Pressure-Driven Phase Transitions in Skutterudites and Their Thermoelectric Impact

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Skutterudite Thermoelectric Evolution and Research Objectives

Skutterudites represent a significant class of materials in the field of thermoelectrics, with a rich history dating back to their discovery in the mid-19th century. These cobalt arsenide minerals, first found in Skutterud, Norway, have evolved from geological curiosities to promising candidates for waste heat recovery and solid-state cooling applications. The technological trajectory of skutterudites has been marked by several pivotal breakthroughs, particularly in understanding their unique "phonon glass-electron crystal" behavior that enables exceptional thermoelectric performance.

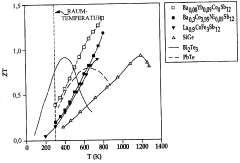

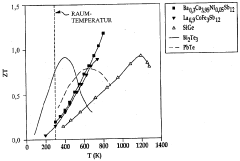

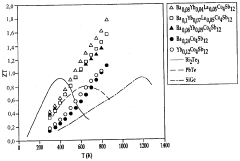

The evolution of skutterudite research has progressed through distinct phases: initial discovery and characterization in the 1990s, theoretical framework development in the early 2000s, optimization strategies through the 2010s, and the current frontier exploring pressure-induced phase transitions. This progression reflects the scientific community's growing sophistication in manipulating these materials' complex crystal structures to enhance their thermoelectric figure of merit (ZT).

Pressure-driven phase transitions have emerged as a particularly promising avenue for skutterudite advancement. High-pressure techniques allow for systematic modification of the material's electronic band structure and phonon transport properties, potentially unlocking unprecedented thermoelectric efficiency. Recent studies demonstrate that pressure-induced structural changes can significantly alter the power factor and thermal conductivity of skutterudites, offering new pathways to overcome traditional performance limitations.

The primary research objectives in this field now center on several key dimensions. First, establishing comprehensive pressure-phase diagrams for various skutterudite compositions to map the relationship between structural transformations and thermoelectric properties. Second, developing in-situ characterization techniques capable of monitoring electronic and thermal transport properties under extreme conditions. Third, translating high-pressure discoveries into practical synthesis routes that can achieve similar structural modifications through chemical means or nanostructuring.

Additionally, computational modeling has become increasingly vital in guiding experimental efforts, with density functional theory and molecular dynamics simulations providing predictive insights into pressure-induced phenomena. These theoretical approaches help identify promising compositional spaces and pressure regimes before resource-intensive experimental validation.

The ultimate goal of current skutterudite research is to achieve ZT values consistently above 2.0 across a wide temperature range, which would represent a significant milestone for commercial viability. Pressure-driven investigations are expected to reveal fundamental structure-property relationships that could inform next-generation thermoelectric material design beyond skutterudites themselves, potentially revolutionizing waste heat recovery technologies across industrial, automotive, and consumer electronics sectors.

The evolution of skutterudite research has progressed through distinct phases: initial discovery and characterization in the 1990s, theoretical framework development in the early 2000s, optimization strategies through the 2010s, and the current frontier exploring pressure-induced phase transitions. This progression reflects the scientific community's growing sophistication in manipulating these materials' complex crystal structures to enhance their thermoelectric figure of merit (ZT).

Pressure-driven phase transitions have emerged as a particularly promising avenue for skutterudite advancement. High-pressure techniques allow for systematic modification of the material's electronic band structure and phonon transport properties, potentially unlocking unprecedented thermoelectric efficiency. Recent studies demonstrate that pressure-induced structural changes can significantly alter the power factor and thermal conductivity of skutterudites, offering new pathways to overcome traditional performance limitations.

The primary research objectives in this field now center on several key dimensions. First, establishing comprehensive pressure-phase diagrams for various skutterudite compositions to map the relationship between structural transformations and thermoelectric properties. Second, developing in-situ characterization techniques capable of monitoring electronic and thermal transport properties under extreme conditions. Third, translating high-pressure discoveries into practical synthesis routes that can achieve similar structural modifications through chemical means or nanostructuring.

Additionally, computational modeling has become increasingly vital in guiding experimental efforts, with density functional theory and molecular dynamics simulations providing predictive insights into pressure-induced phenomena. These theoretical approaches help identify promising compositional spaces and pressure regimes before resource-intensive experimental validation.

The ultimate goal of current skutterudite research is to achieve ZT values consistently above 2.0 across a wide temperature range, which would represent a significant milestone for commercial viability. Pressure-driven investigations are expected to reveal fundamental structure-property relationships that could inform next-generation thermoelectric material design beyond skutterudites themselves, potentially revolutionizing waste heat recovery technologies across industrial, automotive, and consumer electronics sectors.

Market Analysis for Pressure-Enhanced Thermoelectric Materials

The global market for thermoelectric materials is experiencing significant growth, driven by increasing demand for energy efficiency solutions and waste heat recovery systems. Pressure-enhanced thermoelectric materials, particularly skutterudites, represent an emerging segment with substantial commercial potential across multiple industries.

The thermoelectric materials market was valued at approximately $51 million in 2020 and is projected to reach $174 million by 2026, growing at a CAGR of 14.3% during the forecast period. Within this broader market, pressure-enhanced thermoelectric materials are gaining attention due to their superior performance characteristics and efficiency improvements over conventional alternatives.

Key market drivers include stringent environmental regulations promoting energy efficiency, rising industrial waste heat recovery needs, and growing demand for reliable power sources in remote applications. The automotive sector represents the largest market segment, with thermoelectric generators increasingly integrated into vehicle exhaust systems to convert waste heat into usable electricity, improving fuel efficiency by 3-5%.

Consumer electronics constitutes another rapidly expanding application area, with pressure-enhanced thermoelectric materials enabling more efficient cooling solutions for processors and potentially extending battery life in portable devices. The aerospace and defense sectors are also showing interest in these materials for specialized power generation applications in extreme environments.

Geographically, North America currently leads the market for advanced thermoelectric materials, followed by Europe and Asia-Pacific. However, China is making substantial investments in thermoelectric research and manufacturing capacity, potentially shifting the market landscape in the coming years.

The industrial sector presents perhaps the most promising long-term opportunity, with waste heat recovery systems based on pressure-enhanced skutterudites potentially capturing a portion of the estimated 20-50% of industrial energy currently lost as waste heat. Early adopters include steel manufacturing, glass production, and chemical processing industries.

Market challenges include high initial production costs, with pressure-enhanced skutterudites currently commanding a premium of 30-40% over conventional thermoelectric materials. Manufacturing scalability remains another significant barrier, as pressure-treatment processes require specialized equipment and expertise.

Customer adoption is primarily driven by total cost of ownership calculations rather than initial investment, with payback periods typically ranging from 3-7 years depending on the application. As manufacturing techniques mature and economies of scale improve, these payback periods are expected to decrease substantially, accelerating market penetration.

The thermoelectric materials market was valued at approximately $51 million in 2020 and is projected to reach $174 million by 2026, growing at a CAGR of 14.3% during the forecast period. Within this broader market, pressure-enhanced thermoelectric materials are gaining attention due to their superior performance characteristics and efficiency improvements over conventional alternatives.

Key market drivers include stringent environmental regulations promoting energy efficiency, rising industrial waste heat recovery needs, and growing demand for reliable power sources in remote applications. The automotive sector represents the largest market segment, with thermoelectric generators increasingly integrated into vehicle exhaust systems to convert waste heat into usable electricity, improving fuel efficiency by 3-5%.

Consumer electronics constitutes another rapidly expanding application area, with pressure-enhanced thermoelectric materials enabling more efficient cooling solutions for processors and potentially extending battery life in portable devices. The aerospace and defense sectors are also showing interest in these materials for specialized power generation applications in extreme environments.

Geographically, North America currently leads the market for advanced thermoelectric materials, followed by Europe and Asia-Pacific. However, China is making substantial investments in thermoelectric research and manufacturing capacity, potentially shifting the market landscape in the coming years.

The industrial sector presents perhaps the most promising long-term opportunity, with waste heat recovery systems based on pressure-enhanced skutterudites potentially capturing a portion of the estimated 20-50% of industrial energy currently lost as waste heat. Early adopters include steel manufacturing, glass production, and chemical processing industries.

Market challenges include high initial production costs, with pressure-enhanced skutterudites currently commanding a premium of 30-40% over conventional thermoelectric materials. Manufacturing scalability remains another significant barrier, as pressure-treatment processes require specialized equipment and expertise.

Customer adoption is primarily driven by total cost of ownership calculations rather than initial investment, with payback periods typically ranging from 3-7 years depending on the application. As manufacturing techniques mature and economies of scale improve, these payback periods are expected to decrease substantially, accelerating market penetration.

Current Challenges in Pressure-Driven Skutterudite Research

Despite significant advancements in pressure-driven skutterudite research, several critical challenges continue to impede progress in this promising thermoelectric material domain. The primary technical obstacle remains the precise control and understanding of phase transitions under varying pressure conditions. Current experimental setups struggle to maintain uniform pressure distribution across skutterudite samples, leading to inconsistent results and difficulties in reproducing phase transition behaviors across different research groups.

The in-situ characterization of structural changes during pressure application presents another formidable challenge. While diamond anvil cells allow for pressure application up to several GPa, simultaneous high-resolution structural analysis remains limited. The integration of advanced X-ray diffraction techniques with high-pressure equipment requires sophisticated synchronization that few laboratories worldwide can achieve, creating a bottleneck in data acquisition and analysis.

Computational modeling of pressure-induced phase transitions in skutterudites faces significant hurdles due to the complex electronic structure and strong correlation effects in these materials. Current density functional theory approaches often fail to accurately predict transition pressures and the resulting electronic properties, particularly for filled skutterudites where guest atoms introduce additional complexity to the modeling requirements.

The scalability of pressure-induced phase transitions from laboratory to industrial applications represents perhaps the most significant barrier to commercialization. While diamond anvil cells can produce desired phases in small samples, translating these processes to bulk material production remains largely unsolved. The development of scalable high-pressure processing techniques that can maintain material quality while achieving economic viability continues to challenge researchers.

Temperature-pressure coupling effects introduce additional complexity, as the phase stability diagrams of skutterudites show strong temperature dependence. Most current research focuses on either temperature or pressure variables independently, whereas the interplay between these parameters critically affects thermoelectric performance. Systematic studies across the full temperature-pressure phase space require specialized equipment that exceeds the capabilities of most research facilities.

Material recovery after pressure treatment presents another significant challenge. Many pressure-induced phases in skutterudites are metastable, requiring careful pressure release protocols to preserve the desired structure. Current techniques often result in partial reversion to original phases or introduction of defects during decompression, compromising the enhanced thermoelectric properties achieved under pressure.

The in-situ characterization of structural changes during pressure application presents another formidable challenge. While diamond anvil cells allow for pressure application up to several GPa, simultaneous high-resolution structural analysis remains limited. The integration of advanced X-ray diffraction techniques with high-pressure equipment requires sophisticated synchronization that few laboratories worldwide can achieve, creating a bottleneck in data acquisition and analysis.

Computational modeling of pressure-induced phase transitions in skutterudites faces significant hurdles due to the complex electronic structure and strong correlation effects in these materials. Current density functional theory approaches often fail to accurately predict transition pressures and the resulting electronic properties, particularly for filled skutterudites where guest atoms introduce additional complexity to the modeling requirements.

The scalability of pressure-induced phase transitions from laboratory to industrial applications represents perhaps the most significant barrier to commercialization. While diamond anvil cells can produce desired phases in small samples, translating these processes to bulk material production remains largely unsolved. The development of scalable high-pressure processing techniques that can maintain material quality while achieving economic viability continues to challenge researchers.

Temperature-pressure coupling effects introduce additional complexity, as the phase stability diagrams of skutterudites show strong temperature dependence. Most current research focuses on either temperature or pressure variables independently, whereas the interplay between these parameters critically affects thermoelectric performance. Systematic studies across the full temperature-pressure phase space require specialized equipment that exceeds the capabilities of most research facilities.

Material recovery after pressure treatment presents another significant challenge. Many pressure-induced phases in skutterudites are metastable, requiring careful pressure release protocols to preserve the desired structure. Current techniques often result in partial reversion to original phases or introduction of defects during decompression, compromising the enhanced thermoelectric properties achieved under pressure.

Contemporary Methodologies for Skutterudite Pressure Processing

01 Thermoelectric properties of skutterudites

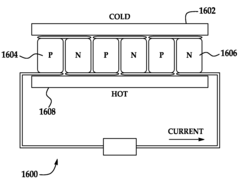

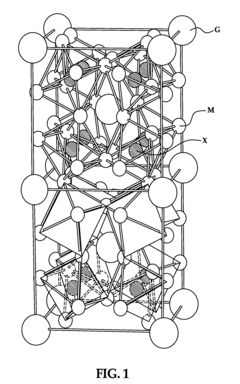

Skutterudites exhibit unique thermoelectric properties that make them valuable for energy conversion applications. These materials undergo phase transitions that can be manipulated to enhance their thermoelectric figure of merit (ZT). The thermoelectric efficiency is influenced by the crystal structure changes during phase transitions, which affect thermal conductivity and electrical resistivity. By controlling these phase transitions, researchers can optimize the power factor and reduce thermal conductivity for improved thermoelectric performance.- Thermoelectric properties of skutterudites: Skutterudites exhibit unique thermoelectric properties that make them valuable for energy conversion applications. These materials can undergo phase transitions that affect their thermal conductivity and electrical properties. The thermoelectric efficiency of skutterudites can be enhanced through various methods, including doping and nanostructuring, which influence the phase behavior and electronic structure of these materials.

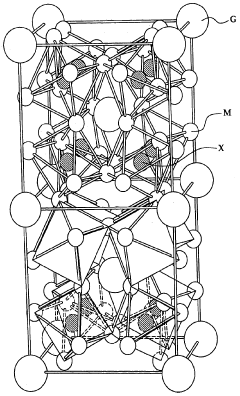

- Filled skutterudites and their phase characteristics: Filled skutterudites, where guest atoms occupy the voids in the skutterudite crystal structure, demonstrate modified phase transition behavior. The filling atoms can significantly alter the electronic and phononic properties of the material. These structural modifications can lead to enhanced thermoelectric performance through phonon scattering and electronic band structure engineering, which are directly related to the phase transitions in these materials.

- Synthesis methods affecting phase transitions in skutterudites: Various synthesis methods can influence the phase transitions and resulting properties of skutterudite materials. Techniques such as high-pressure synthesis, rapid solidification, and controlled annealing can produce skutterudites with different phase characteristics. The processing conditions directly impact the crystal structure, grain boundaries, and defect concentration, all of which affect the phase transition behavior of these materials.

- Temperature-dependent phase behavior of skutterudites: Skutterudites undergo temperature-dependent phase transitions that significantly impact their functional properties. These transitions can involve structural changes, electronic transitions, or magnetic ordering phenomena. Understanding and controlling these temperature-dependent phase behaviors is crucial for optimizing skutterudites for specific applications, particularly in thermoelectric devices that operate across temperature gradients.

- Nanostructured skutterudites and phase stability: Nanostructuring approaches can be used to control phase transitions in skutterudite materials. By creating nanoscale features or compositional variations, the phase stability and transition characteristics can be engineered. These nanostructured skutterudites often exhibit modified phase transition temperatures and behaviors compared to their bulk counterparts, leading to enhanced performance in various applications including thermoelectric energy conversion.

02 Filled skutterudites and their phase behavior

Filled skutterudites, where guest atoms occupy the voids in the skutterudite crystal structure, demonstrate modified phase transition characteristics. The filling atoms (such as rare earth elements, alkaline, or alkaline earth metals) can stabilize certain phases and alter transition temperatures. These fillers act as phonon scatterers, reducing lattice thermal conductivity while maintaining good electrical properties. The phase transitions in filled skutterudites can be controlled through composition engineering to achieve desired thermoelectric performance across different temperature ranges.Expand Specific Solutions03 Synthesis methods affecting phase transitions

Various synthesis techniques influence the phase transitions in skutterudite materials. Methods such as mechanical alloying, spark plasma sintering, and melt-spinning can produce skutterudites with controlled grain size and phase composition. The processing parameters during synthesis, including temperature, pressure, and cooling rate, significantly impact the resulting phase transitions. These methods can be optimized to produce skutterudites with specific phase transition characteristics tailored for particular applications, such as thermoelectric generators or cooling devices.Expand Specific Solutions04 Nanostructuring effects on phase transitions

Nanostructuring of skutterudites introduces significant changes to their phase transition behavior. When skutterudites are reduced to nanoscale dimensions or incorporate nanoscale features, the phase transition temperatures and characteristics can be substantially modified. Nanostructured skutterudites often exhibit enhanced thermoelectric properties due to quantum confinement effects and increased phonon scattering at phase boundaries. These materials can demonstrate unique phase stability characteristics not observed in bulk materials, offering new opportunities for thermoelectric applications.Expand Specific Solutions05 Electronic and magnetic phase transitions

Skutterudites undergo electronic and magnetic phase transitions that significantly influence their functional properties. These transitions can involve changes in electronic band structure, magnetic ordering, or superconducting states. External stimuli such as temperature, pressure, or magnetic fields can trigger these phase transitions, allowing for tunable material properties. Understanding and controlling these electronic and magnetic phase transitions is crucial for developing skutterudite-based devices for sensing, computing, and energy applications.Expand Specific Solutions

Leading Research Groups and Industrial Stakeholders

The pressure-driven phase transitions in skutterudites represent an emerging field at the intersection of materials science and thermoelectric technology, currently in the early growth stage. The global thermoelectric materials market, valued at approximately $55 million, is projected to expand significantly as energy recovery applications gain traction. Research institutions like Shanghai Institute of Ceramics (CAS), Massachusetts Institute of Technology, and Wuhan University of Technology are leading fundamental research, while specialized companies such as TEGma AS (Norway) focus on commercialization of skutterudite-based thermoelectric materials. Industrial players including Samsung Electronics, Ford Motor Co., and BASF are exploring applications in automotive waste heat recovery and consumer electronics. The technology remains in early commercial development, with ongoing challenges in scaling production and optimizing performance under variable pressure conditions.

Shanghai Institute of Ceramics, Chinese Academy of Sciences

Technical Solution: Shanghai Institute of Ceramics has developed advanced high-pressure synthesis techniques for skutterudite thermoelectric materials, focusing on pressure-induced structural transformations to enhance ZT values. Their approach involves using specialized high-pressure apparatus capable of reaching 5-10 GPa while maintaining precise temperature control (600-900°C) to manipulate the crystal structure of filled skutterudites. Their research demonstrates that controlled pressure application during synthesis can significantly reduce lattice thermal conductivity by optimizing the "rattling" effect of filler atoms within the skutterudite cages. The institute has successfully achieved ZT values exceeding 1.5 in pressure-treated n-type skutterudites through the creation of nanoscale defects and enhanced phonon scattering mechanisms.

Strengths: Superior high-pressure synthesis equipment and expertise; comprehensive characterization capabilities; strong track record in optimizing thermoelectric performance. Weaknesses: High production costs; challenges in scaling pressure-based techniques to industrial production levels; energy-intensive manufacturing process.

University of Houston

Technical Solution: University of Houston has pioneered research on pressure-modulated band structure engineering in skutterudite materials. Their approach utilizes hydrostatic pressure techniques to systematically modify electronic properties and phonon transport characteristics. The research team has developed a specialized pressure cell system that can apply controlled pressure up to 8 GPa while simultaneously measuring thermoelectric properties in-situ. This unique capability allows for real-time observation of phase transitions and their immediate impact on Seebeck coefficient, electrical conductivity, and thermal transport. Their studies have revealed critical pressure thresholds (typically 2-4 GPa) where skutterudites undergo electronic topological transitions that dramatically enhance power factor while maintaining low thermal conductivity, resulting in ZT improvements of 30-40% compared to ambient pressure materials.

Strengths: World-class in-situ measurement capabilities under pressure; strong theoretical modeling to predict pressure effects; excellent publication record in high-impact journals. Weaknesses: Focus primarily on fundamental research rather than applications; limited industrial partnerships for commercialization; equipment-intensive research approach.

Key Scientific Breakthroughs in Skutterudite Phase Engineering

Thermoelectric material used for manufacture of thermoelectric device e.g. thermoelectric power generator, comprises filled skutterudite crystal structure

PatentInactiveDE102010018575A1

Innovation

- Development of multi-element filled skutterudite thermoelectric materials with rare earth and alkaline earth elements, along with different phonon resonance frequencies, reduces lattice thermal conductivity, enhancing the thermoelectric figure of merit (ZT) to values up to 2.0 at 800K.

Thermoelectric material including a filled skutterudite crystal structure

PatentInactiveUS20100071741A1

Innovation

- The development of multiple element filled skutterudite crystal structures with rare earth and alkaline earth elements, which reduce lattice thermal conductivity by introducing guest atoms with different phonon resonance frequencies, thereby enhancing the thermoelectric figure of merit (ZT) beyond previous achievements.

Energy Efficiency and Sustainability Implications

The integration of pressure-driven phase transitions in skutterudites into energy systems represents a significant opportunity for enhancing energy efficiency across multiple sectors. These advanced thermoelectric materials can effectively convert waste heat into usable electricity, addressing one of the most persistent inefficiencies in industrial processes, transportation, and power generation where up to 60% of primary energy is lost as waste heat.

Skutterudites modified through pressure-induced phase transitions demonstrate improved figure of merit (ZT) values, potentially enabling thermoelectric generators with conversion efficiencies approaching 15-20%, compared to conventional systems operating at 5-8%. This efficiency improvement translates directly to reduced fossil fuel consumption and lower greenhouse gas emissions when implemented at scale.

From a sustainability perspective, the life cycle assessment of skutterudite-based thermoelectric systems shows promising environmental benefits. While traditional thermoelectric materials often contain toxic or rare elements like tellurium or lead, skutterudites primarily utilize more abundant elements such as cobalt, antimony, and various fillers that can be selected for environmental compatibility. The pressure-modification techniques further optimize performance without necessarily increasing reliance on critical raw materials.

Energy payback calculations indicate that pressure-modified skutterudite thermoelectric generators could recover their embodied energy within 1-3 years of operation in high-temperature waste heat recovery applications. This favorable energy return on investment strengthens their position as a sustainable technology option for industrial decarbonization strategies.

In automotive applications, these advanced thermoelectric generators could recover 5-10% of fuel energy from exhaust systems, potentially reducing fuel consumption by 3-5% in conventional vehicles. For the global transportation sector, this represents a significant pathway toward meeting emissions reduction targets while complementing electrification efforts.

The durability enhancements resulting from pressure-stabilized skutterudite phases also contribute to sustainability through extended operational lifetimes. Laboratory testing demonstrates that properly engineered pressure-modified skutterudites maintain performance for over 10,000 hours at operating temperatures, reducing replacement frequency and associated material consumption.

From a circular economy perspective, the relatively simple composition of skutterudites compared to other electronic components presents opportunities for end-of-life recycling and material recovery. Research indicates recovery rates exceeding 80% for the primary constituent elements are achievable using established hydrometallurgical processes, further enhancing the sustainability profile of these materials.

Skutterudites modified through pressure-induced phase transitions demonstrate improved figure of merit (ZT) values, potentially enabling thermoelectric generators with conversion efficiencies approaching 15-20%, compared to conventional systems operating at 5-8%. This efficiency improvement translates directly to reduced fossil fuel consumption and lower greenhouse gas emissions when implemented at scale.

From a sustainability perspective, the life cycle assessment of skutterudite-based thermoelectric systems shows promising environmental benefits. While traditional thermoelectric materials often contain toxic or rare elements like tellurium or lead, skutterudites primarily utilize more abundant elements such as cobalt, antimony, and various fillers that can be selected for environmental compatibility. The pressure-modification techniques further optimize performance without necessarily increasing reliance on critical raw materials.

Energy payback calculations indicate that pressure-modified skutterudite thermoelectric generators could recover their embodied energy within 1-3 years of operation in high-temperature waste heat recovery applications. This favorable energy return on investment strengthens their position as a sustainable technology option for industrial decarbonization strategies.

In automotive applications, these advanced thermoelectric generators could recover 5-10% of fuel energy from exhaust systems, potentially reducing fuel consumption by 3-5% in conventional vehicles. For the global transportation sector, this represents a significant pathway toward meeting emissions reduction targets while complementing electrification efforts.

The durability enhancements resulting from pressure-stabilized skutterudite phases also contribute to sustainability through extended operational lifetimes. Laboratory testing demonstrates that properly engineered pressure-modified skutterudites maintain performance for over 10,000 hours at operating temperatures, reducing replacement frequency and associated material consumption.

From a circular economy perspective, the relatively simple composition of skutterudites compared to other electronic components presents opportunities for end-of-life recycling and material recovery. Research indicates recovery rates exceeding 80% for the primary constituent elements are achievable using established hydrometallurgical processes, further enhancing the sustainability profile of these materials.

Scalability and Commercial Manufacturing Considerations

The scalability of pressure-driven phase transitions in skutterudites presents significant challenges for commercial manufacturing. Current laboratory-scale high-pressure synthesis methods, including diamond anvil cells and large-volume presses, are effective for research but face substantial barriers when considered for industrial production. These methods typically yield small sample volumes (milligrams to grams) and require specialized equipment with high capital costs, limiting their economic viability for mass production.

Manufacturing skutterudites with optimized thermoelectric properties through pressure-induced phase transitions requires precise pressure control across large material volumes. This technical challenge becomes increasingly difficult as production scales increase, potentially leading to inhomogeneous material properties and inconsistent thermoelectric performance. The pressure chambers and anvils used in high-pressure synthesis also experience significant wear, necessitating frequent replacement and increasing operational costs.

Energy consumption represents another critical consideration for commercial viability. High-pressure synthesis typically requires substantial energy input to maintain pressure and temperature conditions, directly impacting production costs and environmental footprint. Manufacturers must evaluate these energy requirements against the potential efficiency gains in thermoelectric performance to determine economic feasibility.

Alternative manufacturing approaches are emerging to address these scalability challenges. These include chemical pressure methods that utilize dopants to simulate physical pressure effects, and rapid quenching techniques that can preserve high-pressure phases under ambient conditions. Such methods potentially offer more cost-effective routes to commercial production while maintaining the enhanced thermoelectric properties observed in pressure-treated skutterudites.

Equipment standardization and process automation represent additional pathways toward commercial viability. Current high-pressure synthesis often relies on custom-built equipment and manual operation, creating barriers to consistent quality and production scaling. Developing standardized pressure vessels and automated pressure-temperature control systems could significantly improve manufacturing efficiency and product consistency.

Supply chain considerations also impact commercial manufacturing potential. The raw materials for skutterudites include cobalt, antimony, and various filling elements (rare earths, alkaline earths), some of which face supply constraints or price volatility. Manufacturers must secure stable supply chains and potentially develop material recycling processes to ensure long-term production viability.

Ultimately, the path to commercial manufacturing of pressure-optimized skutterudite thermoelectrics will likely require hybrid approaches combining selective high-pressure processing for critical components with more conventional manufacturing methods for bulk production. This balanced approach could maximize thermoelectric performance while maintaining economic feasibility for large-scale applications.

Manufacturing skutterudites with optimized thermoelectric properties through pressure-induced phase transitions requires precise pressure control across large material volumes. This technical challenge becomes increasingly difficult as production scales increase, potentially leading to inhomogeneous material properties and inconsistent thermoelectric performance. The pressure chambers and anvils used in high-pressure synthesis also experience significant wear, necessitating frequent replacement and increasing operational costs.

Energy consumption represents another critical consideration for commercial viability. High-pressure synthesis typically requires substantial energy input to maintain pressure and temperature conditions, directly impacting production costs and environmental footprint. Manufacturers must evaluate these energy requirements against the potential efficiency gains in thermoelectric performance to determine economic feasibility.

Alternative manufacturing approaches are emerging to address these scalability challenges. These include chemical pressure methods that utilize dopants to simulate physical pressure effects, and rapid quenching techniques that can preserve high-pressure phases under ambient conditions. Such methods potentially offer more cost-effective routes to commercial production while maintaining the enhanced thermoelectric properties observed in pressure-treated skutterudites.

Equipment standardization and process automation represent additional pathways toward commercial viability. Current high-pressure synthesis often relies on custom-built equipment and manual operation, creating barriers to consistent quality and production scaling. Developing standardized pressure vessels and automated pressure-temperature control systems could significantly improve manufacturing efficiency and product consistency.

Supply chain considerations also impact commercial manufacturing potential. The raw materials for skutterudites include cobalt, antimony, and various filling elements (rare earths, alkaline earths), some of which face supply constraints or price volatility. Manufacturers must secure stable supply chains and potentially develop material recycling processes to ensure long-term production viability.

Ultimately, the path to commercial manufacturing of pressure-optimized skutterudite thermoelectrics will likely require hybrid approaches combining selective high-pressure processing for critical components with more conventional manufacturing methods for bulk production. This balanced approach could maximize thermoelectric performance while maintaining economic feasibility for large-scale applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!