Skutterudite Thermal Conductivity Suppression: Point Defects vs Grain Boundaries

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Skutterudite Thermal Management Background and Objectives

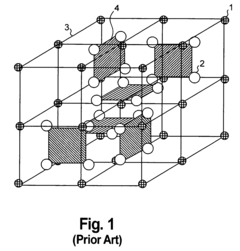

Skutterudite compounds have emerged as promising thermoelectric materials due to their unique crystal structure and favorable electronic properties. First discovered in the 19th century and named after the mining town of Skutterud in Norway, these cobalt arsenide-based materials have gained significant attention in the thermoelectric research community over the past three decades. The fundamental challenge in thermoelectric materials development lies in simultaneously optimizing electrical conductivity while minimizing thermal conductivity - a seemingly contradictory requirement that has driven extensive research in material science.

The evolution of skutterudite research has progressed through several distinct phases. Initial investigations focused on understanding the basic crystallographic and electronic properties of these materials. This was followed by the discovery of the "phonon glass-electron crystal" concept in the 1990s, which recognized skutterudites as ideal candidates for thermoelectric applications due to their cage-like structure that can host rattling atoms to disrupt phonon transport while maintaining good electrical properties.

Recent technological advances have enabled more sophisticated approaches to thermal conductivity suppression in skutterudites. The field has witnessed a transition from simple elemental filling of the structural cages to complex multi-filling strategies, nanostructuring approaches, and precise defect engineering. This progression reflects the growing understanding of phonon transport mechanisms and the various ways to disrupt them effectively.

The primary technical objective of current research is to determine the most effective approach for thermal conductivity suppression in skutterudites: whether through point defect engineering or grain boundary manipulation. Point defects, including atomic substitutions, vacancies, and interstitials, can scatter phonons effectively at high frequencies but have limited impact on mid-to-low frequency phonons. Conversely, grain boundaries can scatter a broader phonon spectrum but may simultaneously degrade electrical properties.

Our research aims to quantitatively compare these two approaches, evaluating their relative effectiveness across different temperature ranges, their impact on electrical transport properties, and their practical feasibility in large-scale manufacturing. We seek to establish clear design principles for skutterudite-based thermoelectric materials that optimize the balance between point defect and grain boundary engineering.

The ultimate goal is to develop skutterudite materials with significantly reduced thermal conductivity (below 1 W/mK) while maintaining electrical conductivity above 1000 S/cm, thereby achieving ZT values exceeding 2 across a broad temperature range. This would represent a substantial advancement over current state-of-the-art skutterudite materials and potentially enable widespread application in waste heat recovery systems, particularly in automotive and industrial settings.

The evolution of skutterudite research has progressed through several distinct phases. Initial investigations focused on understanding the basic crystallographic and electronic properties of these materials. This was followed by the discovery of the "phonon glass-electron crystal" concept in the 1990s, which recognized skutterudites as ideal candidates for thermoelectric applications due to their cage-like structure that can host rattling atoms to disrupt phonon transport while maintaining good electrical properties.

Recent technological advances have enabled more sophisticated approaches to thermal conductivity suppression in skutterudites. The field has witnessed a transition from simple elemental filling of the structural cages to complex multi-filling strategies, nanostructuring approaches, and precise defect engineering. This progression reflects the growing understanding of phonon transport mechanisms and the various ways to disrupt them effectively.

The primary technical objective of current research is to determine the most effective approach for thermal conductivity suppression in skutterudites: whether through point defect engineering or grain boundary manipulation. Point defects, including atomic substitutions, vacancies, and interstitials, can scatter phonons effectively at high frequencies but have limited impact on mid-to-low frequency phonons. Conversely, grain boundaries can scatter a broader phonon spectrum but may simultaneously degrade electrical properties.

Our research aims to quantitatively compare these two approaches, evaluating their relative effectiveness across different temperature ranges, their impact on electrical transport properties, and their practical feasibility in large-scale manufacturing. We seek to establish clear design principles for skutterudite-based thermoelectric materials that optimize the balance between point defect and grain boundary engineering.

The ultimate goal is to develop skutterudite materials with significantly reduced thermal conductivity (below 1 W/mK) while maintaining electrical conductivity above 1000 S/cm, thereby achieving ZT values exceeding 2 across a broad temperature range. This would represent a substantial advancement over current state-of-the-art skutterudite materials and potentially enable widespread application in waste heat recovery systems, particularly in automotive and industrial settings.

Market Applications and Demand for Thermoelectric Materials

The global thermoelectric materials market has witnessed significant growth in recent years, driven by increasing demand for energy-efficient technologies and waste heat recovery systems. The market was valued at approximately $51.6 billion in 2022 and is projected to reach $79.5 billion by 2028, growing at a CAGR of 7.5%. This growth trajectory underscores the expanding applications of thermoelectric materials across various industries.

Skutterudite-based thermoelectric materials have emerged as particularly promising candidates for commercial applications due to their excellent performance in mid-to-high temperature ranges (400-700°C). Their ability to convert waste heat into electricity makes them valuable in automotive, industrial manufacturing, and power generation sectors where significant thermal energy is typically wasted.

In the automotive industry, thermoelectric generators (TEGs) utilizing skutterudites are being integrated into exhaust systems to recover waste heat and improve fuel efficiency. Major automotive manufacturers including BMW, Ford, and Toyota have invested in research programs to develop skutterudite-based TEGs, with the potential to improve vehicle fuel efficiency by 3-5%.

The industrial sector represents another significant market, where skutterudite materials are being employed in waste heat recovery systems for energy-intensive processes such as steel production, glass manufacturing, and cement production. These applications not only reduce energy consumption but also help companies meet increasingly stringent carbon emission regulations.

Space exploration constitutes a specialized but high-value application area. NASA and other space agencies utilize skutterudite-based radioisotope thermoelectric generators (RTGs) for deep space missions where solar power is impractical. The reliability and longevity of these power sources are critical for mission success, making the thermal conductivity properties of skutterudites particularly valuable.

Consumer electronics represents an emerging market for miniaturized thermoelectric cooling systems based on skutterudite materials. Applications include temperature regulation in high-performance computing systems, wearable devices, and portable cooling/heating products.

The growing focus on green energy solutions has created additional demand for thermoelectric materials in renewable energy systems. Skutterudites are being investigated for solar-thermal hybrid systems and geothermal energy applications, where their ability to operate efficiently at varying temperature gradients provides significant advantages.

Market analysis indicates that the demand for high-performance thermoelectric materials is increasingly driven by efficiency requirements. Advancements in thermal conductivity suppression techniques—whether through point defects or grain boundary engineering—directly impact market adoption by improving the figure of merit (ZT) and consequently the conversion efficiency of thermoelectric devices.

Skutterudite-based thermoelectric materials have emerged as particularly promising candidates for commercial applications due to their excellent performance in mid-to-high temperature ranges (400-700°C). Their ability to convert waste heat into electricity makes them valuable in automotive, industrial manufacturing, and power generation sectors where significant thermal energy is typically wasted.

In the automotive industry, thermoelectric generators (TEGs) utilizing skutterudites are being integrated into exhaust systems to recover waste heat and improve fuel efficiency. Major automotive manufacturers including BMW, Ford, and Toyota have invested in research programs to develop skutterudite-based TEGs, with the potential to improve vehicle fuel efficiency by 3-5%.

The industrial sector represents another significant market, where skutterudite materials are being employed in waste heat recovery systems for energy-intensive processes such as steel production, glass manufacturing, and cement production. These applications not only reduce energy consumption but also help companies meet increasingly stringent carbon emission regulations.

Space exploration constitutes a specialized but high-value application area. NASA and other space agencies utilize skutterudite-based radioisotope thermoelectric generators (RTGs) for deep space missions where solar power is impractical. The reliability and longevity of these power sources are critical for mission success, making the thermal conductivity properties of skutterudites particularly valuable.

Consumer electronics represents an emerging market for miniaturized thermoelectric cooling systems based on skutterudite materials. Applications include temperature regulation in high-performance computing systems, wearable devices, and portable cooling/heating products.

The growing focus on green energy solutions has created additional demand for thermoelectric materials in renewable energy systems. Skutterudites are being investigated for solar-thermal hybrid systems and geothermal energy applications, where their ability to operate efficiently at varying temperature gradients provides significant advantages.

Market analysis indicates that the demand for high-performance thermoelectric materials is increasingly driven by efficiency requirements. Advancements in thermal conductivity suppression techniques—whether through point defects or grain boundary engineering—directly impact market adoption by improving the figure of merit (ZT) and consequently the conversion efficiency of thermoelectric devices.

Current Challenges in Skutterudite Thermal Conductivity Control

Despite significant advancements in skutterudite-based thermoelectric materials, controlling thermal conductivity remains a fundamental challenge that limits their widespread commercial application. The primary obstacle lies in simultaneously maintaining high electrical conductivity while effectively suppressing phonon transport. Current research reveals a complex interplay between point defects and grain boundaries as thermal conductivity suppression mechanisms, with each approach presenting distinct advantages and limitations.

Point defect engineering, while theoretically promising, faces significant implementation challenges. The precise control of defect concentration, distribution, and stability at operating temperatures (often exceeding 400°C) presents substantial manufacturing difficulties. Additionally, researchers struggle to quantitatively predict the impact of specific defect types on the overall thermal transport properties, making systematic optimization problematic.

Grain boundary engineering encounters equally formidable obstacles. The current fabrication techniques cannot reliably produce uniform grain size distributions or controlled boundary characteristics across bulk samples. This inconsistency leads to significant performance variations between nominally identical materials, hampering quality control and scalability for industrial production.

The temperature dependence of thermal conductivity suppression mechanisms represents another critical challenge. Many skutterudite compositions exhibit excellent performance at moderate temperatures but lose effectiveness at their intended high-temperature operating conditions due to defect healing or grain coarsening. This temperature instability significantly reduces the practical efficiency of these materials in real-world applications.

Measurement standardization presents an additional hurdle. Different research groups employ varying techniques for thermal conductivity characterization, leading to inconsistent reporting and difficulties in comparing results across studies. The lack of standardized testing protocols specifically designed for skutterudites complicates the evaluation of new suppression strategies.

Computational modeling limitations further impede progress. Current simulation approaches struggle to accurately capture the multiscale nature of thermal transport in these complex materials, particularly the interaction between point defects and grain boundaries. The computational resources required for accurate modeling of realistic microstructures often exceed practical limitations.

The cost-performance balance remains problematic for commercial viability. While certain approaches achieve impressive thermal conductivity reduction, they often rely on expensive dopants or complex processing techniques that significantly increase production costs without proportional performance gains. Finding economically viable solutions that maintain performance integrity continues to challenge researchers and industry stakeholders alike.

Point defect engineering, while theoretically promising, faces significant implementation challenges. The precise control of defect concentration, distribution, and stability at operating temperatures (often exceeding 400°C) presents substantial manufacturing difficulties. Additionally, researchers struggle to quantitatively predict the impact of specific defect types on the overall thermal transport properties, making systematic optimization problematic.

Grain boundary engineering encounters equally formidable obstacles. The current fabrication techniques cannot reliably produce uniform grain size distributions or controlled boundary characteristics across bulk samples. This inconsistency leads to significant performance variations between nominally identical materials, hampering quality control and scalability for industrial production.

The temperature dependence of thermal conductivity suppression mechanisms represents another critical challenge. Many skutterudite compositions exhibit excellent performance at moderate temperatures but lose effectiveness at their intended high-temperature operating conditions due to defect healing or grain coarsening. This temperature instability significantly reduces the practical efficiency of these materials in real-world applications.

Measurement standardization presents an additional hurdle. Different research groups employ varying techniques for thermal conductivity characterization, leading to inconsistent reporting and difficulties in comparing results across studies. The lack of standardized testing protocols specifically designed for skutterudites complicates the evaluation of new suppression strategies.

Computational modeling limitations further impede progress. Current simulation approaches struggle to accurately capture the multiscale nature of thermal transport in these complex materials, particularly the interaction between point defects and grain boundaries. The computational resources required for accurate modeling of realistic microstructures often exceed practical limitations.

The cost-performance balance remains problematic for commercial viability. While certain approaches achieve impressive thermal conductivity reduction, they often rely on expensive dopants or complex processing techniques that significantly increase production costs without proportional performance gains. Finding economically viable solutions that maintain performance integrity continues to challenge researchers and industry stakeholders alike.

Comparative Analysis of Point Defect vs Grain Boundary Approaches

01 Filled skutterudites for reduced thermal conductivity

Skutterudites can be filled with atoms or elements to reduce thermal conductivity while maintaining good electrical properties. These 'fillers' occupy the voids in the skutterudite crystal structure and act as phonon scatterers, disrupting heat transfer through the material. Common fillers include rare earth elements, alkaline earth metals, or other atoms that can fit within the skutterudite cage structure. This approach is particularly valuable for thermoelectric applications where low thermal conductivity is desired.- Filled skutterudites for reduced thermal conductivity: Filled skutterudites incorporate guest atoms (fillers) into the voids of the skutterudite crystal structure to reduce thermal conductivity. These filler atoms act as phonon scatterers, disrupting heat transfer through the lattice. Common fillers include rare earth elements, alkaline earth metals, and other elements that can fit within the skutterudite cage structure. This approach is widely used to enhance thermoelectric performance by maintaining electrical conductivity while reducing thermal conductivity.

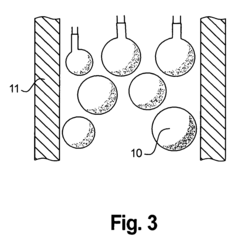

- Nanostructuring approaches for thermal conductivity reduction: Nanostructuring techniques are employed to reduce the thermal conductivity of skutterudites while preserving their electrical properties. These approaches include creating nanocomposites, introducing nanoinclusions, developing hierarchical structures, and boundary engineering. Nanostructured skutterudites provide additional phonon scattering interfaces at various length scales, effectively reducing thermal conductivity across a wide range of phonon wavelengths and enhancing overall thermoelectric performance.

- Compositional optimization for thermal conductivity control: The thermal conductivity of skutterudites can be controlled through compositional optimization, including precise doping strategies, substitutional alloying, and multi-element filling. By carefully adjusting the elemental composition and stoichiometry, researchers can fine-tune the electronic structure and phonon transport properties. This approach allows for systematic reduction of thermal conductivity while optimizing other thermoelectric parameters such as Seebeck coefficient and electrical conductivity.

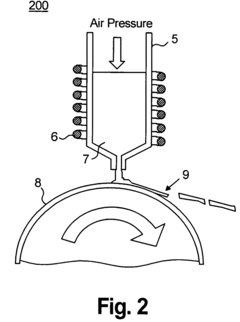

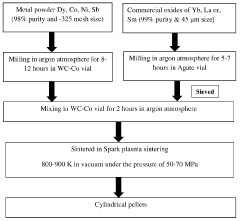

- Fabrication methods affecting thermal conductivity: Various fabrication methods significantly impact the thermal conductivity of skutterudite materials. Techniques such as melt-spinning, spark plasma sintering, hot pressing, ball milling, and other advanced synthesis approaches can create specific microstructures that enhance phonon scattering. The processing parameters, including temperature, pressure, and cooling rates, directly influence grain size, defect concentration, and phase distribution, all of which affect thermal transport properties.

- Measurement and characterization of thermal conductivity: Accurate measurement and characterization of thermal conductivity in skutterudites are essential for material development and optimization. Various techniques are employed, including laser flash method, steady-state methods, thermal diffusivity measurements, and advanced microscopy for structural analysis. These measurements help researchers understand the fundamental mechanisms of thermal transport in skutterudites and evaluate the effectiveness of different strategies for reducing thermal conductivity.

02 Nanostructuring approaches to reduce thermal conductivity

Nanostructuring of skutterudites can significantly reduce thermal conductivity through increased phonon scattering at interfaces. Methods include creating nanocomposites, introducing nanoinclusions, developing core-shell structures, or producing nanoporous skutterudites. These approaches create additional interfaces that scatter phonons without substantially affecting electron transport, thereby improving the thermoelectric figure of merit by reducing thermal conductivity while maintaining electrical conductivity.Expand Specific Solutions03 Doping and substitution strategies for thermal conductivity control

Chemical doping and atomic substitution in skutterudite structures can effectively modify thermal conductivity. By partially replacing atoms in the skutterudite framework with elements of different atomic mass or bonding characteristics, phonon transport can be disrupted while electronic properties are maintained or enhanced. Multiple-element doping strategies can create point defects and mass fluctuations that scatter phonons across different frequency ranges, leading to broader spectrum reduction in thermal conductivity.Expand Specific Solutions04 Measurement and characterization of thermal conductivity in skutterudites

Various techniques are employed to accurately measure and characterize the thermal conductivity of skutterudite materials. These include laser flash methods, steady-state techniques, thermal transport property measurements, and scanning thermal microscopy. Advanced characterization methods help understand the relationship between skutterudite structure and thermal properties, enabling the development of materials with optimized thermal conductivity for specific applications.Expand Specific Solutions05 Fabrication methods affecting thermal conductivity

The fabrication process significantly influences the thermal conductivity of skutterudite materials. Methods such as spark plasma sintering, hot pressing, melt-spinning, ball milling, and solution-based synthesis can create different microstructures and defect concentrations that affect phonon transport. Process parameters like sintering temperature, pressure, and cooling rate can be optimized to achieve desired thermal conductivity values. Post-processing treatments may further modify the thermal transport properties of skutterudite materials.Expand Specific Solutions

Leading Research Groups and Companies in Skutterudite Development

The thermal conductivity suppression in skutterudites represents a competitive landscape in the emerging thermoelectric materials sector. Currently in the growth phase, this field is characterized by increasing research intensity and commercial applications, with a projected market size reaching several hundred million dollars by 2030. Academic institutions like MIT, California Institute of Technology, and Boston College lead fundamental research, while industrial players demonstrate varying technological maturity. Companies including Toshiba Materials, Toyota Central R&D Labs, and TEGma AS have developed advanced skutterudite materials with optimized point defect and grain boundary engineering. Semiconductor manufacturers such as Intel, Fujitsu, and Applied Materials are increasingly investing in this technology for waste heat recovery applications, indicating growing commercial viability despite remaining challenges in mass production and cost-effectiveness.

Massachusetts Institute of Technology

Technical Solution: MIT has developed advanced skutterudite materials with engineered point defects to suppress thermal conductivity while maintaining electrical conductivity. Their approach involves introducing foreign atoms (such as rare earth elements) into the skutterudite cage structure to create "rattling" effects that scatter phonons. MIT researchers have demonstrated that strategic placement of point defects can reduce thermal conductivity by up to 50% compared to pristine skutterudites. They've also pioneered computational models that predict optimal defect concentrations and distributions for maximizing the figure of merit (ZT) in thermoelectric applications. Their work includes novel synthesis methods that allow precise control over defect formation during material processing, enabling tunable thermal properties for specific application requirements.

Strengths: Exceptional precision in defect engineering with atomic-level control; strong integration of computational modeling with experimental validation; comprehensive understanding of phonon transport mechanisms. Weaknesses: Higher manufacturing costs associated with precise defect control; potential challenges in scaling production to industrial levels; some approaches may require rare or expensive dopant materials.

Toyota Motor Corp.

Technical Solution: Toyota Motor Corporation has developed proprietary skutterudite materials optimized for automotive thermoelectric applications, focusing on both point defect and grain boundary engineering. Their approach emphasizes practical aspects of thermal conductivity suppression that maintain reliability under automotive operating conditions. Toyota's research has demonstrated that carefully controlled filling of skutterudite voids with multiple filler atoms (Yb, Ba, La) creates effective point defects that reduce thermal conductivity by disrupting phonon transport. They've also pioneered manufacturing techniques that create stable grain boundaries through controlled oxidation processes during sintering. Toyota has integrated these materials into prototype thermoelectric generators that demonstrate up to 5% conversion efficiency in vehicle exhaust heat recovery systems, representing a significant advancement for automotive waste heat utilization.

Strengths: Excellent material stability under thermal cycling conditions; optimization for automotive operating environments; practical focus on manufacturability and cost-effectiveness. Weaknesses: Somewhat lower maximum ZT values compared to laboratory-optimized materials; proprietary nature limits broader scientific community access; primarily optimized for mid-temperature range applications.

Key Scientific Breakthroughs in Skutterudite Phonon Scattering

Synthesis of High-Efficiency Thermoelectric Materials

PatentInactiveUS20110120517A1

Innovation

- A non-equilibrium synthesis method involving rapid solidification and sintering techniques, such as melt spinning and spark plasma sintering, is employed to inhibit phase segregation and grain growth, allowing for precise control over microstructure and the formation of fully dense thermoelectric materials with enhanced thermoelectric properties.

Method of preparation of highly efficient skutterudite thermoelectric materials for thermoelectric modules and the product thereof

PatentActiveIN202111036278A

Innovation

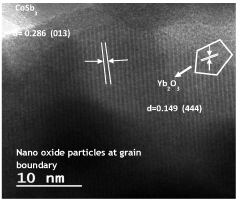

- Development of Dy filled Ni doped Co4Sb12 skutterudites using a powder metallurgy route, incorporating rare-earth oxides to enhance thermoelectric properties, resulting in a cost-effective and time-efficient processing method that reduces lattice thermal conductivity and increases the figure of merit.

Materials Characterization Methods for Skutterudite Structures

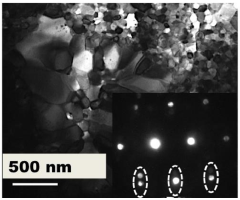

The comprehensive characterization of skutterudite structures is essential for understanding the mechanisms behind thermal conductivity suppression, particularly when comparing the effects of point defects versus grain boundaries. Advanced microscopy techniques, including Scanning Electron Microscopy (SEM) and Transmission Electron Microscopy (TEM), provide critical insights into the microstructural features of skutterudites. SEM enables visualization of grain morphology and distribution, while TEM offers atomic-level resolution necessary for identifying point defects and analyzing grain boundary structures.

X-ray diffraction (XRD) serves as a fundamental tool for phase identification and crystallographic analysis of skutterudites. Through Rietveld refinement of XRD patterns, researchers can determine lattice parameters, quantify phase compositions, and detect structural distortions caused by point defects. Additionally, synchrotron-based XRD techniques offer enhanced resolution for detecting subtle structural changes in doped skutterudites.

Spectroscopic methods provide complementary information about the bonding environment and electronic structure. Raman spectroscopy is particularly valuable for investigating phonon modes in skutterudites, offering insights into how point defects and grain boundaries affect lattice vibrations that directly influence thermal conductivity. X-ray photoelectron spectroscopy (XPS) and energy-dispersive X-ray spectroscopy (EDS) enable precise elemental analysis and chemical state determination.

Thermal transport measurements are crucial for directly assessing the effectiveness of different conductivity suppression strategies. Laser flash analysis (LFA) measures thermal diffusivity, while the 3ω method provides accurate thermal conductivity data for thin films and bulk materials. Temperature-dependent measurements reveal the dominant scattering mechanisms across different temperature ranges, helping distinguish between point defect and grain boundary effects.

Advanced tomographic techniques, including atom probe tomography (APT) and 3D electron tomography, offer three-dimensional visualization of defect distributions and grain boundary networks. These methods are particularly valuable for correlating structural features with thermal transport properties, enabling researchers to optimize skutterudite compositions and processing conditions.

Computational modeling approaches complement experimental characterization by simulating phonon transport across defects and interfaces. Density functional theory (DFT) calculations predict electronic structures and phonon properties, while molecular dynamics simulations model thermal transport at atomic scales. These computational tools help interpret experimental results and guide the design of skutterudites with tailored thermal properties.

X-ray diffraction (XRD) serves as a fundamental tool for phase identification and crystallographic analysis of skutterudites. Through Rietveld refinement of XRD patterns, researchers can determine lattice parameters, quantify phase compositions, and detect structural distortions caused by point defects. Additionally, synchrotron-based XRD techniques offer enhanced resolution for detecting subtle structural changes in doped skutterudites.

Spectroscopic methods provide complementary information about the bonding environment and electronic structure. Raman spectroscopy is particularly valuable for investigating phonon modes in skutterudites, offering insights into how point defects and grain boundaries affect lattice vibrations that directly influence thermal conductivity. X-ray photoelectron spectroscopy (XPS) and energy-dispersive X-ray spectroscopy (EDS) enable precise elemental analysis and chemical state determination.

Thermal transport measurements are crucial for directly assessing the effectiveness of different conductivity suppression strategies. Laser flash analysis (LFA) measures thermal diffusivity, while the 3ω method provides accurate thermal conductivity data for thin films and bulk materials. Temperature-dependent measurements reveal the dominant scattering mechanisms across different temperature ranges, helping distinguish between point defect and grain boundary effects.

Advanced tomographic techniques, including atom probe tomography (APT) and 3D electron tomography, offer three-dimensional visualization of defect distributions and grain boundary networks. These methods are particularly valuable for correlating structural features with thermal transport properties, enabling researchers to optimize skutterudite compositions and processing conditions.

Computational modeling approaches complement experimental characterization by simulating phonon transport across defects and interfaces. Density functional theory (DFT) calculations predict electronic structures and phonon properties, while molecular dynamics simulations model thermal transport at atomic scales. These computational tools help interpret experimental results and guide the design of skutterudites with tailored thermal properties.

Environmental Impact and Sustainability of Skutterudite Materials

The environmental impact and sustainability of skutterudite materials represent critical considerations in their development and application for thermoelectric technologies. Skutterudite compounds, primarily based on cobalt arsenide structures (CoAs3), involve elements such as cobalt, nickel, iron, antimony, and arsenic, which raise significant environmental concerns regarding resource extraction and end-of-life disposal.

Mining operations for these constituent elements, particularly cobalt and arsenic, are associated with substantial environmental degradation, including habitat destruction, soil contamination, and water pollution. The extraction processes often generate toxic waste streams that can persist in ecosystems for extended periods. Furthermore, arsenic compounds present particular environmental hazards due to their toxicity and potential for groundwater contamination.

The manufacturing processes for skutterudite materials typically require high-temperature synthesis methods and energy-intensive procedures, contributing to their overall carbon footprint. The environmental impact varies significantly depending on whether point defect or grain boundary approaches are employed for thermal conductivity suppression, with the latter potentially requiring additional processing steps and energy inputs.

Life cycle assessment (LCA) studies indicate that the environmental benefits of skutterudite-based thermoelectric devices—primarily through waste heat recovery and improved energy efficiency—must be weighed against the environmental costs of production and disposal. The energy payback period for skutterudite thermoelectric generators depends heavily on application scenarios and operational efficiency.

Recent sustainability initiatives have focused on developing more environmentally benign skutterudite variants, including arsenic-free compositions and reduced-cobalt formulations. Research into "green skutterudites" aims to maintain thermoelectric performance while substituting environmentally problematic elements with more abundant and less toxic alternatives.

Recycling and recovery strategies for skutterudite materials remain underdeveloped, presenting a significant sustainability challenge. The complex nature of these materials, particularly those with engineered defects or nanostructured grain boundaries, complicates end-of-life recovery processes. Emerging technologies for selective element recovery from thermoelectric modules show promise but require further development for commercial viability.

Regulatory frameworks governing the use of potentially hazardous elements in skutterudite materials vary globally, with increasing restrictions on arsenic-containing compounds in many jurisdictions. These regulatory considerations may influence the commercial viability of certain skutterudite compositions and manufacturing approaches.

The sustainability trajectory of skutterudite materials ultimately depends on balancing their positive environmental impact through energy efficiency applications against the environmental costs of their production and disposal. Continued research into environmentally benign compositions and improved recycling methodologies will be essential for enhancing the overall sustainability profile of these promising thermoelectric materials.

Mining operations for these constituent elements, particularly cobalt and arsenic, are associated with substantial environmental degradation, including habitat destruction, soil contamination, and water pollution. The extraction processes often generate toxic waste streams that can persist in ecosystems for extended periods. Furthermore, arsenic compounds present particular environmental hazards due to their toxicity and potential for groundwater contamination.

The manufacturing processes for skutterudite materials typically require high-temperature synthesis methods and energy-intensive procedures, contributing to their overall carbon footprint. The environmental impact varies significantly depending on whether point defect or grain boundary approaches are employed for thermal conductivity suppression, with the latter potentially requiring additional processing steps and energy inputs.

Life cycle assessment (LCA) studies indicate that the environmental benefits of skutterudite-based thermoelectric devices—primarily through waste heat recovery and improved energy efficiency—must be weighed against the environmental costs of production and disposal. The energy payback period for skutterudite thermoelectric generators depends heavily on application scenarios and operational efficiency.

Recent sustainability initiatives have focused on developing more environmentally benign skutterudite variants, including arsenic-free compositions and reduced-cobalt formulations. Research into "green skutterudites" aims to maintain thermoelectric performance while substituting environmentally problematic elements with more abundant and less toxic alternatives.

Recycling and recovery strategies for skutterudite materials remain underdeveloped, presenting a significant sustainability challenge. The complex nature of these materials, particularly those with engineered defects or nanostructured grain boundaries, complicates end-of-life recovery processes. Emerging technologies for selective element recovery from thermoelectric modules show promise but require further development for commercial viability.

Regulatory frameworks governing the use of potentially hazardous elements in skutterudite materials vary globally, with increasing restrictions on arsenic-containing compounds in many jurisdictions. These regulatory considerations may influence the commercial viability of certain skutterudite compositions and manufacturing approaches.

The sustainability trajectory of skutterudite materials ultimately depends on balancing their positive environmental impact through energy efficiency applications against the environmental costs of their production and disposal. Continued research into environmentally benign compositions and improved recycling methodologies will be essential for enhancing the overall sustainability profile of these promising thermoelectric materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!