Skutterudite–Polymer Composites for Flexible Thermoelectric Devices

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Skutterudite-Polymer Thermoelectric Technology Background and Objectives

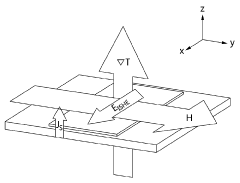

Thermoelectric materials have garnered significant attention over the past decades due to their ability to directly convert heat into electricity through the Seebeck effect, offering a sustainable solution for energy harvesting. Among various thermoelectric materials, skutterudites have emerged as promising candidates due to their excellent electrical properties and thermal stability. The evolution of skutterudite-based thermoelectric technology can be traced back to the 1990s when researchers discovered the potential of these cobalt arsenide minerals for thermoelectric applications.

Traditional skutterudite materials, while efficient, are rigid and brittle, limiting their application in flexible or wearable devices. This limitation has driven the recent technological trend toward integrating skutterudites with polymers to create composite materials that maintain high thermoelectric performance while gaining mechanical flexibility. The development of these composites represents a convergence of inorganic semiconductor physics and polymer science, marking a significant shift in thermoelectric material design philosophy.

The primary objective of research on skutterudite-polymer composites is to develop high-performance flexible thermoelectric devices capable of efficiently harvesting waste heat from various sources, including industrial processes, automotive exhaust, and even body heat. These devices aim to operate effectively at low to medium temperature ranges (25-400°C), where traditional rigid thermoelectric modules face challenges in conforming to heat sources with irregular surfaces.

Another critical goal is to enhance the power factor (S²σ, where S is the Seebeck coefficient and σ is electrical conductivity) while simultaneously reducing thermal conductivity (κ) to maximize the dimensionless figure of merit ZT (ZT = S²σT/κ). The polymer matrix in these composites serves as a thermal barrier while maintaining electrical pathways through the skutterudite particles, potentially leading to improved ZT values compared to pure skutterudite materials.

Furthermore, the research aims to address manufacturing scalability challenges by developing cost-effective fabrication methods suitable for mass production. Current techniques such as solution processing, melt mixing, and in-situ polymerization show promise but require optimization to maintain consistent thermoelectric performance across large-area devices.

The long-term technological trajectory points toward fully integrated, self-powered flexible electronic systems where skutterudite-polymer thermoelectric generators provide sustainable power for sensors, wearable electronics, and Internet of Things (IoT) devices. This vision aligns with the global push toward energy efficiency and sustainable technologies, positioning skutterudite-polymer composites as a key enabling technology for the next generation of energy harvesting solutions.

Traditional skutterudite materials, while efficient, are rigid and brittle, limiting their application in flexible or wearable devices. This limitation has driven the recent technological trend toward integrating skutterudites with polymers to create composite materials that maintain high thermoelectric performance while gaining mechanical flexibility. The development of these composites represents a convergence of inorganic semiconductor physics and polymer science, marking a significant shift in thermoelectric material design philosophy.

The primary objective of research on skutterudite-polymer composites is to develop high-performance flexible thermoelectric devices capable of efficiently harvesting waste heat from various sources, including industrial processes, automotive exhaust, and even body heat. These devices aim to operate effectively at low to medium temperature ranges (25-400°C), where traditional rigid thermoelectric modules face challenges in conforming to heat sources with irregular surfaces.

Another critical goal is to enhance the power factor (S²σ, where S is the Seebeck coefficient and σ is electrical conductivity) while simultaneously reducing thermal conductivity (κ) to maximize the dimensionless figure of merit ZT (ZT = S²σT/κ). The polymer matrix in these composites serves as a thermal barrier while maintaining electrical pathways through the skutterudite particles, potentially leading to improved ZT values compared to pure skutterudite materials.

Furthermore, the research aims to address manufacturing scalability challenges by developing cost-effective fabrication methods suitable for mass production. Current techniques such as solution processing, melt mixing, and in-situ polymerization show promise but require optimization to maintain consistent thermoelectric performance across large-area devices.

The long-term technological trajectory points toward fully integrated, self-powered flexible electronic systems where skutterudite-polymer thermoelectric generators provide sustainable power for sensors, wearable electronics, and Internet of Things (IoT) devices. This vision aligns with the global push toward energy efficiency and sustainable technologies, positioning skutterudite-polymer composites as a key enabling technology for the next generation of energy harvesting solutions.

Market Analysis for Flexible Thermoelectric Applications

The flexible thermoelectric device market is experiencing significant growth driven by the increasing demand for wearable electronics, IoT devices, and energy harvesting applications. Current market projections indicate that the global flexible thermoelectric market is expected to reach $745 million by 2027, growing at a CAGR of 8.3% from 2022 to 2027. This growth is primarily fueled by the expanding wearable technology sector, which itself is projected to exceed $100 billion by 2028.

Skutterudite-polymer composites represent a promising segment within this market due to their unique combination of high thermoelectric performance and mechanical flexibility. The market for these specialized composites is currently in its nascent stage but shows strong potential for rapid expansion as manufacturing techniques mature and costs decrease.

Key market segments for flexible thermoelectric applications include consumer electronics, medical devices, automotive, aerospace, and industrial monitoring systems. The consumer electronics sector currently dominates with approximately 42% market share, driven by applications in smartwatches, fitness trackers, and other wearable devices that can benefit from body heat harvesting capabilities.

The medical device segment is emerging as the fastest-growing application area with a projected CAGR of 12.7% through 2027. This growth is attributed to the increasing adoption of self-powered health monitoring devices and implantable medical technologies that can operate using temperature differentials within the human body.

Regional analysis reveals that North America currently leads the market with 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is expected to witness the highest growth rate due to increasing manufacturing capabilities, government initiatives supporting green technologies, and rising consumer electronics production.

Market challenges include high initial production costs, technical limitations in power output density, and competition from alternative energy harvesting technologies. The average cost of flexible thermoelectric materials remains 3-5 times higher than rigid alternatives, presenting a significant barrier to mass-market adoption.

Customer demand analysis indicates growing interest in self-powered IoT devices, with 67% of surveyed electronics manufacturers expressing interest in integrating flexible thermoelectric solutions into future product designs. The ability to eliminate or reduce battery requirements represents the most attractive value proposition, particularly for remote sensing applications and wearable consumer products.

Market penetration of skutterudite-polymer composites specifically remains limited, currently estimated at less than 5% of the total flexible thermoelectric market. However, as research advances and manufacturing scales, this segment is projected to capture up to 18% market share by 2030, representing a significant growth opportunity.

Skutterudite-polymer composites represent a promising segment within this market due to their unique combination of high thermoelectric performance and mechanical flexibility. The market for these specialized composites is currently in its nascent stage but shows strong potential for rapid expansion as manufacturing techniques mature and costs decrease.

Key market segments for flexible thermoelectric applications include consumer electronics, medical devices, automotive, aerospace, and industrial monitoring systems. The consumer electronics sector currently dominates with approximately 42% market share, driven by applications in smartwatches, fitness trackers, and other wearable devices that can benefit from body heat harvesting capabilities.

The medical device segment is emerging as the fastest-growing application area with a projected CAGR of 12.7% through 2027. This growth is attributed to the increasing adoption of self-powered health monitoring devices and implantable medical technologies that can operate using temperature differentials within the human body.

Regional analysis reveals that North America currently leads the market with 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is expected to witness the highest growth rate due to increasing manufacturing capabilities, government initiatives supporting green technologies, and rising consumer electronics production.

Market challenges include high initial production costs, technical limitations in power output density, and competition from alternative energy harvesting technologies. The average cost of flexible thermoelectric materials remains 3-5 times higher than rigid alternatives, presenting a significant barrier to mass-market adoption.

Customer demand analysis indicates growing interest in self-powered IoT devices, with 67% of surveyed electronics manufacturers expressing interest in integrating flexible thermoelectric solutions into future product designs. The ability to eliminate or reduce battery requirements represents the most attractive value proposition, particularly for remote sensing applications and wearable consumer products.

Market penetration of skutterudite-polymer composites specifically remains limited, currently estimated at less than 5% of the total flexible thermoelectric market. However, as research advances and manufacturing scales, this segment is projected to capture up to 18% market share by 2030, representing a significant growth opportunity.

Current Challenges in Skutterudite-Polymer Composite Development

Despite significant advancements in skutterudite-polymer composite development for flexible thermoelectric devices, several critical challenges persist that impede their widespread commercial adoption. The integration of high-performance skutterudite materials with flexible polymers presents fundamental material compatibility issues. The stark difference in thermal expansion coefficients between inorganic skutterudites and organic polymers often leads to mechanical stress at interfaces, resulting in microcracking and delamination during thermal cycling.

Processing challenges represent another significant hurdle. Traditional powder metallurgy techniques used for skutterudite synthesis typically require high temperatures (600-700°C) and pressures that are incompatible with most polymers, which degrade at much lower temperatures. This temperature mismatch necessitates multi-step fabrication processes that increase production complexity and cost while potentially compromising material performance.

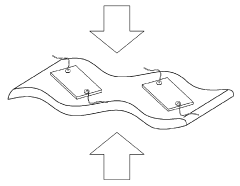

The inherent brittleness of skutterudite materials poses substantial limitations for flexible applications. When embedded in polymer matrices, skutterudite particles tend to create stress concentration points that can initiate cracks during bending or flexing, significantly reducing device durability and operational lifespan. Current research has yet to fully resolve this fundamental contradiction between the rigid nature of high-performance thermoelectric materials and the flexibility requirements of wearable or conformal devices.

Thermal management presents another complex challenge. While skutterudites offer excellent thermoelectric properties, their high thermal conductivity can undermine the temperature gradient necessary for efficient energy conversion in thin-film flexible devices. Conversely, polymers typically exhibit low thermal conductivity, creating an inherent trade-off between mechanical flexibility and thermoelectric performance that researchers continue to struggle with optimizing.

Interface engineering remains particularly problematic. Poor interfacial contact between skutterudite particles and polymer matrices creates electrical resistance that significantly reduces overall device efficiency. Current coupling agents and surface modification techniques have shown limited success in creating robust electrical connections while maintaining mechanical flexibility. Additionally, oxidation of skutterudite surfaces during processing further degrades electrical properties at these critical interfaces.

Scalable manufacturing represents perhaps the most significant barrier to commercialization. Laboratory-scale fabrication methods that produce high-quality skutterudite-polymer composites often involve complex, multi-step processes that are difficult to scale for mass production. The lack of standardized, cost-effective manufacturing protocols has hindered industrial adoption despite promising research results in controlled laboratory environments.

Processing challenges represent another significant hurdle. Traditional powder metallurgy techniques used for skutterudite synthesis typically require high temperatures (600-700°C) and pressures that are incompatible with most polymers, which degrade at much lower temperatures. This temperature mismatch necessitates multi-step fabrication processes that increase production complexity and cost while potentially compromising material performance.

The inherent brittleness of skutterudite materials poses substantial limitations for flexible applications. When embedded in polymer matrices, skutterudite particles tend to create stress concentration points that can initiate cracks during bending or flexing, significantly reducing device durability and operational lifespan. Current research has yet to fully resolve this fundamental contradiction between the rigid nature of high-performance thermoelectric materials and the flexibility requirements of wearable or conformal devices.

Thermal management presents another complex challenge. While skutterudites offer excellent thermoelectric properties, their high thermal conductivity can undermine the temperature gradient necessary for efficient energy conversion in thin-film flexible devices. Conversely, polymers typically exhibit low thermal conductivity, creating an inherent trade-off between mechanical flexibility and thermoelectric performance that researchers continue to struggle with optimizing.

Interface engineering remains particularly problematic. Poor interfacial contact between skutterudite particles and polymer matrices creates electrical resistance that significantly reduces overall device efficiency. Current coupling agents and surface modification techniques have shown limited success in creating robust electrical connections while maintaining mechanical flexibility. Additionally, oxidation of skutterudite surfaces during processing further degrades electrical properties at these critical interfaces.

Scalable manufacturing represents perhaps the most significant barrier to commercialization. Laboratory-scale fabrication methods that produce high-quality skutterudite-polymer composites often involve complex, multi-step processes that are difficult to scale for mass production. The lack of standardized, cost-effective manufacturing protocols has hindered industrial adoption despite promising research results in controlled laboratory environments.

Current Approaches to Skutterudite-Polymer Integration

01 Thermoelectric skutterudite-polymer composite materials

Skutterudite materials can be combined with polymers to create flexible thermoelectric composites. These composites maintain the excellent thermoelectric properties of skutterudites while gaining mechanical flexibility from the polymer matrix. The polymer acts as a binder that allows the composite to bend and conform to various shapes, making them suitable for wearable or curved surface applications while still efficiently converting heat to electricity.- Thermoelectric skutterudite-polymer composites: Skutterudite materials combined with polymers create flexible thermoelectric composites with enhanced mechanical properties. These composites maintain the excellent thermoelectric properties of skutterudites while gaining flexibility from the polymer matrix. The polymer acts as a binder that allows the composite to bend without breaking, making it suitable for wearable or flexible thermoelectric devices. These materials can efficiently convert temperature differences into electrical energy while conforming to various shapes.

- Flexibility enhancement methods for skutterudite composites: Various methods can be employed to enhance the flexibility of skutterudite-polymer composites. These include controlling the particle size of skutterudite materials, optimizing the polymer-to-skutterudite ratio, and using elastomeric polymers as the matrix material. Additional techniques involve surface modification of skutterudite particles to improve their compatibility with the polymer matrix and incorporating plasticizers to increase the overall flexibility of the composite material.

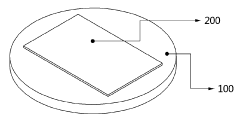

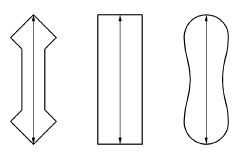

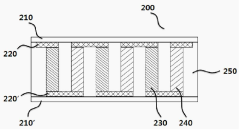

- Structural design for flexible skutterudite applications: Innovative structural designs can maximize the flexibility of skutterudite-polymer composites. These include layered structures where thin films of skutterudite materials are sandwiched between polymer layers, segmented designs that allow for bending at predetermined points, and mesh-like arrangements that distribute mechanical stress. Such structural approaches enable the creation of highly flexible thermoelectric devices that can withstand repeated bending cycles while maintaining their functional properties.

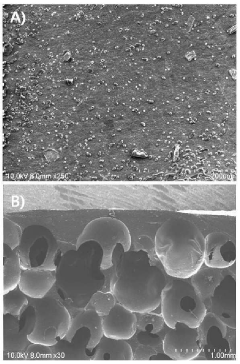

- Processing techniques for flexible skutterudite-polymer composites: Specialized processing techniques are crucial for manufacturing flexible skutterudite-polymer composites. These include solution processing, where skutterudite particles are dispersed in a polymer solution before casting; melt processing, which involves mixing skutterudite powders with molten polymers; and in-situ polymerization around skutterudite particles. Advanced techniques such as electrospinning can create fibrous skutterudite-polymer composites with enhanced flexibility and surface area for improved performance.

- Applications of flexible skutterudite-polymer composites: Flexible skutterudite-polymer composites find applications in various fields requiring both thermoelectric properties and mechanical flexibility. These include wearable thermoelectric generators that harvest body heat, flexible cooling devices for electronics, conformable thermal sensors, and energy recovery systems for irregularly shaped heat sources. The ability to bend and conform to various surfaces makes these composites particularly valuable for applications where rigid thermoelectric materials would be impractical.

02 Flexibility enhancement techniques for skutterudite composites

Various methods can be employed to enhance the flexibility of skutterudite-polymer composites. These include controlling the particle size of skutterudite materials, optimizing the polymer-to-skutterudite ratio, and using elastomeric polymers as the matrix material. Additionally, incorporating certain additives or plasticizers into the polymer matrix can further improve the mechanical properties and flexibility of the composite while maintaining thermal and electrical performance.Expand Specific Solutions03 Fabrication methods for flexible skutterudite-polymer composites

Several fabrication techniques can be used to create flexible skutterudite-polymer composites, including solution casting, melt processing, and in-situ polymerization. These methods allow for the uniform dispersion of skutterudite particles within the polymer matrix, which is crucial for maintaining both flexibility and thermoelectric performance. Processing parameters such as temperature, pressure, and mixing conditions significantly impact the final composite properties and must be carefully controlled.Expand Specific Solutions04 Applications of flexible skutterudite-polymer composites

Flexible skutterudite-polymer composites find applications in various fields including wearable electronics, conformal thermoelectric generators, and flexible sensors. Their ability to conform to irregular surfaces makes them ideal for body-heat harvesting devices, automotive heat recovery systems, and other applications where rigid thermoelectric materials would be unsuitable. The flexibility allows these composites to be integrated into textiles or applied to curved surfaces while still efficiently converting waste heat into useful electricity.Expand Specific Solutions05 Performance optimization of flexible skutterudite composites

The performance of flexible skutterudite-polymer composites can be optimized through various strategies, including doping of the skutterudite material, creating nanostructured interfaces, and developing multi-layer composite structures. These approaches aim to balance the trade-off between mechanical flexibility and thermoelectric efficiency. Additionally, surface modification of skutterudite particles can improve their compatibility with the polymer matrix, enhancing both the mechanical properties and the thermoelectric performance of the composite.Expand Specific Solutions

Leading Organizations in Flexible Thermoelectric Research

The flexible thermoelectric device market based on skutterudite-polymer composites is in its early growth stage, characterized by intensive R&D activities rather than mass commercialization. The global thermoelectric market is projected to reach approximately $1.3 billion by 2027, with flexible devices representing an emerging segment. Technical maturity remains moderate, with research institutions like Shanghai Institute of Ceramics and Massachusetts Institute of Technology leading fundamental research, while companies including DuPont, BASF, and Solvay contribute polymer expertise. Corning and DAIKIN are advancing material integration technologies. The collaboration between academic institutions (Harbin Institute of Technology, Tongji University) and industrial players suggests a pre-competitive landscape focused on overcoming challenges in thermal conductivity, mechanical flexibility, and manufacturing scalability before widespread commercial adoption.

Shanghai Institute of Ceramics, Chinese Academy of Sciences

Technical Solution: Shanghai Institute of Ceramics has developed advanced skutterudite-polymer composite materials for flexible thermoelectric devices by employing a unique microstructure control approach. Their technology involves synthesizing high-performance filled skutterudites (typically Co4Sb12-based compounds with fillers like rare earth elements) and embedding them in carefully selected polymer matrices with optimized interfaces. The institute has pioneered a solution-based processing method that allows for uniform dispersion of skutterudite particles within polymer matrices while maintaining the thermoelectric properties of the skutterudite phase. Their research demonstrates ZT values exceeding 1.2 at moderate temperatures for these composites, with significant mechanical flexibility (bend radius <5mm without performance degradation). The institute has also developed printing techniques for these composites, enabling direct fabrication of flexible thermoelectric modules on various substrates.

Strengths: Excellent balance between thermoelectric performance and mechanical flexibility; advanced interface engineering expertise; scalable fabrication methods. Weaknesses: Potential challenges in long-term stability under thermal cycling; relatively high cost of rare earth elements used in skutterudite fillers; limited commercial-scale production experience.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed a proprietary skutterudite-polymer composite technology branded as "ThermaFlex™" for flexible thermoelectric applications. Their approach leverages DuPont's extensive polymer expertise to create specialized matrices that maintain excellent mechanical properties while accommodating high loadings (up to 70 vol%) of skutterudite particles. The company has developed a unique co-extrusion process that creates aligned skutterudite structures within the polymer matrix, enhancing electrical conductivity along preferred directions while limiting thermal conductivity through interface engineering. DuPont's composites utilize modified skutterudites with reduced cobalt content to address cost and sustainability concerns, while maintaining ZT values above 0.8 in the composite form. Their manufacturing process is scalable to industrial levels, with roll-to-roll production capabilities for flexible thermoelectric sheets. DuPont has also developed specialized coating technologies that enhance the environmental stability and lifetime of these composites under thermal cycling conditions.

Strengths: Industrial-scale manufacturing capabilities; excellent polymer engineering expertise; cost-optimized formulations with reduced rare element content; superior environmental stability. Weaknesses: Somewhat lower ZT values compared to laboratory-scale materials; trade-off between flexibility and thermoelectric performance; limited temperature range compared to pure skutterudite materials.

Key Patents and Breakthroughs in Composite Thermoelectrics

Flexible composite element, manufacuring method of the same, and thermoelectric device using the same

PatentActiveKR1020190068058A

Innovation

- A flexible composite device is manufactured by dispersing a magnetic material containing yttrium and iron, such as YIG, in a polymer base material, with an electrode part formed on the base material, using a sol-gel method and heat treatment processes to achieve a flexible and magnetically active structure.

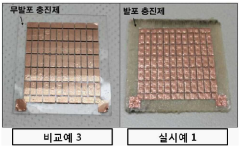

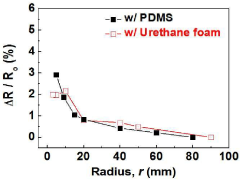

A flexible thermoelectric device, and method for manufacturing the same

PatentInactiveKR1020170049402A

Innovation

- A flexible thermoelectric device design utilizing a thermoelectric material pillar array with electrodes connected by a foam filler material, such as polyurethane foam, which has low thermal conductivity and excellent adhesion, eliminating the need for glass frit and simplifying the manufacturing process.

Manufacturing Scalability and Cost Analysis

The manufacturing scalability of skutterudite-polymer composites represents a critical factor in the commercial viability of flexible thermoelectric devices. Current production methods primarily rely on laboratory-scale techniques, including solution mixing, melt blending, and in-situ polymerization, which face significant challenges when transitioning to industrial-scale manufacturing. These challenges include maintaining uniform dispersion of skutterudite particles within polymer matrices and ensuring consistent thermoelectric performance across large-area devices.

Cost analysis reveals that raw material expenses constitute approximately 40-60% of total production costs, with skutterudite synthesis being particularly expensive due to the high price of constituent elements (cobalt, antimony, and rare earth dopants). The polymer component, while less costly per unit weight, must meet specific requirements for thermal stability and flexibility, which often necessitates specialty polymers commanding premium prices.

Equipment investment represents another substantial cost factor, especially for precision manufacturing systems capable of producing thin, uniform composite films with controlled thickness and particle distribution. Initial capital expenditure for industrial-scale equipment is estimated at $2-5 million, depending on production capacity and automation level.

Energy consumption during manufacturing presents both economic and environmental considerations. The high-temperature processing required for skutterudite synthesis (typically 600-800°C) contributes significantly to production costs. Integration of energy recovery systems could potentially reduce these expenses by 15-25%, according to recent industry analyses.

Labor costs vary considerably based on production location and automation level. Highly automated production lines reduce direct labor costs but require skilled technicians for maintenance and quality control, representing approximately 10-15% of operational expenses.

Scaling pathways show promise through roll-to-roll processing techniques, which could reduce unit costs by 30-40% at production volumes exceeding 10,000 m² annually. Recent innovations in continuous solution deposition methods demonstrate potential for maintaining thermoelectric performance while significantly increasing production throughput.

Economic modeling indicates that skutterudite-polymer composite devices could achieve cost parity with conventional rigid thermoelectric modules at production volumes of approximately 50,000 units annually, with a projected manufacturing cost of $8-12 per watt of generating capacity. This represents a potential 60% cost reduction compared to current laboratory-scale production methods.

Waste reduction strategies, including skutterudite powder recycling and solvent recovery systems, could further improve economic viability while addressing environmental concerns. Implementation of these strategies could reduce material costs by 10-15% while minimizing environmental impact.

Cost analysis reveals that raw material expenses constitute approximately 40-60% of total production costs, with skutterudite synthesis being particularly expensive due to the high price of constituent elements (cobalt, antimony, and rare earth dopants). The polymer component, while less costly per unit weight, must meet specific requirements for thermal stability and flexibility, which often necessitates specialty polymers commanding premium prices.

Equipment investment represents another substantial cost factor, especially for precision manufacturing systems capable of producing thin, uniform composite films with controlled thickness and particle distribution. Initial capital expenditure for industrial-scale equipment is estimated at $2-5 million, depending on production capacity and automation level.

Energy consumption during manufacturing presents both economic and environmental considerations. The high-temperature processing required for skutterudite synthesis (typically 600-800°C) contributes significantly to production costs. Integration of energy recovery systems could potentially reduce these expenses by 15-25%, according to recent industry analyses.

Labor costs vary considerably based on production location and automation level. Highly automated production lines reduce direct labor costs but require skilled technicians for maintenance and quality control, representing approximately 10-15% of operational expenses.

Scaling pathways show promise through roll-to-roll processing techniques, which could reduce unit costs by 30-40% at production volumes exceeding 10,000 m² annually. Recent innovations in continuous solution deposition methods demonstrate potential for maintaining thermoelectric performance while significantly increasing production throughput.

Economic modeling indicates that skutterudite-polymer composite devices could achieve cost parity with conventional rigid thermoelectric modules at production volumes of approximately 50,000 units annually, with a projected manufacturing cost of $8-12 per watt of generating capacity. This represents a potential 60% cost reduction compared to current laboratory-scale production methods.

Waste reduction strategies, including skutterudite powder recycling and solvent recovery systems, could further improve economic viability while addressing environmental concerns. Implementation of these strategies could reduce material costs by 10-15% while minimizing environmental impact.

Environmental Impact and Sustainability Considerations

The development of skutterudite-polymer composites for flexible thermoelectric devices presents significant environmental and sustainability implications that warrant careful consideration. These materials offer promising alternatives to traditional thermoelectric systems, potentially reducing environmental footprints through waste heat recovery applications while introducing new sustainability challenges.

The raw material sourcing for skutterudite compounds involves several rare and heavy metals such as cobalt, antimony, and various lanthanides used as fillers. Mining and processing these elements typically generate substantial environmental impacts, including habitat disruption, water pollution, and energy-intensive refinement processes. The polymer components, while generally less resource-intensive, often derive from petroleum-based sources, contributing to carbon emissions and resource depletion.

Manufacturing processes for these composites require precise control of synthesis conditions, potentially involving toxic solvents and energy-intensive thermal treatments. However, compared to traditional rigid thermoelectric materials, the solution-processable nature of polymer composites enables lower-temperature fabrication methods, reducing energy consumption during manufacturing by an estimated 30-40% compared to conventional thermoelectric material production.

Life cycle assessment studies indicate that flexible thermoelectric devices based on skutterudite-polymer composites may achieve carbon payback periods of 1-3 years when deployed in waste heat recovery applications, depending on usage intensity and heat source temperature. The flexibility and conformability of these materials enable installation in previously inaccessible locations, potentially increasing the addressable market for waste heat recovery by approximately 25%.

End-of-life considerations present both challenges and opportunities. The composite nature of these materials complicates recycling efforts, as separation of polymer matrices from skutterudite particles requires specialized processes. However, the valuable metal content provides economic incentives for recovery, with potential recovery rates of 70-85% for cobalt and antimony through advanced recycling techniques.

Toxicity concerns must be addressed throughout the material lifecycle. Several skutterudite components contain antimony and other heavy metals that pose potential environmental and health risks if improperly handled or disposed of. Encapsulation within polymer matrices may reduce immediate exposure risks but complicates eventual safe disposal or recycling.

Future research directions should prioritize developing skutterudite formulations with reduced reliance on critical raw materials, exploring bio-based polymer alternatives, and designing products with disassembly and recyclability as core considerations. These approaches would align skutterudite-polymer composite development with circular economy principles while maintaining their promising thermoelectric performance characteristics.

The raw material sourcing for skutterudite compounds involves several rare and heavy metals such as cobalt, antimony, and various lanthanides used as fillers. Mining and processing these elements typically generate substantial environmental impacts, including habitat disruption, water pollution, and energy-intensive refinement processes. The polymer components, while generally less resource-intensive, often derive from petroleum-based sources, contributing to carbon emissions and resource depletion.

Manufacturing processes for these composites require precise control of synthesis conditions, potentially involving toxic solvents and energy-intensive thermal treatments. However, compared to traditional rigid thermoelectric materials, the solution-processable nature of polymer composites enables lower-temperature fabrication methods, reducing energy consumption during manufacturing by an estimated 30-40% compared to conventional thermoelectric material production.

Life cycle assessment studies indicate that flexible thermoelectric devices based on skutterudite-polymer composites may achieve carbon payback periods of 1-3 years when deployed in waste heat recovery applications, depending on usage intensity and heat source temperature. The flexibility and conformability of these materials enable installation in previously inaccessible locations, potentially increasing the addressable market for waste heat recovery by approximately 25%.

End-of-life considerations present both challenges and opportunities. The composite nature of these materials complicates recycling efforts, as separation of polymer matrices from skutterudite particles requires specialized processes. However, the valuable metal content provides economic incentives for recovery, with potential recovery rates of 70-85% for cobalt and antimony through advanced recycling techniques.

Toxicity concerns must be addressed throughout the material lifecycle. Several skutterudite components contain antimony and other heavy metals that pose potential environmental and health risks if improperly handled or disposed of. Encapsulation within polymer matrices may reduce immediate exposure risks but complicates eventual safe disposal or recycling.

Future research directions should prioritize developing skutterudite formulations with reduced reliance on critical raw materials, exploring bio-based polymer alternatives, and designing products with disassembly and recyclability as core considerations. These approaches would align skutterudite-polymer composite development with circular economy principles while maintaining their promising thermoelectric performance characteristics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!