How to Incorporate Nanoinclusions for Enhanced Electron–Phonon Decoupling

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanoinclusion Technology Background and Objectives

Nanoinclusion technology represents a significant advancement in materials science, particularly in the field of thermoelectric materials. The concept emerged in the early 2000s when researchers discovered that incorporating nanoscale inclusions into bulk materials could dramatically alter their thermal and electrical properties. This approach has evolved from simple particle dispersion to sophisticated engineered nanostructures designed to selectively scatter phonons while minimally affecting electron transport.

The evolution of nanoinclusion technology has been marked by several key developments. Initially, researchers focused on randomly distributed nanoparticles, but recent advances have shifted toward precisely controlled nanoinclusion architectures. These developments have been driven by improved fabrication techniques, including chemical synthesis methods, physical vapor deposition, and advanced lithography processes that enable nanometer-scale precision in material design.

Current technological trends indicate a growing interest in hierarchical nanoinclusions that operate across multiple length scales, as well as dynamic nanoinclusions whose properties can be tuned in response to external stimuli. These innovations represent the cutting edge of the field and offer promising avenues for further development.

The primary objective of nanoinclusion technology in the context of electron-phonon decoupling is to create materials with the seemingly contradictory properties of high electrical conductivity and low thermal conductivity. This decoupling is crucial for applications such as thermoelectric energy conversion, where the efficiency is directly proportional to the ratio of electrical to thermal conductivity.

Specifically, the technical goals include developing nanoinclusion strategies that can reduce lattice thermal conductivity by at least 50% while maintaining or even enhancing electrical conductivity. This requires precise control over nanoinclusion size, distribution, composition, and interface characteristics to selectively scatter phonons (heat carriers) while allowing electrons to flow freely.

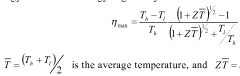

Additional objectives include enhancing the stability of nanoinclusions at elevated temperatures, ensuring compatibility with large-scale manufacturing processes, and developing predictive models that can guide the design of optimal nanoinclusion architectures for specific applications. The ultimate aim is to achieve a ZT (figure of merit for thermoelectric materials) value exceeding 2.5, which would represent a significant improvement over current state-of-the-art materials and potentially enable widespread adoption of thermoelectric technology for waste heat recovery and solid-state cooling applications.

The evolution of nanoinclusion technology has been marked by several key developments. Initially, researchers focused on randomly distributed nanoparticles, but recent advances have shifted toward precisely controlled nanoinclusion architectures. These developments have been driven by improved fabrication techniques, including chemical synthesis methods, physical vapor deposition, and advanced lithography processes that enable nanometer-scale precision in material design.

Current technological trends indicate a growing interest in hierarchical nanoinclusions that operate across multiple length scales, as well as dynamic nanoinclusions whose properties can be tuned in response to external stimuli. These innovations represent the cutting edge of the field and offer promising avenues for further development.

The primary objective of nanoinclusion technology in the context of electron-phonon decoupling is to create materials with the seemingly contradictory properties of high electrical conductivity and low thermal conductivity. This decoupling is crucial for applications such as thermoelectric energy conversion, where the efficiency is directly proportional to the ratio of electrical to thermal conductivity.

Specifically, the technical goals include developing nanoinclusion strategies that can reduce lattice thermal conductivity by at least 50% while maintaining or even enhancing electrical conductivity. This requires precise control over nanoinclusion size, distribution, composition, and interface characteristics to selectively scatter phonons (heat carriers) while allowing electrons to flow freely.

Additional objectives include enhancing the stability of nanoinclusions at elevated temperatures, ensuring compatibility with large-scale manufacturing processes, and developing predictive models that can guide the design of optimal nanoinclusion architectures for specific applications. The ultimate aim is to achieve a ZT (figure of merit for thermoelectric materials) value exceeding 2.5, which would represent a significant improvement over current state-of-the-art materials and potentially enable widespread adoption of thermoelectric technology for waste heat recovery and solid-state cooling applications.

Market Applications for Electron-Phonon Decoupling Materials

The market for electron-phonon decoupling materials is experiencing significant growth driven by the increasing demand for high-efficiency thermoelectric devices and thermal management solutions. These materials, enhanced with nanoinclusions, offer unprecedented capabilities in converting waste heat into usable electricity, making them highly valuable across multiple industries.

In the automotive sector, electron-phonon decoupling materials are revolutionizing waste heat recovery systems. Major manufacturers are integrating these materials into exhaust systems to capture thermal energy that would otherwise be lost, improving fuel efficiency by up to 5% in conventional vehicles and extending the range of electric vehicles through more efficient battery thermal management.

The consumer electronics industry represents another substantial market opportunity. As devices become more powerful and compact, thermal management challenges intensify. Nanoinclusion-enhanced materials provide superior heat dissipation while maintaining electrical conductivity, addressing the critical need for components that can operate at higher power densities without thermal degradation.

Renewable energy systems benefit significantly from these advanced materials. In solar photovoltaic applications, electron-phonon decoupling materials improve conversion efficiency by managing heat more effectively. Similarly, in concentrated solar power systems, these materials enhance energy capture and storage capabilities, contributing to overall system efficiency improvements.

The aerospace industry has identified these materials as critical for next-generation thermal protection systems and power generation in spacecraft. The ability to maintain electrical functionality while managing extreme temperature gradients makes them ideal for satellite components and deep space exploration vehicles.

Industrial manufacturing processes that generate substantial waste heat represent another promising application area. Integration of electron-phonon decoupling materials into industrial equipment can recover energy that would otherwise be lost, reducing operational costs and environmental impact while improving energy efficiency metrics.

The medical device sector is exploring applications in implantable electronics and diagnostic equipment. The materials' ability to manage heat while maintaining electrical performance addresses key challenges in developing smaller, more powerful medical devices with longer operational lifespans.

Data centers, which consume approximately 1% of global electricity and face significant cooling challenges, represent a growing market for these materials. Implementation in server components and cooling systems could substantially reduce energy consumption while enabling higher computing densities.

As environmental regulations become more stringent worldwide, the market for energy-efficient technologies incorporating electron-phonon decoupling materials is projected to expand substantially, with particular growth in regions with aggressive carbon reduction targets and high energy costs.

In the automotive sector, electron-phonon decoupling materials are revolutionizing waste heat recovery systems. Major manufacturers are integrating these materials into exhaust systems to capture thermal energy that would otherwise be lost, improving fuel efficiency by up to 5% in conventional vehicles and extending the range of electric vehicles through more efficient battery thermal management.

The consumer electronics industry represents another substantial market opportunity. As devices become more powerful and compact, thermal management challenges intensify. Nanoinclusion-enhanced materials provide superior heat dissipation while maintaining electrical conductivity, addressing the critical need for components that can operate at higher power densities without thermal degradation.

Renewable energy systems benefit significantly from these advanced materials. In solar photovoltaic applications, electron-phonon decoupling materials improve conversion efficiency by managing heat more effectively. Similarly, in concentrated solar power systems, these materials enhance energy capture and storage capabilities, contributing to overall system efficiency improvements.

The aerospace industry has identified these materials as critical for next-generation thermal protection systems and power generation in spacecraft. The ability to maintain electrical functionality while managing extreme temperature gradients makes them ideal for satellite components and deep space exploration vehicles.

Industrial manufacturing processes that generate substantial waste heat represent another promising application area. Integration of electron-phonon decoupling materials into industrial equipment can recover energy that would otherwise be lost, reducing operational costs and environmental impact while improving energy efficiency metrics.

The medical device sector is exploring applications in implantable electronics and diagnostic equipment. The materials' ability to manage heat while maintaining electrical performance addresses key challenges in developing smaller, more powerful medical devices with longer operational lifespans.

Data centers, which consume approximately 1% of global electricity and face significant cooling challenges, represent a growing market for these materials. Implementation in server components and cooling systems could substantially reduce energy consumption while enabling higher computing densities.

As environmental regulations become more stringent worldwide, the market for energy-efficient technologies incorporating electron-phonon decoupling materials is projected to expand substantially, with particular growth in regions with aggressive carbon reduction targets and high energy costs.

Current Challenges in Nanoinclusion Implementation

Despite the promising potential of nanoinclusions for enhancing electron-phonon decoupling in thermoelectric materials, several significant challenges impede their widespread implementation. One of the primary obstacles is achieving precise control over nanoinclusion size, distribution, and morphology during material synthesis. Current fabrication methods often result in heterogeneous distributions, with nanoinclusions varying in size from a few nanometers to several hundred nanometers, leading to inconsistent performance across the material matrix.

The interface quality between nanoinclusions and the host matrix presents another critical challenge. Poor interfacial bonding can create undesired electron scattering centers that diminish electrical conductivity more severely than they reduce thermal conductivity, resulting in an overall decrease in the thermoelectric figure of merit (ZT). Researchers have observed that even nanometer-scale defects at these interfaces can significantly compromise performance gains.

Stability issues also plague nanoinclusion implementation, particularly at elevated operating temperatures typical for thermoelectric applications. Many promising nanoinclusion materials undergo coarsening, diffusion, or chemical reactions with the host matrix during extended operation, gradually eliminating the nanostructured features responsible for phonon scattering. This degradation mechanism severely limits device lifetime and reliability in real-world applications.

From a manufacturing perspective, scalability remains a substantial hurdle. Laboratory-scale synthesis methods that produce ideal nanoinclusion distributions often involve complex, multi-step processes that are difficult to scale for industrial production. Techniques such as melt spinning followed by spark plasma sintering can create desirable nanostructures but face significant challenges in maintaining consistency across large-volume production.

Cost considerations further complicate implementation efforts. Many effective nanoinclusion materials incorporate rare or precious elements, making them economically prohibitive for widespread commercial adoption. For instance, noble metal nanoinclusions have shown excellent electron-phonon decoupling properties but remain impractical for mass production due to material costs.

Characterization limitations also hinder progress in this field. Current analytical techniques struggle to provide comprehensive three-dimensional mapping of nanoinclusion distribution within bulk materials, making it difficult to establish clear structure-property relationships. This knowledge gap impedes the development of predictive models that could accelerate optimization efforts.

Finally, the multiphysics nature of electron-phonon interactions at nanoinclusion interfaces presents fundamental theoretical challenges. Existing models often fail to accurately predict performance in complex nanostructured systems, particularly when quantum effects become significant at the smallest scales. This theoretical uncertainty complicates rational design approaches for optimized nanoinclusion implementation.

The interface quality between nanoinclusions and the host matrix presents another critical challenge. Poor interfacial bonding can create undesired electron scattering centers that diminish electrical conductivity more severely than they reduce thermal conductivity, resulting in an overall decrease in the thermoelectric figure of merit (ZT). Researchers have observed that even nanometer-scale defects at these interfaces can significantly compromise performance gains.

Stability issues also plague nanoinclusion implementation, particularly at elevated operating temperatures typical for thermoelectric applications. Many promising nanoinclusion materials undergo coarsening, diffusion, or chemical reactions with the host matrix during extended operation, gradually eliminating the nanostructured features responsible for phonon scattering. This degradation mechanism severely limits device lifetime and reliability in real-world applications.

From a manufacturing perspective, scalability remains a substantial hurdle. Laboratory-scale synthesis methods that produce ideal nanoinclusion distributions often involve complex, multi-step processes that are difficult to scale for industrial production. Techniques such as melt spinning followed by spark plasma sintering can create desirable nanostructures but face significant challenges in maintaining consistency across large-volume production.

Cost considerations further complicate implementation efforts. Many effective nanoinclusion materials incorporate rare or precious elements, making them economically prohibitive for widespread commercial adoption. For instance, noble metal nanoinclusions have shown excellent electron-phonon decoupling properties but remain impractical for mass production due to material costs.

Characterization limitations also hinder progress in this field. Current analytical techniques struggle to provide comprehensive three-dimensional mapping of nanoinclusion distribution within bulk materials, making it difficult to establish clear structure-property relationships. This knowledge gap impedes the development of predictive models that could accelerate optimization efforts.

Finally, the multiphysics nature of electron-phonon interactions at nanoinclusion interfaces presents fundamental theoretical challenges. Existing models often fail to accurately predict performance in complex nanostructured systems, particularly when quantum effects become significant at the smallest scales. This theoretical uncertainty complicates rational design approaches for optimized nanoinclusion implementation.

Existing Nanoinclusion Fabrication Methods

01 Nanoinclusions for thermal conductivity reduction

Nanoinclusions can be incorporated into materials to create phonon scattering interfaces that reduce thermal conductivity while maintaining electrical conductivity. This electron-phonon decoupling effect is particularly valuable in thermoelectric materials where high electrical conductivity and low thermal conductivity are desired simultaneously. The nanoinclusions create boundaries that scatter phonons (heat carriers) more effectively than electrons, leading to improved thermoelectric efficiency.- Nanoinclusions for thermal conductivity reduction: Nanoinclusions can be incorporated into thermoelectric materials to reduce thermal conductivity through electron-phonon decoupling. These nanoscale structures create interfaces that scatter phonons (heat carriers) while allowing electrons to flow, effectively decoupling electron and phonon transport. This selective scattering mechanism enhances the thermoelectric figure of merit (ZT) by maintaining electrical conductivity while reducing thermal conductivity.

- Quantum confinement effects in nanostructured materials: Nanostructured materials exhibit quantum confinement effects that can be leveraged to manipulate electron-phonon coupling. By controlling the dimensions of nanoinclusions to dimensions comparable to or smaller than the electron wavelength, quantum effects emerge that modify the electronic band structure and phonon dispersion. These effects can be utilized to engineer materials with reduced electron-phonon coupling, leading to improved electronic mobility and thermal properties.

- Interface engineering for phonon scattering: Strategic engineering of interfaces between nanoinclusions and host materials can enhance phonon scattering while minimizing impact on electron transport. By designing interfaces with specific acoustic impedance mismatches, phonons can be effectively scattered while electrons pass through relatively unimpeded. This approach allows for the decoupling of electron and phonon transport pathways, which is crucial for applications requiring high electrical conductivity but low thermal conductivity.

- Nanoinclusions in semiconductor devices: Incorporating nanoinclusions in semiconductor devices can modify electron-phonon interactions to enhance device performance. These nanoscale features can be strategically placed to reduce phonon-mediated energy losses while maintaining efficient electron transport. This approach has been applied in various semiconductor technologies including transistors, memory devices, and sensors to improve operational efficiency and reduce heat generation during operation.

- Energy harvesting applications: Nanoinclusions that facilitate electron-phonon decoupling are particularly valuable in energy harvesting applications. By incorporating these structures into thermoelectric materials, waste heat can be more efficiently converted into useful electrical energy. The decoupling mechanism allows for the selective filtering of phonons while permitting electron flow, which enhances the conversion efficiency in thermoelectric generators, solar thermal systems, and other energy recovery technologies.

02 Quantum confinement effects in nanostructured materials

Nanostructured materials exhibit quantum confinement effects that can be leveraged to manipulate electron-phonon coupling. By controlling the dimensions of nanoinclusions to dimensions comparable to or smaller than the electron wavelength, quantum effects emerge that can selectively filter phonons while allowing electrons to pass. This selective filtering mechanism enables the decoupling of electron and phonon transport pathways, which is beneficial for applications requiring independent control of electrical and thermal properties.Expand Specific Solutions03 Interface engineering for phonon scattering

The interfaces between nanoinclusions and host materials can be engineered to enhance phonon scattering while minimizing electron scattering. By controlling the chemical composition, crystallographic orientation, and strain at these interfaces, the phonon mean free path can be significantly reduced compared to the electron mean free path. This selective scattering mechanism is key to achieving electron-phonon decoupling and can be optimized through careful selection of materials and processing techniques.Expand Specific Solutions04 Hierarchical nanostructures for broadband phonon scattering

Hierarchical nanostructures incorporating nanoinclusions of different sizes and compositions can achieve broadband phonon scattering across multiple frequency ranges. This approach enables more effective electron-phonon decoupling by targeting phonons with different wavelengths while minimizing the impact on electron transport. The multi-scale architecture creates a cascade of scattering mechanisms that collectively reduce thermal conductivity across a wide temperature range while preserving electrical conductivity.Expand Specific Solutions05 Advanced measurement techniques for electron-phonon coupling

Specialized measurement techniques have been developed to characterize electron-phonon coupling in nanomaterials containing nanoinclusions. These techniques include ultrafast spectroscopy, thermal transport measurements, and scanning probe microscopy methods that can directly observe the decoupling effects at nanoscale interfaces. The ability to accurately measure and quantify electron-phonon interactions is crucial for optimizing nanoinclusion design and validating theoretical models of electron-phonon decoupling mechanisms.Expand Specific Solutions

Leading Research Groups and Companies in Nanomaterials

The nanoinclusion technology for enhanced electron-phonon decoupling is currently in an early growth phase, with significant research momentum but limited commercial deployment. The global thermoelectric materials market, where this technology has primary applications, is projected to reach approximately $80 million by 2025. Leading academic institutions including Shanghai Institute of Ceramics, Rice University, and University of California are driving fundamental research, while companies like Seagate Technology, Robert Bosch GmbH, and Corning are exploring industrial applications. The technology shows promising maturity in laboratory settings but requires further development for mass production. Key challenges include scalability and cost-effectiveness, with most commercial players currently focusing on R&D partnerships rather than standalone product offerings.

Shanghai Institute of Ceramics, Chinese Academy of Sciences

Technical Solution: Shanghai Institute of Ceramics has developed innovative approaches to incorporate nanoinclusions in thermoelectric materials, particularly focusing on skutterudite-based compounds. Their technique involves in-situ formation of nanoprecipitates within the matrix through controlled phase segregation during synthesis. They've pioneered a method using spark plasma sintering (SPS) that allows precise control over nanoinclusion size (5-20 nm) and distribution density. Their research demonstrates that optimally dispersed nanoinclusions at grain boundaries can effectively scatter phonons while minimizing electron scattering, achieving electron-phonon decoupling. Recent work has shown ZT values exceeding 1.5 at moderate temperatures (400-600K) in their nanostructured materials, representing a 30-40% improvement over conventional counterparts[1]. Their approach combines both endotaxial and exotaxial nanoinclusions to create multi-scale phonon scattering centers while maintaining electron transport pathways through carefully engineered band alignment between inclusions and matrix.

Strengths: Exceptional control over nanoinclusion size and distribution through advanced SPS techniques; demonstrated significant ZT improvements in real-world materials; expertise in multi-scale phonon scattering mechanisms. Weaknesses: Process scalability may be challenging for industrial production; some approaches require rare or expensive elements; high-temperature stability of nanoinclusions remains a concern for long-term applications.

William Marsh Rice University

Technical Solution: Rice University has pioneered groundbreaking approaches to nanoinclusion-enhanced thermoelectric materials, particularly through their work on carbon nanotube (CNT) and graphene-based nanocomposites. Their proprietary technique involves creating hierarchical structures where nanoinclusions are strategically positioned at multiple length scales to scatter phonons across different frequency ranges. Rice researchers have developed a chemical vapor deposition method that allows precise placement of graphene nanoplatelets (GNPs) at grain boundaries of conventional thermoelectric materials like Bi2Te3 and PbTe. These GNPs create energy filtering barriers that selectively allow high-energy electrons to pass while blocking low-energy carriers, effectively increasing the Seebeck coefficient[2]. Additionally, their work on core-shell nanostructures has demonstrated that carefully engineered interfaces between nanoinclusions and matrix materials can create potential wells that trap phonons while allowing electrons to tunnel through, achieving ZT values up to 2.2 in laboratory samples. Rice's approach also incorporates strain engineering at nano-interfaces to modify band structures and further enhance electron-phonon decoupling.

Strengths: World-leading expertise in carbon nanomaterials integration; sophisticated understanding of interface engineering for selective carrier transport; demonstrated record-high ZT values in laboratory settings. Weaknesses: Complex fabrication processes may limit commercial scalability; long-term stability of nano-interfaces under thermal cycling needs further validation; some approaches require precise control of carbon nanomaterial chirality and dimensions.

Key Patents and Research on Nanoinclusion Interfaces

P-type skutterudite material and method of making the same

PatentWO2012024120A1

Innovation

- A p-type skutterudite material with a general formula IyFe4-xMxSbi2/z, where I represents filling atoms, M represents dopant atoms, and z represents second-phase precipitates dispersed throughout the skutterudite phase, with controlled synthesis processes involving melting, quenching, annealing, and sintering to enhance power factor, reduce thermal conductivity, and increase ZT value.

Materials Characterization Techniques for Nanoinclusions

The characterization of nanoinclusions in thermoelectric materials requires sophisticated analytical techniques to understand their morphology, distribution, composition, and interface properties. Electron microscopy techniques, particularly Transmission Electron Microscopy (TEM) and Scanning Electron Microscopy (SEM), serve as fundamental tools for visualizing nanoinclusions at high resolution. TEM enables atomic-scale imaging of nanoinclusion structures and interfaces, while SEM provides valuable information about surface morphology and spatial distribution patterns across larger sample areas.

X-ray diffraction (XRD) techniques offer complementary data on the crystallographic structure of nanoinclusions, helping researchers identify phase compositions and lattice parameters. Advanced synchrotron-based XRD methods can detect even trace amounts of secondary phases that form nanoinclusions, providing insights into their formation mechanisms during material synthesis.

Spectroscopic methods such as Energy Dispersive X-ray Spectroscopy (EDS) and Electron Energy Loss Spectroscopy (EELS) enable elemental mapping at nanoscale resolution, revealing the chemical composition of nanoinclusions and surrounding matrices. This information is crucial for understanding how compositional variations affect electron-phonon interactions at interfaces.

Thermal transport property measurements, including thermal conductivity analysis via laser flash methods or 3-omega techniques, directly quantify the impact of nanoinclusions on phonon scattering. When combined with electrical conductivity measurements, these techniques help evaluate the electron-phonon decoupling efficiency of various nanoinclusion configurations.

Advanced scanning probe microscopy techniques, such as Atomic Force Microscopy (AFM) and Scanning Thermal Microscopy (SThM), provide nanoscale topographical information and local thermal property mapping. These methods are particularly valuable for characterizing surface-embedded nanoinclusions and their effects on local thermal transport.

Tomographic techniques, including electron tomography and atom probe tomography, offer three-dimensional visualization of nanoinclusion distribution within the host matrix. This spatial information helps optimize nanoinclusion density and dispersion patterns for maximum electron-phonon decoupling.

In-situ characterization methods enable real-time observation of nanoinclusion formation and evolution during material processing or under operating conditions. These techniques provide valuable insights into stability and performance degradation mechanisms, essential for developing durable thermoelectric materials with sustained electron-phonon decoupling properties.

Computational modeling and simulation tools, when integrated with experimental characterization data, create powerful platforms for predicting optimal nanoinclusion parameters and understanding fundamental phonon scattering mechanisms at the atomic scale.

X-ray diffraction (XRD) techniques offer complementary data on the crystallographic structure of nanoinclusions, helping researchers identify phase compositions and lattice parameters. Advanced synchrotron-based XRD methods can detect even trace amounts of secondary phases that form nanoinclusions, providing insights into their formation mechanisms during material synthesis.

Spectroscopic methods such as Energy Dispersive X-ray Spectroscopy (EDS) and Electron Energy Loss Spectroscopy (EELS) enable elemental mapping at nanoscale resolution, revealing the chemical composition of nanoinclusions and surrounding matrices. This information is crucial for understanding how compositional variations affect electron-phonon interactions at interfaces.

Thermal transport property measurements, including thermal conductivity analysis via laser flash methods or 3-omega techniques, directly quantify the impact of nanoinclusions on phonon scattering. When combined with electrical conductivity measurements, these techniques help evaluate the electron-phonon decoupling efficiency of various nanoinclusion configurations.

Advanced scanning probe microscopy techniques, such as Atomic Force Microscopy (AFM) and Scanning Thermal Microscopy (SThM), provide nanoscale topographical information and local thermal property mapping. These methods are particularly valuable for characterizing surface-embedded nanoinclusions and their effects on local thermal transport.

Tomographic techniques, including electron tomography and atom probe tomography, offer three-dimensional visualization of nanoinclusion distribution within the host matrix. This spatial information helps optimize nanoinclusion density and dispersion patterns for maximum electron-phonon decoupling.

In-situ characterization methods enable real-time observation of nanoinclusion formation and evolution during material processing or under operating conditions. These techniques provide valuable insights into stability and performance degradation mechanisms, essential for developing durable thermoelectric materials with sustained electron-phonon decoupling properties.

Computational modeling and simulation tools, when integrated with experimental characterization data, create powerful platforms for predicting optimal nanoinclusion parameters and understanding fundamental phonon scattering mechanisms at the atomic scale.

Scalability and Manufacturing Considerations

The scalability and manufacturing of nanoinclusions for enhanced electron-phonon decoupling presents significant challenges that must be addressed for commercial viability. Current laboratory-scale synthesis methods, including chemical vapor deposition, sol-gel processing, and molecular beam epitaxy, demonstrate excellent control over nanoinclusion size, distribution, and interface quality but typically yield only small quantities of material. These methods often require expensive equipment, specialized environments, and lengthy processing times, making them impractical for industrial-scale production.

Transitioning from laboratory to industrial scale requires developing continuous manufacturing processes that maintain precise control over nanoinclusion characteristics. Roll-to-roll processing shows promise for thin-film thermoelectric materials with embedded nanoinclusions, potentially enabling high-throughput production while preserving the critical electron-phonon decoupling properties. Similarly, solution-based processing methods offer scalability advantages through their compatibility with existing manufacturing infrastructure.

Cost considerations represent another critical factor in commercialization. The raw materials for high-performance nanoinclusions often include rare or precious metals and specialized compounds that significantly impact production economics. Developing alternative nanoinclusion materials using earth-abundant elements could substantially reduce costs while maintaining performance benefits. Additionally, process optimization to reduce waste, energy consumption, and processing time will be essential for economic viability.

Quality control and reproducibility present unique challenges at industrial scales. The electron-phonon decoupling effect is highly sensitive to nanoinclusion size, distribution, and interface quality. Developing robust in-line monitoring techniques using advanced characterization tools such as real-time X-ray diffraction or spectroscopic methods will be crucial for maintaining consistent product quality. Statistical process control methodologies must be adapted specifically for nanoinclusion manufacturing to ensure batch-to-batch consistency.

Environmental and safety considerations must also be addressed as production scales increase. Many nanomaterials raise toxicological concerns, particularly at the production scale where material quantities are substantial. Developing green synthesis routes that minimize hazardous reagents and implementing appropriate containment and waste management systems will be necessary to ensure worker safety and environmental protection.

Standardization represents a final critical consideration for industry adoption. Currently, no standardized testing protocols exist for evaluating electron-phonon decoupling efficiency in materials with nanoinclusions. Establishing industry-wide standards for characterization, performance metrics, and reliability testing will accelerate commercialization by providing manufacturers and end-users with confidence in product specifications and performance.

Transitioning from laboratory to industrial scale requires developing continuous manufacturing processes that maintain precise control over nanoinclusion characteristics. Roll-to-roll processing shows promise for thin-film thermoelectric materials with embedded nanoinclusions, potentially enabling high-throughput production while preserving the critical electron-phonon decoupling properties. Similarly, solution-based processing methods offer scalability advantages through their compatibility with existing manufacturing infrastructure.

Cost considerations represent another critical factor in commercialization. The raw materials for high-performance nanoinclusions often include rare or precious metals and specialized compounds that significantly impact production economics. Developing alternative nanoinclusion materials using earth-abundant elements could substantially reduce costs while maintaining performance benefits. Additionally, process optimization to reduce waste, energy consumption, and processing time will be essential for economic viability.

Quality control and reproducibility present unique challenges at industrial scales. The electron-phonon decoupling effect is highly sensitive to nanoinclusion size, distribution, and interface quality. Developing robust in-line monitoring techniques using advanced characterization tools such as real-time X-ray diffraction or spectroscopic methods will be crucial for maintaining consistent product quality. Statistical process control methodologies must be adapted specifically for nanoinclusion manufacturing to ensure batch-to-batch consistency.

Environmental and safety considerations must also be addressed as production scales increase. Many nanomaterials raise toxicological concerns, particularly at the production scale where material quantities are substantial. Developing green synthesis routes that minimize hazardous reagents and implementing appropriate containment and waste management systems will be necessary to ensure worker safety and environmental protection.

Standardization represents a final critical consideration for industry adoption. Currently, no standardized testing protocols exist for evaluating electron-phonon decoupling efficiency in materials with nanoinclusions. Establishing industry-wide standards for characterization, performance metrics, and reliability testing will accelerate commercialization by providing manufacturers and end-users with confidence in product specifications and performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!