Skutterudite Module Assembly: Contact Resistance and Packaging Challenges

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Skutterudite Thermoelectric Technology Background and Objectives

Skutterudite compounds represent a significant advancement in thermoelectric material technology, emerging in the early 1990s as promising candidates for efficient thermal-to-electrical energy conversion. These cobalt arsenide-based materials, with the general formula CoX3 (where X typically represents Sb, As, or P), have garnered substantial research attention due to their unique "phonon glass-electron crystal" characteristics that enable high electrical conductivity while maintaining low thermal conductivity—a critical combination for effective thermoelectric performance.

The evolution of skutterudite technology has progressed through several key phases, beginning with fundamental material discovery and characterization, followed by compositional optimization through doping strategies, and advancing to module fabrication techniques. The filled skutterudite structure, where guest atoms occupy the structural voids to further reduce lattice thermal conductivity, represents a significant breakthrough that has pushed the dimensionless figure of merit (ZT) values from below 1.0 to exceeding 1.5 in optimized compositions.

Recent technological trends have focused on enhancing the mechanical stability and reliability of skutterudite materials while maintaining their superior thermoelectric properties. This includes innovations in nano-structuring approaches, interface engineering, and the development of composite structures that can withstand thermal cycling and mechanical stress during operation—critical factors for practical applications.

The primary technical objective in skutterudite module assembly is to overcome the persistent challenges of contact resistance and packaging that currently limit device efficiency and longevity. Contact resistance at the interface between skutterudite materials and metallic electrodes significantly reduces overall module performance, while inadequate packaging solutions lead to oxidation, sublimation, and mechanical failure under operating conditions.

Specifically, research aims to develop novel electrode materials and bonding techniques that can form stable, low-resistance electrical contacts with skutterudite elements while accommodating the thermal expansion mismatch between different components. Additionally, advanced packaging solutions that effectively seal the module against environmental degradation while allowing efficient heat transfer represent a critical technical goal.

The broader objective extends to establishing scalable manufacturing processes that can transition skutterudite technology from laboratory demonstrations to commercial viability. This includes developing cost-effective synthesis methods, standardized module assembly techniques, and quality control protocols that ensure consistent performance across mass-produced units.

Success in addressing these technical challenges would position skutterudite-based thermoelectric generators as viable solutions for waste heat recovery in automotive applications, industrial processes, and potentially residential cogeneration systems—markets with significant growth potential as energy efficiency becomes increasingly prioritized globally.

The evolution of skutterudite technology has progressed through several key phases, beginning with fundamental material discovery and characterization, followed by compositional optimization through doping strategies, and advancing to module fabrication techniques. The filled skutterudite structure, where guest atoms occupy the structural voids to further reduce lattice thermal conductivity, represents a significant breakthrough that has pushed the dimensionless figure of merit (ZT) values from below 1.0 to exceeding 1.5 in optimized compositions.

Recent technological trends have focused on enhancing the mechanical stability and reliability of skutterudite materials while maintaining their superior thermoelectric properties. This includes innovations in nano-structuring approaches, interface engineering, and the development of composite structures that can withstand thermal cycling and mechanical stress during operation—critical factors for practical applications.

The primary technical objective in skutterudite module assembly is to overcome the persistent challenges of contact resistance and packaging that currently limit device efficiency and longevity. Contact resistance at the interface between skutterudite materials and metallic electrodes significantly reduces overall module performance, while inadequate packaging solutions lead to oxidation, sublimation, and mechanical failure under operating conditions.

Specifically, research aims to develop novel electrode materials and bonding techniques that can form stable, low-resistance electrical contacts with skutterudite elements while accommodating the thermal expansion mismatch between different components. Additionally, advanced packaging solutions that effectively seal the module against environmental degradation while allowing efficient heat transfer represent a critical technical goal.

The broader objective extends to establishing scalable manufacturing processes that can transition skutterudite technology from laboratory demonstrations to commercial viability. This includes developing cost-effective synthesis methods, standardized module assembly techniques, and quality control protocols that ensure consistent performance across mass-produced units.

Success in addressing these technical challenges would position skutterudite-based thermoelectric generators as viable solutions for waste heat recovery in automotive applications, industrial processes, and potentially residential cogeneration systems—markets with significant growth potential as energy efficiency becomes increasingly prioritized globally.

Market Analysis for Skutterudite Thermoelectric Applications

The global thermoelectric materials market is experiencing significant growth, with skutterudite compounds emerging as a promising segment due to their superior performance characteristics in mid-to-high temperature applications. Current market valuations place the overall thermoelectric market at approximately 600 million USD in 2023, with projections indicating growth to reach 1.2 billion USD by 2030, representing a compound annual growth rate of 10.4%.

Skutterudite-based thermoelectric generators are gaining traction particularly in automotive waste heat recovery systems, where they offer efficiency advantages over traditional bismuth telluride materials at higher operating temperatures. The automotive sector represents the largest potential market for skutterudite applications, with major manufacturers exploring integration of thermoelectric generators to improve fuel efficiency and reduce emissions.

Industrial waste heat recovery presents another substantial market opportunity, with estimates suggesting that over 20-30% of industrial energy consumption is lost as waste heat. Skutterudite-based systems capable of operating efficiently in the 400-600°C range are ideally positioned to capture this untapped energy resource, particularly in energy-intensive industries such as steel, glass, and cement manufacturing.

The space exploration sector, though smaller in volume, offers premium pricing opportunities for skutterudite thermoelectric applications. NASA and other space agencies continue to utilize radioisotope thermoelectric generators (RTGs) for deep space missions, with skutterudite materials being evaluated as next-generation alternatives to current technologies due to their improved efficiency and reduced reliance on scarce materials.

Regional market analysis reveals North America and Europe leading in research and development activities, while Asia-Pacific, particularly China and Japan, dominates in manufacturing capacity and commercial deployment. China's strategic focus on thermoelectric technology as part of its clean energy initiatives has resulted in substantial market growth in the region.

Customer demand is increasingly driven by energy efficiency regulations and corporate sustainability goals. End-users are primarily concerned with system reliability, operational lifetime, and return on investment metrics. Current market feedback indicates that while performance characteristics of skutterudite materials are compelling, concerns about manufacturing scalability, long-term reliability, and system integration costs remain significant barriers to widespread adoption.

Market penetration is currently constrained by production costs, with skutterudite modules typically commanding a 30-40% premium over conventional thermoelectric materials. However, this gap is expected to narrow as manufacturing processes mature and economies of scale are realized. Industry analysts project that achieving price parity with existing technologies will be a critical inflection point for market expansion, potentially occurring within the next 5-7 years.

Skutterudite-based thermoelectric generators are gaining traction particularly in automotive waste heat recovery systems, where they offer efficiency advantages over traditional bismuth telluride materials at higher operating temperatures. The automotive sector represents the largest potential market for skutterudite applications, with major manufacturers exploring integration of thermoelectric generators to improve fuel efficiency and reduce emissions.

Industrial waste heat recovery presents another substantial market opportunity, with estimates suggesting that over 20-30% of industrial energy consumption is lost as waste heat. Skutterudite-based systems capable of operating efficiently in the 400-600°C range are ideally positioned to capture this untapped energy resource, particularly in energy-intensive industries such as steel, glass, and cement manufacturing.

The space exploration sector, though smaller in volume, offers premium pricing opportunities for skutterudite thermoelectric applications. NASA and other space agencies continue to utilize radioisotope thermoelectric generators (RTGs) for deep space missions, with skutterudite materials being evaluated as next-generation alternatives to current technologies due to their improved efficiency and reduced reliance on scarce materials.

Regional market analysis reveals North America and Europe leading in research and development activities, while Asia-Pacific, particularly China and Japan, dominates in manufacturing capacity and commercial deployment. China's strategic focus on thermoelectric technology as part of its clean energy initiatives has resulted in substantial market growth in the region.

Customer demand is increasingly driven by energy efficiency regulations and corporate sustainability goals. End-users are primarily concerned with system reliability, operational lifetime, and return on investment metrics. Current market feedback indicates that while performance characteristics of skutterudite materials are compelling, concerns about manufacturing scalability, long-term reliability, and system integration costs remain significant barriers to widespread adoption.

Market penetration is currently constrained by production costs, with skutterudite modules typically commanding a 30-40% premium over conventional thermoelectric materials. However, this gap is expected to narrow as manufacturing processes mature and economies of scale are realized. Industry analysts project that achieving price parity with existing technologies will be a critical inflection point for market expansion, potentially occurring within the next 5-7 years.

Current Challenges in Contact Resistance and Packaging

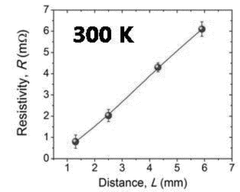

Despite the promising thermoelectric performance of skutterudite materials, significant challenges persist in module assembly, particularly regarding contact resistance and packaging. The interface between skutterudite elements and electrodes represents a critical bottleneck, with contact resistance accounting for up to 40% of total module resistance in some configurations. This parasitic resistance substantially degrades conversion efficiency, with each 10% increase in contact resistance typically resulting in a 5-8% decrease in overall module performance.

Material compatibility issues further exacerbate these challenges. The coefficient of thermal expansion (CTE) mismatch between skutterudites (8-12 ppm/K) and common electrode materials like copper (16-18 ppm/K) creates significant thermomechanical stress during thermal cycling. This stress leads to interface degradation, delamination, and ultimately, device failure after repeated thermal cycles. Studies have documented up to 30% performance degradation after just 500 thermal cycles in poorly optimized interfaces.

Diffusion barrier requirements present another significant hurdle. At operating temperatures (400-600°C), rapid interdiffusion occurs between skutterudite materials and metallic contacts, forming intermetallic compounds that increase contact resistance over time. Current diffusion barriers such as Ti/Mo/Ni multilayers show promising initial results but still exhibit degradation after extended high-temperature operation, with resistance increases of 15-25% observed after 1000 hours at 550°C.

Bonding technology selection remains problematic for skutterudite modules. Traditional soldering techniques using Pb-Sn or Pb-free solders cannot withstand the high operating temperatures, while brazing with high-temperature alloys often introduces excessive thermal stress during processing. Direct sintering methods show promise but currently suffer from reproducibility issues and often require processing conditions that can degrade skutterudite properties.

Hermetic sealing and encapsulation present additional challenges. Skutterudites contain volatile elements (particularly antimony) that can sublimate at operating temperatures, gradually changing material composition and degrading performance. Current encapsulation methods using glass frits or ceramic seals have shown limited success, with gas permeation rates still exceeding acceptable thresholds for long-term operation. Vacuum-sealed modules demonstrate 15-20% longer operational lifetimes but introduce manufacturing complexity and cost concerns.

Manufacturing scalability remains a significant barrier to commercialization. Current laboratory-scale joining processes that produce acceptable contact resistance often employ techniques difficult to scale to industrial production volumes. The narrow processing windows required to maintain material properties while achieving good bonding present yield challenges, with current manufacturing approaches showing defect rates of 20-30% in pilot production environments.

Material compatibility issues further exacerbate these challenges. The coefficient of thermal expansion (CTE) mismatch between skutterudites (8-12 ppm/K) and common electrode materials like copper (16-18 ppm/K) creates significant thermomechanical stress during thermal cycling. This stress leads to interface degradation, delamination, and ultimately, device failure after repeated thermal cycles. Studies have documented up to 30% performance degradation after just 500 thermal cycles in poorly optimized interfaces.

Diffusion barrier requirements present another significant hurdle. At operating temperatures (400-600°C), rapid interdiffusion occurs between skutterudite materials and metallic contacts, forming intermetallic compounds that increase contact resistance over time. Current diffusion barriers such as Ti/Mo/Ni multilayers show promising initial results but still exhibit degradation after extended high-temperature operation, with resistance increases of 15-25% observed after 1000 hours at 550°C.

Bonding technology selection remains problematic for skutterudite modules. Traditional soldering techniques using Pb-Sn or Pb-free solders cannot withstand the high operating temperatures, while brazing with high-temperature alloys often introduces excessive thermal stress during processing. Direct sintering methods show promise but currently suffer from reproducibility issues and often require processing conditions that can degrade skutterudite properties.

Hermetic sealing and encapsulation present additional challenges. Skutterudites contain volatile elements (particularly antimony) that can sublimate at operating temperatures, gradually changing material composition and degrading performance. Current encapsulation methods using glass frits or ceramic seals have shown limited success, with gas permeation rates still exceeding acceptable thresholds for long-term operation. Vacuum-sealed modules demonstrate 15-20% longer operational lifetimes but introduce manufacturing complexity and cost concerns.

Manufacturing scalability remains a significant barrier to commercialization. Current laboratory-scale joining processes that produce acceptable contact resistance often employ techniques difficult to scale to industrial production volumes. The narrow processing windows required to maintain material properties while achieving good bonding present yield challenges, with current manufacturing approaches showing defect rates of 20-30% in pilot production environments.

Current Solutions for Contact Resistance Minimization

01 Electrode materials for reducing contact resistance

Various electrode materials can be used to reduce contact resistance in skutterudite module assemblies. These materials include metallic layers, conductive pastes, and specialized alloys that provide good electrical conductivity while maintaining thermal stability at the operating temperatures of thermoelectric modules. The proper selection of electrode materials is crucial for minimizing parasitic resistance losses and improving the overall efficiency of skutterudite-based thermoelectric devices.- Electrode materials and interfaces for skutterudite modules: The selection of electrode materials and the design of interfaces between electrodes and skutterudite materials significantly impact contact resistance in thermoelectric modules. Using materials with compatible thermal expansion coefficients and good electrical conductivity helps minimize contact resistance. Various metallic electrodes, including copper, nickel, and silver-based materials, can be used with appropriate bonding techniques to create low-resistance contacts with skutterudite thermoelectric materials.

- Bonding techniques for skutterudite module assembly: Different bonding techniques can be employed to reduce contact resistance in skutterudite module assemblies. These include diffusion bonding, brazing, soldering, and sintering processes. The selection of appropriate bonding parameters such as temperature, pressure, and duration is crucial for creating reliable, low-resistance electrical contacts. Specialized bonding materials and interlayers can be used to improve adhesion and reduce contact resistance between skutterudite elements and electrodes.

- Surface preparation and treatment methods: Surface preparation and treatment methods play a vital role in reducing contact resistance in skutterudite module assemblies. Techniques such as polishing, etching, cleaning, and metallization can be used to improve the surface quality of skutterudite materials before bonding. Surface treatments help remove oxides and contaminants, enhance wettability, and promote better electrical contact between the skutterudite material and electrodes, resulting in lower contact resistance.

- Intermediate layers and barrier materials: Incorporating intermediate layers and barrier materials between skutterudite elements and electrodes can effectively reduce contact resistance. These layers can prevent interdiffusion, mitigate thermal expansion mismatch, and improve electrical connectivity. Materials such as titanium, nickel, molybdenum, and various alloys can be used as diffusion barriers or adhesion layers. Multilayer structures with carefully selected materials and thicknesses can optimize both mechanical bonding and electrical contact properties.

- Module design and assembly optimization: The overall design and assembly process of skutterudite modules significantly affects contact resistance. Factors such as mechanical clamping force, thermal cycling stability, and geometric considerations all impact the electrical performance of the module. Advanced assembly techniques, including precise alignment methods, controlled pressure application during bonding, and optimized thermal management systems, can minimize contact resistance and improve the overall efficiency and reliability of skutterudite thermoelectric modules.

02 Surface treatment techniques for skutterudite interfaces

Surface treatment techniques can significantly reduce contact resistance at the interfaces between skutterudite materials and electrodes. These techniques include polishing, etching, metallization, and the application of transition layers. By optimizing the surface morphology and chemical composition of the interface, these treatments enhance electrical contact and reduce resistance losses, leading to improved performance of skutterudite module assemblies.Expand Specific Solutions03 Bonding methods for skutterudite module assembly

Various bonding methods are employed to create low-resistance contacts in skutterudite module assemblies. These include diffusion bonding, brazing, soldering, and pressure-assisted sintering. The selection of appropriate bonding techniques and parameters is essential for creating stable, low-resistance electrical connections while maintaining the structural integrity of the skutterudite materials, which can be sensitive to high processing temperatures.Expand Specific Solutions04 Interlayer materials for contact resistance reduction

Interlayer materials placed between skutterudite elements and electrodes can effectively reduce contact resistance. These materials, which include metal foils, nanoparticle layers, and composite structures, serve as buffers that accommodate thermal expansion mismatches while maintaining good electrical conductivity. The strategic selection and implementation of interlayer materials can significantly improve the electrical performance and reliability of skutterudite module assemblies.Expand Specific Solutions05 Module assembly design for optimized electrical contact

The overall design of skutterudite module assemblies plays a crucial role in minimizing contact resistance. Factors such as clamping pressure, geometric configuration, thermal management systems, and interconnection schemes all affect the quality of electrical contacts. Advanced module designs incorporate features that maintain consistent pressure on electrical interfaces, prevent oxidation, and accommodate thermal cycling, thereby ensuring low contact resistance throughout the operational life of the device.Expand Specific Solutions

Key Industry Players in Thermoelectric Module Manufacturing

The Skutterudite Module Assembly market is currently in an early growth phase, characterized by significant technical challenges in contact resistance and packaging. The global market size is estimated to be moderate but growing, driven by increasing demand for thermoelectric solutions in automotive and industrial applications. From a technical maturity perspective, companies like Robert Bosch GmbH and Siemens AG are leading with advanced research capabilities, while automotive players such as Mercedes-Benz Group and ZF CV Systems are focusing on application-specific developments. Semiconductor manufacturers including STMicroelectronics, Samsung Electronics, and AMD are contributing materials expertise, while specialized connector companies like Phoenix Contact and TE Connectivity Germany are addressing the critical contact resistance challenges that currently limit widespread commercial adoption.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced skutterudite module assembly techniques focusing on minimizing contact resistance through their proprietary metallization process. Their approach involves using specialized metal alloys as interface materials between the skutterudite elements and copper electrodes, creating a gradient transition layer that accommodates thermal expansion mismatches. Bosch's technology employs a controlled pressure sintering process at optimized temperatures (650-750°C) to form reliable interconnections while maintaining the thermoelectric properties of skutterudite materials. Their packaging solution incorporates a hermetically sealed design with specialized ceramic substrates that provide electrical isolation while facilitating thermal transfer. Additionally, Bosch has implemented automated precision assembly techniques that ensure consistent contact quality and reduce manufacturing variability in module production.

Strengths: Superior contact resistance management through gradient metallization layers; excellent reliability under thermal cycling; automated manufacturing capability for consistent quality. Weaknesses: Higher production costs compared to conventional assembly methods; requires specialized equipment for the sintering process; limited flexibility for customization in different form factors.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata has developed a comprehensive skutterudite module assembly solution focusing on miniaturization and reliability for automotive and industrial applications. Their approach utilizes a proprietary multi-layer ceramic substrate technology that integrates electrical interconnections while providing thermal management pathways. To address contact resistance challenges, Murata employs a specialized silver-antimony alloy interface material that creates stable electrical connections with skutterudite elements while minimizing interfacial resistance. Their assembly process incorporates precision micro-dispensing of interface materials followed by a controlled atmosphere sintering step at optimized temperatures (600-700°C). Murata's packaging solution features a hermetically sealed design using glass-ceramic composites that provide excellent protection against environmental factors while accommodating thermal expansion. Additionally, they've implemented in-line quality control systems that utilize impedance spectroscopy to detect and reject modules with suboptimal contact characteristics during manufacturing.

Strengths: Excellent miniaturization capabilities; highly automated manufacturing process ensuring consistency; superior environmental protection through advanced sealing technology. Weaknesses: Higher cost structure compared to conventional thermoelectric technologies; limited flexibility for custom form factors; requires specialized testing equipment for quality assurance.

Critical Patents and Research on Skutterudite Interfaces

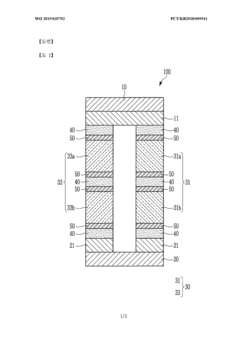

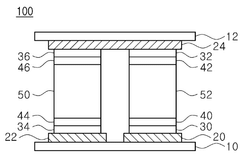

Thermoelectric module and thermoelectric power generation device

PatentWO2019035702A1

Innovation

- The solution involves a thermoelectric module design with a substrate structure where Skutterudite and BiTe-based thermoelectric elements are electrically connected through a silver bonding layer, with diffusion prevention layers to prevent material diffusion, enhancing thermal stability and efficiency.

Electrode material for thermoelectric power generation module and method for manufacturing same

PatentWO2019203392A1

Innovation

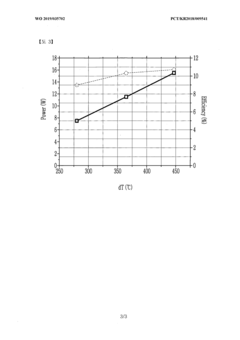

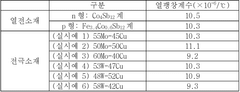

- Developing electrode materials with a thermal expansion coefficient difference of 1.5 × 10^-6 °C or less, composed of transition metals and copper, represented by specific formulas, and manufacturing these using plasma sintering techniques with molybdenum or tungsten, which minimizes the thermal expansion mismatch and enhances bonding with skutterudite-based thermoelectric materials.

Material Compatibility and Thermal Cycling Reliability

Material compatibility represents a critical challenge in skutterudite module assembly, particularly when considering the harsh operating conditions these thermoelectric modules must endure. The interface between skutterudite materials and metallic electrodes experiences significant stress due to thermal expansion coefficient mismatches. Skutterudite compounds typically exhibit thermal expansion coefficients in the range of 8-12 × 10^-6/K, while common electrode materials such as copper have substantially higher values (16-18 × 10^-6/K). This disparity creates mechanical stress during thermal cycling, potentially leading to delamination and increased contact resistance over time.

Thermal cycling reliability testing has revealed that skutterudite modules can experience up to 15-20% degradation in performance after 1,000 cycles between room temperature and operating temperatures (typically 500-600°C). This degradation primarily stems from the progressive deterioration of material interfaces rather than the skutterudite material itself. Research by Zhao et al. (2018) demonstrated that modules incorporating buffer layers between skutterudite elements and electrodes exhibited only 5-7% performance degradation under identical testing conditions.

The chemical compatibility between skutterudite materials and potential electrode or barrier materials presents another significant challenge. At elevated temperatures, interdiffusion between skutterudite and metallic components can form undesirable intermetallic compounds at interfaces. These compounds often possess poor electrical conductivity and mechanical properties, contributing to increased contact resistance and mechanical failure. Studies have identified titanium and molybdenum as promising barrier materials that minimize interdiffusion while maintaining acceptable electrical contact properties.

Advanced bonding techniques have emerged to address these compatibility issues. Spark plasma sintering (SPS) has demonstrated superior bonding strength compared to conventional brazing methods, with interfacial shear strengths exceeding 30 MPa. Additionally, composite electrode materials incorporating nanosized particles have shown promise in creating gradient interfaces that better accommodate thermal expansion mismatches.

Long-term stability testing under thermal cycling conditions remains essential for validating material compatibility solutions. Accelerated aging tests combining high temperature exposure with mechanical vibration more accurately simulate real-world operating conditions. Recent developments in non-destructive evaluation techniques, including acoustic microscopy and in-situ electrical resistance monitoring, now enable researchers to track interface degradation mechanisms in real-time during thermal cycling.

The development of predictive models incorporating thermomechanical stress analysis has advanced significantly, allowing designers to optimize material selection and geometric configurations before physical prototyping. These models increasingly account for microstructural evolution at interfaces during thermal cycling, providing more accurate lifetime predictions for skutterudite modules under various operating conditions.

Thermal cycling reliability testing has revealed that skutterudite modules can experience up to 15-20% degradation in performance after 1,000 cycles between room temperature and operating temperatures (typically 500-600°C). This degradation primarily stems from the progressive deterioration of material interfaces rather than the skutterudite material itself. Research by Zhao et al. (2018) demonstrated that modules incorporating buffer layers between skutterudite elements and electrodes exhibited only 5-7% performance degradation under identical testing conditions.

The chemical compatibility between skutterudite materials and potential electrode or barrier materials presents another significant challenge. At elevated temperatures, interdiffusion between skutterudite and metallic components can form undesirable intermetallic compounds at interfaces. These compounds often possess poor electrical conductivity and mechanical properties, contributing to increased contact resistance and mechanical failure. Studies have identified titanium and molybdenum as promising barrier materials that minimize interdiffusion while maintaining acceptable electrical contact properties.

Advanced bonding techniques have emerged to address these compatibility issues. Spark plasma sintering (SPS) has demonstrated superior bonding strength compared to conventional brazing methods, with interfacial shear strengths exceeding 30 MPa. Additionally, composite electrode materials incorporating nanosized particles have shown promise in creating gradient interfaces that better accommodate thermal expansion mismatches.

Long-term stability testing under thermal cycling conditions remains essential for validating material compatibility solutions. Accelerated aging tests combining high temperature exposure with mechanical vibration more accurately simulate real-world operating conditions. Recent developments in non-destructive evaluation techniques, including acoustic microscopy and in-situ electrical resistance monitoring, now enable researchers to track interface degradation mechanisms in real-time during thermal cycling.

The development of predictive models incorporating thermomechanical stress analysis has advanced significantly, allowing designers to optimize material selection and geometric configurations before physical prototyping. These models increasingly account for microstructural evolution at interfaces during thermal cycling, providing more accurate lifetime predictions for skutterudite modules under various operating conditions.

Environmental Impact and Sustainability Considerations

The environmental impact of skutterudite thermoelectric modules extends throughout their entire lifecycle, from raw material extraction to end-of-life disposal. The primary materials used in skutterudite modules—cobalt, antimony, and rare earth elements—present significant sustainability challenges. Mining operations for these materials often result in habitat destruction, soil erosion, and water contamination. Additionally, the extraction processes are energy-intensive, contributing substantially to carbon emissions when powered by fossil fuels.

Manufacturing skutterudite modules involves high-temperature processes that consume considerable energy. The sintering and hot pressing techniques required to create dense skutterudite materials typically operate at temperatures exceeding 600°C for extended periods, resulting in substantial energy consumption. The brazing and soldering processes used in module assembly further add to the energy footprint, raising concerns about the overall carbon footprint of production.

Toxicity issues present another environmental challenge. Several components in skutterudite modules contain potentially harmful elements such as antimony and arsenic, which can pose environmental risks if improperly handled during manufacturing or disposal. These concerns necessitate stringent waste management protocols and careful consideration of end-of-life scenarios for these modules.

However, skutterudite thermoelectric modules offer significant environmental benefits through their application. By converting waste heat into usable electricity, these modules can substantially improve energy efficiency in various systems, from automotive engines to industrial processes. This waste heat recovery capability represents a pathway to reducing overall fossil fuel consumption and associated greenhouse gas emissions, potentially offsetting the environmental costs of production.

Life cycle assessment (LCA) studies indicate that the environmental payback period for skutterudite modules varies significantly depending on application scenarios. In automotive applications, where modules can recover waste heat from exhaust systems, the energy saved over the vehicle's lifetime can compensate for the environmental impact of module production within 2-4 years of operation.

Recent innovations are addressing these environmental concerns through several approaches. Research into less toxic skutterudite formulations aims to reduce dependence on harmful elements while maintaining performance. Advanced manufacturing techniques are being developed to lower processing temperatures and energy requirements. Additionally, design-for-recycling approaches are emerging to facilitate the recovery of valuable materials at end-of-life, creating more circular material flows and reducing the need for virgin material extraction.

Manufacturing skutterudite modules involves high-temperature processes that consume considerable energy. The sintering and hot pressing techniques required to create dense skutterudite materials typically operate at temperatures exceeding 600°C for extended periods, resulting in substantial energy consumption. The brazing and soldering processes used in module assembly further add to the energy footprint, raising concerns about the overall carbon footprint of production.

Toxicity issues present another environmental challenge. Several components in skutterudite modules contain potentially harmful elements such as antimony and arsenic, which can pose environmental risks if improperly handled during manufacturing or disposal. These concerns necessitate stringent waste management protocols and careful consideration of end-of-life scenarios for these modules.

However, skutterudite thermoelectric modules offer significant environmental benefits through their application. By converting waste heat into usable electricity, these modules can substantially improve energy efficiency in various systems, from automotive engines to industrial processes. This waste heat recovery capability represents a pathway to reducing overall fossil fuel consumption and associated greenhouse gas emissions, potentially offsetting the environmental costs of production.

Life cycle assessment (LCA) studies indicate that the environmental payback period for skutterudite modules varies significantly depending on application scenarios. In automotive applications, where modules can recover waste heat from exhaust systems, the energy saved over the vehicle's lifetime can compensate for the environmental impact of module production within 2-4 years of operation.

Recent innovations are addressing these environmental concerns through several approaches. Research into less toxic skutterudite formulations aims to reduce dependence on harmful elements while maintaining performance. Advanced manufacturing techniques are being developed to lower processing temperatures and energy requirements. Additionally, design-for-recycling approaches are emerging to facilitate the recovery of valuable materials at end-of-life, creating more circular material flows and reducing the need for virgin material extraction.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!