PCM Life-Cycle Assessment: Environmental Benefits vs Material Risks

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PCM LCA Background and Objectives

Phase Change Materials (PCMs) have gained significant attention in recent years due to their potential to enhance energy efficiency and thermal management in various applications. The life-cycle assessment (LCA) of PCMs is a crucial aspect of evaluating their overall environmental impact and sustainability. This technical research report aims to provide a comprehensive overview of the background and objectives of PCM LCA studies.

PCMs are substances that can absorb, store, and release large amounts of latent heat during phase transitions, typically between solid and liquid states. This unique property makes them valuable for thermal energy storage and temperature regulation in buildings, textiles, electronics, and other industries. As the global focus on sustainable development and energy conservation intensifies, understanding the environmental implications of PCMs throughout their life cycle becomes increasingly important.

The primary objective of PCM LCA studies is to assess the environmental benefits and potential risks associated with these materials from cradle to grave. This includes evaluating the environmental impacts of raw material extraction, manufacturing processes, transportation, use phase, and end-of-life disposal or recycling. By conducting comprehensive LCAs, researchers and industry professionals can make informed decisions about the sustainability of PCM applications and identify areas for improvement in their life cycle.

One of the key drivers for PCM LCA research is the growing concern over climate change and the need to reduce greenhouse gas emissions. PCMs have the potential to significantly reduce energy consumption in buildings and other applications, thereby lowering carbon footprints. However, the production and disposal of PCMs may also have environmental impacts that need to be carefully considered and quantified.

Another important aspect of PCM LCA studies is the assessment of material risks associated with different types of PCMs. This includes evaluating the toxicity, flammability, and long-term stability of various PCM formulations. Understanding these risks is crucial for ensuring the safe and sustainable use of PCMs in different applications and for developing appropriate regulations and guidelines for their handling and disposal.

The evolution of PCM technology has led to the development of various types of PCMs, including organic, inorganic, and eutectic mixtures. Each type has its own set of environmental benefits and potential risks, which need to be carefully evaluated through LCA studies. This diversity in PCM formulations also presents challenges in standardizing LCA methodologies and comparing results across different studies.

As the field of PCM research continues to advance, LCA studies are becoming increasingly sophisticated, incorporating new methodologies and data sources. This includes the use of advanced modeling techniques, real-world performance data, and consideration of regional variations in energy grids and waste management systems. These advancements aim to provide more accurate and comprehensive assessments of the environmental impacts of PCMs throughout their life cycle.

PCMs are substances that can absorb, store, and release large amounts of latent heat during phase transitions, typically between solid and liquid states. This unique property makes them valuable for thermal energy storage and temperature regulation in buildings, textiles, electronics, and other industries. As the global focus on sustainable development and energy conservation intensifies, understanding the environmental implications of PCMs throughout their life cycle becomes increasingly important.

The primary objective of PCM LCA studies is to assess the environmental benefits and potential risks associated with these materials from cradle to grave. This includes evaluating the environmental impacts of raw material extraction, manufacturing processes, transportation, use phase, and end-of-life disposal or recycling. By conducting comprehensive LCAs, researchers and industry professionals can make informed decisions about the sustainability of PCM applications and identify areas for improvement in their life cycle.

One of the key drivers for PCM LCA research is the growing concern over climate change and the need to reduce greenhouse gas emissions. PCMs have the potential to significantly reduce energy consumption in buildings and other applications, thereby lowering carbon footprints. However, the production and disposal of PCMs may also have environmental impacts that need to be carefully considered and quantified.

Another important aspect of PCM LCA studies is the assessment of material risks associated with different types of PCMs. This includes evaluating the toxicity, flammability, and long-term stability of various PCM formulations. Understanding these risks is crucial for ensuring the safe and sustainable use of PCMs in different applications and for developing appropriate regulations and guidelines for their handling and disposal.

The evolution of PCM technology has led to the development of various types of PCMs, including organic, inorganic, and eutectic mixtures. Each type has its own set of environmental benefits and potential risks, which need to be carefully evaluated through LCA studies. This diversity in PCM formulations also presents challenges in standardizing LCA methodologies and comparing results across different studies.

As the field of PCM research continues to advance, LCA studies are becoming increasingly sophisticated, incorporating new methodologies and data sources. This includes the use of advanced modeling techniques, real-world performance data, and consideration of regional variations in energy grids and waste management systems. These advancements aim to provide more accurate and comprehensive assessments of the environmental impacts of PCMs throughout their life cycle.

Market Demand for Sustainable PCMs

The market demand for sustainable Phase Change Materials (PCMs) has been steadily increasing in recent years, driven by growing environmental concerns and the push for energy-efficient solutions across various industries. PCMs, known for their ability to absorb, store, and release large amounts of latent heat during phase transitions, have found applications in diverse sectors such as building and construction, textiles, electronics, and energy storage systems.

In the building and construction industry, there is a significant demand for sustainable PCMs to enhance thermal management and reduce energy consumption. As governments worldwide implement stricter energy efficiency regulations, the adoption of PCM-based solutions in buildings has become more prevalent. These materials are integrated into walls, ceilings, and floors to regulate indoor temperatures, potentially reducing heating and cooling costs by up to 30%.

The textile industry has also shown increased interest in sustainable PCMs, particularly for the development of smart and adaptive clothing. PCM-infused fabrics can provide thermal comfort by absorbing excess body heat when the wearer is hot and releasing it when they are cold. This application has gained traction in sportswear, outdoor gear, and protective clothing markets.

In the electronics sector, the demand for sustainable PCMs is driven by the need for efficient thermal management solutions in increasingly compact and powerful devices. PCMs are being incorporated into electronic components and cooling systems to prevent overheating and extend the lifespan of devices, addressing the growing concern of electronic waste.

The renewable energy sector presents another significant market for sustainable PCMs, particularly in solar thermal energy storage systems. As the world transitions towards cleaner energy sources, PCMs offer a promising solution for storing excess energy during peak production periods and releasing it during times of high demand, thereby improving the overall efficiency of renewable energy systems.

However, the market demand for sustainable PCMs is not without challenges. Concerns about the environmental impact of certain PCM materials, particularly those derived from petroleum-based sources, have led to increased research and development efforts focused on bio-based and naturally derived alternatives. This shift towards more sustainable PCM options is expected to further drive market growth in the coming years.

The global market for PCMs, including sustainable variants, is projected to experience substantial growth. Factors such as increasing awareness of energy conservation, stringent building codes, and the rising adoption of green technologies are expected to fuel this growth. Additionally, ongoing research into new, more efficient, and environmentally friendly PCM formulations is likely to expand the potential applications and market opportunities for sustainable PCMs across various industries.

In the building and construction industry, there is a significant demand for sustainable PCMs to enhance thermal management and reduce energy consumption. As governments worldwide implement stricter energy efficiency regulations, the adoption of PCM-based solutions in buildings has become more prevalent. These materials are integrated into walls, ceilings, and floors to regulate indoor temperatures, potentially reducing heating and cooling costs by up to 30%.

The textile industry has also shown increased interest in sustainable PCMs, particularly for the development of smart and adaptive clothing. PCM-infused fabrics can provide thermal comfort by absorbing excess body heat when the wearer is hot and releasing it when they are cold. This application has gained traction in sportswear, outdoor gear, and protective clothing markets.

In the electronics sector, the demand for sustainable PCMs is driven by the need for efficient thermal management solutions in increasingly compact and powerful devices. PCMs are being incorporated into electronic components and cooling systems to prevent overheating and extend the lifespan of devices, addressing the growing concern of electronic waste.

The renewable energy sector presents another significant market for sustainable PCMs, particularly in solar thermal energy storage systems. As the world transitions towards cleaner energy sources, PCMs offer a promising solution for storing excess energy during peak production periods and releasing it during times of high demand, thereby improving the overall efficiency of renewable energy systems.

However, the market demand for sustainable PCMs is not without challenges. Concerns about the environmental impact of certain PCM materials, particularly those derived from petroleum-based sources, have led to increased research and development efforts focused on bio-based and naturally derived alternatives. This shift towards more sustainable PCM options is expected to further drive market growth in the coming years.

The global market for PCMs, including sustainable variants, is projected to experience substantial growth. Factors such as increasing awareness of energy conservation, stringent building codes, and the rising adoption of green technologies are expected to fuel this growth. Additionally, ongoing research into new, more efficient, and environmentally friendly PCM formulations is likely to expand the potential applications and market opportunities for sustainable PCMs across various industries.

PCM Environmental Challenges

Phase Change Materials (PCMs) present significant environmental challenges throughout their life cycle, despite their potential for energy conservation. The production of PCMs often involves energy-intensive processes and the use of potentially harmful chemicals, raising concerns about their carbon footprint and environmental impact from the outset.

During their operational phase, PCMs can contribute to reduced energy consumption in buildings and other applications. However, the long-term stability and performance of these materials remain a concern. Degradation of PCMs over time may lead to reduced efficiency and the need for frequent replacements, potentially offsetting their initial environmental benefits.

The disposal and end-of-life management of PCMs pose additional environmental risks. Many PCMs are not biodegradable and may contain toxic substances that can leach into soil and water systems if not properly handled. The lack of established recycling processes for most PCMs exacerbates this issue, potentially leading to increased landfill waste or incineration, both of which have negative environmental consequences.

Furthermore, the environmental impact of PCMs varies significantly depending on the specific type of material used. Organic PCMs, while often considered more environmentally friendly, may have issues with flammability and thermal stability. Inorganic PCMs, on the other hand, can be more stable but may involve more resource-intensive production processes and pose greater challenges for disposal.

The encapsulation of PCMs, necessary for many applications, introduces additional environmental considerations. The materials used for encapsulation, often plastics or metals, add to the overall environmental footprint of PCM systems and complicate end-of-life management.

There are also concerns about the potential release of PCMs into the environment during use, particularly in applications where they are in direct contact with air or water. This could lead to unintended consequences for local ecosystems and potentially human health.

The energy and resource requirements for the transportation and installation of PCM systems must also be considered in their overall environmental assessment. In some cases, the benefits of PCMs in reducing operational energy consumption may be partially offset by the energy expended in their production, transportation, and installation.

Addressing these environmental challenges requires a holistic approach to PCM development and application. This includes improving production processes to reduce energy consumption and harmful emissions, developing more stable and long-lasting PCM formulations, and creating effective recycling and disposal methods. Additionally, comprehensive life cycle assessments are crucial to accurately evaluate the true environmental impact of PCMs across different applications and scenarios.

During their operational phase, PCMs can contribute to reduced energy consumption in buildings and other applications. However, the long-term stability and performance of these materials remain a concern. Degradation of PCMs over time may lead to reduced efficiency and the need for frequent replacements, potentially offsetting their initial environmental benefits.

The disposal and end-of-life management of PCMs pose additional environmental risks. Many PCMs are not biodegradable and may contain toxic substances that can leach into soil and water systems if not properly handled. The lack of established recycling processes for most PCMs exacerbates this issue, potentially leading to increased landfill waste or incineration, both of which have negative environmental consequences.

Furthermore, the environmental impact of PCMs varies significantly depending on the specific type of material used. Organic PCMs, while often considered more environmentally friendly, may have issues with flammability and thermal stability. Inorganic PCMs, on the other hand, can be more stable but may involve more resource-intensive production processes and pose greater challenges for disposal.

The encapsulation of PCMs, necessary for many applications, introduces additional environmental considerations. The materials used for encapsulation, often plastics or metals, add to the overall environmental footprint of PCM systems and complicate end-of-life management.

There are also concerns about the potential release of PCMs into the environment during use, particularly in applications where they are in direct contact with air or water. This could lead to unintended consequences for local ecosystems and potentially human health.

The energy and resource requirements for the transportation and installation of PCM systems must also be considered in their overall environmental assessment. In some cases, the benefits of PCMs in reducing operational energy consumption may be partially offset by the energy expended in their production, transportation, and installation.

Addressing these environmental challenges requires a holistic approach to PCM development and application. This includes improving production processes to reduce energy consumption and harmful emissions, developing more stable and long-lasting PCM formulations, and creating effective recycling and disposal methods. Additionally, comprehensive life cycle assessments are crucial to accurately evaluate the true environmental impact of PCMs across different applications and scenarios.

Current PCM LCA Methodologies

01 Energy efficiency and thermal management

Phase Change Materials (PCMs) offer significant environmental benefits through improved energy efficiency and thermal management. They can absorb, store, and release large amounts of latent heat during phase transitions, helping to regulate temperature in buildings and reduce energy consumption for heating and cooling. This property makes PCMs valuable in sustainable construction and energy-saving applications.- Energy efficiency and thermal management: Phase Change Materials (PCMs) offer significant environmental benefits through improved energy efficiency and thermal management. They can absorb, store, and release large amounts of latent heat during phase transitions, helping to regulate temperature in buildings and reduce energy consumption for heating and cooling. This property makes PCMs valuable for sustainable construction and energy-saving applications.

- Renewable energy storage: PCMs play a crucial role in renewable energy storage systems, particularly in solar thermal applications. They can store excess energy during peak production periods and release it when needed, enhancing the efficiency and reliability of renewable energy sources. This capability contributes to reducing reliance on fossil fuels and decreasing greenhouse gas emissions.

- Material risks and safety concerns: Despite their benefits, PCMs pose certain material risks that need to be addressed. These include potential leakage, corrosion of containment materials, and long-term stability issues. Some PCMs may also present fire hazards or release harmful substances if not properly encapsulated or managed. Ensuring the safe handling, containment, and disposal of PCMs is crucial to mitigate these risks.

- Environmental impact of PCM production and disposal: The production and disposal of PCMs can have environmental implications. While they offer energy-saving benefits during use, the manufacturing process of some PCMs may involve energy-intensive methods or the use of potentially harmful chemicals. Additionally, the end-of-life disposal of PCM-containing products requires careful consideration to prevent environmental contamination and ensure proper recycling or safe disposal practices.

- Advancements in eco-friendly PCM formulations: Research is ongoing to develop more environmentally friendly PCM formulations. This includes exploring bio-based PCMs derived from renewable sources, improving the biodegradability of materials, and enhancing the overall lifecycle sustainability of PCM products. These advancements aim to maximize the environmental benefits of PCMs while minimizing potential negative impacts associated with their production, use, and disposal.

02 Renewable energy storage

PCMs play a crucial role in renewable energy storage systems, particularly in solar thermal applications. They can store excess energy during peak production periods and release it when needed, enhancing the efficiency and reliability of renewable energy sources. This capability contributes to reducing reliance on fossil fuels and decreasing greenhouse gas emissions.Expand Specific Solutions03 Waste heat recovery and utilization

PCMs can be used in waste heat recovery systems to capture and utilize thermal energy that would otherwise be lost. This application improves overall energy efficiency in industrial processes and power generation, leading to reduced energy consumption and lower environmental impact. PCMs enable the storage and later use of waste heat, contributing to a more circular and sustainable energy economy.Expand Specific Solutions04 Material risks and safety concerns

Despite their benefits, PCMs pose certain material risks that need to be addressed. These include potential leakage, chemical stability issues over long-term use, and compatibility with containment materials. Some PCMs may also present fire safety risks or release harmful substances if not properly encapsulated or managed. Ensuring the long-term stability and safety of PCM systems is crucial for their widespread adoption and environmental sustainability.Expand Specific Solutions05 Environmental impact of PCM production and disposal

The production and end-of-life disposal of PCMs can have environmental implications. While they offer energy-saving benefits during use, the manufacturing process of some PCMs may involve energy-intensive steps or the use of potentially harmful chemicals. Additionally, the disposal or recycling of PCM-containing products at the end of their lifecycle needs careful consideration to minimize environmental impact and ensure proper waste management.Expand Specific Solutions

Key Players in PCM Industry

The PCM Life-Cycle Assessment market is in a growth phase, driven by increasing demand for sustainable energy storage solutions. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, PCM solutions are advancing rapidly, with companies like Sunamp Ltd. and H2Go Power Ltd. developing innovative storage systems. Major chemical manufacturers such as BASF Corp., LG Chem Ltd., and DuPont de Nemours, Inc. are investing in PCM research and development, indicating a maturing technology landscape. However, the industry still faces challenges in balancing environmental benefits with potential material risks, necessitating ongoing research and development efforts from both academic institutions and corporate players.

LG Chem Ltd.

Technical Solution: LG Chem has made significant strides in PCM technology, particularly in the field of battery thermal management systems. Their approach to PCM life-cycle assessment focuses on enhancing energy density and reducing environmental impact. LG Chem's PCM solutions for electric vehicle batteries have shown to improve battery life by up to 20% through efficient thermal regulation[4]. The company has also developed bio-based PCMs, utilizing renewable resources to minimize environmental risks[5]. LG Chem's life-cycle assessments indicate that their PCM-enhanced batteries can reduce the overall carbon footprint of electric vehicles by up to 15% compared to conventional cooling systems[6].

Strengths: Strong integration with battery technology, focus on electric vehicle applications, and development of bio-based PCMs. Weaknesses: Limited applications outside of battery technology and potential scalability issues for bio-based PCMs.

Sunamp Ltd.

Technical Solution: Sunamp specializes in thermal energy storage using phase change materials, with a strong focus on sustainability and life-cycle assessment. Their patented PCM technology, Plentigrade, is designed to be non-toxic and fully recyclable, addressing key environmental concerns[7]. Sunamp's heat batteries using PCMs have demonstrated energy savings of up to 50% in domestic hot water systems compared to traditional methods[8]. The company has conducted comprehensive life-cycle assessments, showing that their PCM solutions can reduce CO2 emissions by up to 1 tonne per year in a typical household application[9]. Sunamp is also exploring the use of second-life EV batteries in conjunction with their PCM technology to further enhance sustainability.

Strengths: Highly focused on PCM applications for energy storage, strong emphasis on recyclability and non-toxic materials. Weaknesses: Limited market presence compared to larger corporations and potential challenges in scaling up production to meet growing demand.

Critical PCM LCA Studies

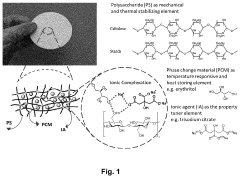

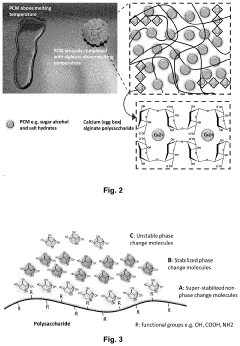

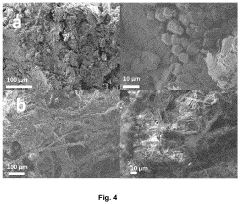

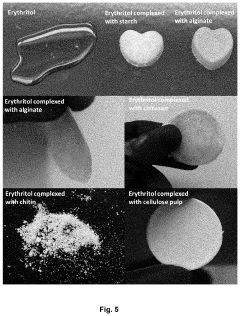

Phase change polysaccharide-based bio-complexes with tunable thermophysical properties and preparation method thereof

PatentPendingUS20230203358A1

Innovation

- Development of biocompatible phase change bio-complexes composed of PCMs and polysaccharides, where polysaccharides provide mechanical and thermal stabilization, and PCMs offer temperature-responsive properties, using sugar alcohols and salt hydrates with ionic agents for compatibility and tunable thermophysical properties, enabling high heat storage capacity and structural stability.

Phase change material

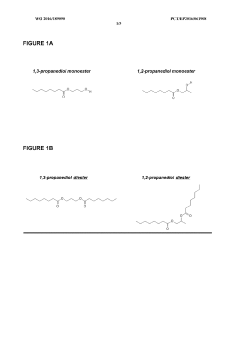

PatentWO2016189090A1

Innovation

- Development of 1,3-propanediol fatty acid esters as phase change materials, which are fully bio-based, renewable, and biodegradable, offering high latent heat and narrow melting temperature ranges, and can be produced from food-grade raw materials for use in temperature regulation articles and food packaging.

Regulatory Framework for PCMs

The regulatory framework for Phase Change Materials (PCMs) is a complex and evolving landscape that significantly impacts their development, application, and market adoption. As PCMs gain prominence in various sectors, including building materials, energy storage, and thermal management systems, regulatory bodies worldwide are adapting to address the unique characteristics and potential risks associated with these materials.

At the international level, organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) are working to establish standardized testing methods and performance criteria for PCMs. These efforts aim to create a unified approach to evaluating PCM properties, ensuring consistency in product quality and performance across different manufacturers and applications.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation plays a crucial role in governing the use of PCMs. REACH requires manufacturers and importers to assess and manage the risks associated with substances they produce or import, including those used in PCM formulations. This regulation ensures that potential environmental and health impacts are thoroughly evaluated before PCMs can be brought to market.

The United States Environmental Protection Agency (EPA) oversees the regulation of PCMs under the Toxic Substances Control Act (TSCA). The TSCA mandates that new chemical substances, including novel PCM formulations, undergo a premanufacture notification (PMN) process. This process allows the EPA to assess potential risks and, if necessary, impose restrictions or require additional testing before approving the substance for commercial use.

Building codes and energy efficiency standards are also evolving to incorporate PCMs. For instance, the International Energy Conservation Code (IECC) and ASHRAE standards are beginning to recognize the potential of PCMs in improving building energy performance. These codes are gradually being updated to include provisions for PCM integration in construction materials and HVAC systems.

Safety regulations, particularly those related to fire safety, are of paramount importance for PCMs used in building applications. Many jurisdictions require PCMs to meet specific fire resistance and smoke emission standards before they can be incorporated into construction materials. The development of these standards is an ongoing process, with regulatory bodies working closely with industry stakeholders to establish appropriate safety criteria.

As the environmental impact of PCMs becomes a growing concern, regulations surrounding their disposal and recycling are also emerging. The European Union's Waste Electrical and Electronic Equipment (WEEE) Directive, for example, is being expanded to address the end-of-life management of products containing PCMs, particularly in electronic cooling applications.

At the international level, organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) are working to establish standardized testing methods and performance criteria for PCMs. These efforts aim to create a unified approach to evaluating PCM properties, ensuring consistency in product quality and performance across different manufacturers and applications.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation plays a crucial role in governing the use of PCMs. REACH requires manufacturers and importers to assess and manage the risks associated with substances they produce or import, including those used in PCM formulations. This regulation ensures that potential environmental and health impacts are thoroughly evaluated before PCMs can be brought to market.

The United States Environmental Protection Agency (EPA) oversees the regulation of PCMs under the Toxic Substances Control Act (TSCA). The TSCA mandates that new chemical substances, including novel PCM formulations, undergo a premanufacture notification (PMN) process. This process allows the EPA to assess potential risks and, if necessary, impose restrictions or require additional testing before approving the substance for commercial use.

Building codes and energy efficiency standards are also evolving to incorporate PCMs. For instance, the International Energy Conservation Code (IECC) and ASHRAE standards are beginning to recognize the potential of PCMs in improving building energy performance. These codes are gradually being updated to include provisions for PCM integration in construction materials and HVAC systems.

Safety regulations, particularly those related to fire safety, are of paramount importance for PCMs used in building applications. Many jurisdictions require PCMs to meet specific fire resistance and smoke emission standards before they can be incorporated into construction materials. The development of these standards is an ongoing process, with regulatory bodies working closely with industry stakeholders to establish appropriate safety criteria.

As the environmental impact of PCMs becomes a growing concern, regulations surrounding their disposal and recycling are also emerging. The European Union's Waste Electrical and Electronic Equipment (WEEE) Directive, for example, is being expanded to address the end-of-life management of products containing PCMs, particularly in electronic cooling applications.

PCM End-of-Life Management

The end-of-life management of Phase Change Materials (PCMs) is a critical aspect of their life cycle assessment, balancing environmental benefits against potential material risks. As PCMs reach the end of their useful life, proper disposal and recycling strategies become essential to mitigate environmental impacts and maximize resource efficiency.

One of the primary challenges in PCM end-of-life management is the diverse range of materials used, including organic compounds, salt hydrates, and eutectic mixtures. Each type requires specific handling and processing methods to ensure safe and environmentally responsible disposal. For organic PCMs, such as paraffins and fatty acids, thermal decomposition or controlled incineration may be viable options, provided that emissions are carefully monitored and controlled.

Salt hydrates and inorganic PCMs present unique challenges due to their potential for environmental contamination if improperly disposed of. Recycling and recovery processes for these materials often involve separation techniques, such as filtration or crystallization, to extract the valuable components for reuse. However, the economic viability of such processes remains a significant consideration in their widespread adoption.

The development of closed-loop systems for PCM applications is gaining traction as a sustainable approach to end-of-life management. These systems aim to design products with PCMs that can be easily disassembled, recovered, and reprocessed at the end of their life cycle. This approach not only reduces waste but also conserves resources and energy associated with the production of new PCMs.

Emerging technologies in material recovery are showing promise for improving the efficiency and cost-effectiveness of PCM recycling. Advanced separation techniques, such as supercritical fluid extraction and membrane filtration, are being explored to recover high-purity PCMs from end-of-life products. These methods could potentially overcome some of the economic barriers currently limiting widespread PCM recycling.

The regulatory landscape surrounding PCM disposal and recycling is evolving, with increasing emphasis on extended producer responsibility and circular economy principles. Manufacturers are being encouraged, and in some cases required, to implement take-back programs and establish recycling infrastructure for their PCM-containing products. This shift in responsibility is driving innovation in product design and end-of-life management strategies.

As the use of PCMs continues to grow across various sectors, including building materials, textiles, and energy storage systems, the importance of effective end-of-life management becomes increasingly apparent. Balancing the environmental benefits of PCMs during their use phase with the potential risks and impacts at the end of their life cycle remains a key challenge for researchers, manufacturers, and policymakers alike.

One of the primary challenges in PCM end-of-life management is the diverse range of materials used, including organic compounds, salt hydrates, and eutectic mixtures. Each type requires specific handling and processing methods to ensure safe and environmentally responsible disposal. For organic PCMs, such as paraffins and fatty acids, thermal decomposition or controlled incineration may be viable options, provided that emissions are carefully monitored and controlled.

Salt hydrates and inorganic PCMs present unique challenges due to their potential for environmental contamination if improperly disposed of. Recycling and recovery processes for these materials often involve separation techniques, such as filtration or crystallization, to extract the valuable components for reuse. However, the economic viability of such processes remains a significant consideration in their widespread adoption.

The development of closed-loop systems for PCM applications is gaining traction as a sustainable approach to end-of-life management. These systems aim to design products with PCMs that can be easily disassembled, recovered, and reprocessed at the end of their life cycle. This approach not only reduces waste but also conserves resources and energy associated with the production of new PCMs.

Emerging technologies in material recovery are showing promise for improving the efficiency and cost-effectiveness of PCM recycling. Advanced separation techniques, such as supercritical fluid extraction and membrane filtration, are being explored to recover high-purity PCMs from end-of-life products. These methods could potentially overcome some of the economic barriers currently limiting widespread PCM recycling.

The regulatory landscape surrounding PCM disposal and recycling is evolving, with increasing emphasis on extended producer responsibility and circular economy principles. Manufacturers are being encouraged, and in some cases required, to implement take-back programs and establish recycling infrastructure for their PCM-containing products. This shift in responsibility is driving innovation in product design and end-of-life management strategies.

As the use of PCMs continues to grow across various sectors, including building materials, textiles, and energy storage systems, the importance of effective end-of-life management becomes increasingly apparent. Balancing the environmental benefits of PCMs during their use phase with the potential risks and impacts at the end of their life cycle remains a key challenge for researchers, manufacturers, and policymakers alike.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!