PCM Thermal Interface Materials for Electronics Cooling: Design & Performance Benchmarks

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PCM TIM Background and Objectives

Phase change materials (PCMs) have emerged as a promising solution for thermal management in electronics cooling applications. The development of PCM-based thermal interface materials (TIMs) represents a significant advancement in addressing the growing thermal challenges faced by modern electronic devices. This research focuses on the design and performance benchmarks of PCM TIMs for electronics cooling, aiming to explore their potential in enhancing heat dissipation and improving overall device efficiency.

The evolution of electronic devices has been characterized by increasing power densities and miniaturization, leading to more intense thermal management requirements. Traditional cooling methods have struggled to keep pace with these demands, necessitating innovative approaches to heat dissipation. PCM TIMs offer a unique advantage by leveraging the latent heat of phase change to absorb and distribute thermal energy more effectively than conventional materials.

The primary objective of this research is to comprehensively investigate the design principles and performance metrics of PCM TIMs in the context of electronics cooling. This includes analyzing the thermal properties of various PCM formulations, exploring their integration with existing TIM technologies, and evaluating their effectiveness in real-world applications. By establishing clear performance benchmarks, this study aims to provide a foundation for future developments in PCM TIM technology.

A key focus of this research is to understand the relationship between PCM composition, phase change temperature, and thermal conductivity. These factors significantly influence the material's ability to manage heat loads effectively across different operating conditions. Additionally, the study will examine the long-term stability and reliability of PCM TIMs, addressing concerns about material degradation and performance consistency over extended periods of use.

The research also aims to explore the potential of hybrid PCM TIMs, which combine the benefits of phase change materials with other advanced thermal management technologies. This approach could lead to the development of more versatile and efficient thermal interface solutions capable of addressing a wider range of thermal challenges in electronic devices.

Furthermore, this study will investigate the scalability of PCM TIM technology, from small-scale applications in personal electronics to larger systems such as data centers and telecommunications equipment. Understanding the adaptability of PCM TIMs across different scales and thermal environments is crucial for assessing their broader impact on the electronics industry.

By establishing a comprehensive understanding of PCM TIM design principles and performance benchmarks, this research seeks to accelerate the adoption of these materials in electronics cooling applications. The outcomes of this study are expected to contribute significantly to the development of more efficient, reliable, and sustainable thermal management solutions for next-generation electronic devices.

The evolution of electronic devices has been characterized by increasing power densities and miniaturization, leading to more intense thermal management requirements. Traditional cooling methods have struggled to keep pace with these demands, necessitating innovative approaches to heat dissipation. PCM TIMs offer a unique advantage by leveraging the latent heat of phase change to absorb and distribute thermal energy more effectively than conventional materials.

The primary objective of this research is to comprehensively investigate the design principles and performance metrics of PCM TIMs in the context of electronics cooling. This includes analyzing the thermal properties of various PCM formulations, exploring their integration with existing TIM technologies, and evaluating their effectiveness in real-world applications. By establishing clear performance benchmarks, this study aims to provide a foundation for future developments in PCM TIM technology.

A key focus of this research is to understand the relationship between PCM composition, phase change temperature, and thermal conductivity. These factors significantly influence the material's ability to manage heat loads effectively across different operating conditions. Additionally, the study will examine the long-term stability and reliability of PCM TIMs, addressing concerns about material degradation and performance consistency over extended periods of use.

The research also aims to explore the potential of hybrid PCM TIMs, which combine the benefits of phase change materials with other advanced thermal management technologies. This approach could lead to the development of more versatile and efficient thermal interface solutions capable of addressing a wider range of thermal challenges in electronic devices.

Furthermore, this study will investigate the scalability of PCM TIM technology, from small-scale applications in personal electronics to larger systems such as data centers and telecommunications equipment. Understanding the adaptability of PCM TIMs across different scales and thermal environments is crucial for assessing their broader impact on the electronics industry.

By establishing a comprehensive understanding of PCM TIM design principles and performance benchmarks, this research seeks to accelerate the adoption of these materials in electronics cooling applications. The outcomes of this study are expected to contribute significantly to the development of more efficient, reliable, and sustainable thermal management solutions for next-generation electronic devices.

Electronics Cooling Market Analysis

The electronics cooling market has experienced significant growth in recent years, driven by the increasing demand for thermal management solutions in various electronic devices and systems. This market encompasses a wide range of products and technologies designed to dissipate heat and maintain optimal operating temperatures for electronic components.

The global electronics cooling market is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to remain strong over the next five years. This growth is primarily attributed to the rising adoption of advanced electronic devices across industries, including consumer electronics, automotive, aerospace, and telecommunications.

One of the key factors driving market expansion is the miniaturization trend in electronics. As devices become smaller and more powerful, the need for efficient cooling solutions becomes increasingly critical. This has led to a surge in demand for innovative thermal management technologies, including phase change materials (PCMs) and advanced thermal interface materials (TIMs).

The market for PCM-based thermal interface materials for electronics cooling is particularly promising. These materials offer several advantages over traditional cooling solutions, including improved thermal conductivity, enhanced heat dissipation, and the ability to maintain consistent temperatures during thermal cycling. As a result, PCM-based TIMs are gaining traction in high-performance computing, data centers, and mobile devices.

Regional analysis reveals that Asia-Pacific dominates the electronics cooling market, followed by North America and Europe. The Asia-Pacific region's leadership is primarily due to the presence of major electronics manufacturing hubs in countries like China, Japan, South Korea, and Taiwan. Additionally, the rapid growth of the consumer electronics industry in emerging economies such as India and Southeast Asian nations is contributing to the region's market dominance.

In terms of end-user segments, the consumer electronics sector remains the largest contributor to the electronics cooling market. However, other sectors such as automotive electronics, aerospace and defense, and healthcare are also experiencing significant growth in demand for thermal management solutions. This diversification of end-user applications is expected to further propel market growth in the coming years.

The competitive landscape of the electronics cooling market is characterized by the presence of both established players and innovative startups. Key market players are focusing on research and development activities to introduce advanced cooling technologies and gain a competitive edge. Collaborations between material suppliers, device manufacturers, and research institutions are becoming increasingly common, driving innovation in the field of thermal management.

The global electronics cooling market is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to remain strong over the next five years. This growth is primarily attributed to the rising adoption of advanced electronic devices across industries, including consumer electronics, automotive, aerospace, and telecommunications.

One of the key factors driving market expansion is the miniaturization trend in electronics. As devices become smaller and more powerful, the need for efficient cooling solutions becomes increasingly critical. This has led to a surge in demand for innovative thermal management technologies, including phase change materials (PCMs) and advanced thermal interface materials (TIMs).

The market for PCM-based thermal interface materials for electronics cooling is particularly promising. These materials offer several advantages over traditional cooling solutions, including improved thermal conductivity, enhanced heat dissipation, and the ability to maintain consistent temperatures during thermal cycling. As a result, PCM-based TIMs are gaining traction in high-performance computing, data centers, and mobile devices.

Regional analysis reveals that Asia-Pacific dominates the electronics cooling market, followed by North America and Europe. The Asia-Pacific region's leadership is primarily due to the presence of major electronics manufacturing hubs in countries like China, Japan, South Korea, and Taiwan. Additionally, the rapid growth of the consumer electronics industry in emerging economies such as India and Southeast Asian nations is contributing to the region's market dominance.

In terms of end-user segments, the consumer electronics sector remains the largest contributor to the electronics cooling market. However, other sectors such as automotive electronics, aerospace and defense, and healthcare are also experiencing significant growth in demand for thermal management solutions. This diversification of end-user applications is expected to further propel market growth in the coming years.

The competitive landscape of the electronics cooling market is characterized by the presence of both established players and innovative startups. Key market players are focusing on research and development activities to introduce advanced cooling technologies and gain a competitive edge. Collaborations between material suppliers, device manufacturers, and research institutions are becoming increasingly common, driving innovation in the field of thermal management.

PCM TIM State-of-the-Art and Challenges

Phase Change Material (PCM) Thermal Interface Materials (TIMs) have emerged as a promising solution for electronics cooling, addressing the increasing thermal management challenges in modern electronic devices. The current state-of-the-art in PCM TIMs showcases significant advancements in material composition, thermal performance, and application techniques.

Recent developments in PCM TIMs have focused on enhancing their thermal conductivity and phase change properties. Researchers have successfully incorporated various nanoparticles, such as graphene, carbon nanotubes, and metallic particles, into PCM matrices to improve heat transfer capabilities. These composite PCM TIMs have demonstrated thermal conductivities ranging from 1 to 5 W/mK, a substantial improvement over traditional thermal greases.

Another area of progress is the optimization of phase change temperatures. State-of-the-art PCM TIMs now offer a wide range of melting points, typically between 40°C and 80°C, allowing for better tailoring to specific electronic cooling applications. This customization enables more efficient heat dissipation during device operation cycles.

Despite these advancements, PCM TIMs face several challenges that hinder their widespread adoption. One major issue is the potential for pump-out and dry-out effects, where the PCM material may leak or migrate from the interface during thermal cycling. This can lead to decreased thermal performance over time and potential reliability issues in electronic devices.

Thermal stability and long-term performance of PCM TIMs remain concerns, particularly in high-temperature applications. Some PCM materials may degrade or lose their phase change properties after prolonged exposure to elevated temperatures, reducing their effectiveness in heat management.

Another challenge lies in achieving a balance between thermal conductivity and mechanical compliance. While higher filler content can improve thermal conductivity, it often results in increased stiffness, potentially leading to thermal stress issues in delicate electronic components.

Manufacturing and integration challenges also persist. Ensuring uniform dispersion of fillers within the PCM matrix and developing cost-effective, scalable production methods for high-performance PCM TIMs are ongoing areas of research and development.

Lastly, the environmental impact and recyclability of PCM TIMs are becoming increasingly important considerations. Developing eco-friendly PCM materials and establishing effective recycling processes for electronic components containing these materials are emerging challenges that the industry must address.

Recent developments in PCM TIMs have focused on enhancing their thermal conductivity and phase change properties. Researchers have successfully incorporated various nanoparticles, such as graphene, carbon nanotubes, and metallic particles, into PCM matrices to improve heat transfer capabilities. These composite PCM TIMs have demonstrated thermal conductivities ranging from 1 to 5 W/mK, a substantial improvement over traditional thermal greases.

Another area of progress is the optimization of phase change temperatures. State-of-the-art PCM TIMs now offer a wide range of melting points, typically between 40°C and 80°C, allowing for better tailoring to specific electronic cooling applications. This customization enables more efficient heat dissipation during device operation cycles.

Despite these advancements, PCM TIMs face several challenges that hinder their widespread adoption. One major issue is the potential for pump-out and dry-out effects, where the PCM material may leak or migrate from the interface during thermal cycling. This can lead to decreased thermal performance over time and potential reliability issues in electronic devices.

Thermal stability and long-term performance of PCM TIMs remain concerns, particularly in high-temperature applications. Some PCM materials may degrade or lose their phase change properties after prolonged exposure to elevated temperatures, reducing their effectiveness in heat management.

Another challenge lies in achieving a balance between thermal conductivity and mechanical compliance. While higher filler content can improve thermal conductivity, it often results in increased stiffness, potentially leading to thermal stress issues in delicate electronic components.

Manufacturing and integration challenges also persist. Ensuring uniform dispersion of fillers within the PCM matrix and developing cost-effective, scalable production methods for high-performance PCM TIMs are ongoing areas of research and development.

Lastly, the environmental impact and recyclability of PCM TIMs are becoming increasingly important considerations. Developing eco-friendly PCM materials and establishing effective recycling processes for electronic components containing these materials are emerging challenges that the industry must address.

Current PCM TIM Design Solutions

01 PCM composition and thermal properties

Phase Change Materials (PCMs) used in thermal interface materials are designed to enhance thermal performance. These materials undergo phase transitions at specific temperatures, absorbing or releasing heat in the process. The composition of PCMs can be tailored to achieve desired melting points and latent heat capacities, optimizing their effectiveness in managing thermal energy in electronic devices.- PCM composition and properties: Phase Change Materials (PCMs) used in thermal interface materials are designed with specific compositions and properties to enhance thermal performance. These materials undergo phase transitions at desired temperatures, absorbing or releasing latent heat. The composition often includes organic or inorganic compounds with high latent heat capacity, tailored melting points, and thermal conductivity enhancers.

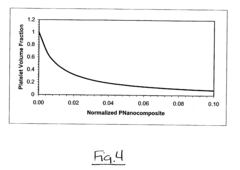

- Thermal conductivity enhancement: Various methods are employed to improve the thermal conductivity of PCM-based thermal interface materials. These include incorporating high thermal conductivity fillers such as metal particles, carbon nanotubes, or graphene. The enhanced thermal conductivity allows for more efficient heat transfer across the interface, improving overall thermal performance.

- Encapsulation and form-stability: To prevent leakage and maintain structural integrity during phase change, PCMs are often encapsulated or made form-stable. Techniques include microencapsulation, shape-stabilization with supporting matrices, and the use of containment structures. These methods ensure that the PCM remains in place and functions effectively over multiple thermal cycles.

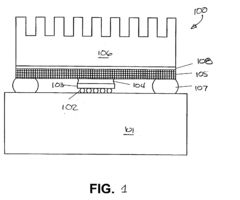

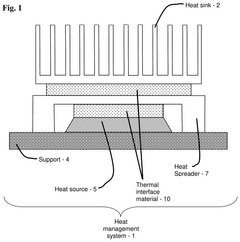

- Integration with heat spreaders and sinks: PCM thermal interface materials are designed to integrate effectively with heat spreaders and heat sinks. This involves optimizing the interface thickness, ensuring good surface contact, and sometimes incorporating the PCM directly into the heat sink structure. The goal is to minimize thermal resistance and maximize heat dissipation from the heat source to the cooling system.

- Thermal cycling and reliability: The performance of PCM thermal interface materials under repeated thermal cycling is crucial for long-term reliability. Research focuses on maintaining consistent thermal performance over numerous heating and cooling cycles, preventing degradation or separation of components, and ensuring stable thermal contact resistance. This involves studying fatigue behavior, thermal expansion matching, and developing materials with high thermal stability.

02 Integration of PCMs in thermal interface materials

PCMs are incorporated into thermal interface materials to improve heat dissipation in electronic components. These composite materials combine the thermal conductivity of traditional interface materials with the heat absorption capabilities of PCMs. The integration process involves dispersing PCM particles or encapsulating them within a matrix, ensuring uniform distribution and preventing leakage during phase transitions.Expand Specific Solutions03 Thermal performance enhancement techniques

Various techniques are employed to enhance the thermal performance of PCM-based thermal interface materials. These may include the use of high thermal conductivity fillers, surface modification of PCM particles, and optimization of particle size distribution. Advanced manufacturing processes, such as 3D printing or spray coating, can also be utilized to create tailored structures that maximize heat transfer efficiency.Expand Specific Solutions04 Characterization and testing methods

Accurate characterization and testing of PCM thermal interface materials are crucial for evaluating their performance. Methods such as differential scanning calorimetry, laser flash analysis, and thermal impedance testing are used to measure thermal properties, phase transition behavior, and overall heat dissipation efficiency. These techniques help in optimizing material formulations and predicting real-world performance in electronic devices.Expand Specific Solutions05 Application-specific PCM thermal interface solutions

PCM thermal interface materials are tailored for specific applications in electronics cooling. This includes customized solutions for high-power density devices, wearable electronics, and aerospace applications. The design considerations involve factors such as operating temperature range, power cycling requirements, and long-term reliability. Advanced formulations may incorporate additives to enhance flame retardancy, electrical insulation, or mechanical properties.Expand Specific Solutions

Key Players in PCM TIM Industry

The research on PCM Thermal Interface Materials for Electronics Cooling is in a growth phase, with increasing market demand driven by the need for efficient thermal management in electronic devices. The global market for thermal interface materials is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with major players like Intel, IBM, and Samsung Electronics investing in R&D to develop innovative solutions. Companies such as Henkel and Laird Technologies are also contributing to the maturation of PCM-based thermal interface materials. While the technology is evolving, it has not yet reached full maturity, presenting opportunities for further improvements in performance and cost-effectiveness.

Intel Corp.

Technical Solution: Intel has developed advanced PCM (Phase Change Material) thermal interface materials for electronics cooling. Their solution incorporates microencapsulated PCM particles within a polymer matrix, creating a composite TIM with enhanced thermal conductivity and phase change properties[1]. This material can absorb and release latent heat during phase transitions, effectively managing temperature spikes in high-performance processors. Intel's PCM TIM also features a tailored melting point range (50-80°C) to match typical operating temperatures of electronic devices[3]. The company has further improved the material's performance by optimizing particle size distribution and incorporating high thermal conductivity fillers like boron nitride[5].

Strengths: Excellent thermal management for high-performance processors, customizable melting point range, improved reliability. Weaknesses: Potentially higher cost compared to traditional TIMs, limited effectiveness in extreme temperature conditions.

Samsung Electronics Co., Ltd.

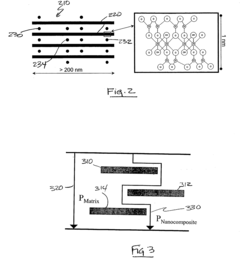

Technical Solution: Samsung has invested in PCM thermal interface materials research for electronics cooling, focusing on ultra-thin form factors for mobile devices. Their approach involves using nano-sized PCM particles dispersed in a graphene-based matrix, creating a flexible and highly conductive TIM[2]. This nanocomposite PCM TIM offers improved thermal conductivity (up to 5 W/mK) while maintaining the phase change benefits. Samsung's solution also incorporates a proprietary encapsulation technique that prevents PCM leakage and enhances long-term stability[4]. The company has demonstrated a 15-20% improvement in heat dissipation efficiency in smartphone applications using their PCM TIM technology[6].

Strengths: Excellent for ultra-thin mobile devices, high thermal conductivity, improved stability. Weaknesses: May be less suitable for high-power applications, potential scalability challenges in manufacturing.

Core PCM TIM Innovations

Phase change thermal interface materials including exfoliated clay

PatentInactiveUS20040191503A1

Innovation

- A nanocomposite phase change thermal interface material is developed, comprising matrix polymers, thermally conductive fillers, and layered clay materials, where the clay particles are exfoliated to create a tortuous path that enhances thermal conductivity and reduces diffusion of gases and volatile components, thereby improving the material's reliability and performance under acceleration stress and thermal cycling conditions.

Thermal interface materials

PatentActiveUS12130095B2

Innovation

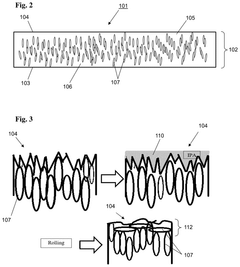

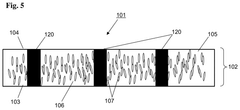

- A thermal interface material comprising a sheet with a base material and anisotropically oriented thermally conductive elements, which are preferentially aligned to enhance thermal conduction, and a method of fabricating this material by stacking layers with anisotropically oriented thermally conductive elements and compressing them to form a monolithic sheet.

Thermal Management Standards

Thermal management standards play a crucial role in ensuring the reliability and performance of electronic devices, particularly in the context of PCM thermal interface materials for electronics cooling. These standards provide guidelines for the design, testing, and evaluation of thermal management solutions, enabling manufacturers and engineers to develop effective cooling systems that meet industry requirements.

One of the primary thermal management standards relevant to PCM thermal interface materials is JEDEC JESD51, which outlines methods for thermal testing of electronic packages. This standard series includes specific guidelines for measuring thermal resistance and thermal characterization parameters, which are essential for evaluating the performance of PCM thermal interface materials in electronics cooling applications.

The ASTM D5470 standard is another important reference for thermal interface material testing. It provides a standardized method for measuring the thermal transmission properties of thermal interface materials, including PCM-based solutions. This standard ensures consistency in testing procedures and allows for accurate comparisons between different thermal interface materials.

ISO 22007 is a comprehensive standard that addresses the determination of thermal conductivity and thermal diffusivity for plastics and other materials. While not specifically tailored to PCM thermal interface materials, it offers valuable insights into thermal property measurement techniques that can be applied to these materials.

The IPC-4101 standard, although primarily focused on laminate materials for printed circuit boards, includes specifications for thermal management materials used in electronic assemblies. This standard can provide guidance on the integration of PCM thermal interface materials into overall electronic cooling solutions.

For reliability assessment, the IEC 60068 series of environmental testing standards is often applied to electronic components and materials, including thermal interface materials. These standards outline procedures for thermal cycling, thermal shock, and other environmental stress tests that are critical for evaluating the long-term performance of PCM thermal interface materials in electronics cooling applications.

In the context of design and performance benchmarks for PCM thermal interface materials, these standards collectively provide a framework for evaluating key parameters such as thermal conductivity, thermal resistance, phase change temperature, and long-term stability. They enable manufacturers to develop materials that meet specific thermal management requirements and allow engineers to make informed decisions when selecting appropriate cooling solutions for electronic devices.

One of the primary thermal management standards relevant to PCM thermal interface materials is JEDEC JESD51, which outlines methods for thermal testing of electronic packages. This standard series includes specific guidelines for measuring thermal resistance and thermal characterization parameters, which are essential for evaluating the performance of PCM thermal interface materials in electronics cooling applications.

The ASTM D5470 standard is another important reference for thermal interface material testing. It provides a standardized method for measuring the thermal transmission properties of thermal interface materials, including PCM-based solutions. This standard ensures consistency in testing procedures and allows for accurate comparisons between different thermal interface materials.

ISO 22007 is a comprehensive standard that addresses the determination of thermal conductivity and thermal diffusivity for plastics and other materials. While not specifically tailored to PCM thermal interface materials, it offers valuable insights into thermal property measurement techniques that can be applied to these materials.

The IPC-4101 standard, although primarily focused on laminate materials for printed circuit boards, includes specifications for thermal management materials used in electronic assemblies. This standard can provide guidance on the integration of PCM thermal interface materials into overall electronic cooling solutions.

For reliability assessment, the IEC 60068 series of environmental testing standards is often applied to electronic components and materials, including thermal interface materials. These standards outline procedures for thermal cycling, thermal shock, and other environmental stress tests that are critical for evaluating the long-term performance of PCM thermal interface materials in electronics cooling applications.

In the context of design and performance benchmarks for PCM thermal interface materials, these standards collectively provide a framework for evaluating key parameters such as thermal conductivity, thermal resistance, phase change temperature, and long-term stability. They enable manufacturers to develop materials that meet specific thermal management requirements and allow engineers to make informed decisions when selecting appropriate cooling solutions for electronic devices.

Environmental Impact of PCM TIMs

The environmental impact of Phase Change Material (PCM) Thermal Interface Materials (TIMs) for electronics cooling is a critical consideration in the development and implementation of these advanced thermal management solutions. PCM TIMs offer significant advantages in terms of thermal performance and reliability, but their environmental implications must be carefully evaluated throughout their lifecycle.

During the production phase, the manufacturing of PCM TIMs involves the use of various materials, including polymers, metals, and phase change substances. The extraction and processing of these raw materials can have environmental consequences, such as energy consumption, greenhouse gas emissions, and potential resource depletion. However, the precise environmental footprint depends on the specific materials used and the manufacturing processes employed.

In the application phase, PCM TIMs contribute to improved thermal management in electronic devices, potentially leading to enhanced energy efficiency and extended product lifespans. This can result in reduced electronic waste and lower overall energy consumption, which are positive environmental outcomes. The ability of PCM TIMs to maintain consistent thermal performance over time may also reduce the need for frequent replacements, further minimizing waste generation.

End-of-life considerations for PCM TIMs are an important aspect of their environmental impact. The recyclability and disposal methods for these materials vary depending on their composition. Some PCM TIMs may be recyclable, while others might require special handling or disposal procedures. The presence of metallic components or certain polymers can complicate recycling processes, potentially leading to increased waste if not properly managed.

The use of PCM TIMs in electronics cooling can indirectly contribute to reduced environmental impact through improved device performance and longevity. By effectively managing heat dissipation, these materials can prevent premature failure of electronic components, reducing the frequency of replacements and associated electronic waste. Additionally, the enhanced thermal management can allow for more compact and efficient device designs, potentially reducing material usage in electronics manufacturing.

However, it is essential to consider the potential release of chemicals or microplastics from PCM TIMs during their use or disposal. Depending on the specific formulation, there may be concerns about the leaching of substances into the environment, particularly if the materials are not properly contained or disposed of at the end of their life cycle.

As research in PCM TIMs progresses, there is a growing focus on developing more environmentally friendly formulations. This includes exploring bio-based PCMs, using recyclable materials, and designing for easier disassembly and recycling. These efforts aim to minimize the environmental impact while maintaining or improving the thermal performance of PCM TIMs in electronics cooling applications.

During the production phase, the manufacturing of PCM TIMs involves the use of various materials, including polymers, metals, and phase change substances. The extraction and processing of these raw materials can have environmental consequences, such as energy consumption, greenhouse gas emissions, and potential resource depletion. However, the precise environmental footprint depends on the specific materials used and the manufacturing processes employed.

In the application phase, PCM TIMs contribute to improved thermal management in electronic devices, potentially leading to enhanced energy efficiency and extended product lifespans. This can result in reduced electronic waste and lower overall energy consumption, which are positive environmental outcomes. The ability of PCM TIMs to maintain consistent thermal performance over time may also reduce the need for frequent replacements, further minimizing waste generation.

End-of-life considerations for PCM TIMs are an important aspect of their environmental impact. The recyclability and disposal methods for these materials vary depending on their composition. Some PCM TIMs may be recyclable, while others might require special handling or disposal procedures. The presence of metallic components or certain polymers can complicate recycling processes, potentially leading to increased waste if not properly managed.

The use of PCM TIMs in electronics cooling can indirectly contribute to reduced environmental impact through improved device performance and longevity. By effectively managing heat dissipation, these materials can prevent premature failure of electronic components, reducing the frequency of replacements and associated electronic waste. Additionally, the enhanced thermal management can allow for more compact and efficient device designs, potentially reducing material usage in electronics manufacturing.

However, it is essential to consider the potential release of chemicals or microplastics from PCM TIMs during their use or disposal. Depending on the specific formulation, there may be concerns about the leaching of substances into the environment, particularly if the materials are not properly contained or disposed of at the end of their life cycle.

As research in PCM TIMs progresses, there is a growing focus on developing more environmentally friendly formulations. This includes exploring bio-based PCMs, using recyclable materials, and designing for easier disassembly and recycling. These efforts aim to minimize the environmental impact while maintaining or improving the thermal performance of PCM TIMs in electronics cooling applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!