal (PGEC), introduced by Slack in the 1990s, has been instrumental in guiding skutterudite research, suggesting that ideal thermoelectric materials should conduct electricity like crystals while impeding heat flow like glasses.

Nanostructuring approaches emerged as a promising strategy to selectively reduce the lattice component of thermal conductivity without significantly compromising electrical performance. This technique involves introducing nanoscale features within the skutterudite matrix to scatter phonons (heat carriers) while allowing electrons to flow relatively unimpeded. The evolution of these approaches has progressed from simple void filling (with atoms like La, Ce, Yb) to more sophisticated methods including nano-inclusions, grain boundary engineering, and hierarchical architectures spanning multiple length scales.

Recent technological advancements in material synthesis, characterization, and computational modeling have accelerated progress in this field. High-resolution transmission electron microscopy, neutron scattering, and advanced thermal transport measurements have provided unprecedented insights into phonon transport mechanisms in nanostructured skutterudites. Concurrently, density functional theory calculations and molecular dynamics simulations have enabled researchers to predict and optimize nanostructuring strategies before experimental implementation.

The primary objective of current research in nanostructured skutterudites is to achieve ZT values consistently above 2 across a wide temperature range, which would make these materials commercially viable for thermoelectric power generation and cooling applications. Specific technical goals include developing scalable synthesis methods for precisely controlled nanostructures, understanding the fundamental phonon scattering mechanisms at different length scales, and designing hierarchical architectures that can effectively scatter the full phonon spectrum.

Beyond efficiency improvements, research aims to address challenges related to thermal stability, mechanical robustness, and cost-effective manufacturing of nanostructured skutterudites. The ultimate goal is to position these materials as a sustainable solution for waste heat recovery in industrial processes, automotive applications, and potentially for distributed power generation in remote locations.

The fundamental challenge in thermoelectric materials lies in the interdependence of thermal conductivity, electrical conductivity, and Seebeck coefficient. Skutterudites naturally possess good electrical properties but suffer from relatively high thermal conductivity, which limits their thermoelectric figure of merit (ZT). The concept of phonon-glass electron-crystal (PGEC), introduced by Slack in the 1990s, has been instrumental in guiding skutterudite research, suggesting that ideal thermoelectric materials should conduct electricity like crystals while impeding heat flow like glasses.

Nanostructuring approaches emerged as a promising strategy to selectively reduce the lattice component of thermal conductivity without significantly compromising electrical performance. This technique involves introducing nanoscale features within the skutterudite matrix to scatter phonons (heat carriers) while allowing electrons to flow relatively unimpeded. The evolution of these approaches has progressed from simple void filling (with atoms like La, Ce, Yb) to more sophisticated methods including nano-inclusions, grain boundary engineering, and hierarchical architectures spanning multiple length scales.

Recent technological advancements in material synthesis, characterization, and computational modeling have accelerated progress in this field. High-resolution transmission electron microscopy, neutron scattering, and advanced thermal transport measurements have provided unprecedented insights into phonon transport mechanisms in nanostructured skutterudites. Concurrently, density functional theory calculations and molecular dynamics simulations have enabled researchers to predict and optimize nanostructuring strategies before experimental implementation.

The primary objective of current research in nanostructured skutterudites is to achieve ZT values consistently above 2 across a wide temperature range, which would make these materials commercially viable for thermoelectric power generation and cooling applications. Specific technical goals include developing scalable synthesis methods for precisely controlled nanostructures, understanding the fundamental phonon scattering mechanisms at different length scales, and designing hierarchical architectures that can effectively scatter the full phonon spectrum.

Beyond efficiency improvements, research aims to address challenges related to thermal stability, mechanical robustness, and cost-effective manufacturing of nanostructured skutterudites. The ultimate goal is to position these materials as a sustainable solution for waste heat recovery in industrial processes, automotive applications, and potentially for distributed power generation in remote locations.

Thermoelectric Market Demand Analysis

The thermoelectric market has experienced significant growth in recent years, driven by increasing demand for energy-efficient technologies and waste heat recovery systems. The global thermoelectric market was valued at approximately 593 million USD in 2020 and is projected to reach 1,450 million USD by 2028, growing at a CAGR of 11.9% during the forecast period. This growth trajectory underscores the expanding commercial interest in advanced thermoelectric materials, including skutterudites.

The automotive sector represents one of the largest application areas for thermoelectric materials, accounting for roughly 35% of the total market share. Major automotive manufacturers are increasingly incorporating thermoelectric generators (TEGs) to convert waste heat from exhaust systems into usable electricity, thereby improving fuel efficiency and reducing emissions. This trend aligns with stringent global regulations on vehicle emissions and fuel economy standards.

Consumer electronics constitutes another significant market segment, with approximately 25% market share. The miniaturization of electronic devices and the growing need for portable power sources have created substantial demand for efficient thermoelectric cooling solutions. Skutterudite-based thermoelectric materials, with their enhanced efficiency through nanostructuring approaches, are particularly well-positioned to address these needs.

Industrial waste heat recovery systems represent a rapidly growing application area, with an estimated annual growth rate of 13.5%. Industries such as steel, glass, and cement production generate substantial waste heat, creating significant opportunities for thermoelectric technology implementation. The enhanced ZT values achieved through nanostructured skutterudites make these materials increasingly viable for industrial-scale applications.

Regional market analysis reveals that North America and Asia-Pacific dominate the thermoelectric market, collectively accounting for over 70% of global demand. China, Japan, and South Korea have emerged as key manufacturing hubs and research centers for advanced thermoelectric materials, including nanostructured skutterudites. Government initiatives supporting clean energy technologies in these regions further stimulate market growth.

The market demand for high-performance thermoelectric materials is increasingly focused on materials with higher ZT values, which directly correlates with conversion efficiency. Nanostructured skutterudites, with their potential to achieve ZT values exceeding 1.5 through reduced lattice thermal conductivity, are attracting significant commercial interest. Industry stakeholders are particularly interested in skutterudite-based solutions that can operate efficiently in the mid-temperature range (400-700K), which is ideal for many waste heat recovery applications.

The automotive sector represents one of the largest application areas for thermoelectric materials, accounting for roughly 35% of the total market share. Major automotive manufacturers are increasingly incorporating thermoelectric generators (TEGs) to convert waste heat from exhaust systems into usable electricity, thereby improving fuel efficiency and reducing emissions. This trend aligns with stringent global regulations on vehicle emissions and fuel economy standards.

Consumer electronics constitutes another significant market segment, with approximately 25% market share. The miniaturization of electronic devices and the growing need for portable power sources have created substantial demand for efficient thermoelectric cooling solutions. Skutterudite-based thermoelectric materials, with their enhanced efficiency through nanostructuring approaches, are particularly well-positioned to address these needs.

Industrial waste heat recovery systems represent a rapidly growing application area, with an estimated annual growth rate of 13.5%. Industries such as steel, glass, and cement production generate substantial waste heat, creating significant opportunities for thermoelectric technology implementation. The enhanced ZT values achieved through nanostructured skutterudites make these materials increasingly viable for industrial-scale applications.

Regional market analysis reveals that North America and Asia-Pacific dominate the thermoelectric market, collectively accounting for over 70% of global demand. China, Japan, and South Korea have emerged as key manufacturing hubs and research centers for advanced thermoelectric materials, including nanostructured skutterudites. Government initiatives supporting clean energy technologies in these regions further stimulate market growth.

The market demand for high-performance thermoelectric materials is increasingly focused on materials with higher ZT values, which directly correlates with conversion efficiency. Nanostructured skutterudites, with their potential to achieve ZT values exceeding 1.5 through reduced lattice thermal conductivity, are attracting significant commercial interest. Industry stakeholders are particularly interested in skutterudite-based solutions that can operate efficiently in the mid-temperature range (400-700K), which is ideal for many waste heat recovery applications.

Current Challenges in Skutterudite Thermal Conductivity Reduction

Despite significant advancements in skutterudite-based thermoelectric materials, several critical challenges persist in effectively reducing their lattice thermal conductivity. The inherent cage-like crystal structure of skutterudites, while beneficial for phonon scattering, presents complex optimization problems when implementing nanostructuring approaches. Current research faces difficulties in precisely controlling the size, distribution, and interface characteristics of nanoscale features within the skutterudite matrix.

One major challenge is achieving uniform dispersion of nanoparticles throughout the skutterudite matrix. Agglomeration frequently occurs during synthesis processes, creating inhomogeneous thermal transport properties across the material. This non-uniformity significantly reduces the effectiveness of phonon scattering mechanisms and compromises overall thermoelectric performance. Researchers continue to struggle with developing scalable synthesis methods that can maintain nanoscale feature consistency across bulk samples.

Interface engineering between the skutterudite matrix and embedded nanostructures represents another significant hurdle. Poor interfacial bonding can create thermal resistance discontinuities that paradoxically increase rather than decrease thermal conductivity in certain directions. Additionally, these interfaces often exhibit instability at elevated operating temperatures, leading to degradation of the nanostructured features over time and diminishing long-term performance reliability.

The multi-scale nature of phonon transport in skutterudites further complicates optimization efforts. Different phonon wavelengths require different scattering mechanism sizes, necessitating hierarchical nanostructuring approaches. Current fabrication techniques struggle to simultaneously implement and control features across multiple length scales (from atomic to mesoscale) in a single material system.

Chemical compatibility between skutterudite matrices and introduced nanophases presents additional challenges. Many potentially effective nanostructuring materials react unfavorably with skutterudites during high-temperature processing, forming unwanted compounds that can degrade thermoelectric properties. This chemical reactivity limits the selection of viable nanoinclusion materials and constrains processing parameters.

Mechanical stability issues also plague nanostructured skutterudites. The introduction of nanoscale features often compromises mechanical integrity, leading to microcracking and reduced material lifetime under thermal cycling conditions. This trade-off between thermal conductivity reduction and mechanical robustness represents a significant barrier to practical application.

Finally, cost-effective manufacturing remains an obstacle to widespread implementation. Current nanostructuring approaches typically involve complex, multi-step processes with expensive precursors and equipment. Developing economically viable production methods that maintain precise nanostructural control while enabling industrial-scale manufacturing continues to challenge researchers in this field.

One major challenge is achieving uniform dispersion of nanoparticles throughout the skutterudite matrix. Agglomeration frequently occurs during synthesis processes, creating inhomogeneous thermal transport properties across the material. This non-uniformity significantly reduces the effectiveness of phonon scattering mechanisms and compromises overall thermoelectric performance. Researchers continue to struggle with developing scalable synthesis methods that can maintain nanoscale feature consistency across bulk samples.

Interface engineering between the skutterudite matrix and embedded nanostructures represents another significant hurdle. Poor interfacial bonding can create thermal resistance discontinuities that paradoxically increase rather than decrease thermal conductivity in certain directions. Additionally, these interfaces often exhibit instability at elevated operating temperatures, leading to degradation of the nanostructured features over time and diminishing long-term performance reliability.

The multi-scale nature of phonon transport in skutterudites further complicates optimization efforts. Different phonon wavelengths require different scattering mechanism sizes, necessitating hierarchical nanostructuring approaches. Current fabrication techniques struggle to simultaneously implement and control features across multiple length scales (from atomic to mesoscale) in a single material system.

Chemical compatibility between skutterudite matrices and introduced nanophases presents additional challenges. Many potentially effective nanostructuring materials react unfavorably with skutterudites during high-temperature processing, forming unwanted compounds that can degrade thermoelectric properties. This chemical reactivity limits the selection of viable nanoinclusion materials and constrains processing parameters.

Mechanical stability issues also plague nanostructured skutterudites. The introduction of nanoscale features often compromises mechanical integrity, leading to microcracking and reduced material lifetime under thermal cycling conditions. This trade-off between thermal conductivity reduction and mechanical robustness represents a significant barrier to practical application.

Finally, cost-effective manufacturing remains an obstacle to widespread implementation. Current nanostructuring approaches typically involve complex, multi-step processes with expensive precursors and equipment. Developing economically viable production methods that maintain precise nanostructural control while enabling industrial-scale manufacturing continues to challenge researchers in this field.

Current Nanostructuring Methods for Skutterudites

01 Filled skutterudites for reduced thermal conductivity

Filling the voids in skutterudite crystal structures with atoms or ions (such as rare earth elements, alkaline earth metals, or alkali metals) can significantly reduce lattice thermal conductivity. These 'filler' atoms act as phonon scatterers, disrupting the phonon transport through the crystal lattice. This approach maintains the favorable electrical properties of skutterudites while reducing thermal conductivity, which is beneficial for thermoelectric applications.- Filled skutterudites for reduced thermal conductivity: Filling the voids in skutterudite crystal structures with atoms or ions (such as rare earth elements, alkaline earth metals, or other filler atoms) can significantly reduce lattice thermal conductivity. These filler atoms act as rattlers that scatter phonons within the crystal structure, disrupting heat transfer pathways. This approach maintains the electrical properties while reducing thermal conductivity, making filled skutterudites excellent thermoelectric materials with enhanced figure of merit (ZT).

- Nanostructuring and composite approaches: Incorporating nanostructures or forming composites with skutterudites can effectively reduce lattice thermal conductivity. Techniques include creating nanocomposites, introducing nanoinclusions, developing core-shell structures, or forming heterostructures. These approaches create additional phonon scattering interfaces at various length scales, disrupting phonon transport while preserving electron mobility. The increased phonon scattering at interfaces significantly reduces thermal conductivity without substantially degrading electrical properties.

- Substitutional doping and alloying: Substitutional doping or alloying in skutterudite structures involves replacing atoms in the crystal lattice with different elements to create mass fluctuation and strain field fluctuation. This approach introduces point defects and local distortions in the crystal structure that effectively scatter phonons across different frequency ranges. Common substitutions include partial replacement of Co with Fe, Ni, or other transition metals, or substituting Sb with other pnictogen elements, creating mass disorder that reduces lattice thermal conductivity.

- Multiple filling and double-filled skutterudites: Multiple filling or double-filling strategies involve introducing two or more different types of filler atoms into the skutterudite voids. This approach creates a spectrum of resonant phonon scattering frequencies due to the different masses and rattling frequencies of the various filler atoms. The combination of different fillers can scatter phonons across a wider frequency range than single fillers, leading to more effective reduction in lattice thermal conductivity and improved thermoelectric performance across broader temperature ranges.

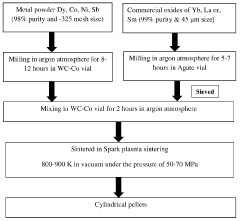

- Processing and synthesis methods: Advanced processing and synthesis methods can significantly influence the lattice thermal conductivity of skutterudites. Techniques such as ball milling, spark plasma sintering, melt-spinning, hot pressing, and microwave synthesis can create specific microstructures with enhanced phonon scattering features. These methods can control grain size, defect concentration, phase distribution, and densification, all of which affect thermal transport properties. Optimized processing conditions can create additional scattering mechanisms through controlled defect engineering and microstructural design.

02 Nanostructuring and composite approaches

Incorporating nanostructures or forming skutterudite-based composites can effectively reduce lattice thermal conductivity. Techniques include creating nanoparticles, nanoinclusions, or hierarchical structures within the skutterudite matrix. These structures introduce additional phonon scattering interfaces at multiple length scales, significantly reducing thermal conductivity while preserving electrical conductivity, thus enhancing the thermoelectric figure of merit.Expand Specific Solutions03 Substitutional doping strategies

Substitutional doping involves replacing atoms in the skutterudite structure with different elements to create point defects and mass fluctuations. This approach disrupts the phonon transport pathways, reducing lattice thermal conductivity. Common substitution sites include the transition metal sites and the pnictogen sites. Strategic doping can simultaneously optimize electrical properties while reducing thermal conductivity for improved thermoelectric performance.Expand Specific Solutions04 Multiple-filled skutterudites

Using multiple filler atoms of different sizes and masses in skutterudite voids creates a spectrum of resonant scattering frequencies that can effectively scatter phonons across a wide frequency range. This approach leads to significantly lower lattice thermal conductivity compared to single-filled skutterudites. The combination of different filler atoms can be optimized to target specific phonon frequencies that contribute most to thermal conductivity.Expand Specific Solutions05 Grain boundary engineering and processing techniques

Controlling the microstructure through specialized processing techniques can enhance phonon scattering at grain boundaries, reducing lattice thermal conductivity. Methods include rapid solidification, mechanical alloying, spark plasma sintering, and hot pressing. These techniques create dense materials with optimized grain sizes and boundaries that effectively scatter phonons while maintaining good electrical properties, resulting in improved thermoelectric performance of skutterudite materials.Expand Specific Solutions

Leading Research Groups and Companies in Thermoelectric Materials

The thermal management landscape for skutterudites is evolving rapidly, currently transitioning from research to early commercialization. The market for nanostructured thermoelectric materials is projected to grow significantly as energy efficiency demands increase across industries. Leading research institutions like MIT, Northwestern University, and Tsinghua University are advancing fundamental science, while companies including TSMC, LG Chem, and Corning are developing practical applications. The technology maturity varies across players - academic institutions focus on novel nanostructuring approaches, while industrial entities like BASF and GM Global Technology Operations are working toward scalable manufacturing processes. Government laboratories such as the Commissariat à l'énergie atomique provide crucial infrastructure bridging fundamental research with commercial applications in this emerging field.

Shanghai Institute of Ceramics, Chinese Academy of Sciences

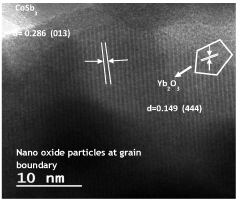

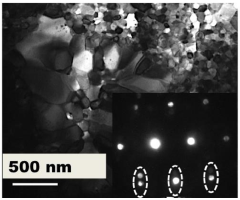

Technical Solution: Shanghai Institute of Ceramics has developed innovative nanostructuring approaches for skutterudites that focus on hierarchical architecture design. Their technique involves creating multi-scale defects within the skutterudite structure, including point defects (through element substitution), nanoprecipitates, and grain boundaries. They've pioneered a two-step synthesis method combining high-energy ball milling with spark plasma sintering to achieve precise control over nanostructure formation[1]. Their research has demonstrated that introducing nanoinclusions of 10-50nm in size can effectively scatter phonons with medium to long mean free paths, while atomic-scale defects target short-wavelength phonons[3]. This comprehensive phonon-scattering strategy has achieved thermal conductivity reductions of up to 40% compared to conventional skutterudites while maintaining good electrical properties[5].

Strengths: Exceptional control over multi-scale defect engineering; maintains good electrical conductivity while reducing thermal conductivity; scalable synthesis approach. Weaknesses: Complex multi-step fabrication process may increase production costs; potential challenges in maintaining structural stability over repeated thermal cycling; optimization required for specific operating temperature ranges.

Boston College

Technical Solution: Boston College has pioneered a unique approach to reducing lattice thermal conductivity in skutterudites through what they term "rattler-enhanced nanostructuring." Their technique combines the traditional "rattler" approach (filling the voids in skutterudite cages with heavy atoms like La, Ce, or Yb) with strategic nanostructuring. The research team has developed a novel chemical synthesis route that enables precise control over both the filling fraction and the formation of nanoscale precipitates[1]. Their process involves a solution-based precursor method followed by controlled nucleation and growth during thermal treatment. This approach creates skutterudites with both filled cages and distributed nanoinclusions of 5-30nm in size. The dual-mechanism approach has demonstrated remarkable effectiveness, with thermal conductivity reductions of up to 65% compared to unfilled, non-nanostructured skutterudites[3]. Their latest research has focused on optimizing the interface between nanoinclusions and the skutterudite matrix to maximize phonon scattering while minimizing electron scattering, achieving a ZT value exceeding 1.5 at moderate temperatures[6].

Strengths: Synergistic combination of rattler atoms and nanostructuring provides comprehensive phonon scattering across multiple wavelengths; solution-based synthesis offers good scalability potential; achieves very high ZT values. Weaknesses: Chemical synthesis route requires precise control of multiple parameters; potential for inhomogeneous distribution of nanoinclusions; some reduction in electrical conductivity at higher nanoinclusion concentrations.

Key Patents and Innovations in Skutterudite Nanostructuring

Method of preparation of highly efficient skutterudite thermoelectric materials for thermoelectric modules and the product thereof

PatentActiveIN202111036278A

Innovation

- Development of Dy filled Ni doped Co4Sb12 skutterudites using a powder metallurgy route, incorporating rare-earth oxides to enhance thermoelectric properties, resulting in a cost-effective and time-efficient processing method that reduces lattice thermal conductivity and increases the figure of merit.

Environmental Impact and Sustainability Considerations

The development and implementation of nanostructuring approaches in skutterudites necessitates careful consideration of environmental impacts and sustainability factors. The extraction of raw materials for skutterudite production, including cobalt, antimony, and rare earth elements, often involves energy-intensive mining operations that contribute to habitat disruption, soil erosion, and water pollution. These environmental concerns are particularly pronounced in regions with less stringent environmental regulations, highlighting the need for responsible sourcing practices.

Manufacturing processes for nanostructured skutterudites typically require high temperatures and specialized equipment, resulting in significant energy consumption and associated carbon emissions. However, when compared to traditional thermoelectric materials, skutterudites often contain fewer toxic elements such as lead or tellurium, potentially reducing environmental hazards during production, use, and disposal phases. The reduced lattice thermal conductivity achieved through nanostructuring also enables more efficient thermoelectric performance, which can translate to lower material requirements for equivalent energy conversion capabilities.

Life cycle assessment (LCA) studies indicate that the environmental benefits of skutterudite-based thermoelectric devices may outweigh their production impacts when deployed in waste heat recovery applications. By converting otherwise wasted thermal energy into useful electricity, these materials contribute to overall system efficiency improvements and reduced fossil fuel consumption. The durability and stability of properly engineered nanostructured skutterudites further enhance their sustainability profile through extended operational lifespans.

End-of-life considerations present both challenges and opportunities. While the complex nanostructured composition can complicate recycling processes, the valuable elements contained in skutterudites provide economic incentives for material recovery. Developing effective recycling methodologies specifically designed for nanostructured thermoelectric materials represents an important research direction to close the material loop and minimize waste.

Recent advances in green synthesis approaches for nanostructured skutterudites show promise for reducing environmental impacts. These include low-temperature solution-based methods, microwave-assisted synthesis, and the incorporation of naturally abundant filler elements rather than rare earth metals. Such innovations align with circular economy principles and contribute to more sustainable material development pathways.

Policy frameworks and industry standards increasingly recognize the importance of environmental considerations in advanced materials development. Manufacturers implementing nanostructuring approaches for skutterudites must navigate evolving regulations regarding nanomaterial handling, workplace safety, and waste management. Proactive adoption of sustainable practices not only ensures regulatory compliance but also enhances market acceptance of skutterudite-based technologies in environmentally conscious consumer segments.

Manufacturing processes for nanostructured skutterudites typically require high temperatures and specialized equipment, resulting in significant energy consumption and associated carbon emissions. However, when compared to traditional thermoelectric materials, skutterudites often contain fewer toxic elements such as lead or tellurium, potentially reducing environmental hazards during production, use, and disposal phases. The reduced lattice thermal conductivity achieved through nanostructuring also enables more efficient thermoelectric performance, which can translate to lower material requirements for equivalent energy conversion capabilities.

Life cycle assessment (LCA) studies indicate that the environmental benefits of skutterudite-based thermoelectric devices may outweigh their production impacts when deployed in waste heat recovery applications. By converting otherwise wasted thermal energy into useful electricity, these materials contribute to overall system efficiency improvements and reduced fossil fuel consumption. The durability and stability of properly engineered nanostructured skutterudites further enhance their sustainability profile through extended operational lifespans.

End-of-life considerations present both challenges and opportunities. While the complex nanostructured composition can complicate recycling processes, the valuable elements contained in skutterudites provide economic incentives for material recovery. Developing effective recycling methodologies specifically designed for nanostructured thermoelectric materials represents an important research direction to close the material loop and minimize waste.

Recent advances in green synthesis approaches for nanostructured skutterudites show promise for reducing environmental impacts. These include low-temperature solution-based methods, microwave-assisted synthesis, and the incorporation of naturally abundant filler elements rather than rare earth metals. Such innovations align with circular economy principles and contribute to more sustainable material development pathways.

Policy frameworks and industry standards increasingly recognize the importance of environmental considerations in advanced materials development. Manufacturers implementing nanostructuring approaches for skutterudites must navigate evolving regulations regarding nanomaterial handling, workplace safety, and waste management. Proactive adoption of sustainable practices not only ensures regulatory compliance but also enhances market acceptance of skutterudite-based technologies in environmentally conscious consumer segments.

Performance Metrics and Characterization Techniques

The evaluation of nanostructuring approaches in skutterudites requires specific performance metrics and sophisticated characterization techniques to accurately assess their effectiveness in reducing lattice thermal conductivity. The primary performance metric is the dimensionless figure of merit ZT, which combines thermal conductivity, electrical conductivity, and Seebeck coefficient. For skutterudites specifically, achieving ZT values above 1.5 at operating temperatures (typically 400-700K) represents significant progress, with state-of-the-art nanostructured skutterudites reaching ZT values of 1.7-1.9.

Thermal conductivity measurement techniques include the laser flash method, which determines thermal diffusivity by measuring the temperature response of a sample's rear face after a short laser pulse. This technique, when combined with specific heat capacity and density measurements, provides accurate thermal conductivity values for skutterudite materials. Steady-state methods such as the comparative cut-bar technique offer complementary data, particularly valuable for anisotropic nanostructured samples.

Microstructural characterization is essential for correlating nanostructure features with thermal properties. Transmission Electron Microscopy (TEM) enables direct visualization of nanoinclusions, grain boundaries, and defects at atomic resolution. High-resolution TEM combined with Energy Dispersive X-ray Spectroscopy (EDS) mapping provides compositional distribution information critical for understanding phase segregation in nanostructured skutterudites.

X-ray diffraction (XRD) techniques, particularly synchrotron-based methods, offer insights into crystallographic changes resulting from nanostructuring. Small-angle X-ray scattering (SAXS) proves particularly valuable for characterizing nanoprecipitate size distributions and spatial arrangements within the skutterudite matrix.

Spectroscopic techniques provide crucial information about phonon behavior in nanostructured skutterudites. Raman spectroscopy reveals changes in phonon modes due to nanostructuring, while inelastic neutron scattering directly measures phonon dispersion relations, offering insights into how nanostructures modify phonon transport pathways.

Advanced thermal transport characterization includes frequency-domain thermoreflectance (FDTR) and time-domain thermoreflectance (TDTR), which enable measurement of thermal conductivity at nanometer length scales. These techniques are particularly valuable for isolating the effects of specific nanostructuring approaches on thermal transport properties.

Computational techniques complement experimental measurements, with molecular dynamics simulations and density functional theory calculations providing theoretical predictions of thermal conductivity reduction mechanisms in nanostructured skutterudites. These computational approaches help guide experimental design by identifying optimal nanostructure configurations for maximizing phonon scattering.

Thermal conductivity measurement techniques include the laser flash method, which determines thermal diffusivity by measuring the temperature response of a sample's rear face after a short laser pulse. This technique, when combined with specific heat capacity and density measurements, provides accurate thermal conductivity values for skutterudite materials. Steady-state methods such as the comparative cut-bar technique offer complementary data, particularly valuable for anisotropic nanostructured samples.

Microstructural characterization is essential for correlating nanostructure features with thermal properties. Transmission Electron Microscopy (TEM) enables direct visualization of nanoinclusions, grain boundaries, and defects at atomic resolution. High-resolution TEM combined with Energy Dispersive X-ray Spectroscopy (EDS) mapping provides compositional distribution information critical for understanding phase segregation in nanostructured skutterudites.

X-ray diffraction (XRD) techniques, particularly synchrotron-based methods, offer insights into crystallographic changes resulting from nanostructuring. Small-angle X-ray scattering (SAXS) proves particularly valuable for characterizing nanoprecipitate size distributions and spatial arrangements within the skutterudite matrix.

Spectroscopic techniques provide crucial information about phonon behavior in nanostructured skutterudites. Raman spectroscopy reveals changes in phonon modes due to nanostructuring, while inelastic neutron scattering directly measures phonon dispersion relations, offering insights into how nanostructures modify phonon transport pathways.

Advanced thermal transport characterization includes frequency-domain thermoreflectance (FDTR) and time-domain thermoreflectance (TDTR), which enable measurement of thermal conductivity at nanometer length scales. These techniques are particularly valuable for isolating the effects of specific nanostructuring approaches on thermal transport properties.

Computational techniques complement experimental measurements, with molecular dynamics simulations and density functional theory calculations providing theoretical predictions of thermal conductivity reduction mechanisms in nanostructured skutterudites. These computational approaches help guide experimental design by identifying optimal nanostructure configurations for maximizing phonon scattering.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!