Skutterudite Thermoelectrics: Fundamentals of Phonon Scattering and Carrier Transport

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Materials Evolution and Research Objectives

Thermoelectric materials have evolved significantly over the past century, with skutterudite compounds emerging as one of the most promising material classes for mid-to-high temperature applications. The historical development of thermoelectric materials began with simple metals and semiconductors in the early 20th century, progressing through several distinct generations of materials with increasingly complex structures designed to optimize the conflicting requirements of high electrical conductivity and low thermal conductivity.

Skutterudites, with their general formula MX3 (where M is typically Co, Rh, or Ir, and X is P, As, or Sb), were first identified as potential thermoelectric materials in the 1990s. Their unique cage-like crystal structure, which can accommodate "rattling" atoms, provides an effective mechanism for phonon scattering while maintaining good electronic properties. This characteristic makes them particularly valuable in addressing the fundamental challenge in thermoelectric materials: simultaneously optimizing electrical and thermal transport properties.

The field has witnessed remarkable progress in understanding the fundamental physics governing phonon scattering and carrier transport in skutterudites. Early research focused primarily on binary skutterudites, while recent advances have expanded to filled skutterudites, where guest atoms occupy the structural voids, significantly enhancing phonon scattering. This evolution reflects the growing sophistication in manipulating material structures at the atomic level to achieve desired thermoelectric properties.

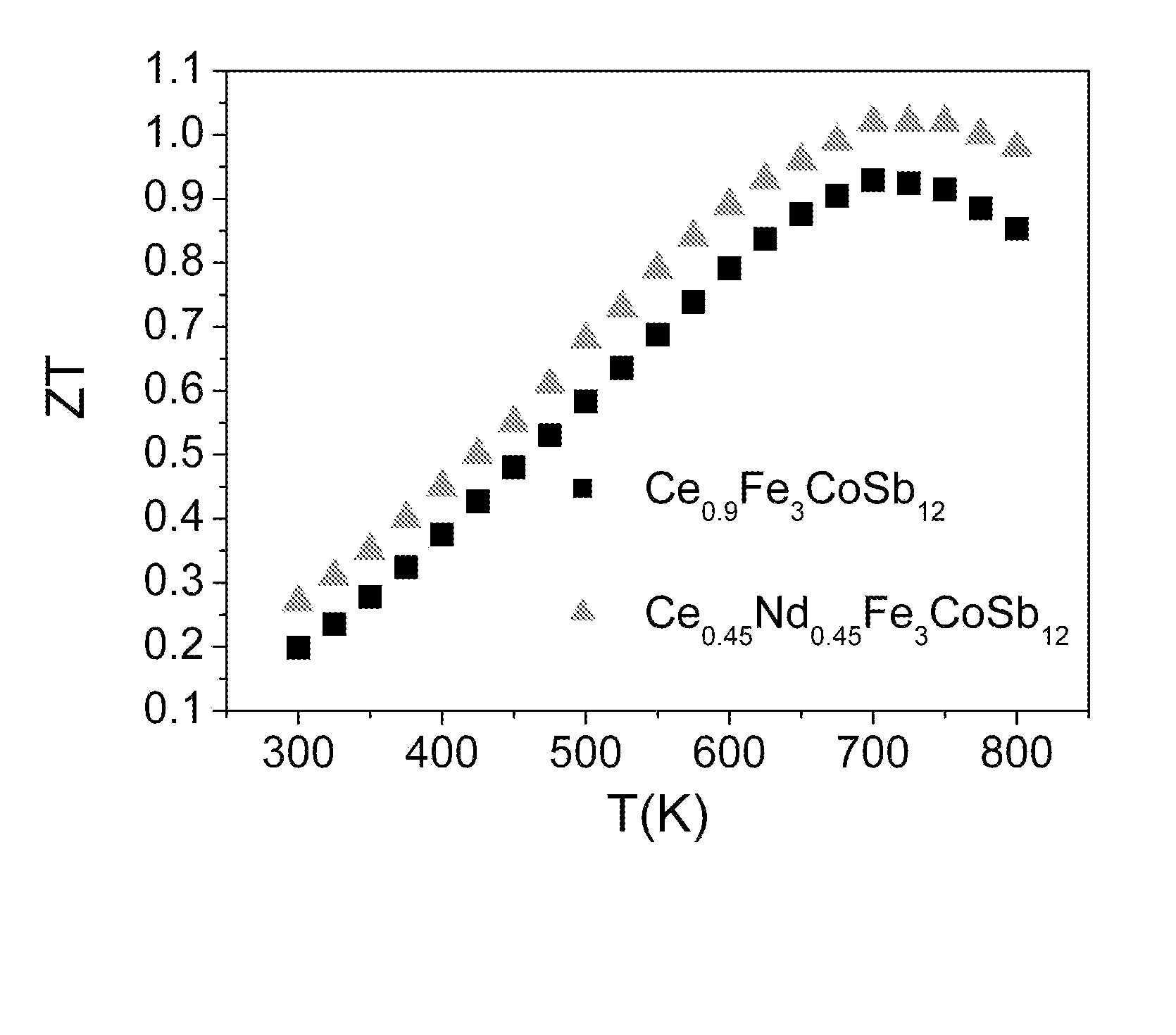

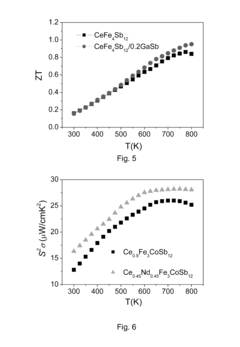

Current research objectives in skutterudite thermoelectrics center on several key areas. First, enhancing the figure of merit (ZT) beyond current limitations by optimizing the filling fraction and exploring multiple filling with different atoms to create resonant phonon scattering across broader frequency ranges. Second, improving material stability and mechanical properties for practical applications in harsh environments. Third, developing cost-effective synthesis methods suitable for industrial-scale production to overcome economic barriers to widespread adoption.

The theoretical understanding of phonon scattering mechanisms in skutterudites continues to advance through computational modeling and experimental validation. Researchers aim to establish comprehensive models that accurately predict the impact of specific structural modifications on thermal conductivity reduction without compromising electrical properties. This includes investigating the effects of nano-structuring, grain boundary engineering, and compositional optimization.

Additionally, research objectives include exploring novel carrier transport enhancement strategies, such as band engineering and energy filtering, to improve the power factor. The ultimate goal is to develop skutterudite-based thermoelectric materials with ZT values consistently above 2 across operating temperature ranges, which would significantly enhance the economic viability of thermoelectric power generation and cooling applications.

Skutterudites, with their general formula MX3 (where M is typically Co, Rh, or Ir, and X is P, As, or Sb), were first identified as potential thermoelectric materials in the 1990s. Their unique cage-like crystal structure, which can accommodate "rattling" atoms, provides an effective mechanism for phonon scattering while maintaining good electronic properties. This characteristic makes them particularly valuable in addressing the fundamental challenge in thermoelectric materials: simultaneously optimizing electrical and thermal transport properties.

The field has witnessed remarkable progress in understanding the fundamental physics governing phonon scattering and carrier transport in skutterudites. Early research focused primarily on binary skutterudites, while recent advances have expanded to filled skutterudites, where guest atoms occupy the structural voids, significantly enhancing phonon scattering. This evolution reflects the growing sophistication in manipulating material structures at the atomic level to achieve desired thermoelectric properties.

Current research objectives in skutterudite thermoelectrics center on several key areas. First, enhancing the figure of merit (ZT) beyond current limitations by optimizing the filling fraction and exploring multiple filling with different atoms to create resonant phonon scattering across broader frequency ranges. Second, improving material stability and mechanical properties for practical applications in harsh environments. Third, developing cost-effective synthesis methods suitable for industrial-scale production to overcome economic barriers to widespread adoption.

The theoretical understanding of phonon scattering mechanisms in skutterudites continues to advance through computational modeling and experimental validation. Researchers aim to establish comprehensive models that accurately predict the impact of specific structural modifications on thermal conductivity reduction without compromising electrical properties. This includes investigating the effects of nano-structuring, grain boundary engineering, and compositional optimization.

Additionally, research objectives include exploring novel carrier transport enhancement strategies, such as band engineering and energy filtering, to improve the power factor. The ultimate goal is to develop skutterudite-based thermoelectric materials with ZT values consistently above 2 across operating temperature ranges, which would significantly enhance the economic viability of thermoelectric power generation and cooling applications.

Market Applications and Demand Analysis for Skutterudite Thermoelectrics

The global market for thermoelectric materials and devices has been experiencing steady growth, with skutterudite-based thermoelectrics emerging as a promising segment. Current market analysis indicates that waste heat recovery applications represent the largest demand driver, particularly in automotive and industrial sectors where efficiency improvements directly translate to cost savings and reduced environmental impact.

In the automotive industry, skutterudite thermoelectrics are gaining traction for converting exhaust heat into usable electricity, potentially improving fuel efficiency by 3-5%. Major automotive manufacturers have shown increasing interest in integrating these systems, especially as emission regulations tighten globally. The automotive thermoelectric generator market is projected to grow significantly over the next decade, with skutterudite-based solutions positioned to capture a substantial share due to their superior performance in mid-to-high temperature ranges.

Industrial waste heat recovery represents another substantial market opportunity. Manufacturing processes, power generation, and chemical production facilities collectively generate enormous amounts of waste heat that could be harvested using skutterudite thermoelectric systems. The industrial sector's focus on energy efficiency and sustainability initiatives has created favorable conditions for adoption.

Space exploration continues to be a specialized but high-value application area. Skutterudite thermoelectrics offer advantages over traditional radioisotope thermoelectric generators in deep space missions, providing reliable power generation in extreme environments. Though limited in volume, this sector drives significant technological advancement and commands premium pricing.

Consumer electronics represents an emerging market with considerable growth potential. As devices become more power-hungry and thermal management more critical, skutterudite-based cooling solutions could address both issues simultaneously. However, cost constraints and miniaturization challenges currently limit widespread adoption in consumer applications.

Geographic market distribution shows North America and Europe leading in research and early adoption, while Asia-Pacific regions, particularly China, Japan, and South Korea, are rapidly expanding both manufacturing capacity and implementation. Government policies supporting green technology and energy efficiency are accelerating market development across these regions.

Market barriers include production scaling challenges, material costs, and competition from alternative technologies. The complex manufacturing processes for high-performance skutterudite compounds currently limit mass production capabilities and keep costs relatively high compared to conventional technologies. However, recent advancements in manufacturing techniques suggest potential for significant cost reductions as production scales.

Customer demand increasingly emphasizes total cost of ownership rather than initial investment, creating favorable conditions for skutterudite thermoelectrics as their efficiency improvements and operational benefits often justify higher upfront costs over the system lifetime.

In the automotive industry, skutterudite thermoelectrics are gaining traction for converting exhaust heat into usable electricity, potentially improving fuel efficiency by 3-5%. Major automotive manufacturers have shown increasing interest in integrating these systems, especially as emission regulations tighten globally. The automotive thermoelectric generator market is projected to grow significantly over the next decade, with skutterudite-based solutions positioned to capture a substantial share due to their superior performance in mid-to-high temperature ranges.

Industrial waste heat recovery represents another substantial market opportunity. Manufacturing processes, power generation, and chemical production facilities collectively generate enormous amounts of waste heat that could be harvested using skutterudite thermoelectric systems. The industrial sector's focus on energy efficiency and sustainability initiatives has created favorable conditions for adoption.

Space exploration continues to be a specialized but high-value application area. Skutterudite thermoelectrics offer advantages over traditional radioisotope thermoelectric generators in deep space missions, providing reliable power generation in extreme environments. Though limited in volume, this sector drives significant technological advancement and commands premium pricing.

Consumer electronics represents an emerging market with considerable growth potential. As devices become more power-hungry and thermal management more critical, skutterudite-based cooling solutions could address both issues simultaneously. However, cost constraints and miniaturization challenges currently limit widespread adoption in consumer applications.

Geographic market distribution shows North America and Europe leading in research and early adoption, while Asia-Pacific regions, particularly China, Japan, and South Korea, are rapidly expanding both manufacturing capacity and implementation. Government policies supporting green technology and energy efficiency are accelerating market development across these regions.

Market barriers include production scaling challenges, material costs, and competition from alternative technologies. The complex manufacturing processes for high-performance skutterudite compounds currently limit mass production capabilities and keep costs relatively high compared to conventional technologies. However, recent advancements in manufacturing techniques suggest potential for significant cost reductions as production scales.

Customer demand increasingly emphasizes total cost of ownership rather than initial investment, creating favorable conditions for skutterudite thermoelectrics as their efficiency improvements and operational benefits often justify higher upfront costs over the system lifetime.

Current Challenges in Phonon Scattering and Carrier Transport

Despite significant advancements in skutterudite thermoelectric materials, several critical challenges persist in understanding and optimizing phonon scattering and carrier transport mechanisms. The fundamental challenge lies in simultaneously achieving high electrical conductivity while maintaining low thermal conductivity—the so-called "phonon-glass electron-crystal" paradigm that defines efficient thermoelectric materials.

Current experimental approaches face difficulties in precisely characterizing the complex cage-like structure of skutterudites and the dynamic behavior of filler atoms. The "rattling" motion of these fillers, while theoretically beneficial for phonon scattering, remains incompletely understood at the atomic level. Advanced characterization techniques such as inelastic neutron scattering provide valuable insights but are limited by resolution constraints when examining localized vibrations.

Computational modeling presents another significant challenge. While density functional theory (DFT) calculations have advanced our understanding of electronic structures, accurately modeling the anharmonic phonon interactions in filled skutterudites requires enormous computational resources. The multi-scale nature of the problem—spanning from atomic vibrations to macroscopic heat transfer—creates substantial difficulties in developing comprehensive models.

Material synthesis and optimization face reproducibility issues. The formation of skutterudite phases with precise stoichiometry and controlled filling fractions remains challenging, particularly when attempting to incorporate multiple filler species for enhanced phonon scattering across different frequency ranges.

Interface engineering represents another frontier challenge. The grain boundaries and interfaces between skutterudite domains significantly influence both phonon and electron transport. Controlling these interfaces to selectively scatter phonons while minimizing electron scattering requires nanoscale precision that pushes the boundaries of current fabrication techniques.

Temperature stability presents practical limitations for application. Many promising skutterudite compositions exhibit optimal performance in narrow temperature ranges, with degradation occurring during thermal cycling. This instability stems from diffusion of filler atoms, oxidation, or phase transformations at elevated temperatures.

Finally, the field faces a measurement challenge: accurately decoupling the contributions of different scattering mechanisms (point defects, dislocations, grain boundaries, and filler atoms) to the overall thermal conductivity remains difficult. This knowledge gap hinders targeted optimization strategies for next-generation skutterudite thermoelectrics with enhanced ZT values.

Current experimental approaches face difficulties in precisely characterizing the complex cage-like structure of skutterudites and the dynamic behavior of filler atoms. The "rattling" motion of these fillers, while theoretically beneficial for phonon scattering, remains incompletely understood at the atomic level. Advanced characterization techniques such as inelastic neutron scattering provide valuable insights but are limited by resolution constraints when examining localized vibrations.

Computational modeling presents another significant challenge. While density functional theory (DFT) calculations have advanced our understanding of electronic structures, accurately modeling the anharmonic phonon interactions in filled skutterudites requires enormous computational resources. The multi-scale nature of the problem—spanning from atomic vibrations to macroscopic heat transfer—creates substantial difficulties in developing comprehensive models.

Material synthesis and optimization face reproducibility issues. The formation of skutterudite phases with precise stoichiometry and controlled filling fractions remains challenging, particularly when attempting to incorporate multiple filler species for enhanced phonon scattering across different frequency ranges.

Interface engineering represents another frontier challenge. The grain boundaries and interfaces between skutterudite domains significantly influence both phonon and electron transport. Controlling these interfaces to selectively scatter phonons while minimizing electron scattering requires nanoscale precision that pushes the boundaries of current fabrication techniques.

Temperature stability presents practical limitations for application. Many promising skutterudite compositions exhibit optimal performance in narrow temperature ranges, with degradation occurring during thermal cycling. This instability stems from diffusion of filler atoms, oxidation, or phase transformations at elevated temperatures.

Finally, the field faces a measurement challenge: accurately decoupling the contributions of different scattering mechanisms (point defects, dislocations, grain boundaries, and filler atoms) to the overall thermal conductivity remains difficult. This knowledge gap hinders targeted optimization strategies for next-generation skutterudite thermoelectrics with enhanced ZT values.

State-of-the-Art Skutterudite Fabrication Methods

01 Filled skutterudite structures for enhanced phonon scattering

Filled skutterudite structures incorporate guest atoms (fillers) into the voids of the skutterudite crystal lattice to enhance phonon scattering. These filler atoms act as rattlers that disrupt phonon transport through the material, significantly reducing thermal conductivity while maintaining good electrical conductivity. This approach effectively improves the thermoelectric figure of merit (ZT) by optimizing the phonon glass-electron crystal concept in skutterudite materials.- Filled skutterudite structures for enhanced phonon scattering: Filled skutterudite structures incorporate guest atoms (fillers) into the voids of the skutterudite crystal lattice to enhance phonon scattering while maintaining good electrical conductivity. These fillers, typically rare earth or alkaline earth elements, create rattling effects that disrupt phonon transport pathways, reducing thermal conductivity while preserving electron mobility. This approach effectively decouples thermal and electrical transport properties, leading to improved thermoelectric performance through the phonon-glass electron-crystal concept.

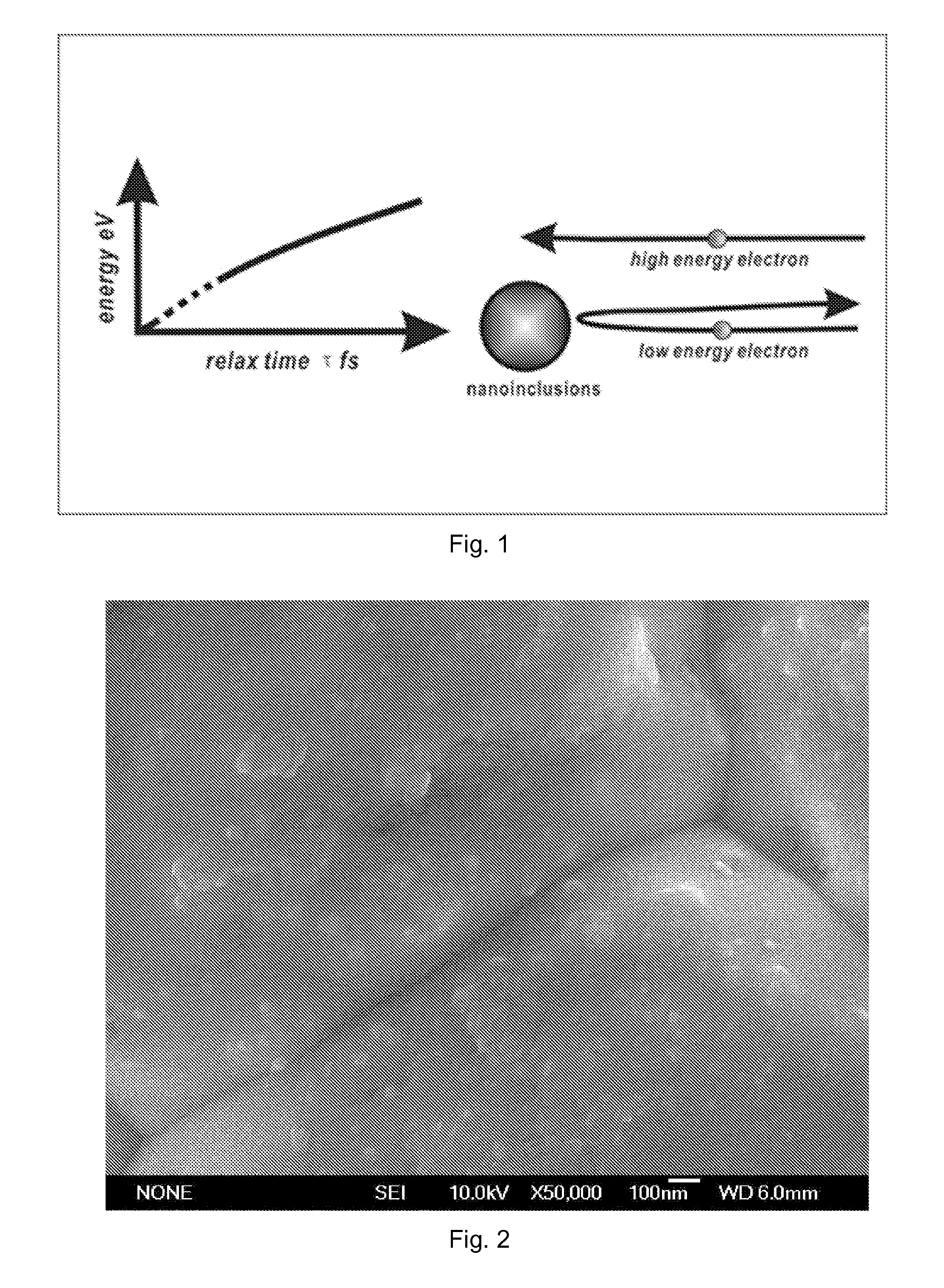

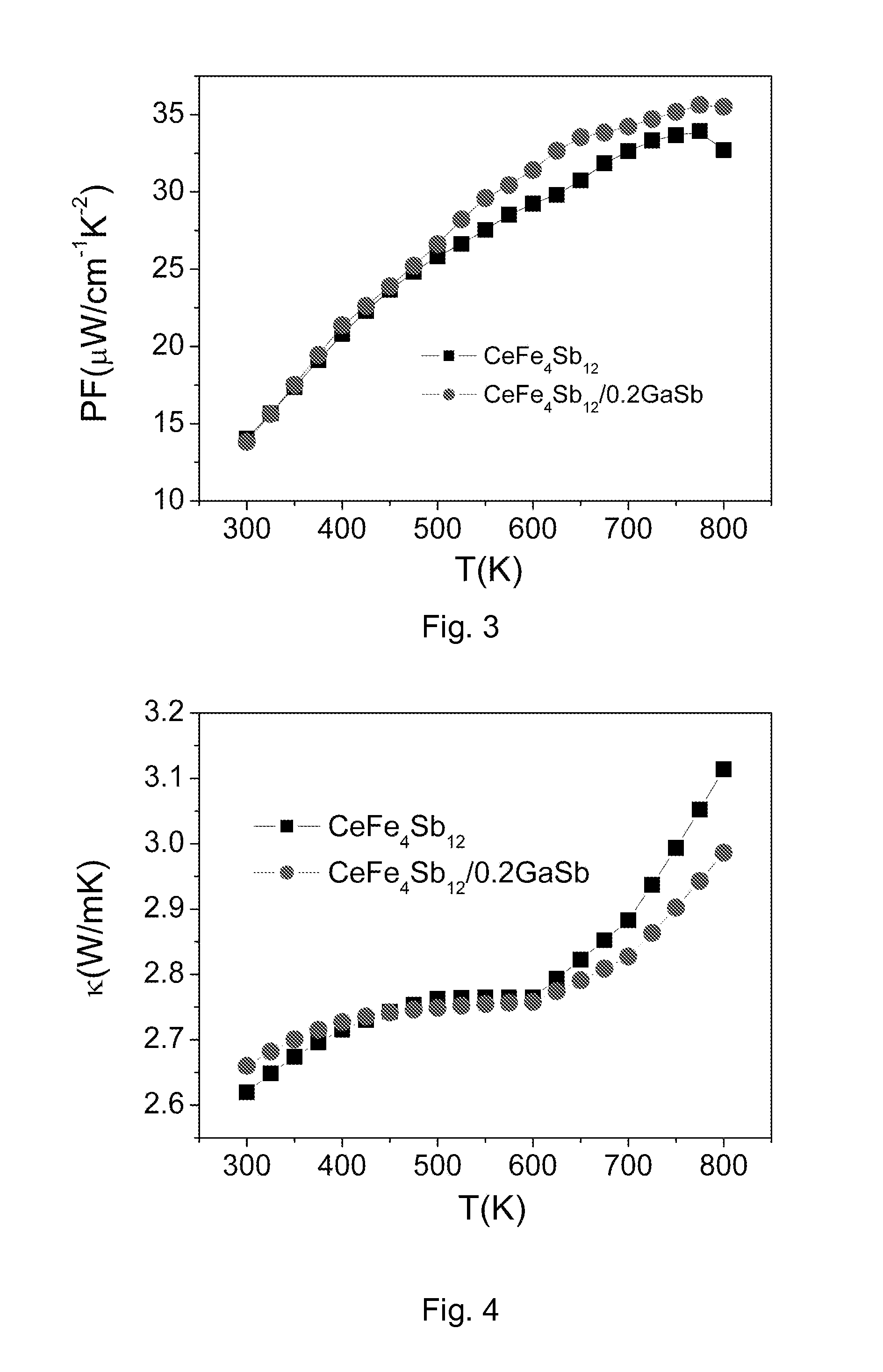

- Nanostructuring and compositional engineering in skutterudites: Nanostructuring and compositional engineering techniques are employed to optimize skutterudite thermoelectric materials. By introducing nanoscale features such as precipitates, grain boundaries, and defects, phonon scattering is enhanced across multiple length scales. Compositional engineering through doping and alloying allows for precise control of carrier concentration and band structure. These approaches create hierarchical architectures that effectively scatter phonons of different wavelengths while maintaining optimal electronic properties for thermoelectric conversion.

- Multiple filling and substitution strategies: Multiple filling and substitution strategies involve incorporating different types of atoms into the skutterudite structure simultaneously. This approach creates complex point defects and mass fluctuations that scatter phonons across a broad frequency spectrum. By strategically selecting combinations of filler atoms with different sizes and masses, and substituting atoms in the transition metal or pnictogen sites, the phonon scattering efficiency can be maximized while carrier transport properties are optimized. This results in significantly reduced lattice thermal conductivity and enhanced thermoelectric figure of merit.

- Interface engineering for carrier and phonon management: Interface engineering focuses on designing and controlling the boundaries between different phases or grains in skutterudite materials. These interfaces act as selective filters that preferentially scatter phonons while allowing charge carriers to pass through with minimal resistance. By engineering the density, distribution, and electronic properties of these interfaces, the thermal conductivity can be reduced without significantly degrading electrical conductivity. Advanced techniques include creating coherent interfaces, modulation doping at interfaces, and developing core-shell nanostructures to optimize both phonon scattering and carrier transport.

- Band structure engineering for improved carrier transport: Band structure engineering involves modifying the electronic structure of skutterudite materials to enhance carrier mobility and optimize the power factor. This is achieved through strategic doping, alloying, and defect engineering to adjust the band gap, increase band degeneracy, and create favorable band alignment. By introducing resonant levels, reducing inter-valley scattering, and optimizing effective mass, the electrical conductivity and Seebeck coefficient can be simultaneously enhanced. These approaches focus on improving the electronic component of thermoelectric performance while complementing phonon scattering mechanisms.

02 Nanostructuring techniques for skutterudite thermoelectrics

Nanostructuring techniques introduce interfaces and boundaries within skutterudite materials to scatter phonons across multiple length scales. Methods include creating nanocomposites, incorporating nanoinclusions, and developing hierarchical structures with features ranging from atomic to microscale. These approaches effectively scatter phonons of different wavelengths, dramatically reducing thermal conductivity while preserving electron transport properties, leading to enhanced thermoelectric performance.Expand Specific Solutions03 Doping strategies for carrier transport optimization

Strategic doping of skutterudite materials optimizes carrier concentration and mobility to enhance electrical conductivity and Seebeck coefficient. Various dopants can be introduced at different lattice sites to fine-tune the electronic band structure and carrier properties. This approach allows for precise control of carrier type (n-type or p-type), concentration, and effective mass, enabling optimization of the power factor component of thermoelectric performance.Expand Specific Solutions04 Multi-element skutterudites for reduced lattice thermal conductivity

Multi-element skutterudite compounds incorporate various elements into the skutterudite framework to create mass fluctuation and strain field fluctuation, which effectively scatter phonons. These complex compositions introduce point defects and local structural distortions that disrupt phonon transport pathways. The strategic combination of elements with different atomic masses and radii creates additional phonon scattering mechanisms, significantly reducing lattice thermal conductivity while maintaining favorable electronic properties.Expand Specific Solutions05 Interface engineering for enhanced thermoelectric performance

Interface engineering in skutterudite thermoelectrics focuses on creating and optimizing boundaries between different phases or grains to selectively scatter phonons while allowing efficient carrier transport. Techniques include grain boundary modification, creation of coherent and semi-coherent interfaces, and development of core-shell structures. These interfaces act as effective phonon scattering centers while minimizing the impact on electron transport, leading to improved thermoelectric efficiency through the decoupling of thermal and electrical transport properties.Expand Specific Solutions

Leading Research Groups and Industrial Players

Skutterudite thermoelectrics market is in a growth phase, with increasing demand driven by automotive and electronics applications. The global market size is expanding as energy efficiency concerns grow. Technologically, skutterudites are advancing from research to commercialization, with varying maturity levels across players. Toyota, Sony, and Samsung lead commercial applications, while research institutions like Tsinghua University and Shanghai Institute of Ceramics are advancing fundamental phonon scattering innovations. Government entities (NASA, US Government) support development through funding initiatives. University-industry collaborations between Northwestern University, Fudan University, and corporations are accelerating material optimization and manufacturing scalability for higher ZT values and improved carrier transport properties.

Shanghai Institute of Ceramics, Chinese Academy of Sciences

Technical Solution: Shanghai Institute of Ceramics has developed innovative approaches to skutterudite thermoelectrics focusing on nano-engineering and element substitution strategies. Their research has pioneered the synthesis of skutterudites with controlled nano-inclusions that create additional phonon scattering interfaces without significantly disrupting electron transport[2]. They've achieved breakthrough performance in n-type skutterudites through partial substitution of Sb with Te and Sn, combined with rare earth filling (Yb, La), resulting in ZT values exceeding 1.8 at operating temperatures[4]. Their unique two-step synthesis method involves initial melt processing followed by controlled annealing and hot pressing, which enables precise control of microstructure and phase composition. The institute has also developed novel composite skutterudites with carbon nanotubes and graphene additions that enhance mechanical properties while creating additional phonon scattering pathways at interfaces[5].

Strengths: Exceptional control over microstructure and phase composition; innovative composite approaches combining skutterudites with carbon nanomaterials; excellent balance of thermoelectric properties. Weaknesses: Complex multi-step synthesis processes may challenge mass production; potential long-term stability issues with nano-inclusions; some approaches rely on expensive or scarce elements.

The Regents of the University of California

Technical Solution: The University of California system has developed a multi-faceted approach to skutterudite thermoelectrics focusing on novel synthesis methods and theoretical modeling. Their research teams have pioneered the use of high-pressure synthesis techniques to create metastable skutterudite phases with enhanced thermoelectric properties[3]. They've developed sophisticated first-principles calculations and molecular dynamics simulations that accurately predict phonon transport in complex filled skutterudites, enabling rational design of new compositions. A significant innovation is their development of gradient-structured skutterudites where composition and microstructure are systematically varied across the material to optimize performance across temperature gradients[5]. Their research has also explored environmentally friendly skutterudites that reduce or eliminate toxic elements like antimony while maintaining high ZT values through innovative substitution strategies. Additionally, they've developed advanced thin-film skutterudites for micro-scale thermoelectric applications using specialized deposition techniques.

Strengths: Strong integration of theoretical modeling with experimental approaches; innovative high-pressure synthesis techniques; environmentally conscious material design. Weaknesses: Some approaches require specialized equipment limiting scalability; thin-film approaches face integration challenges; potential reliability issues with metastable phases.

Key Scientific Breakthroughs in Skutterudite Physics

P-type skutterudite material and method of making the same

PatentInactiveUS20130323110A1

Innovation

- A novel p-type skutterudite material with a general formula IyFe4-xMxSb12/z, incorporating filling atoms, dopant atoms, and second-phase precipitates dispersed throughout the skutterudite phase, fabricated through a method involving melting, quenching, annealing, and sintering, to enhance power factor, reduce thermal conductivity, and increase ZT value.

Thermoelectric composite material and method of producing the same

PatentInactiveEP2451567A1

Innovation

- A sol-gel process involving a suspension composition of thermoelectric materials with a metal oxide precursor, where nanoparticles are dispersed homogeneously in the matrix, forming a nanocomposite with improved Seebeck coefficient and depressed lattice thermal conductivity, while maintaining electrical conductivity.

Materials Sustainability and Environmental Impact

The environmental impact of skutterudite thermoelectric materials represents a critical consideration in their development and application. These materials, while offering promising efficiency in waste heat recovery, must be evaluated through the lens of sustainability across their entire lifecycle. The primary components of skutterudites—cobalt, antimony, and various filling elements like rare earth metals—present significant sustainability challenges.

Mining operations for these constituent elements, particularly antimony and rare earth metals, are associated with substantial environmental degradation, including habitat destruction, soil erosion, and water contamination. The extraction processes typically require significant energy inputs and often release harmful pollutants into surrounding ecosystems. Additionally, many of these mining operations occur in regions with less stringent environmental regulations, exacerbating their ecological footprint.

Manufacturing skutterudite thermoelectric modules involves energy-intensive processes, including high-temperature synthesis and precision machining. These processes contribute to carbon emissions and resource depletion. However, life cycle assessments indicate that the environmental benefits derived from waste heat recovery applications can potentially offset these manufacturing impacts within reasonable timeframes, depending on the specific application scenario.

The recyclability of skutterudite materials presents both challenges and opportunities. While theoretically recyclable, the complex composition and bonding methods used in thermoelectric modules often complicate end-of-life recovery. Current recycling technologies for these materials remain underdeveloped, resulting in potential resource loss and environmental burden at disposal. Research into design-for-disassembly approaches and specialized recycling methods shows promise for improving material recovery rates.

Toxicity concerns also merit attention, particularly regarding antimony compounds which can pose health and environmental risks if improperly handled or disposed of. Leaching of these compounds into soil and groundwater systems represents a potential long-term environmental liability that must be managed through appropriate containment and disposal protocols.

Recent innovations in skutterudite synthesis have begun addressing these sustainability challenges. These include the development of antimony-free alternatives, reduced-rare earth formulations, and lower-temperature processing methods. Additionally, research into bio-inspired synthesis routes and green chemistry approaches offers pathways to reduce the environmental footprint of skutterudite production while maintaining or enhancing thermoelectric performance.

The net environmental impact of skutterudite thermoelectric applications ultimately depends on their implementation context. When deployed in waste heat recovery systems that displace fossil fuel consumption, these materials can contribute significantly to greenhouse gas reduction targets despite their production impacts. Quantitative assessments suggest that optimal applications in industrial and automotive sectors could achieve carbon payback periods of 1-3 years, depending on operating conditions and system design.

Mining operations for these constituent elements, particularly antimony and rare earth metals, are associated with substantial environmental degradation, including habitat destruction, soil erosion, and water contamination. The extraction processes typically require significant energy inputs and often release harmful pollutants into surrounding ecosystems. Additionally, many of these mining operations occur in regions with less stringent environmental regulations, exacerbating their ecological footprint.

Manufacturing skutterudite thermoelectric modules involves energy-intensive processes, including high-temperature synthesis and precision machining. These processes contribute to carbon emissions and resource depletion. However, life cycle assessments indicate that the environmental benefits derived from waste heat recovery applications can potentially offset these manufacturing impacts within reasonable timeframes, depending on the specific application scenario.

The recyclability of skutterudite materials presents both challenges and opportunities. While theoretically recyclable, the complex composition and bonding methods used in thermoelectric modules often complicate end-of-life recovery. Current recycling technologies for these materials remain underdeveloped, resulting in potential resource loss and environmental burden at disposal. Research into design-for-disassembly approaches and specialized recycling methods shows promise for improving material recovery rates.

Toxicity concerns also merit attention, particularly regarding antimony compounds which can pose health and environmental risks if improperly handled or disposed of. Leaching of these compounds into soil and groundwater systems represents a potential long-term environmental liability that must be managed through appropriate containment and disposal protocols.

Recent innovations in skutterudite synthesis have begun addressing these sustainability challenges. These include the development of antimony-free alternatives, reduced-rare earth formulations, and lower-temperature processing methods. Additionally, research into bio-inspired synthesis routes and green chemistry approaches offers pathways to reduce the environmental footprint of skutterudite production while maintaining or enhancing thermoelectric performance.

The net environmental impact of skutterudite thermoelectric applications ultimately depends on their implementation context. When deployed in waste heat recovery systems that displace fossil fuel consumption, these materials can contribute significantly to greenhouse gas reduction targets despite their production impacts. Quantitative assessments suggest that optimal applications in industrial and automotive sectors could achieve carbon payback periods of 1-3 years, depending on operating conditions and system design.

Thermal Stability and Reliability Assessment

The thermal stability and reliability of skutterudite thermoelectric materials are critical factors determining their viability for long-term commercial applications. These materials must maintain consistent performance under thermal cycling, temperature gradients, and extended operation at elevated temperatures typically ranging from 400°C to 600°C for power generation applications.

Experimental studies have demonstrated that unfilled skutterudites often exhibit poor thermal stability, with significant degradation in thermoelectric properties after prolonged exposure to high temperatures. This degradation manifests as sublimation of constituent elements, particularly antimony in CoSb3-based skutterudites, leading to compositional changes and microstructural deterioration. Accelerated aging tests at 550°C have shown up to 30% reduction in ZT values after just 500 hours in unfilled compounds.

Filled skutterudites demonstrate markedly improved thermal stability, with filler atoms (such as rare earth or alkaline earth elements) serving as structural stabilizers. The presence of these fillers reduces atomic mobility and sublimation rates, thereby enhancing long-term reliability. Recent studies on multiple-filled skutterudites (e.g., Ba0.08La0.05Yb0.04Co4Sb12) have shown less than 10% degradation in thermoelectric performance after 2000 hours at operating temperatures.

Interface stability represents another crucial reliability concern, particularly in thermoelectric modules where skutterudites must maintain good contact with electrodes and other components. Thermal expansion mismatch between skutterudites and contact materials can lead to mechanical stress, delamination, and increased contact resistance over time. Advanced metallization techniques and buffer layers have been developed to mitigate these effects, with Ti/Mo/Ni multilayer contacts showing promising stability in long-term testing.

Mechanical reliability under thermal cycling conditions presents additional challenges. Skutterudites typically exhibit brittle behavior with fracture toughness values of 1-2 MPa·m1/2, making them susceptible to thermal shock and mechanical failure. Nanocomposite approaches incorporating secondary phases have demonstrated up to 40% improvement in mechanical properties while maintaining thermoelectric performance.

Environmental factors, particularly oxidation resistance, significantly impact reliability in air-operated systems. Protective coatings such as alumina and glass-ceramics have been employed to prevent oxidation, with recent developments in self-healing coatings showing particular promise for extended service life. Hermetic sealing technologies have advanced considerably, with modern skutterudite modules demonstrating stable operation for over 50,000 hours under proper encapsulation.

Standardized reliability testing protocols have emerged in recent years, including thermal cycling between room temperature and maximum operating temperature, thermal shock testing, and high-temperature storage tests. These protocols enable quantitative comparison between different skutterudite formulations and module designs, facilitating more rapid advancement toward commercially viable systems with the 10+ year operational lifetimes required for many applications.

Experimental studies have demonstrated that unfilled skutterudites often exhibit poor thermal stability, with significant degradation in thermoelectric properties after prolonged exposure to high temperatures. This degradation manifests as sublimation of constituent elements, particularly antimony in CoSb3-based skutterudites, leading to compositional changes and microstructural deterioration. Accelerated aging tests at 550°C have shown up to 30% reduction in ZT values after just 500 hours in unfilled compounds.

Filled skutterudites demonstrate markedly improved thermal stability, with filler atoms (such as rare earth or alkaline earth elements) serving as structural stabilizers. The presence of these fillers reduces atomic mobility and sublimation rates, thereby enhancing long-term reliability. Recent studies on multiple-filled skutterudites (e.g., Ba0.08La0.05Yb0.04Co4Sb12) have shown less than 10% degradation in thermoelectric performance after 2000 hours at operating temperatures.

Interface stability represents another crucial reliability concern, particularly in thermoelectric modules where skutterudites must maintain good contact with electrodes and other components. Thermal expansion mismatch between skutterudites and contact materials can lead to mechanical stress, delamination, and increased contact resistance over time. Advanced metallization techniques and buffer layers have been developed to mitigate these effects, with Ti/Mo/Ni multilayer contacts showing promising stability in long-term testing.

Mechanical reliability under thermal cycling conditions presents additional challenges. Skutterudites typically exhibit brittle behavior with fracture toughness values of 1-2 MPa·m1/2, making them susceptible to thermal shock and mechanical failure. Nanocomposite approaches incorporating secondary phases have demonstrated up to 40% improvement in mechanical properties while maintaining thermoelectric performance.

Environmental factors, particularly oxidation resistance, significantly impact reliability in air-operated systems. Protective coatings such as alumina and glass-ceramics have been employed to prevent oxidation, with recent developments in self-healing coatings showing particular promise for extended service life. Hermetic sealing technologies have advanced considerably, with modern skutterudite modules demonstrating stable operation for over 50,000 hours under proper encapsulation.

Standardized reliability testing protocols have emerged in recent years, including thermal cycling between room temperature and maximum operating temperature, thermal shock testing, and high-temperature storage tests. These protocols enable quantitative comparison between different skutterudite formulations and module designs, facilitating more rapid advancement toward commercially viable systems with the 10+ year operational lifetimes required for many applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!