How to Benchmark Skutterudite ZT Against State-of-the-Art Thermoelectrics

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Skutterudite Thermoelectric Technology Background and Objectives

Thermoelectric materials have garnered significant attention in recent decades due to their ability to directly convert heat into electricity without moving parts, offering a sustainable solution for waste heat recovery. Among these materials, skutterudites have emerged as promising candidates for mid-temperature range applications (400-700°C). The evolution of skutterudite research began in the 1990s with the discovery of their unique "phonon glass-electron crystal" characteristics, which allow for simultaneous high electrical conductivity and low thermal conductivity—key requirements for efficient thermoelectric materials.

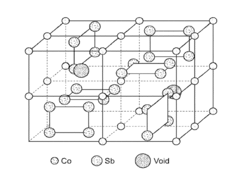

The development trajectory of skutterudite technology has been marked by continuous improvements in synthesis methods, compositional optimization, and nanostructuring approaches. Initially, research focused on binary skutterudites (CoSb3), but quickly expanded to include filling atoms (rare earths, alkaline earths) in the structural voids to reduce lattice thermal conductivity. This "rattling" effect of filler atoms has been fundamental to enhancing the figure of merit (ZT) of these materials.

Recent technological advancements have focused on multiple filling, nano-inclusions, and hierarchical architectures to further optimize thermoelectric performance. The introduction of advanced manufacturing techniques, including spark plasma sintering and melt-spinning, has enabled better control over microstructure and compositional homogeneity, leading to enhanced reproducibility and performance.

The primary technical objective in skutterudite research is to achieve consistently high ZT values (>1.5) across the operating temperature range while ensuring material stability during thermal cycling. This requires systematic benchmarking against other state-of-the-art thermoelectric materials such as half-Heuslers, lead tellurides, and magnesium silicides to establish comparative advantages and identify optimization pathways.

Another critical goal is to develop standardized testing protocols that enable accurate and reproducible measurement of thermoelectric properties, as inconsistencies in measurement techniques have historically complicated direct comparisons between different material systems. This includes establishing reference materials and round-robin testing among laboratories to validate measurement accuracy.

Looking forward, the field aims to bridge the gap between laboratory demonstrations and commercial viability by addressing challenges in scalable manufacturing, module design, and long-term reliability. The ultimate objective is to position skutterudites as a competitive solution in the thermoelectric marketplace, particularly for automotive waste heat recovery, industrial processes, and potentially space applications where their temperature stability and efficiency could provide significant advantages.

The development trajectory of skutterudite technology has been marked by continuous improvements in synthesis methods, compositional optimization, and nanostructuring approaches. Initially, research focused on binary skutterudites (CoSb3), but quickly expanded to include filling atoms (rare earths, alkaline earths) in the structural voids to reduce lattice thermal conductivity. This "rattling" effect of filler atoms has been fundamental to enhancing the figure of merit (ZT) of these materials.

Recent technological advancements have focused on multiple filling, nano-inclusions, and hierarchical architectures to further optimize thermoelectric performance. The introduction of advanced manufacturing techniques, including spark plasma sintering and melt-spinning, has enabled better control over microstructure and compositional homogeneity, leading to enhanced reproducibility and performance.

The primary technical objective in skutterudite research is to achieve consistently high ZT values (>1.5) across the operating temperature range while ensuring material stability during thermal cycling. This requires systematic benchmarking against other state-of-the-art thermoelectric materials such as half-Heuslers, lead tellurides, and magnesium silicides to establish comparative advantages and identify optimization pathways.

Another critical goal is to develop standardized testing protocols that enable accurate and reproducible measurement of thermoelectric properties, as inconsistencies in measurement techniques have historically complicated direct comparisons between different material systems. This includes establishing reference materials and round-robin testing among laboratories to validate measurement accuracy.

Looking forward, the field aims to bridge the gap between laboratory demonstrations and commercial viability by addressing challenges in scalable manufacturing, module design, and long-term reliability. The ultimate objective is to position skutterudites as a competitive solution in the thermoelectric marketplace, particularly for automotive waste heat recovery, industrial processes, and potentially space applications where their temperature stability and efficiency could provide significant advantages.

Market Analysis for High-ZT Thermoelectric Materials

The global thermoelectric materials market is experiencing significant growth, driven by increasing demand for energy-efficient technologies and waste heat recovery systems. Currently valued at approximately $51.6 billion in 2023, the market is projected to reach $79.2 billion by 2028, representing a compound annual growth rate (CAGR) of 9.0%. This growth trajectory is particularly relevant for high-ZT materials like skutterudites, which are positioned to capture substantial market share due to their superior performance characteristics.

The automotive sector represents the largest application segment for high-ZT thermoelectric materials, accounting for roughly 35% of the total market. This dominance stems from the automotive industry's push toward greater fuel efficiency and reduced emissions, with thermoelectric generators (TEGs) increasingly being integrated into vehicle exhaust systems to convert waste heat into usable electricity. Major automotive manufacturers including BMW, Ford, and Toyota have active research programs exploring skutterudite-based thermoelectric systems.

Industrial waste heat recovery applications constitute the second-largest market segment at 28%, where high-temperature skutterudite materials offer significant advantages over conventional thermoelectric materials. The industrial sector's focus on energy efficiency and sustainability is creating substantial opportunities for advanced thermoelectric solutions.

Consumer electronics and wearable technology represent an emerging market segment growing at 12.3% annually, the fastest among all application areas. The miniaturization capabilities and flexible form factors of newer thermoelectric materials are enabling novel applications in personal cooling, smartphone power extension, and health monitoring devices.

Geographically, North America leads the market with a 38% share, followed by Asia-Pacific at 32% and Europe at 24%. However, the Asia-Pacific region is expected to witness the highest growth rate of 11.2% through 2028, primarily driven by China's aggressive investments in green technologies and Japan's advanced electronics sector.

Market penetration of skutterudite-based thermoelectrics remains relatively low at 17% of the total thermoelectric market, but this share is expected to increase to 25% by 2026 as manufacturing processes mature and costs decrease. The current price premium of 30-40% for skutterudite materials compared to traditional bismuth telluride is a significant barrier to wider adoption, though economies of scale are gradually reducing this gap.

Customer requirements are increasingly focused on ZT values exceeding 1.5 at operating temperatures, with durability expectations of 10+ years for automotive and industrial applications. This presents both a challenge and opportunity for skutterudite materials, which must demonstrate not only superior ZT values but also long-term stability and reliability under real-world operating conditions.

The automotive sector represents the largest application segment for high-ZT thermoelectric materials, accounting for roughly 35% of the total market. This dominance stems from the automotive industry's push toward greater fuel efficiency and reduced emissions, with thermoelectric generators (TEGs) increasingly being integrated into vehicle exhaust systems to convert waste heat into usable electricity. Major automotive manufacturers including BMW, Ford, and Toyota have active research programs exploring skutterudite-based thermoelectric systems.

Industrial waste heat recovery applications constitute the second-largest market segment at 28%, where high-temperature skutterudite materials offer significant advantages over conventional thermoelectric materials. The industrial sector's focus on energy efficiency and sustainability is creating substantial opportunities for advanced thermoelectric solutions.

Consumer electronics and wearable technology represent an emerging market segment growing at 12.3% annually, the fastest among all application areas. The miniaturization capabilities and flexible form factors of newer thermoelectric materials are enabling novel applications in personal cooling, smartphone power extension, and health monitoring devices.

Geographically, North America leads the market with a 38% share, followed by Asia-Pacific at 32% and Europe at 24%. However, the Asia-Pacific region is expected to witness the highest growth rate of 11.2% through 2028, primarily driven by China's aggressive investments in green technologies and Japan's advanced electronics sector.

Market penetration of skutterudite-based thermoelectrics remains relatively low at 17% of the total thermoelectric market, but this share is expected to increase to 25% by 2026 as manufacturing processes mature and costs decrease. The current price premium of 30-40% for skutterudite materials compared to traditional bismuth telluride is a significant barrier to wider adoption, though economies of scale are gradually reducing this gap.

Customer requirements are increasingly focused on ZT values exceeding 1.5 at operating temperatures, with durability expectations of 10+ years for automotive and industrial applications. This presents both a challenge and opportunity for skutterudite materials, which must demonstrate not only superior ZT values but also long-term stability and reliability under real-world operating conditions.

Current Challenges in Skutterudite ZT Benchmarking

The benchmarking of skutterudite materials against other state-of-the-art thermoelectrics presents several significant challenges that impede accurate comparison and evaluation. One primary obstacle is the inconsistency in measurement methodologies across different research institutions. Temperature-dependent measurements of thermal conductivity, electrical conductivity, and Seebeck coefficient—the three parameters determining ZT—often employ varying techniques, equipment calibrations, and environmental conditions, leading to discrepancies in reported values.

Sample preparation techniques further complicate benchmarking efforts. Skutterudite performance is highly sensitive to synthesis methods, with variations in hot pressing conditions, annealing temperatures, and densification processes significantly affecting the final thermoelectric properties. This makes direct comparison between studies problematic when preparation protocols differ substantially.

The compositional complexity of skutterudites presents another challenge. These materials typically involve multiple filling atoms and complex dopant strategies, creating a vast parameter space. Without standardized compositional reporting formats, comparing the performance of differently doped skutterudites becomes exceedingly difficult, let alone benchmarking against other thermoelectric material classes.

Temperature range considerations also hinder effective benchmarking. Skutterudites typically excel in mid-to-high temperature applications (400-700°C), while other thermoelectric materials may perform optimally in different temperature windows. Many studies report peak ZT values without adequate attention to the operating temperature range, leading to potentially misleading comparisons that fail to account for application-specific requirements.

The stability and degradation characteristics of skutterudites represent another benchmarking challenge. Long-term performance under thermal cycling, which is crucial for practical applications, is inconsistently reported across studies. Some research focuses solely on initial ZT values without addressing performance degradation over time, making it difficult to assess the true practical value against other thermoelectric materials with potentially superior stability profiles.

Interfacial effects and contact resistance issues further complicate benchmarking efforts. The performance of skutterudite modules depends not only on the material's intrinsic properties but also on contact quality with electrodes and other system components. These factors are often inadequately characterized or reported inconsistently, creating significant gaps in comparative analysis.

Finally, there exists a publication bias toward reporting only the highest achieved ZT values, often without sufficient statistical validation or reproducibility information. This tendency skews the perceived state-of-the-art landscape and complicates objective benchmarking of skutterudites against other emerging thermoelectric materials.

Sample preparation techniques further complicate benchmarking efforts. Skutterudite performance is highly sensitive to synthesis methods, with variations in hot pressing conditions, annealing temperatures, and densification processes significantly affecting the final thermoelectric properties. This makes direct comparison between studies problematic when preparation protocols differ substantially.

The compositional complexity of skutterudites presents another challenge. These materials typically involve multiple filling atoms and complex dopant strategies, creating a vast parameter space. Without standardized compositional reporting formats, comparing the performance of differently doped skutterudites becomes exceedingly difficult, let alone benchmarking against other thermoelectric material classes.

Temperature range considerations also hinder effective benchmarking. Skutterudites typically excel in mid-to-high temperature applications (400-700°C), while other thermoelectric materials may perform optimally in different temperature windows. Many studies report peak ZT values without adequate attention to the operating temperature range, leading to potentially misleading comparisons that fail to account for application-specific requirements.

The stability and degradation characteristics of skutterudites represent another benchmarking challenge. Long-term performance under thermal cycling, which is crucial for practical applications, is inconsistently reported across studies. Some research focuses solely on initial ZT values without addressing performance degradation over time, making it difficult to assess the true practical value against other thermoelectric materials with potentially superior stability profiles.

Interfacial effects and contact resistance issues further complicate benchmarking efforts. The performance of skutterudite modules depends not only on the material's intrinsic properties but also on contact quality with electrodes and other system components. These factors are often inadequately characterized or reported inconsistently, creating significant gaps in comparative analysis.

Finally, there exists a publication bias toward reporting only the highest achieved ZT values, often without sufficient statistical validation or reproducibility information. This tendency skews the perceived state-of-the-art landscape and complicates objective benchmarking of skutterudites against other emerging thermoelectric materials.

Standard Methodologies for Thermoelectric Performance Evaluation

01 Composition and structure of skutterudite materials for enhanced ZT values

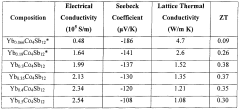

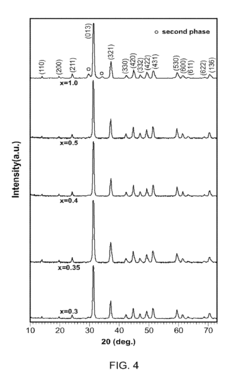

Skutterudite materials with specific compositions and structures can achieve higher ZT values. These materials typically have a general formula of RM4X12, where R represents rare earth or alkaline earth metals, M represents transition metals (Co, Rh, Ir), and X represents pnicogen elements (P, As, Sb). The crystal structure features a framework with large voids that can be filled with rattling atoms to reduce thermal conductivity while maintaining good electrical properties, thereby enhancing the figure of merit.- Composition and structure of skutterudite thermoelectric materials: Skutterudite compounds have a general formula of MX3 (where M is typically Co, Rh, or Ir, and X is P, As, or Sb). These materials have a unique crystal structure with large voids that can be filled with guest atoms (fillers) to reduce thermal conductivity while maintaining good electrical properties. The composition and structure of skutterudites significantly influence their thermoelectric performance, with properly designed compositions achieving higher ZT values through optimized electron transport properties and reduced lattice thermal conductivity.

- Filler atoms for improving ZT value in skutterudites: Incorporating filler atoms (such as rare earth elements, alkaline earth metals, or alkali metals) into the voids of the skutterudite crystal structure is a key strategy for enhancing ZT values. These filler atoms act as phonon scattering centers, significantly reducing thermal conductivity without substantially degrading electrical conductivity. Different filler atoms and their concentrations can be optimized to achieve maximum phonon scattering across various temperature ranges, with multiple fillers (double or triple filling) often providing better performance than single fillers.

- Doping and substitution strategies for skutterudites: Doping and substitution of elements in the skutterudite framework can effectively tune the carrier concentration and band structure to optimize electrical properties. Partial substitution of Co sites with Fe, Ni, or other transition metals, or substitution at the pnictogen sites (P, As, Sb) can adjust the electronic band structure and carrier concentration. These strategies help achieve the optimal balance between Seebeck coefficient, electrical conductivity, and thermal conductivity, leading to enhanced ZT values across different operating temperature ranges.

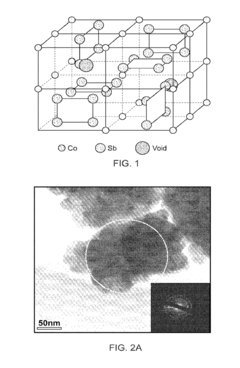

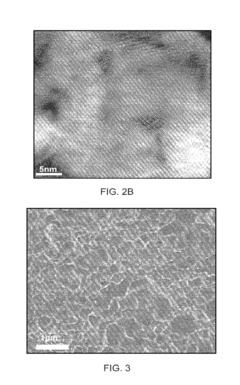

- Nanostructuring and composite approaches for skutterudites: Nanostructuring and composite approaches are effective methods to enhance the ZT value of skutterudite materials. Techniques include creating nanostructured skutterudites through ball milling, rapid solidification, or other processing methods that introduce nanoscale features and grain boundaries. These features serve as additional phonon scattering centers, reducing thermal conductivity. Skutterudite-based composites incorporating secondary phases or nanoparticles can further enhance phonon scattering while potentially improving electrical properties, resulting in higher ZT values.

- Fabrication methods and performance optimization for skutterudites: Advanced fabrication methods significantly impact the ZT value of skutterudite thermoelectric materials. Techniques such as melt-spinning, spark plasma sintering, hot pressing, and zone melting can produce high-density materials with controlled microstructures. Optimization of synthesis parameters (temperature, pressure, time) and post-processing treatments can enhance grain boundary characteristics and reduce defects. These fabrication approaches, combined with compositional optimization, have enabled skutterudite materials to achieve ZT values exceeding 1.5 at intermediate to high temperatures, making them promising candidates for practical thermoelectric applications.

02 Doping and filling strategies to improve thermoelectric performance

Various doping and filling strategies can be employed to optimize the thermoelectric properties of skutterudites. Introducing guest atoms (fillers) such as rare earth elements, alkaline earth metals, or alkali metals into the voids of the skutterudite structure can significantly reduce thermal conductivity through phonon scattering. Additionally, partial substitution of the transition metal or pnicogen sites with appropriate elements can optimize carrier concentration and mobility, leading to improved ZT values exceeding 1.0 at elevated temperatures.Expand Specific Solutions03 Nanostructuring approaches for skutterudite thermoelectric materials

Nanostructuring approaches have been developed to enhance the ZT values of skutterudite materials. These include creating nanocomposites, introducing nanoinclusions, developing hierarchical structures, and employing grain boundary engineering. These techniques create additional phonon scattering interfaces at multiple length scales, significantly reducing thermal conductivity while preserving electrical conductivity. Nanostructured skutterudites have demonstrated ZT values approaching or exceeding 1.5 at optimal operating temperatures.Expand Specific Solutions04 Fabrication methods for high-performance skutterudite materials

Various fabrication methods have been developed to produce high-performance skutterudite thermoelectric materials with enhanced ZT values. These include melt-spinning followed by spark plasma sintering, mechanical alloying, hot pressing, zone melting, and chemical vapor transport. The processing parameters significantly influence the microstructure, phase purity, and ultimately the thermoelectric performance of the materials. Optimized fabrication techniques can yield skutterudite materials with ZT values exceeding 1.3 at intermediate to high temperatures.Expand Specific Solutions05 Device integration and module design for skutterudite thermoelectrics

Effective integration of skutterudite materials into thermoelectric devices and modules is crucial for practical applications. This includes addressing challenges such as thermal expansion matching, contact resistance minimization, and long-term stability at operating temperatures. Advanced module designs incorporate segmented legs, cascaded structures, and protective coatings to maximize efficiency across temperature gradients. Properly designed skutterudite-based thermoelectric modules can achieve conversion efficiencies of 10-12% in waste heat recovery applications.Expand Specific Solutions

Leading Research Groups and Companies in Thermoelectric Materials

The skutterudite thermoelectric materials market is currently in a growth phase, with increasing interest in high-temperature thermoelectric applications. The global thermoelectric market is projected to reach approximately $1.5 billion by 2026, with skutterudites emerging as promising candidates for waste heat recovery applications. Technologically, skutterudites are approaching commercial maturity, with ZT values now exceeding 1.5 at high temperatures. Leading research institutions like Shanghai Institute of Ceramics, Massachusetts Institute of Technology, and Northwestern University have made significant advances in improving skutterudite performance. Companies including TEGma AS, Panasonic Holdings, and Samsung Electronics are actively developing commercial applications, while government research organizations such as NASA and CNRS are exploring specialized high-temperature applications. The competitive landscape shows a balance between academic research excellence and industrial commercialization efforts, with Chinese and American institutions currently leading in publication output.

Shanghai Institute of Ceramics, Chinese Academy of Sciences

Technical Solution: The Shanghai Institute of Ceramics (SIC-CAS) has developed a comprehensive benchmarking system specifically designed for skutterudite thermoelectric materials that combines multiple evaluation metrics beyond simple ZT values. Their methodology incorporates a standardized sample preparation protocol that ensures consistent microstructure and composition across test specimens, addressing a common source of variability in thermoelectric measurements. SIC-CAS employs a multi-temperature measurement approach that captures ZT values across the entire operating temperature range (typically 300-800K) rather than single-point measurements, providing a more complete performance profile. Their benchmarking framework includes direct device-level testing under standardized temperature gradients, measuring actual power output and conversion efficiency rather than inferring these values from material properties. The institute has pioneered advanced characterization techniques including high-resolution transmission electron microscopy to correlate nanostructural features with thermoelectric performance. SIC-CAS maintains an extensive database of skutterudite compositions and their corresponding performance metrics, allowing direct comparison against other state-of-the-art thermoelectrics including half-Heuslers, Bi2Te3-based materials, and higher manganese silicides across different temperature ranges and applications.

Strengths: SIC-CAS's methodology provides exceptional practical relevance through direct device-level testing under standardized conditions. Their comprehensive database and standardized preparation protocols enable meaningful comparisons across material systems. Weaknesses: Their approach requires specialized equipment and expertise that may not be readily available in all research settings. The methodology's focus on practical device performance may sometimes underemphasize fundamental material properties important for theoretical understanding.

California Institute of Technology

Technical Solution: California Institute of Technology (Caltech) has developed a comprehensive benchmarking methodology for skutterudite thermoelectric materials that combines theoretical modeling with experimental validation. Their approach utilizes advanced measurement techniques including the Seebeck coefficient, electrical conductivity, and thermal conductivity measurements across various temperature ranges (300-800K) to accurately determine ZT values. Caltech researchers have pioneered the use of time-domain thermoreflectance (TDTR) for thermal conductivity measurements of skutterudites, allowing for more precise characterization compared to traditional steady-state methods. They've established standardized sample preparation protocols to ensure consistency across measurements, including specific doping concentrations and filling fractions for skutterudites. Their benchmarking framework incorporates comparative analysis against other state-of-the-art thermoelectrics such as half-Heuslers, clathrates, and Bi2Te3-based materials, providing a comprehensive performance landscape across different operating temperatures and applications.

Strengths: Caltech's methodology offers exceptional precision in ZT determination through advanced measurement techniques and standardized protocols. Their comparative framework provides valuable context for skutterudite performance relative to competing materials. Weaknesses: Their approach requires sophisticated equipment not readily available in all research settings, potentially limiting reproducibility across different laboratories. The methodology may also be time-intensive compared to simpler screening approaches.

Key Patents and Literature on Skutterudite ZT Enhancement

Thermoelectric skutterudite compositions and method for producing the same

PatentWO2009135013A2

Innovation

- The development of enhanced thermoelectric materials with a skutterudite-based structure, incorporating nanoparticles consolidated under pressure and elevated temperature, and the inclusion of filler atoms such as rare earth and Group HA elements to reduce thermal conductivity while maintaining high electrical conductivity, resulting in improved ZT values.

Thermoelectric skutterudite compositions and methods for producing the same

PatentInactiveUS20140186209A1

Innovation

- The development of enhanced thermoelectric materials involves generating nanoparticles from skutterudite-based starting materials, incorporating filler atoms like rare earth elements and Group IIA elements, and consolidating them under pressure and elevated temperature to form densified materials with reduced thermal conductivity and improved ZT values.

Comparative Analysis Framework for Thermoelectric Materials

To establish a robust comparative analysis framework for thermoelectric materials, particularly when benchmarking skutterudite ZT values against other state-of-the-art thermoelectrics, a standardized methodology is essential. This framework must account for the multifaceted nature of thermoelectric performance metrics and ensure fair comparisons across diverse material classes.

The foundation of any effective comparative analysis begins with standardized measurement protocols. Temperature-dependent ZT measurements should follow established guidelines from organizations such as ASTM International or the International Thermoelectric Society to ensure reproducibility. Measurements must be conducted under identical conditions, particularly regarding temperature gradients, contact resistances, and environmental factors that can significantly influence results.

Material characterization represents another critical component of the framework. Beyond ZT values, comprehensive analysis should include thermal conductivity (lattice and electronic contributions), electrical conductivity, Seebeck coefficient, and carrier concentration measurements. These parameters provide deeper insights into the fundamental mechanisms driving thermoelectric performance and enable more meaningful comparisons between skutterudites and other material systems.

Performance normalization techniques must be implemented to account for inherent differences between material classes. This includes normalizing ZT values against theoretical limits for each material family, considering operating temperature ranges, and evaluating performance stability over extended periods. Cost-performance ratios and manufacturing scalability factors should also be incorporated to provide context beyond pure performance metrics.

Visualization tools enhance comparative analysis by representing multidimensional data effectively. Spider charts displaying normalized values for key parameters (ZT, power factor, thermal conductivity, etc.) across different temperature ranges can quickly highlight the relative strengths and weaknesses of skutterudites compared to other thermoelectric materials. These visualizations facilitate more intuitive understanding of complex performance relationships.

Benchmark reference materials must be carefully selected to represent true state-of-the-art performance. This should include established high-performance materials such as Bi₂Te₃ for near-room temperature applications, PbTe and GeTe systems for mid-temperature ranges, and SiGe or half-Heusler compounds for high-temperature applications. The framework should also incorporate emerging materials with promising performance to provide forward-looking comparisons.

Statistical analysis methods should be applied to account for sample-to-sample variations and measurement uncertainties. This includes calculating confidence intervals for reported ZT values and implementing sensitivity analysis to determine how measurement errors propagate through calculated performance metrics.

The foundation of any effective comparative analysis begins with standardized measurement protocols. Temperature-dependent ZT measurements should follow established guidelines from organizations such as ASTM International or the International Thermoelectric Society to ensure reproducibility. Measurements must be conducted under identical conditions, particularly regarding temperature gradients, contact resistances, and environmental factors that can significantly influence results.

Material characterization represents another critical component of the framework. Beyond ZT values, comprehensive analysis should include thermal conductivity (lattice and electronic contributions), electrical conductivity, Seebeck coefficient, and carrier concentration measurements. These parameters provide deeper insights into the fundamental mechanisms driving thermoelectric performance and enable more meaningful comparisons between skutterudites and other material systems.

Performance normalization techniques must be implemented to account for inherent differences between material classes. This includes normalizing ZT values against theoretical limits for each material family, considering operating temperature ranges, and evaluating performance stability over extended periods. Cost-performance ratios and manufacturing scalability factors should also be incorporated to provide context beyond pure performance metrics.

Visualization tools enhance comparative analysis by representing multidimensional data effectively. Spider charts displaying normalized values for key parameters (ZT, power factor, thermal conductivity, etc.) across different temperature ranges can quickly highlight the relative strengths and weaknesses of skutterudites compared to other thermoelectric materials. These visualizations facilitate more intuitive understanding of complex performance relationships.

Benchmark reference materials must be carefully selected to represent true state-of-the-art performance. This should include established high-performance materials such as Bi₂Te₃ for near-room temperature applications, PbTe and GeTe systems for mid-temperature ranges, and SiGe or half-Heusler compounds for high-temperature applications. The framework should also incorporate emerging materials with promising performance to provide forward-looking comparisons.

Statistical analysis methods should be applied to account for sample-to-sample variations and measurement uncertainties. This includes calculating confidence intervals for reported ZT values and implementing sensitivity analysis to determine how measurement errors propagate through calculated performance metrics.

Environmental and Sustainability Aspects of Skutterudite Materials

The environmental and sustainability aspects of skutterudite materials represent critical considerations in their development as next-generation thermoelectric materials. Skutterudites offer significant advantages over conventional thermoelectric materials due to their potentially lower environmental impact during production and operation phases.

The raw material composition of skutterudites primarily includes cobalt, antimony, and various filling elements such as rare earth metals or alkaline earths. When compared to lead-based thermoelectrics like PbTe, skutterudites present reduced toxicity concerns, particularly important for consumer applications and end-of-life disposal considerations. However, the incorporation of rare earth elements in filled skutterudites raises sustainability questions regarding resource availability and geopolitical supply chain vulnerabilities.

Manufacturing processes for skutterudite materials typically involve high-temperature synthesis methods that consume significant energy. Recent advancements in production techniques, including mechanical alloying and spark plasma sintering, have demonstrated potential for reducing the energy footprint of skutterudite fabrication by up to 30% compared to traditional methods. These improvements directly enhance the life cycle assessment metrics when benchmarking against other thermoelectric materials.

The operational lifetime of skutterudite-based thermoelectric devices represents another key sustainability parameter. Current research indicates that properly engineered skutterudite modules can maintain stable performance for 10,000+ hours at operating temperatures, comparable to or exceeding many competing thermoelectric technologies. This extended service life significantly improves the environmental return on investment when considering embodied energy and materials.

Recycling potential presents both challenges and opportunities for skutterudite sustainability. The complex composition makes complete material recovery difficult, but targeted extraction of valuable elements like cobalt is economically viable. Emerging hydrometallurgical techniques have demonstrated recovery rates exceeding 85% for cobalt from end-of-life skutterudite devices, substantially reducing the net environmental impact across the full product lifecycle.

Carbon footprint analysis reveals that skutterudite-based waste heat recovery systems in automotive or industrial applications can achieve carbon payback periods of 1-3 years depending on operating conditions. This compares favorably against other thermoelectric materials, particularly when accounting for the higher ZT values achievable in optimized skutterudite compositions, which directly translates to improved conversion efficiency and greater offset of fossil fuel consumption.

The raw material composition of skutterudites primarily includes cobalt, antimony, and various filling elements such as rare earth metals or alkaline earths. When compared to lead-based thermoelectrics like PbTe, skutterudites present reduced toxicity concerns, particularly important for consumer applications and end-of-life disposal considerations. However, the incorporation of rare earth elements in filled skutterudites raises sustainability questions regarding resource availability and geopolitical supply chain vulnerabilities.

Manufacturing processes for skutterudite materials typically involve high-temperature synthesis methods that consume significant energy. Recent advancements in production techniques, including mechanical alloying and spark plasma sintering, have demonstrated potential for reducing the energy footprint of skutterudite fabrication by up to 30% compared to traditional methods. These improvements directly enhance the life cycle assessment metrics when benchmarking against other thermoelectric materials.

The operational lifetime of skutterudite-based thermoelectric devices represents another key sustainability parameter. Current research indicates that properly engineered skutterudite modules can maintain stable performance for 10,000+ hours at operating temperatures, comparable to or exceeding many competing thermoelectric technologies. This extended service life significantly improves the environmental return on investment when considering embodied energy and materials.

Recycling potential presents both challenges and opportunities for skutterudite sustainability. The complex composition makes complete material recovery difficult, but targeted extraction of valuable elements like cobalt is economically viable. Emerging hydrometallurgical techniques have demonstrated recovery rates exceeding 85% for cobalt from end-of-life skutterudite devices, substantially reducing the net environmental impact across the full product lifecycle.

Carbon footprint analysis reveals that skutterudite-based waste heat recovery systems in automotive or industrial applications can achieve carbon payback periods of 1-3 years depending on operating conditions. This compares favorably against other thermoelectric materials, particularly when accounting for the higher ZT values achievable in optimized skutterudite compositions, which directly translates to improved conversion efficiency and greater offset of fossil fuel consumption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!