Dynamic Power Distribution Innovation in 454 Big Block Engines

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

454 Engine Power Evolution

The 454 big block engine, introduced by Chevrolet in 1970, has undergone significant power evolution over the decades. Initially designed for high-performance applications, this engine has seen continuous improvements in power output and efficiency through various technological advancements.

In its early years, the 454 engine produced around 360-390 horsepower, depending on the specific configuration. This was achieved through traditional methods such as high compression ratios, aggressive camshaft profiles, and large-bore carburetion. As emission regulations tightened in the mid-1970s, power output temporarily decreased, but engineers found innovative ways to maintain performance while meeting new standards.

The 1980s and 1990s saw a resurgence in power output for the 454, largely due to the introduction of electronic fuel injection (EFI) systems. This technology allowed for more precise fuel metering and ignition timing, resulting in improved combustion efficiency and increased power. By the late 1990s, some 454 engines were capable of producing over 500 horsepower in stock form.

The turn of the millennium brought further advancements in engine management systems and materials technology. Computer-controlled engine management units (ECUs) enabled real-time adjustments to fuel and ignition parameters, optimizing performance across a wide range of operating conditions. Additionally, the use of lightweight materials such as aluminum for cylinder heads and intake manifolds helped reduce overall engine weight while improving thermal efficiency.

In recent years, the focus has shifted towards improving the 454's power-to-weight ratio and fuel efficiency without sacrificing performance. This has been achieved through the implementation of variable valve timing (VVT) systems, direct fuel injection, and advanced turbocharging technologies. These innovations have allowed modern 454 engines to produce upwards of 600 horsepower while maintaining reasonable fuel economy and meeting stringent emissions standards.

The latest frontier in 454 engine power evolution is the integration of hybrid and electric assist technologies. While still in the experimental stages for high-performance applications, these systems promise to provide instantaneous torque boost and improved overall efficiency. This represents a significant departure from traditional power enhancement methods and signals a new era in big block engine development.

Throughout its evolution, the 454 big block engine has remained a symbol of American muscle and engineering prowess. Its ability to adapt to changing regulations and market demands while continually increasing power output is a testament to the ingenuity of automotive engineers and the enduring appeal of high-performance engines.

In its early years, the 454 engine produced around 360-390 horsepower, depending on the specific configuration. This was achieved through traditional methods such as high compression ratios, aggressive camshaft profiles, and large-bore carburetion. As emission regulations tightened in the mid-1970s, power output temporarily decreased, but engineers found innovative ways to maintain performance while meeting new standards.

The 1980s and 1990s saw a resurgence in power output for the 454, largely due to the introduction of electronic fuel injection (EFI) systems. This technology allowed for more precise fuel metering and ignition timing, resulting in improved combustion efficiency and increased power. By the late 1990s, some 454 engines were capable of producing over 500 horsepower in stock form.

The turn of the millennium brought further advancements in engine management systems and materials technology. Computer-controlled engine management units (ECUs) enabled real-time adjustments to fuel and ignition parameters, optimizing performance across a wide range of operating conditions. Additionally, the use of lightweight materials such as aluminum for cylinder heads and intake manifolds helped reduce overall engine weight while improving thermal efficiency.

In recent years, the focus has shifted towards improving the 454's power-to-weight ratio and fuel efficiency without sacrificing performance. This has been achieved through the implementation of variable valve timing (VVT) systems, direct fuel injection, and advanced turbocharging technologies. These innovations have allowed modern 454 engines to produce upwards of 600 horsepower while maintaining reasonable fuel economy and meeting stringent emissions standards.

The latest frontier in 454 engine power evolution is the integration of hybrid and electric assist technologies. While still in the experimental stages for high-performance applications, these systems promise to provide instantaneous torque boost and improved overall efficiency. This represents a significant departure from traditional power enhancement methods and signals a new era in big block engine development.

Throughout its evolution, the 454 big block engine has remained a symbol of American muscle and engineering prowess. Its ability to adapt to changing regulations and market demands while continually increasing power output is a testament to the ingenuity of automotive engineers and the enduring appeal of high-performance engines.

Market Demand Analysis

The market demand for dynamic power distribution innovation in 454 Big Block engines is driven by several key factors in the automotive and performance vehicle sectors. As emissions regulations become increasingly stringent worldwide, there is a growing need for more efficient and cleaner large-displacement engines. This has created a significant market opportunity for technologies that can optimize power delivery while reducing fuel consumption and emissions.

Performance enthusiasts and racing teams continue to seek ways to extract maximum power from these engines without compromising reliability. This demand is particularly strong in motorsports applications, where even marginal gains in power distribution can translate to competitive advantages on the track. The aftermarket modification industry also plays a crucial role, as consumers look for ways to enhance the performance of their vehicles equipped with 454 Big Block engines.

In the commercial sector, there is a substantial market for improved 454 Big Block engines in heavy-duty trucks, marine applications, and industrial equipment. These industries require engines that can deliver high torque and power output while meeting increasingly strict environmental standards. The ability to dynamically distribute power based on load conditions can significantly improve fuel efficiency and reduce operational costs for fleet operators.

The global market for large displacement engines, including 454 Big Blocks, is expected to grow steadily over the next five years. This growth is fueled by the ongoing demand in North America, where these engines remain popular in performance vehicles and certain commercial applications. Emerging markets in Asia and South America are also showing increased interest in high-performance engines, creating new opportunities for innovative power distribution technologies.

However, the market is not without challenges. The shift towards electrification in the automotive industry poses a potential threat to the long-term demand for large combustion engines. This trend is pushing manufacturers to invest in hybrid technologies and advanced power management systems that can bridge the gap between traditional combustion engines and fully electric powertrains.

Despite these challenges, the immediate market demand for dynamic power distribution innovations in 454 Big Block engines remains strong. Manufacturers and aftermarket suppliers who can deliver solutions that enhance performance, improve efficiency, and meet emissions standards are well-positioned to capture significant market share. The key to success lies in developing technologies that can adapt to changing regulatory landscapes while still satisfying the power and performance requirements of enthusiasts and commercial users alike.

Performance enthusiasts and racing teams continue to seek ways to extract maximum power from these engines without compromising reliability. This demand is particularly strong in motorsports applications, where even marginal gains in power distribution can translate to competitive advantages on the track. The aftermarket modification industry also plays a crucial role, as consumers look for ways to enhance the performance of their vehicles equipped with 454 Big Block engines.

In the commercial sector, there is a substantial market for improved 454 Big Block engines in heavy-duty trucks, marine applications, and industrial equipment. These industries require engines that can deliver high torque and power output while meeting increasingly strict environmental standards. The ability to dynamically distribute power based on load conditions can significantly improve fuel efficiency and reduce operational costs for fleet operators.

The global market for large displacement engines, including 454 Big Blocks, is expected to grow steadily over the next five years. This growth is fueled by the ongoing demand in North America, where these engines remain popular in performance vehicles and certain commercial applications. Emerging markets in Asia and South America are also showing increased interest in high-performance engines, creating new opportunities for innovative power distribution technologies.

However, the market is not without challenges. The shift towards electrification in the automotive industry poses a potential threat to the long-term demand for large combustion engines. This trend is pushing manufacturers to invest in hybrid technologies and advanced power management systems that can bridge the gap between traditional combustion engines and fully electric powertrains.

Despite these challenges, the immediate market demand for dynamic power distribution innovations in 454 Big Block engines remains strong. Manufacturers and aftermarket suppliers who can deliver solutions that enhance performance, improve efficiency, and meet emissions standards are well-positioned to capture significant market share. The key to success lies in developing technologies that can adapt to changing regulatory landscapes while still satisfying the power and performance requirements of enthusiasts and commercial users alike.

Current Challenges

The 454 Big Block Engine, renowned for its power and performance, faces several significant challenges in the realm of dynamic power distribution innovation. One of the primary issues is the inherent inefficiency in power delivery across the engine's operating range. Traditional power distribution systems struggle to optimize fuel consumption and power output simultaneously, leading to suboptimal performance in various driving conditions.

Heat management presents another critical challenge. The massive power output of the 454 Big Block Engine generates substantial heat, which can negatively impact engine performance and longevity. Current cooling systems often fall short in effectively dissipating this excess heat, particularly during high-load operations or in extreme environmental conditions.

Emissions control is an increasingly pressing concern for big block engines. Stricter environmental regulations demand cleaner exhaust outputs, which is particularly challenging for high-displacement engines like the 454. Balancing the engine's power characteristics with emission reduction technologies without compromising performance is a complex engineering task.

The weight of the 454 Big Block Engine poses challenges in terms of vehicle dynamics and fuel efficiency. Its substantial mass affects the overall weight distribution of the vehicle, impacting handling and acceleration. Innovative approaches to weight reduction while maintaining structural integrity and power output are necessary.

Advancements in electronic control systems have introduced new challenges in integrating sophisticated power management technologies with the traditional mechanical design of the 454 Big Block Engine. Achieving seamless communication between electronic controls and mechanical components to optimize power distribution is a significant hurdle.

Fuel efficiency remains a persistent challenge, especially given the engine's large displacement and high power output. Developing technologies to improve fuel economy without sacrificing the engine's renowned power characteristics is crucial for its continued relevance in an increasingly efficiency-conscious market.

Lastly, the adaptability of the 454 Big Block Engine to alternative fuels and hybrid technologies presents both a challenge and an opportunity. Integrating these modern powertrain innovations while preserving the engine's core attributes requires substantial engineering efforts and may necessitate fundamental redesigns of certain engine components.

Heat management presents another critical challenge. The massive power output of the 454 Big Block Engine generates substantial heat, which can negatively impact engine performance and longevity. Current cooling systems often fall short in effectively dissipating this excess heat, particularly during high-load operations or in extreme environmental conditions.

Emissions control is an increasingly pressing concern for big block engines. Stricter environmental regulations demand cleaner exhaust outputs, which is particularly challenging for high-displacement engines like the 454. Balancing the engine's power characteristics with emission reduction technologies without compromising performance is a complex engineering task.

The weight of the 454 Big Block Engine poses challenges in terms of vehicle dynamics and fuel efficiency. Its substantial mass affects the overall weight distribution of the vehicle, impacting handling and acceleration. Innovative approaches to weight reduction while maintaining structural integrity and power output are necessary.

Advancements in electronic control systems have introduced new challenges in integrating sophisticated power management technologies with the traditional mechanical design of the 454 Big Block Engine. Achieving seamless communication between electronic controls and mechanical components to optimize power distribution is a significant hurdle.

Fuel efficiency remains a persistent challenge, especially given the engine's large displacement and high power output. Developing technologies to improve fuel economy without sacrificing the engine's renowned power characteristics is crucial for its continued relevance in an increasingly efficiency-conscious market.

Lastly, the adaptability of the 454 Big Block Engine to alternative fuels and hybrid technologies presents both a challenge and an opportunity. Integrating these modern powertrain innovations while preserving the engine's core attributes requires substantial engineering efforts and may necessitate fundamental redesigns of certain engine components.

Existing Power Solutions

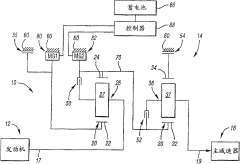

01 Power distribution system for 454 Big Block Engines

The power distribution system for 454 Big Block Engines involves specialized components and configurations to efficiently manage and distribute the high power output. This system may include enhanced electrical components, robust wiring harnesses, and optimized power routing to ensure reliable performance and prevent overheating or electrical failures in high-performance applications.- Power distribution system for 454 Big Block Engines: Advanced power distribution systems designed specifically for 454 Big Block Engines, focusing on efficient energy allocation and management. These systems optimize power delivery to various engine components, enhancing overall performance and reliability.

- Electronic control modules for 454 Big Block Engines: Specialized electronic control modules tailored for 454 Big Block Engines, providing precise management of engine parameters. These modules regulate fuel injection, ignition timing, and other critical functions to maximize power output and efficiency.

- Cooling and lubrication systems for high-performance engines: Advanced cooling and lubrication systems designed to handle the increased heat and stress generated by 454 Big Block Engines. These systems ensure optimal operating temperatures and reduce wear on engine components, contributing to improved power distribution and longevity.

- Fuel delivery and combustion optimization: Innovative fuel delivery and combustion optimization techniques for 454 Big Block Engines. These advancements focus on improving fuel atomization, enhancing air-fuel mixture, and optimizing combustion chamber design to increase power output and efficiency.

- Power transmission and drivetrain enhancements: Specialized power transmission and drivetrain components designed to handle the high torque output of 454 Big Block Engines. These enhancements include reinforced transmissions, heavy-duty clutches, and optimized gear ratios to effectively distribute power to the wheels.

02 Ignition system improvements for 454 Big Block Engines

Advancements in ignition systems for 454 Big Block Engines focus on enhancing spark delivery and timing control. These improvements may include high-output ignition coils, performance distributors, and electronic ignition modules designed to handle the increased power demands and improve overall engine efficiency and reliability.Expand Specific Solutions03 Fuel delivery optimization for 454 Big Block Engines

Optimizing fuel delivery in 454 Big Block Engines involves modifications to the fuel system components and management. This may include high-flow fuel pumps, larger injectors, and advanced fuel management systems to ensure proper fuel distribution and atomization, supporting the engine's high power output while maintaining efficiency.Expand Specific Solutions04 Cooling system enhancements for 454 Big Block Engines

Cooling system enhancements for 454 Big Block Engines are crucial for managing the increased heat generated by high-performance operations. These improvements may include high-capacity radiators, electric cooling fans, and optimized coolant flow paths to maintain optimal operating temperatures and prevent overheating during demanding use.Expand Specific Solutions05 Power management and control systems for 454 Big Block Engines

Advanced power management and control systems for 454 Big Block Engines incorporate electronic control units (ECUs) and sensors to optimize performance. These systems may include programmable engine management, real-time monitoring, and adaptive tuning capabilities to maximize power output while ensuring engine longevity and reliability across various operating conditions.Expand Specific Solutions

Key Industry Players

The dynamic power distribution innovation in 454 Big Block Engines represents a competitive landscape in the mature automotive industry. The market for high-performance engines is substantial, driven by demand from enthusiasts and racing applications. Technologically, this field is advancing rapidly, with companies like Toyota Motor Corp., Honda Motor Co., Ltd., and BYD Co., Ltd. leading the charge in engine efficiency and power management. These firms are leveraging their extensive R&D capabilities to develop cutting-edge solutions. Additionally, academic institutions such as the National University of Defense Technology and Jilin University are contributing to theoretical advancements, potentially influencing future industry directions. The collaboration between industry leaders and research institutions is accelerating innovation in this specialized sector.

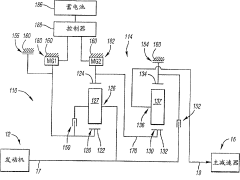

Caterpillar, Inc.

Technical Solution: Caterpillar has developed an innovative Dynamic Power Distribution system for 454 Big Block Engines, focusing on optimizing fuel efficiency and power output. Their approach utilizes advanced electronic control units (ECUs) to continuously monitor engine load, speed, and environmental conditions. The system dynamically adjusts fuel injection timing, duration, and pressure to match the engine's instantaneous power requirements[1]. Additionally, Caterpillar has implemented variable valve actuation technology, allowing for real-time adjustment of valve timing and lift to further enhance power distribution across different operating conditions[3]. This system also incorporates predictive algorithms that anticipate power demands based on historical usage patterns and terrain data, enabling proactive power management[5].

Strengths: Improved fuel efficiency, enhanced power output across various operating conditions, and reduced emissions. Weaknesses: Increased system complexity, potential higher initial costs, and reliance on sophisticated electronic components.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has developed an advanced Dynamic Power Distribution system for 454 Big Block Engines, leveraging their expertise in automotive electronics and fuel systems. Their approach combines high-precision direct fuel injection with intelligent engine management systems. The system utilizes advanced sensors to monitor engine parameters and driving conditions in real-time, adjusting fuel injection patterns and timing to optimize power delivery and efficiency[10]. Bosch has also integrated their innovative start-stop technology, which dynamically shuts off and restarts the engine during idle periods to conserve fuel. Furthermore, they have developed a smart thermal management system that optimizes engine temperature across various operating conditions, contributing to improved power distribution and overall efficiency[12].

Strengths: High precision in fuel delivery and engine management, seamless integration with other vehicle systems, and proven reliability. Weaknesses: Potential high costs due to sophisticated components, complexity in servicing and maintenance, and reliance on proprietary software systems.

Core Innovations Review

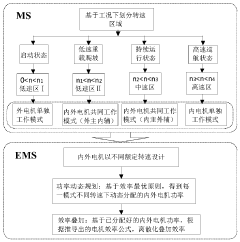

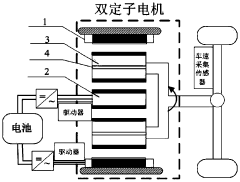

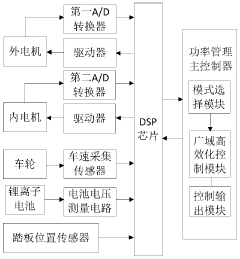

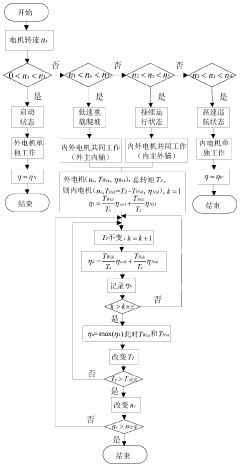

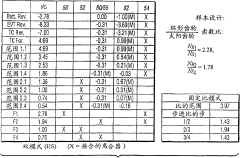

Wide-area high-efficiency dynamic power distribution method for dual-stator vehicle driving motor under multiple operation conditions

PatentActiveCN110149075A

Innovation

- A multi-step approach is adopted: first, the mode selection module is used to divide the working modes according to the vehicle speed, and then the wide-area high-efficiency control method is used to design the internal and external motors according to different rated speeds to form high-efficiency areas that are as dispersed as possible, and through the dynamics of maximizing transient efficiency The power distribution method optimizes the superposition of high-efficiency areas in each mode and expands the overall high-efficiency area of the motor.

Electrically variable transmission having two planetary gear sets with one fixed interconnection

PatentActiveCN100591951C

Innovation

- Using an electric transmission design that includes two planetary gear sets, two motor/generators, and four or five torque transmitting devices, components such as planetary gear sets and clutches enable selective operation in different speed ratio and torque ratio ranges. , providing improved acceleration performance and fuel economy.

Emissions Regulations Impact

The impact of emissions regulations on dynamic power distribution innovation in 454 Big Block engines has been significant and far-reaching. As environmental concerns have grown, regulatory bodies worldwide have implemented increasingly stringent emissions standards for automotive engines, including large displacement units like the 454 Big Block.

These regulations have necessitated substantial changes in engine design and operation, particularly in the realm of power distribution. Traditional 454 Big Block engines, known for their raw power output, have had to evolve to meet modern emissions requirements without sacrificing performance. This has led to innovative approaches in managing power delivery and combustion efficiency.

One key area of focus has been the development of advanced fuel injection systems. These systems allow for more precise control over fuel delivery, optimizing the air-fuel mixture across different engine loads and speeds. This not only helps reduce emissions but also contributes to improved power distribution throughout the engine's operating range.

Variable valve timing (VVT) technology has also played a crucial role in meeting emissions standards while enhancing dynamic power distribution. By adjusting valve timing based on engine speed and load, VVT systems can optimize combustion efficiency and reduce emissions across a wide range of operating conditions. This technology has allowed 454 Big Block engines to maintain their power characteristics while complying with stricter regulations.

Exhaust gas recirculation (EGR) systems have been another important innovation driven by emissions regulations. By recirculating a portion of exhaust gases back into the combustion chamber, EGR systems help reduce nitrogen oxide (NOx) emissions, a key target of many emissions standards. While this can potentially impact power output, innovative designs have minimized performance losses while achieving significant emissions reductions.

The integration of advanced electronic control units (ECUs) has been crucial in managing these various systems to optimize both emissions compliance and power distribution. Modern ECUs can continuously adjust engine parameters in real-time, ensuring optimal performance while staying within emissions limits.

Catalytic converter technology has also seen significant advancements, driven by the need to meet stricter emissions standards. High-flow catalytic converters designed specifically for high-performance engines like the 454 Big Block have been developed, allowing for effective emissions reduction without excessively restricting exhaust flow and power output.

These innovations in dynamic power distribution, driven by emissions regulations, have not only helped 454 Big Block engines remain relevant in an increasingly environmentally conscious market but have also contributed to overall improvements in engine efficiency and performance. As regulations continue to evolve, further innovations in this area are likely to emerge, shaping the future of high-performance engine design.

These regulations have necessitated substantial changes in engine design and operation, particularly in the realm of power distribution. Traditional 454 Big Block engines, known for their raw power output, have had to evolve to meet modern emissions requirements without sacrificing performance. This has led to innovative approaches in managing power delivery and combustion efficiency.

One key area of focus has been the development of advanced fuel injection systems. These systems allow for more precise control over fuel delivery, optimizing the air-fuel mixture across different engine loads and speeds. This not only helps reduce emissions but also contributes to improved power distribution throughout the engine's operating range.

Variable valve timing (VVT) technology has also played a crucial role in meeting emissions standards while enhancing dynamic power distribution. By adjusting valve timing based on engine speed and load, VVT systems can optimize combustion efficiency and reduce emissions across a wide range of operating conditions. This technology has allowed 454 Big Block engines to maintain their power characteristics while complying with stricter regulations.

Exhaust gas recirculation (EGR) systems have been another important innovation driven by emissions regulations. By recirculating a portion of exhaust gases back into the combustion chamber, EGR systems help reduce nitrogen oxide (NOx) emissions, a key target of many emissions standards. While this can potentially impact power output, innovative designs have minimized performance losses while achieving significant emissions reductions.

The integration of advanced electronic control units (ECUs) has been crucial in managing these various systems to optimize both emissions compliance and power distribution. Modern ECUs can continuously adjust engine parameters in real-time, ensuring optimal performance while staying within emissions limits.

Catalytic converter technology has also seen significant advancements, driven by the need to meet stricter emissions standards. High-flow catalytic converters designed specifically for high-performance engines like the 454 Big Block have been developed, allowing for effective emissions reduction without excessively restricting exhaust flow and power output.

These innovations in dynamic power distribution, driven by emissions regulations, have not only helped 454 Big Block engines remain relevant in an increasingly environmentally conscious market but have also contributed to overall improvements in engine efficiency and performance. As regulations continue to evolve, further innovations in this area are likely to emerge, shaping the future of high-performance engine design.

Performance Benchmarking

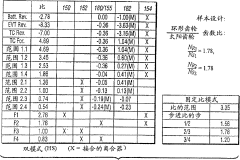

Performance benchmarking is a critical aspect of evaluating the dynamic power distribution innovations in 454 Big Block engines. This process involves comprehensive testing and analysis to quantify the improvements in engine performance, efficiency, and overall power delivery.

To establish a baseline, standard 454 Big Block engines are subjected to a series of controlled tests on dynamometers. These tests measure key performance indicators such as horsepower, torque, fuel consumption, and power-to-weight ratio across various RPM ranges. The results are meticulously recorded and serve as the reference point for comparison.

The innovative dynamic power distribution systems are then integrated into the test engines. These modifications may include advanced electronic control units, variable valve timing mechanisms, or intelligent fuel injection systems. The modified engines undergo the same battery of tests as the baseline models, ensuring consistency in testing conditions and methodologies.

Comparative analysis of the data reveals the impact of the dynamic power distribution innovations. Typically, improvements are observed in areas such as peak horsepower, torque curve smoothness, and throttle response. The analysis also considers factors like fuel efficiency gains and emissions reductions, which are increasingly important in modern engine design.

Real-world performance testing complements the laboratory results. This involves installing the modified engines in vehicles and conducting road tests under various driving conditions. Acceleration times, top speed, and drivability characteristics are assessed to provide a holistic view of the engine's performance in practical scenarios.

Durability and reliability testing form another crucial component of the benchmarking process. Long-duration stress tests are conducted to evaluate the longevity and stability of the new power distribution systems under extreme conditions. This helps identify any potential weaknesses or areas for further refinement in the innovative technologies.

The benchmarking data is then compiled and analyzed to create comprehensive performance profiles. These profiles illustrate the advantages of the dynamic power distribution innovations across different operational parameters. Advanced data visualization techniques are employed to present the findings in an easily interpretable format, highlighting key improvements and any trade-offs.

Finally, the benchmarking results are contextualized within the broader automotive industry standards. This involves comparing the performance metrics of the innovated 454 Big Block engines against competitors' offerings and industry benchmarks. Such comparisons provide valuable insights into the competitive positioning of the new technology and its potential impact on the market.

To establish a baseline, standard 454 Big Block engines are subjected to a series of controlled tests on dynamometers. These tests measure key performance indicators such as horsepower, torque, fuel consumption, and power-to-weight ratio across various RPM ranges. The results are meticulously recorded and serve as the reference point for comparison.

The innovative dynamic power distribution systems are then integrated into the test engines. These modifications may include advanced electronic control units, variable valve timing mechanisms, or intelligent fuel injection systems. The modified engines undergo the same battery of tests as the baseline models, ensuring consistency in testing conditions and methodologies.

Comparative analysis of the data reveals the impact of the dynamic power distribution innovations. Typically, improvements are observed in areas such as peak horsepower, torque curve smoothness, and throttle response. The analysis also considers factors like fuel efficiency gains and emissions reductions, which are increasingly important in modern engine design.

Real-world performance testing complements the laboratory results. This involves installing the modified engines in vehicles and conducting road tests under various driving conditions. Acceleration times, top speed, and drivability characteristics are assessed to provide a holistic view of the engine's performance in practical scenarios.

Durability and reliability testing form another crucial component of the benchmarking process. Long-duration stress tests are conducted to evaluate the longevity and stability of the new power distribution systems under extreme conditions. This helps identify any potential weaknesses or areas for further refinement in the innovative technologies.

The benchmarking data is then compiled and analyzed to create comprehensive performance profiles. These profiles illustrate the advantages of the dynamic power distribution innovations across different operational parameters. Advanced data visualization techniques are employed to present the findings in an easily interpretable format, highlighting key improvements and any trade-offs.

Finally, the benchmarking results are contextualized within the broader automotive industry standards. This involves comparing the performance metrics of the innovated 454 Big Block engines against competitors' offerings and industry benchmarks. Such comparisons provide valuable insights into the competitive positioning of the new technology and its potential impact on the market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!