How to Scale PCM Production: Quality Control and Cost Drivers for Industrial Supply

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PCM Production Overview and Objectives

Phase Change Materials (PCMs) have emerged as a promising technology for thermal energy storage and management across various industries. The production of PCMs at an industrial scale presents both opportunities and challenges, particularly in terms of quality control and cost-effectiveness. This report aims to provide a comprehensive overview of PCM production and outline the objectives for scaling up manufacturing processes.

PCMs are substances that absorb or release large amounts of latent heat during phase transitions, typically between solid and liquid states. Their ability to store and release thermal energy at specific temperature ranges makes them valuable in applications such as building materials, textiles, electronics cooling, and renewable energy systems. The growing demand for energy-efficient solutions has driven increased interest in PCM technology, necessitating the development of large-scale production methods.

The primary objective of scaling PCM production is to meet the rising market demand while maintaining consistent product quality and optimizing costs. This involves addressing several key challenges, including raw material selection, process optimization, quality control measures, and cost reduction strategies. Achieving these goals requires a multifaceted approach that combines materials science, chemical engineering, and advanced manufacturing techniques.

One of the critical aspects of PCM production is the selection and preparation of raw materials. Depending on the desired melting point and application, various organic and inorganic compounds can be used as PCMs. Ensuring the purity and consistency of these materials is crucial for maintaining the performance characteristics of the final product. As production scales up, sourcing high-quality raw materials in large quantities becomes a significant consideration.

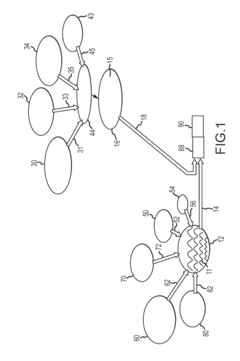

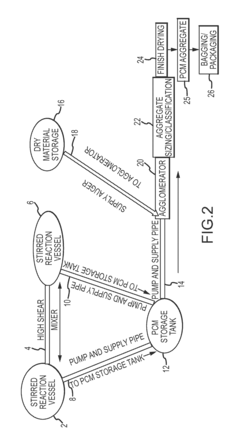

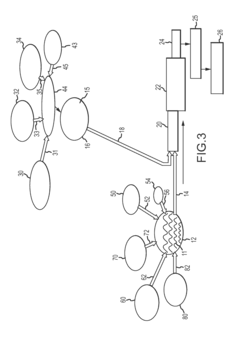

Process optimization plays a vital role in scaling PCM production. This involves designing and implementing efficient manufacturing processes that can handle increased volumes while maintaining product quality. Key areas of focus include mixing and blending techniques, encapsulation methods, and thermal cycling processes. Automation and process control systems are essential for ensuring consistency and reducing human error in large-scale operations.

Quality control is paramount in PCM production, especially as scale increases. Developing robust testing and characterization methods is crucial for verifying the thermal properties, stability, and performance of PCMs. This includes techniques such as differential scanning calorimetry (DSC), thermogravimetric analysis (TGA), and accelerated aging tests. Implementing in-line quality control measures and establishing rigorous quality assurance protocols are essential for maintaining product consistency and meeting industry standards.

Cost management is a critical objective in scaling PCM production. Identifying and addressing the main cost drivers, such as raw materials, energy consumption, labor, and equipment, is essential for achieving economic viability. Strategies for cost reduction may include process optimization to improve yield and reduce waste, exploring alternative raw material sources, and investing in energy-efficient manufacturing technologies.

PCMs are substances that absorb or release large amounts of latent heat during phase transitions, typically between solid and liquid states. Their ability to store and release thermal energy at specific temperature ranges makes them valuable in applications such as building materials, textiles, electronics cooling, and renewable energy systems. The growing demand for energy-efficient solutions has driven increased interest in PCM technology, necessitating the development of large-scale production methods.

The primary objective of scaling PCM production is to meet the rising market demand while maintaining consistent product quality and optimizing costs. This involves addressing several key challenges, including raw material selection, process optimization, quality control measures, and cost reduction strategies. Achieving these goals requires a multifaceted approach that combines materials science, chemical engineering, and advanced manufacturing techniques.

One of the critical aspects of PCM production is the selection and preparation of raw materials. Depending on the desired melting point and application, various organic and inorganic compounds can be used as PCMs. Ensuring the purity and consistency of these materials is crucial for maintaining the performance characteristics of the final product. As production scales up, sourcing high-quality raw materials in large quantities becomes a significant consideration.

Process optimization plays a vital role in scaling PCM production. This involves designing and implementing efficient manufacturing processes that can handle increased volumes while maintaining product quality. Key areas of focus include mixing and blending techniques, encapsulation methods, and thermal cycling processes. Automation and process control systems are essential for ensuring consistency and reducing human error in large-scale operations.

Quality control is paramount in PCM production, especially as scale increases. Developing robust testing and characterization methods is crucial for verifying the thermal properties, stability, and performance of PCMs. This includes techniques such as differential scanning calorimetry (DSC), thermogravimetric analysis (TGA), and accelerated aging tests. Implementing in-line quality control measures and establishing rigorous quality assurance protocols are essential for maintaining product consistency and meeting industry standards.

Cost management is a critical objective in scaling PCM production. Identifying and addressing the main cost drivers, such as raw materials, energy consumption, labor, and equipment, is essential for achieving economic viability. Strategies for cost reduction may include process optimization to improve yield and reduce waste, exploring alternative raw material sources, and investing in energy-efficient manufacturing technologies.

Market Analysis for Industrial PCM Supply

The market for Phase Change Materials (PCMs) in industrial supply chains is experiencing significant growth, driven by increasing demand for energy-efficient solutions across various sectors. The global PCM market is projected to expand at a compound annual growth rate (CAGR) of over 15% in the coming years, with the industrial segment playing a crucial role in this growth trajectory.

Industrial applications of PCMs are diverse, ranging from thermal energy storage systems and building materials to temperature-sensitive packaging and transportation. The construction industry, in particular, is emerging as a key driver for PCM adoption, as these materials offer innovative solutions for passive temperature regulation in buildings, reducing energy consumption and improving overall sustainability.

The automotive sector is another significant market for industrial PCM supply, with applications in battery thermal management for electric vehicles and climate control systems. As the automotive industry continues its shift towards electrification, the demand for high-performance PCMs is expected to surge, creating new opportunities for suppliers and manufacturers.

In the energy sector, PCMs are gaining traction for their ability to enhance the efficiency of renewable energy systems, particularly in solar thermal applications and grid-scale energy storage. This trend aligns with global efforts to transition towards cleaner energy sources, further boosting the market potential for industrial PCM supply.

The Asia-Pacific region is anticipated to be the fastest-growing market for industrial PCMs, driven by rapid industrialization, urbanization, and increasing investments in sustainable technologies. North America and Europe remain significant markets, with a focus on advanced applications and stringent energy efficiency regulations propelling demand.

Key challenges in the industrial PCM supply market include the need for consistent quality control across large-scale production, optimizing cost-effectiveness to compete with traditional materials, and addressing specific performance requirements for diverse industrial applications. Overcoming these challenges will be crucial for suppliers looking to capitalize on the growing market opportunities.

As the market evolves, there is an increasing emphasis on developing bio-based and sustainable PCMs, aligning with broader industry trends towards environmentally friendly solutions. This shift presents both opportunities and challenges for suppliers, necessitating investments in research and development to meet changing market demands while maintaining cost competitiveness.

Industrial applications of PCMs are diverse, ranging from thermal energy storage systems and building materials to temperature-sensitive packaging and transportation. The construction industry, in particular, is emerging as a key driver for PCM adoption, as these materials offer innovative solutions for passive temperature regulation in buildings, reducing energy consumption and improving overall sustainability.

The automotive sector is another significant market for industrial PCM supply, with applications in battery thermal management for electric vehicles and climate control systems. As the automotive industry continues its shift towards electrification, the demand for high-performance PCMs is expected to surge, creating new opportunities for suppliers and manufacturers.

In the energy sector, PCMs are gaining traction for their ability to enhance the efficiency of renewable energy systems, particularly in solar thermal applications and grid-scale energy storage. This trend aligns with global efforts to transition towards cleaner energy sources, further boosting the market potential for industrial PCM supply.

The Asia-Pacific region is anticipated to be the fastest-growing market for industrial PCMs, driven by rapid industrialization, urbanization, and increasing investments in sustainable technologies. North America and Europe remain significant markets, with a focus on advanced applications and stringent energy efficiency regulations propelling demand.

Key challenges in the industrial PCM supply market include the need for consistent quality control across large-scale production, optimizing cost-effectiveness to compete with traditional materials, and addressing specific performance requirements for diverse industrial applications. Overcoming these challenges will be crucial for suppliers looking to capitalize on the growing market opportunities.

As the market evolves, there is an increasing emphasis on developing bio-based and sustainable PCMs, aligning with broader industry trends towards environmentally friendly solutions. This shift presents both opportunities and challenges for suppliers, necessitating investments in research and development to meet changing market demands while maintaining cost competitiveness.

Current Challenges in PCM Manufacturing

The production of Phase Change Materials (PCMs) at an industrial scale presents several significant challenges that manufacturers must overcome to ensure quality and cost-effectiveness. One of the primary hurdles is maintaining consistent thermal properties across large batches. PCMs rely on precise melting and freezing points to function effectively, and even minor variations can significantly impact their performance in applications such as thermal energy storage systems.

Quality control during the manufacturing process is another critical challenge. Ensuring the purity of raw materials and preventing contamination throughout the production line is essential. Impurities can alter the PCM's thermal behavior, reduce its efficiency, and potentially lead to degradation over time. Implementing stringent quality control measures, including regular testing and analysis, is necessary but can be time-consuming and costly.

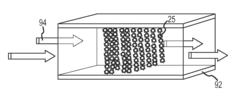

Encapsulation of PCMs, a crucial step for many applications, presents its own set of challenges. Achieving uniform encapsulation that maintains the PCM's thermal properties while providing adequate containment and durability is technically demanding. The encapsulation process must be carefully controlled to prevent leakage and ensure long-term stability, which can be particularly challenging when scaling up production.

Cost management is a significant concern in PCM manufacturing. Raw material costs can fluctuate, impacting overall production expenses. Additionally, the energy-intensive nature of PCM production, particularly in processes requiring precise temperature control, contributes to high operational costs. Balancing these expenses while maintaining product quality is a constant challenge for manufacturers.

Scaling up production while maintaining product consistency is another major hurdle. As batch sizes increase, ensuring uniform mixing, cooling, and processing becomes more complex. This scaling issue can lead to variations in product quality and performance, potentially resulting in increased waste and production costs.

Environmental and safety considerations also pose challenges in PCM manufacturing. Many PCMs are derived from petroleum-based products or contain chemicals that require careful handling and disposal. Developing more sustainable and environmentally friendly PCM formulations, while maintaining desired thermal properties, is an ongoing challenge for the industry.

Lastly, meeting diverse market demands with standardized production processes is challenging. Different applications require PCMs with specific thermal properties, necessitating a flexible manufacturing approach. Balancing the need for customization with the efficiencies of large-scale production remains a significant challenge for PCM manufacturers striving to meet varied market needs while maintaining cost-effectiveness.

Quality control during the manufacturing process is another critical challenge. Ensuring the purity of raw materials and preventing contamination throughout the production line is essential. Impurities can alter the PCM's thermal behavior, reduce its efficiency, and potentially lead to degradation over time. Implementing stringent quality control measures, including regular testing and analysis, is necessary but can be time-consuming and costly.

Encapsulation of PCMs, a crucial step for many applications, presents its own set of challenges. Achieving uniform encapsulation that maintains the PCM's thermal properties while providing adequate containment and durability is technically demanding. The encapsulation process must be carefully controlled to prevent leakage and ensure long-term stability, which can be particularly challenging when scaling up production.

Cost management is a significant concern in PCM manufacturing. Raw material costs can fluctuate, impacting overall production expenses. Additionally, the energy-intensive nature of PCM production, particularly in processes requiring precise temperature control, contributes to high operational costs. Balancing these expenses while maintaining product quality is a constant challenge for manufacturers.

Scaling up production while maintaining product consistency is another major hurdle. As batch sizes increase, ensuring uniform mixing, cooling, and processing becomes more complex. This scaling issue can lead to variations in product quality and performance, potentially resulting in increased waste and production costs.

Environmental and safety considerations also pose challenges in PCM manufacturing. Many PCMs are derived from petroleum-based products or contain chemicals that require careful handling and disposal. Developing more sustainable and environmentally friendly PCM formulations, while maintaining desired thermal properties, is an ongoing challenge for the industry.

Lastly, meeting diverse market demands with standardized production processes is challenging. Different applications require PCMs with specific thermal properties, necessitating a flexible manufacturing approach. Balancing the need for customization with the efficiencies of large-scale production remains a significant challenge for PCM manufacturers striving to meet varied market needs while maintaining cost-effectiveness.

Quality Control Methods in PCM Production

01 Quality control methods for PCM

Various quality control methods are employed to ensure the reliability and performance of Phase Change Materials. These methods may include thermal analysis techniques, microscopy, and spectroscopy to assess the purity, composition, and thermal properties of PCMs. Advanced testing procedures can help identify impurities, measure phase transition temperatures, and evaluate the stability of PCMs over multiple thermal cycles.- Quality control methods for PCM: Various quality control methods are employed to ensure the reliability and performance of Phase Change Materials (PCMs). These methods may include thermal analysis techniques, microscopy, and spectroscopy to assess the purity, composition, and thermal properties of PCMs. Advanced testing procedures can help identify impurities, measure phase transition temperatures, and evaluate the stability of PCMs over multiple thermal cycles.

- Cost reduction strategies for PCM production: Efforts to reduce the cost of PCM production focus on optimizing manufacturing processes, exploring alternative raw materials, and improving scalability. Techniques such as microencapsulation and nanoencapsulation are being developed to enhance the efficiency of PCM production while reducing material costs. Additionally, the use of waste materials or by-products as PCM sources is being investigated to lower overall production expenses.

- PCM integration in electronic devices: The integration of PCMs in electronic devices for thermal management is an area of active research and development. PCMs are being incorporated into various components such as batteries, processors, and memory modules to regulate temperature and improve device performance. This integration requires careful consideration of PCM properties, encapsulation methods, and device design to ensure optimal heat dissipation and cost-effectiveness.

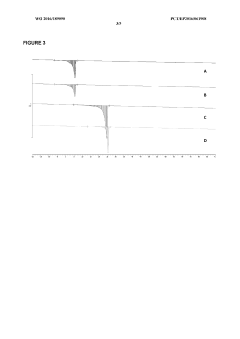

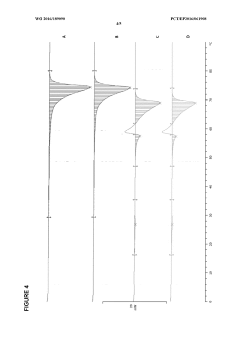

- Characterization techniques for PCM quality assessment: Advanced characterization techniques are crucial for assessing the quality of PCMs. These may include differential scanning calorimetry (DSC), thermogravimetric analysis (TGA), and X-ray diffraction (XRD) to determine thermal properties, phase transition behavior, and crystal structure. Emerging techniques such as hyperspectral imaging and machine learning algorithms are being explored to enhance the accuracy and efficiency of PCM quality assessment.

- Sustainable and low-cost PCM materials: Research is ongoing to develop sustainable and low-cost PCM materials to make thermal energy storage more economically viable. This includes the exploration of bio-based PCMs derived from natural sources, as well as the use of industrial by-products and waste materials. The focus is on identifying materials with suitable thermal properties, long-term stability, and environmental compatibility while maintaining low production costs.

02 Cost reduction strategies for PCM production

Efforts to reduce the cost of PCM production focus on optimizing manufacturing processes, exploring alternative raw materials, and improving scalability. Techniques such as microencapsulation and nanoencapsulation are being developed to enhance the efficiency of PCM production while reducing material costs. Additionally, the use of waste materials or byproducts as PCM sources is being investigated to lower overall production expenses.Expand Specific Solutions03 PCM integration in electronic devices

The integration of PCMs in electronic devices for thermal management is an area of active research and development. PCMs are being incorporated into various components such as batteries, processors, and memory modules to regulate temperature and improve device performance. This integration requires careful consideration of PCM properties, encapsulation methods, and device design to ensure optimal heat dissipation and energy efficiency.Expand Specific Solutions04 Characterization techniques for PCM properties

Advanced characterization techniques are essential for accurately determining the properties of PCMs. These methods include differential scanning calorimetry (DSC), thermogravimetric analysis (TGA), and X-ray diffraction (XRD). Such techniques allow researchers to measure key parameters like latent heat, specific heat capacity, and phase transition temperatures, which are crucial for assessing PCM quality and suitability for specific applications.Expand Specific Solutions05 PCM applications in energy storage systems

PCMs are increasingly being utilized in energy storage systems to improve efficiency and reduce costs. Applications include thermal energy storage for solar power plants, building heating and cooling systems, and grid-scale energy storage. The development of novel PCM formulations and composite materials aims to enhance energy density, thermal conductivity, and long-term stability while maintaining cost-effectiveness for large-scale energy storage solutions.Expand Specific Solutions

Key Players in PCM Industry

The market for Phase Change Materials (PCM) production is in a growth stage, driven by increasing demand for thermal management solutions across various industries. The global PCM market size is projected to expand significantly in the coming years, with a compound annual growth rate exceeding 15%. Technologically, PCM production is advancing, with companies like STATS ChipPAC, IBM, and SAP investing in research and development to improve quality control and reduce costs. However, the technology is not yet fully mature, as evidenced by ongoing efforts to enhance scalability and efficiency. Major players such as Hitachi, GlobalFoundries, and TSMC are actively working on innovative PCM solutions, indicating a competitive landscape with potential for further technological breakthroughs and market consolidation.

GLOBALFOUNDRIES, Inc.

Technical Solution: GlobalFoundries has implemented a comprehensive quality management system for PCM production, focusing on Six Sigma methodologies and lean manufacturing principles. Their approach includes advanced process control (APC) systems that utilize real-time data analytics to optimize PCM deposition and etching processes[4]. The company has also developed proprietary in-line metrology tools that can measure critical PCM parameters with high accuracy and throughput[5]. To address cost drivers, GlobalFoundries has invested in automation and Industry 4.0 technologies, reducing labor costs and improving overall equipment effectiveness (OEE)[6].

Strengths: Diverse technology portfolio, strong presence in specialty nodes, and focus on cost-effective manufacturing. Weaknesses: Trailing behind TSMC in leading-edge nodes and potential challenges in keeping up with the most advanced process technologies.

Taiwan Semiconductor Manufacturing Co., Ltd.

Technical Solution: TSMC has developed advanced process control (APC) systems for PCM production, integrating real-time monitoring and feedback loops to maintain consistent quality. Their approach includes in-line metrology tools and statistical process control (SPC) methods to detect and correct deviations quickly[1]. TSMC's 7nm and 5nm nodes utilize advanced PCM technologies, with plans to implement even more sophisticated quality control measures in their 3nm process[2]. The company has also invested in AI-driven defect detection systems, which can identify subtle patterns and anomalies in PCM production that might escape traditional inspection methods[3].

Strengths: Industry-leading process technology, extensive experience in high-volume manufacturing, and strong R&D capabilities. Weaknesses: High capital expenditure requirements and potential overcapacity risks in cyclical market downturns.

Innovations in PCM Manufacturing Processes

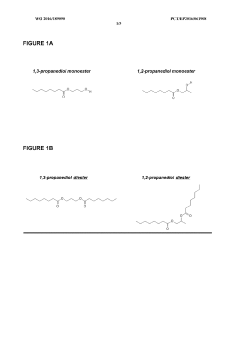

Phase change material-containing composition and related products and methods

PatentInactiveUS20130034732A1

Innovation

- A phase change material-containing composition comprising PCM, sorbent, and cement binder, which can be formulated into various forms such as aggregates or monolithic masses, providing high fire resistance and allowing for easier incorporation into building materials by bypassing costly drying processes, utilizing magnesium phosphate cement and clay sorbents to enhance fire resistance and handling safety.

Phase change material

PatentWO2016189090A1

Innovation

- Development of 1,3-propanediol fatty acid esters as phase change materials, which are fully bio-based, renewable, and biodegradable, offering high latent heat and narrow melting temperature ranges, and can be produced from food-grade raw materials for use in temperature regulation articles and food packaging.

Cost Drivers Analysis in PCM Production

In the production of Phase Change Materials (PCMs), several key cost drivers significantly impact the overall manufacturing expenses and ultimately influence the market competitiveness of the final product. Raw material costs represent a substantial portion of the total production expenses, with the purity and quality of these materials directly affecting the performance of the PCM. High-grade paraffins, fatty acids, and salt hydrates often command premium prices, necessitating careful sourcing strategies to balance quality and cost.

Energy consumption during the production process is another critical cost factor. The melting, purification, and encapsulation of PCMs require significant thermal energy inputs. Implementing energy-efficient technologies and optimizing process parameters can lead to substantial cost savings in this area. Additionally, the scale of production plays a crucial role in determining unit costs, with larger batch sizes typically resulting in economies of scale and reduced per-unit production expenses.

Equipment and infrastructure investments constitute a significant upfront cost in PCM production. Specialized mixing vessels, heat exchangers, and encapsulation machinery are essential for maintaining product quality and consistency. The depreciation of this equipment over time contributes to the ongoing cost structure of PCM manufacturing. Moreover, quality control measures, including testing equipment and procedures, add to the overall production costs but are crucial for ensuring product reliability and performance.

Labor costs, while not as dominant as material or energy expenses, still contribute significantly to the total production costs. Skilled operators and technicians are required to manage the complex production processes and quality control systems. Training and retention of qualified personnel can impact long-term cost efficiency. Furthermore, research and development expenses, although not directly tied to production, are essential for improving existing PCMs and developing new formulations to meet evolving market demands.

Packaging and transportation costs can vary widely depending on the specific application and end-user requirements for the PCMs. Some applications may require specialized containers or handling procedures, which can add to the overall cost structure. Additionally, regulatory compliance and certification processes, particularly for PCMs used in sensitive applications like building materials or food storage, can incur significant expenses that must be factored into the production cost analysis.

By carefully analyzing and optimizing these cost drivers, manufacturers can identify opportunities for cost reduction without compromising product quality. This may involve exploring alternative raw material sources, investing in more efficient production technologies, or streamlining quality control processes. Ultimately, a comprehensive understanding of these cost drivers is essential for scaling PCM production while maintaining competitive pricing in the industrial supply chain.

Energy consumption during the production process is another critical cost factor. The melting, purification, and encapsulation of PCMs require significant thermal energy inputs. Implementing energy-efficient technologies and optimizing process parameters can lead to substantial cost savings in this area. Additionally, the scale of production plays a crucial role in determining unit costs, with larger batch sizes typically resulting in economies of scale and reduced per-unit production expenses.

Equipment and infrastructure investments constitute a significant upfront cost in PCM production. Specialized mixing vessels, heat exchangers, and encapsulation machinery are essential for maintaining product quality and consistency. The depreciation of this equipment over time contributes to the ongoing cost structure of PCM manufacturing. Moreover, quality control measures, including testing equipment and procedures, add to the overall production costs but are crucial for ensuring product reliability and performance.

Labor costs, while not as dominant as material or energy expenses, still contribute significantly to the total production costs. Skilled operators and technicians are required to manage the complex production processes and quality control systems. Training and retention of qualified personnel can impact long-term cost efficiency. Furthermore, research and development expenses, although not directly tied to production, are essential for improving existing PCMs and developing new formulations to meet evolving market demands.

Packaging and transportation costs can vary widely depending on the specific application and end-user requirements for the PCMs. Some applications may require specialized containers or handling procedures, which can add to the overall cost structure. Additionally, regulatory compliance and certification processes, particularly for PCMs used in sensitive applications like building materials or food storage, can incur significant expenses that must be factored into the production cost analysis.

By carefully analyzing and optimizing these cost drivers, manufacturers can identify opportunities for cost reduction without compromising product quality. This may involve exploring alternative raw material sources, investing in more efficient production technologies, or streamlining quality control processes. Ultimately, a comprehensive understanding of these cost drivers is essential for scaling PCM production while maintaining competitive pricing in the industrial supply chain.

Environmental Impact of PCM Manufacturing

The environmental impact of PCM (Phase Change Material) manufacturing is a critical consideration as the industry scales up production to meet growing demand. The production process of PCMs involves several stages that can potentially affect the environment, including raw material extraction, synthesis, and waste management.

One of the primary environmental concerns in PCM manufacturing is energy consumption. The production of high-quality PCMs often requires precise temperature control and energy-intensive processes, which can lead to significant carbon emissions if not managed properly. Manufacturers are increasingly exploring renewable energy sources and energy-efficient technologies to mitigate this impact.

Water usage is another important factor in PCM production. Many PCM manufacturing processes require substantial amounts of water for cooling, cleaning, and as a medium for chemical reactions. Proper water management systems, including recycling and treatment facilities, are essential to reduce water consumption and prevent pollution of local water sources.

Chemical emissions and waste generation are also significant environmental considerations. The synthesis of certain PCMs may involve the use of volatile organic compounds (VOCs) or other potentially harmful chemicals. Implementing advanced emission control systems and adopting green chemistry principles can help minimize the release of these substances into the environment.

Solid waste management is crucial in PCM manufacturing. The production process may generate by-products and waste materials that require proper disposal or recycling. Developing efficient recycling methods for PCM materials at the end of their lifecycle is an emerging area of focus for improving the overall environmental footprint of the industry.

As PCM production scales up, there is an increasing emphasis on life cycle assessment (LCA) to evaluate the environmental impact from cradle to grave. This holistic approach helps identify areas for improvement throughout the entire production and usage cycle of PCMs, enabling manufacturers to make informed decisions about material selection, process optimization, and end-of-life management.

The industry is also exploring bio-based and sustainable raw materials for PCM production as an alternative to petroleum-derived substances. This shift towards renewable resources can significantly reduce the carbon footprint and environmental impact of PCM manufacturing, aligning with global sustainability goals.

One of the primary environmental concerns in PCM manufacturing is energy consumption. The production of high-quality PCMs often requires precise temperature control and energy-intensive processes, which can lead to significant carbon emissions if not managed properly. Manufacturers are increasingly exploring renewable energy sources and energy-efficient technologies to mitigate this impact.

Water usage is another important factor in PCM production. Many PCM manufacturing processes require substantial amounts of water for cooling, cleaning, and as a medium for chemical reactions. Proper water management systems, including recycling and treatment facilities, are essential to reduce water consumption and prevent pollution of local water sources.

Chemical emissions and waste generation are also significant environmental considerations. The synthesis of certain PCMs may involve the use of volatile organic compounds (VOCs) or other potentially harmful chemicals. Implementing advanced emission control systems and adopting green chemistry principles can help minimize the release of these substances into the environment.

Solid waste management is crucial in PCM manufacturing. The production process may generate by-products and waste materials that require proper disposal or recycling. Developing efficient recycling methods for PCM materials at the end of their lifecycle is an emerging area of focus for improving the overall environmental footprint of the industry.

As PCM production scales up, there is an increasing emphasis on life cycle assessment (LCA) to evaluate the environmental impact from cradle to grave. This holistic approach helps identify areas for improvement throughout the entire production and usage cycle of PCMs, enabling manufacturers to make informed decisions about material selection, process optimization, and end-of-life management.

The industry is also exploring bio-based and sustainable raw materials for PCM production as an alternative to petroleum-derived substances. This shift towards renewable resources can significantly reduce the carbon footprint and environmental impact of PCM manufacturing, aligning with global sustainability goals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!