Encapsulation Techniques for PCMs: Materials, Leakage Prevention and Manufacturing Considerations

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PCM Encapsulation Background and Objectives

Phase Change Materials (PCMs) have emerged as a promising solution for thermal energy storage, offering significant potential in various applications ranging from building energy efficiency to thermal management in electronics. The encapsulation of PCMs represents a critical technological advancement in this field, addressing key challenges associated with their practical implementation.

The evolution of PCM encapsulation techniques can be traced back to the early 1980s when researchers began exploring ways to contain and protect these materials. Initially, simple containment methods were employed, but as the understanding of PCM behavior deepened, more sophisticated encapsulation strategies emerged. This progression has been driven by the need to overcome inherent limitations of PCMs, such as leakage, phase segregation, and corrosion of surrounding materials.

The primary objective of PCM encapsulation is to create a stable, efficient, and long-lasting thermal energy storage system. This involves developing techniques that not only prevent leakage but also enhance heat transfer, maintain chemical stability, and ensure compatibility with the surrounding environment. As the technology has advanced, additional goals have come into focus, including improving the mechanical strength of encapsulated PCMs, reducing costs, and enhancing scalability for industrial applications.

Recent years have seen a surge in research activities focused on novel encapsulation materials and methods. This includes the exploration of nano-encapsulation techniques, which promise enhanced thermal properties and greater control over the phase change process. Concurrently, there has been growing interest in bio-based and environmentally friendly encapsulation materials, aligning with global sustainability goals.

The technological trajectory of PCM encapsulation is closely tied to advancements in material science, nanotechnology, and manufacturing processes. As these fields progress, new possibilities for PCM encapsulation continue to emerge. For instance, the development of smart materials that can respond to external stimuli offers exciting prospects for creating adaptive thermal management systems.

Looking ahead, the field of PCM encapsulation is poised for further innovation. Key areas of focus include improving the energy density of encapsulated PCMs, enhancing their long-term stability, and developing more cost-effective manufacturing processes. Additionally, there is a growing emphasis on tailoring encapsulation techniques for specific applications, recognizing that different use cases may require distinct approaches to achieve optimal performance.

The evolution of PCM encapsulation techniques can be traced back to the early 1980s when researchers began exploring ways to contain and protect these materials. Initially, simple containment methods were employed, but as the understanding of PCM behavior deepened, more sophisticated encapsulation strategies emerged. This progression has been driven by the need to overcome inherent limitations of PCMs, such as leakage, phase segregation, and corrosion of surrounding materials.

The primary objective of PCM encapsulation is to create a stable, efficient, and long-lasting thermal energy storage system. This involves developing techniques that not only prevent leakage but also enhance heat transfer, maintain chemical stability, and ensure compatibility with the surrounding environment. As the technology has advanced, additional goals have come into focus, including improving the mechanical strength of encapsulated PCMs, reducing costs, and enhancing scalability for industrial applications.

Recent years have seen a surge in research activities focused on novel encapsulation materials and methods. This includes the exploration of nano-encapsulation techniques, which promise enhanced thermal properties and greater control over the phase change process. Concurrently, there has been growing interest in bio-based and environmentally friendly encapsulation materials, aligning with global sustainability goals.

The technological trajectory of PCM encapsulation is closely tied to advancements in material science, nanotechnology, and manufacturing processes. As these fields progress, new possibilities for PCM encapsulation continue to emerge. For instance, the development of smart materials that can respond to external stimuli offers exciting prospects for creating adaptive thermal management systems.

Looking ahead, the field of PCM encapsulation is poised for further innovation. Key areas of focus include improving the energy density of encapsulated PCMs, enhancing their long-term stability, and developing more cost-effective manufacturing processes. Additionally, there is a growing emphasis on tailoring encapsulation techniques for specific applications, recognizing that different use cases may require distinct approaches to achieve optimal performance.

Market Analysis for PCM Applications

The market for Phase Change Materials (PCMs) and their encapsulation technologies has been experiencing significant growth, driven by the increasing demand for energy-efficient solutions across various industries. The global PCM market is projected to reach several billion dollars by 2025, with a compound annual growth rate (CAGR) exceeding 15% during the forecast period.

The construction sector represents the largest application area for PCMs, accounting for a substantial portion of the market share. The integration of PCMs in building materials for thermal energy storage and management has gained traction due to stringent energy efficiency regulations and the growing emphasis on sustainable construction practices. PCMs are being incorporated into walls, ceilings, and flooring systems to reduce heating and cooling loads, thereby lowering energy consumption and operational costs.

The textile industry has emerged as another promising market for PCM applications, particularly in the development of smart and adaptive clothing. PCM-enhanced fabrics offer temperature regulation properties, providing comfort in varying environmental conditions. This has led to increased adoption in sportswear, outdoor gear, and protective clothing for extreme environments.

In the automotive sector, PCMs are finding applications in battery thermal management systems for electric vehicles (EVs). As the EV market continues to expand, the demand for efficient thermal management solutions using PCMs is expected to grow significantly. PCMs help maintain optimal battery temperature, enhancing performance and extending battery life.

The electronics industry is also adopting PCM-based cooling solutions to address thermal management challenges in high-performance computing and data centers. PCMs offer passive cooling capabilities, reducing energy consumption and improving the reliability of electronic components.

The healthcare and pharmaceutical sectors present emerging opportunities for PCM applications, particularly in temperature-sensitive product storage and transport. PCM-based packaging solutions ensure the maintenance of specific temperature ranges for vaccines, biologics, and other temperature-sensitive medical products during storage and distribution.

Geographically, North America and Europe currently dominate the PCM market, owing to early adoption and supportive regulatory frameworks. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and increasing awareness of energy-efficient technologies.

The market for PCM encapsulation techniques is closely tied to the overall PCM market growth. As the demand for PCMs increases across various applications, there is a parallel need for advanced encapsulation technologies to enhance PCM performance, prevent leakage, and improve long-term stability. This has led to ongoing research and development efforts in materials science and manufacturing processes to create more efficient and cost-effective encapsulation solutions.

The construction sector represents the largest application area for PCMs, accounting for a substantial portion of the market share. The integration of PCMs in building materials for thermal energy storage and management has gained traction due to stringent energy efficiency regulations and the growing emphasis on sustainable construction practices. PCMs are being incorporated into walls, ceilings, and flooring systems to reduce heating and cooling loads, thereby lowering energy consumption and operational costs.

The textile industry has emerged as another promising market for PCM applications, particularly in the development of smart and adaptive clothing. PCM-enhanced fabrics offer temperature regulation properties, providing comfort in varying environmental conditions. This has led to increased adoption in sportswear, outdoor gear, and protective clothing for extreme environments.

In the automotive sector, PCMs are finding applications in battery thermal management systems for electric vehicles (EVs). As the EV market continues to expand, the demand for efficient thermal management solutions using PCMs is expected to grow significantly. PCMs help maintain optimal battery temperature, enhancing performance and extending battery life.

The electronics industry is also adopting PCM-based cooling solutions to address thermal management challenges in high-performance computing and data centers. PCMs offer passive cooling capabilities, reducing energy consumption and improving the reliability of electronic components.

The healthcare and pharmaceutical sectors present emerging opportunities for PCM applications, particularly in temperature-sensitive product storage and transport. PCM-based packaging solutions ensure the maintenance of specific temperature ranges for vaccines, biologics, and other temperature-sensitive medical products during storage and distribution.

Geographically, North America and Europe currently dominate the PCM market, owing to early adoption and supportive regulatory frameworks. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and increasing awareness of energy-efficient technologies.

The market for PCM encapsulation techniques is closely tied to the overall PCM market growth. As the demand for PCMs increases across various applications, there is a parallel need for advanced encapsulation technologies to enhance PCM performance, prevent leakage, and improve long-term stability. This has led to ongoing research and development efforts in materials science and manufacturing processes to create more efficient and cost-effective encapsulation solutions.

Current PCM Encapsulation Challenges

The encapsulation of Phase Change Materials (PCMs) faces several significant challenges that hinder their widespread adoption and optimal performance in various applications. One of the primary concerns is the prevention of leakage, which is crucial for maintaining the integrity and effectiveness of PCM systems. The liquid state of many PCMs during phase transition increases the risk of leakage, potentially compromising the thermal management capabilities and causing damage to surrounding materials or structures.

Material selection for encapsulation presents another major challenge. The encapsulation material must be compatible with the PCM, resistant to corrosion, and capable of withstanding repeated thermal cycling without degradation. Additionally, it should possess adequate thermal conductivity to facilitate efficient heat transfer, while also providing sufficient mechanical strength to contain the PCM under various operating conditions.

The manufacturing process for PCM encapsulation introduces its own set of challenges. Achieving uniform distribution of PCM within the encapsulation material and ensuring consistent quality across large-scale production are complex tasks. The encapsulation process must also be cost-effective and scalable to make PCM solutions economically viable for widespread implementation.

Thermal stability and long-term performance of encapsulated PCMs remain areas of concern. Over numerous thermal cycles, some PCMs may experience phase segregation, subcooling, or changes in their thermal properties, which can significantly impact their effectiveness. Developing encapsulation techniques that maintain the PCM's performance over extended periods and numerous phase change cycles is crucial for the reliability of PCM-based thermal management systems.

Size and shape considerations in PCM encapsulation also present challenges. The dimensions and geometry of the encapsulated PCM can affect heat transfer rates, phase change dynamics, and overall system efficiency. Balancing these factors while meeting application-specific requirements adds complexity to the encapsulation design process.

Lastly, environmental and safety concerns associated with certain PCMs and encapsulation materials pose challenges in terms of regulatory compliance and sustainable development. Addressing these issues requires careful material selection and the development of environmentally friendly encapsulation techniques that do not compromise performance or safety.

Material selection for encapsulation presents another major challenge. The encapsulation material must be compatible with the PCM, resistant to corrosion, and capable of withstanding repeated thermal cycling without degradation. Additionally, it should possess adequate thermal conductivity to facilitate efficient heat transfer, while also providing sufficient mechanical strength to contain the PCM under various operating conditions.

The manufacturing process for PCM encapsulation introduces its own set of challenges. Achieving uniform distribution of PCM within the encapsulation material and ensuring consistent quality across large-scale production are complex tasks. The encapsulation process must also be cost-effective and scalable to make PCM solutions economically viable for widespread implementation.

Thermal stability and long-term performance of encapsulated PCMs remain areas of concern. Over numerous thermal cycles, some PCMs may experience phase segregation, subcooling, or changes in their thermal properties, which can significantly impact their effectiveness. Developing encapsulation techniques that maintain the PCM's performance over extended periods and numerous phase change cycles is crucial for the reliability of PCM-based thermal management systems.

Size and shape considerations in PCM encapsulation also present challenges. The dimensions and geometry of the encapsulated PCM can affect heat transfer rates, phase change dynamics, and overall system efficiency. Balancing these factors while meeting application-specific requirements adds complexity to the encapsulation design process.

Lastly, environmental and safety concerns associated with certain PCMs and encapsulation materials pose challenges in terms of regulatory compliance and sustainable development. Addressing these issues requires careful material selection and the development of environmentally friendly encapsulation techniques that do not compromise performance or safety.

Existing PCM Encapsulation Solutions

01 Microencapsulation of PCMs

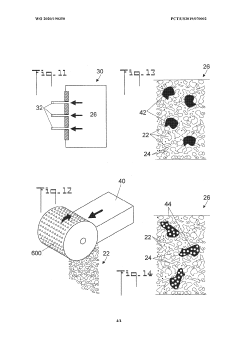

Microencapsulation is a widely used technique for preventing PCM leakage. This method involves enclosing small PCM particles within a protective shell or coating. The microcapsules can be made from various materials such as polymers or inorganic compounds, which provide a barrier against leakage while allowing heat transfer. This technique also helps maintain the shape and structure of the PCM during phase changes.- Microencapsulation of PCMs: Microencapsulation is a widely used technique for preventing PCM leakage. This process involves enclosing small PCM particles within a protective shell or coating. The microcapsules can be made from various materials such as polymers or inorganic compounds, which provide a barrier against leakage while allowing for heat transfer. This method also helps maintain the shape and volume of the PCM during phase transitions.

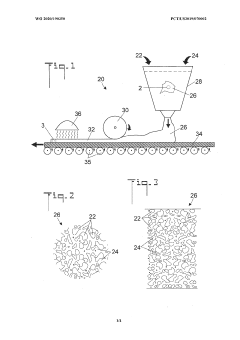

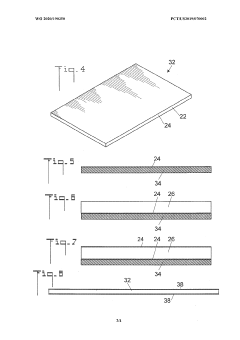

- Shape-stabilized PCMs: Shape-stabilized PCMs are composite materials where the PCM is dispersed within a supporting matrix. This matrix, often made of high-density polyethylene or other polymers, helps retain the PCM in its solid form even when it melts. The supporting structure prevents leakage by containing the liquid PCM within its pores or network, while still allowing for efficient heat storage and release.

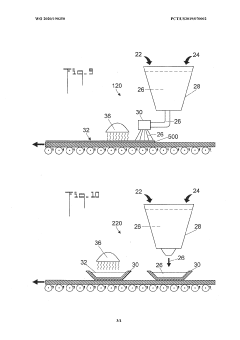

- Macro-encapsulation techniques: Macro-encapsulation involves containing larger quantities of PCM within capsules, pouches, or containers. These larger encapsulations can be made from materials such as plastic, metal, or even concrete. The containers are designed to be leak-proof while allowing for heat transfer. This method is particularly useful for applications requiring larger volumes of PCM, such as in building materials or industrial heat storage systems.

- Surface modification and coating: Surface modification and coating techniques can be applied to PCMs to improve their leak resistance. This can involve treating the surface of the PCM particles with hydrophobic agents or applying a thin, flexible coating. These treatments create a barrier that prevents the PCM from leaking when in its liquid state, while still allowing for efficient heat transfer. This method can be used in conjunction with other encapsulation techniques for enhanced protection.

- Nanocomposite PCM systems: Nanocomposite PCM systems involve incorporating nanoparticles or nanostructures into the PCM or its encapsulation material. These nanoparticles can enhance the thermal properties of the PCM and improve its stability. In some cases, nanostructured materials can be used to create a network that holds the PCM in place, preventing leakage. This approach can lead to more efficient and compact thermal energy storage systems with improved leak resistance.

02 Shape-stabilized PCMs

Shape-stabilized PCMs are composite materials where the PCM is dispersed within a supporting matrix. This matrix, often made of high-density polyethylene or other polymers, helps retain the PCM's shape and prevents leakage even when the PCM is in its liquid state. The supporting structure also enhances the thermal conductivity and mechanical properties of the overall material.Expand Specific Solutions03 Macro-encapsulation techniques

Macro-encapsulation involves containing larger quantities of PCM within containers or pouches. These containers can be made from materials such as metal, plastic, or flexible films. The macro-encapsulation technique allows for easier handling and integration of PCMs into various applications while preventing leakage. It also provides better control over the volume change during phase transitions.Expand Specific Solutions04 Form-stable PCM composites

Form-stable PCM composites are created by blending PCMs with supporting materials such as expanded graphite, carbon nanotubes, or porous materials. These composites maintain their shape and prevent leakage due to capillary forces and surface tension effects. The supporting materials also enhance the thermal conductivity and stability of the PCM, improving overall performance.Expand Specific Solutions05 Nanoencapsulation of PCMs

Nanoencapsulation involves encapsulating PCM particles at the nanoscale, typically using advanced techniques such as interfacial polymerization or in-situ polymerization. This method provides a high surface area-to-volume ratio, enhancing heat transfer efficiency. The nano-sized capsules offer improved stability, reduced leakage, and better integration into various matrices for different applications.Expand Specific Solutions

Key Players in PCM Encapsulation Industry

The encapsulation techniques for Phase Change Materials (PCMs) market is in a growth phase, driven by increasing demand for energy-efficient solutions across various industries. The market size is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with companies like China University of Mining & Technology, Nanyang Technological University, and Consejo Superior de Investigaciones Científicas leading research efforts. Microtek Lab, Inc. and Hangzhou Luer New Material Technology Co., Ltd. are developing innovative encapsulation methods, while PureTemp.com and Insolcorp LLC are focusing on commercial applications. The industry is seeing a blend of academic research and industrial development, with collaborations between universities and companies driving progress in leakage prevention and manufacturing considerations.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies LLC has developed advanced encapsulation techniques for Phase Change Materials (PCMs) using a multi-layer approach. Their method involves creating a core-shell structure where the PCM is encapsulated within a polymer shell. This shell is then further coated with an additional layer of material to enhance thermal stability and prevent leakage. The company has implemented a cross-linking process to improve the mechanical strength of the capsules, allowing them to withstand repeated thermal cycling[1]. They have also incorporated nanoparticles into the shell material to enhance thermal conductivity, improving the overall heat transfer efficiency of the PCM system[2]. Dow's manufacturing process utilizes emulsion polymerization techniques, enabling precise control over capsule size distribution and shell thickness[3].

Strengths: Excellent thermal stability, high encapsulation efficiency, and improved mechanical strength. Weaknesses: Potentially higher production costs due to multi-layer approach and use of specialized materials.

Insolcorp LLC

Technical Solution: Insolcorp LLC has pioneered a unique encapsulation technique for PCMs using a bio-based approach. Their method involves creating a matrix of natural polymers, such as modified cellulose or chitosan, to encapsulate the PCM. This eco-friendly approach not only provides effective containment but also enhances the biodegradability of the final product. Insolcorp's technique includes a proprietary surface treatment process that improves the compatibility between the PCM and the encapsulating material, reducing the risk of leakage[4]. The company has also developed a scalable manufacturing process that utilizes spray drying technology, allowing for high-volume production of microencapsulated PCMs with consistent quality[5]. Their encapsulation method has shown particular success in applications requiring long-term thermal stability, such as in building materials for passive temperature regulation.

Strengths: Environmentally friendly, highly compatible with various PCMs, scalable production. Weaknesses: May have limitations in extreme temperature applications compared to synthetic polymer encapsulations.

Innovative PCM Encapsulation Materials

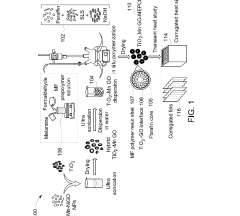

A novel corrugated heat sink with hybrid co-filler interfaced microcapsules for effective thermal management in electronic devices

PatentActiveIN202441038014A

Innovation

- A novel corrugated heat sink incorporating microencapsulated phase change materials (MEPCMs) with a hybrid co-filler interface of titanium dioxide (TiO2) and magnetized graphene oxide (Mn GO) within a melamine formaldehyde resin shell, enhancing thermal conductivity and leakage resistance through in-situ polymerization and vacuum drying processes.

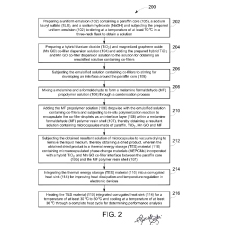

Phase change material products

PatentWO2020190350A1

Innovation

- A method where the phase change material is kept in a solid phase during processing and mixed with a medium that encapsulates it, eliminating the need for pre-encapsulation, using temperature control and curing processes below the PCM's transition temperature to form and solidify the medium around the PCM.

Environmental Impact of PCM Encapsulation

The environmental impact of PCM encapsulation is a critical consideration in the development and application of phase change materials. The encapsulation process itself, as well as the materials used, can have significant implications for sustainability and ecological footprints.

One of the primary environmental concerns is the choice of encapsulation materials. Many traditional encapsulation techniques rely on synthetic polymers, which are often derived from non-renewable resources and may not be biodegradable. This can contribute to long-term environmental pollution, particularly if the encapsulated PCMs are not properly disposed of at the end of their lifecycle. However, recent research has focused on developing more eco-friendly encapsulation materials, such as biopolymers derived from renewable sources like cellulose or chitosan.

The manufacturing process of encapsulated PCMs also plays a crucial role in their environmental impact. Energy-intensive production methods can lead to increased carbon emissions, while the use of harmful solvents or chemicals in the encapsulation process may result in hazardous waste. To mitigate these issues, researchers are exploring greener manufacturing techniques, such as solvent-free processes or the use of supercritical CO2 as an environmentally benign medium for encapsulation.

Leakage prevention is another aspect that intersects with environmental concerns. Effective encapsulation not only ensures the longevity and performance of PCMs but also prevents the release of potentially harmful substances into the environment. This is particularly important for PCMs that may contain toxic or environmentally persistent compounds. Advanced encapsulation techniques that provide robust containment can significantly reduce the risk of environmental contamination.

The end-of-life management of encapsulated PCMs is an emerging area of focus in environmental impact assessments. The recyclability or biodegradability of the encapsulation materials can greatly influence the overall sustainability of PCM applications. Some innovative approaches include designing encapsulation systems that allow for easy separation of the PCM from its shell, facilitating recycling or proper disposal.

Furthermore, the use of encapsulated PCMs in various applications can have indirect environmental benefits. For instance, in building applications, PCMs can enhance energy efficiency, potentially reducing the overall energy consumption and associated carbon emissions. Similarly, in thermal management systems for electronics or vehicles, PCMs can improve performance and longevity, potentially reducing waste from premature equipment failure.

As the field of PCM encapsulation continues to evolve, there is a growing emphasis on life cycle assessments (LCA) to comprehensively evaluate the environmental impact from production to disposal. These assessments help in identifying areas for improvement and guide the development of more sustainable encapsulation techniques and materials.

One of the primary environmental concerns is the choice of encapsulation materials. Many traditional encapsulation techniques rely on synthetic polymers, which are often derived from non-renewable resources and may not be biodegradable. This can contribute to long-term environmental pollution, particularly if the encapsulated PCMs are not properly disposed of at the end of their lifecycle. However, recent research has focused on developing more eco-friendly encapsulation materials, such as biopolymers derived from renewable sources like cellulose or chitosan.

The manufacturing process of encapsulated PCMs also plays a crucial role in their environmental impact. Energy-intensive production methods can lead to increased carbon emissions, while the use of harmful solvents or chemicals in the encapsulation process may result in hazardous waste. To mitigate these issues, researchers are exploring greener manufacturing techniques, such as solvent-free processes or the use of supercritical CO2 as an environmentally benign medium for encapsulation.

Leakage prevention is another aspect that intersects with environmental concerns. Effective encapsulation not only ensures the longevity and performance of PCMs but also prevents the release of potentially harmful substances into the environment. This is particularly important for PCMs that may contain toxic or environmentally persistent compounds. Advanced encapsulation techniques that provide robust containment can significantly reduce the risk of environmental contamination.

The end-of-life management of encapsulated PCMs is an emerging area of focus in environmental impact assessments. The recyclability or biodegradability of the encapsulation materials can greatly influence the overall sustainability of PCM applications. Some innovative approaches include designing encapsulation systems that allow for easy separation of the PCM from its shell, facilitating recycling or proper disposal.

Furthermore, the use of encapsulated PCMs in various applications can have indirect environmental benefits. For instance, in building applications, PCMs can enhance energy efficiency, potentially reducing the overall energy consumption and associated carbon emissions. Similarly, in thermal management systems for electronics or vehicles, PCMs can improve performance and longevity, potentially reducing waste from premature equipment failure.

As the field of PCM encapsulation continues to evolve, there is a growing emphasis on life cycle assessments (LCA) to comprehensively evaluate the environmental impact from production to disposal. These assessments help in identifying areas for improvement and guide the development of more sustainable encapsulation techniques and materials.

Scalability of PCM Encapsulation Methods

The scalability of PCM encapsulation methods is a critical factor in determining the feasibility of large-scale production and application of phase change materials (PCMs) in various industries. As the demand for thermal energy storage solutions continues to grow, the ability to scale up encapsulation techniques becomes increasingly important.

Microencapsulation, one of the most widely used methods for PCM encapsulation, has shown promising potential for scalability. This technique involves creating small capsules containing PCM, typically ranging from 1 to 1000 micrometers in diameter. The scalability of microencapsulation is primarily attributed to its compatibility with existing industrial processes, such as spray drying and in-situ polymerization.

Spray drying, for instance, can be easily scaled up by increasing the size of the drying chamber and adjusting process parameters. This method allows for continuous production of microencapsulated PCMs, making it suitable for large-scale manufacturing. Similarly, in-situ polymerization can be scaled up by employing larger reactors and optimizing reaction conditions.

However, challenges remain in maintaining consistent quality and performance across different production scales. As the production volume increases, issues such as particle size distribution, encapsulation efficiency, and thermal stability may become more pronounced. To address these challenges, advanced process control systems and quality assurance protocols are essential.

Macro-encapsulation techniques, while less common than microencapsulation, also offer scalability potential. These methods involve encapsulating larger volumes of PCM in containers or pouches. The scalability of macro-encapsulation is often limited by the availability of suitable container materials and the complexity of the filling process.

Recent advancements in materials science and manufacturing technologies have opened up new possibilities for scaling PCM encapsulation. For example, the development of novel shell materials with enhanced thermal and mechanical properties has enabled the production of more robust and efficient PCM capsules at larger scales.

Additive manufacturing techniques, such as 3D printing, are also being explored for PCM encapsulation. While currently limited in scale, these methods offer the potential for customized and complex encapsulation designs that could be scaled up in the future through parallel processing or larger printing systems.

As the field of PCM encapsulation continues to evolve, researchers and manufacturers are focusing on developing more efficient and cost-effective scaling strategies. This includes optimizing process parameters, exploring new materials, and integrating advanced automation and control systems to ensure consistent quality across different production scales.

Microencapsulation, one of the most widely used methods for PCM encapsulation, has shown promising potential for scalability. This technique involves creating small capsules containing PCM, typically ranging from 1 to 1000 micrometers in diameter. The scalability of microencapsulation is primarily attributed to its compatibility with existing industrial processes, such as spray drying and in-situ polymerization.

Spray drying, for instance, can be easily scaled up by increasing the size of the drying chamber and adjusting process parameters. This method allows for continuous production of microencapsulated PCMs, making it suitable for large-scale manufacturing. Similarly, in-situ polymerization can be scaled up by employing larger reactors and optimizing reaction conditions.

However, challenges remain in maintaining consistent quality and performance across different production scales. As the production volume increases, issues such as particle size distribution, encapsulation efficiency, and thermal stability may become more pronounced. To address these challenges, advanced process control systems and quality assurance protocols are essential.

Macro-encapsulation techniques, while less common than microencapsulation, also offer scalability potential. These methods involve encapsulating larger volumes of PCM in containers or pouches. The scalability of macro-encapsulation is often limited by the availability of suitable container materials and the complexity of the filling process.

Recent advancements in materials science and manufacturing technologies have opened up new possibilities for scaling PCM encapsulation. For example, the development of novel shell materials with enhanced thermal and mechanical properties has enabled the production of more robust and efficient PCM capsules at larger scales.

Additive manufacturing techniques, such as 3D printing, are also being explored for PCM encapsulation. While currently limited in scale, these methods offer the potential for customized and complex encapsulation designs that could be scaled up in the future through parallel processing or larger printing systems.

As the field of PCM encapsulation continues to evolve, researchers and manufacturers are focusing on developing more efficient and cost-effective scaling strategies. This includes optimizing process parameters, exploring new materials, and integrating advanced automation and control systems to ensure consistent quality across different production scales.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!