How to Accelerate PCM Cycling Tests to Predict 10-Year Performance — Accelerated Protocols

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PCM Cycling Test Acceleration: Background and Objectives

Phase change materials (PCMs) have gained significant attention in recent years due to their potential for thermal energy storage and management. These materials undergo a phase transition, typically between solid and liquid states, absorbing or releasing large amounts of latent heat in the process. This unique property makes PCMs particularly attractive for applications in building energy efficiency, thermal management of electronics, and renewable energy systems.

The development and implementation of PCMs, however, face a critical challenge: the need to predict their long-term performance accurately. PCMs are expected to maintain their thermal properties and cycling stability over many years of operation, often up to a decade or more. This requirement poses a significant hurdle for researchers and manufacturers, as conventional testing methods to evaluate PCM performance over such extended periods are impractical and economically unfeasible.

To address this challenge, the focus has shifted towards developing accelerated cycling test protocols for PCMs. These protocols aim to simulate the effects of long-term use within a much shorter timeframe, allowing researchers to make reliable predictions about a PCM's performance over its intended lifespan. The primary objective of these accelerated tests is to compress years of thermal cycling into weeks or months of laboratory testing, while still accurately reflecting the material's behavior and degradation patterns.

The development of such accelerated protocols is not without its complexities. It requires a deep understanding of the physical and chemical processes that occur during PCM cycling, as well as the factors that influence material degradation over time. These may include thermal stress, chemical reactions, phase separation, and changes in crystallization behavior. Furthermore, the accelerated protocols must be designed to account for various environmental conditions and usage scenarios that the PCM might encounter in real-world applications.

The goal of this technical research is to explore and evaluate methods for accelerating PCM cycling tests to predict 10-year performance accurately. This involves investigating current approaches, identifying their limitations, and proposing innovative solutions to enhance the reliability and efficiency of accelerated testing protocols. By achieving this objective, we aim to significantly reduce the time and resources required for PCM development and validation, ultimately accelerating the adoption of these materials in various energy-efficient applications.

The development and implementation of PCMs, however, face a critical challenge: the need to predict their long-term performance accurately. PCMs are expected to maintain their thermal properties and cycling stability over many years of operation, often up to a decade or more. This requirement poses a significant hurdle for researchers and manufacturers, as conventional testing methods to evaluate PCM performance over such extended periods are impractical and economically unfeasible.

To address this challenge, the focus has shifted towards developing accelerated cycling test protocols for PCMs. These protocols aim to simulate the effects of long-term use within a much shorter timeframe, allowing researchers to make reliable predictions about a PCM's performance over its intended lifespan. The primary objective of these accelerated tests is to compress years of thermal cycling into weeks or months of laboratory testing, while still accurately reflecting the material's behavior and degradation patterns.

The development of such accelerated protocols is not without its complexities. It requires a deep understanding of the physical and chemical processes that occur during PCM cycling, as well as the factors that influence material degradation over time. These may include thermal stress, chemical reactions, phase separation, and changes in crystallization behavior. Furthermore, the accelerated protocols must be designed to account for various environmental conditions and usage scenarios that the PCM might encounter in real-world applications.

The goal of this technical research is to explore and evaluate methods for accelerating PCM cycling tests to predict 10-year performance accurately. This involves investigating current approaches, identifying their limitations, and proposing innovative solutions to enhance the reliability and efficiency of accelerated testing protocols. By achieving this objective, we aim to significantly reduce the time and resources required for PCM development and validation, ultimately accelerating the adoption of these materials in various energy-efficient applications.

Market Demand for Long-Term PCM Performance Prediction

The market demand for long-term PCM (Phase Change Material) performance prediction has been steadily growing, driven by the increasing adoption of PCM in various industries and applications. As energy efficiency and thermal management become critical concerns across sectors, the need for reliable, long-lasting PCM solutions has intensified. This demand is particularly pronounced in industries such as building and construction, electronics, automotive, and renewable energy storage.

In the building sector, PCM is increasingly integrated into construction materials and HVAC systems to enhance energy efficiency and thermal comfort. Developers and building owners require accurate long-term performance predictions to justify the initial investment and ensure sustained benefits over the building's lifecycle. Similarly, in the electronics industry, where thermal management is crucial for device longevity and performance, manufacturers seek PCM solutions with proven long-term stability and effectiveness.

The automotive industry's shift towards electric vehicles has also fueled the demand for PCM performance prediction. As thermal management becomes more critical in EV battery systems, automakers need assurance of PCM effectiveness over the vehicle's lifespan. In renewable energy storage applications, such as concentrated solar power plants, the long-term stability of PCM-based thermal energy storage systems is essential for project viability and operational efficiency.

This growing market demand has led to increased pressure on PCM manufacturers and researchers to develop accelerated testing protocols that can reliably predict 10-year performance. Traditional testing methods, which often require years of real-time cycling, are no longer sufficient to meet the rapid pace of innovation and market demands. Stakeholders across industries are seeking faster, more accurate ways to assess PCM longevity and performance degradation over time.

The ability to predict long-term PCM performance quickly and accurately has become a competitive advantage in the market. It allows manufacturers to develop and bring new PCM formulations to market more rapidly, reduces the risk associated with new product adoption, and enables more informed decision-making for end-users. This has created a significant opportunity for research institutions and testing laboratories to develop and validate accelerated testing protocols that can reliably simulate years of PCM cycling in a fraction of the time.

As sustainability and energy efficiency continue to drive global initiatives, the demand for long-term PCM performance prediction is expected to grow further. Industries are increasingly looking for solutions that not only offer immediate benefits but also demonstrate long-term reliability and effectiveness. This trend underscores the critical need for advanced testing methodologies that can keep pace with market demands and technological advancements in PCM development.

In the building sector, PCM is increasingly integrated into construction materials and HVAC systems to enhance energy efficiency and thermal comfort. Developers and building owners require accurate long-term performance predictions to justify the initial investment and ensure sustained benefits over the building's lifecycle. Similarly, in the electronics industry, where thermal management is crucial for device longevity and performance, manufacturers seek PCM solutions with proven long-term stability and effectiveness.

The automotive industry's shift towards electric vehicles has also fueled the demand for PCM performance prediction. As thermal management becomes more critical in EV battery systems, automakers need assurance of PCM effectiveness over the vehicle's lifespan. In renewable energy storage applications, such as concentrated solar power plants, the long-term stability of PCM-based thermal energy storage systems is essential for project viability and operational efficiency.

This growing market demand has led to increased pressure on PCM manufacturers and researchers to develop accelerated testing protocols that can reliably predict 10-year performance. Traditional testing methods, which often require years of real-time cycling, are no longer sufficient to meet the rapid pace of innovation and market demands. Stakeholders across industries are seeking faster, more accurate ways to assess PCM longevity and performance degradation over time.

The ability to predict long-term PCM performance quickly and accurately has become a competitive advantage in the market. It allows manufacturers to develop and bring new PCM formulations to market more rapidly, reduces the risk associated with new product adoption, and enables more informed decision-making for end-users. This has created a significant opportunity for research institutions and testing laboratories to develop and validate accelerated testing protocols that can reliably simulate years of PCM cycling in a fraction of the time.

As sustainability and energy efficiency continue to drive global initiatives, the demand for long-term PCM performance prediction is expected to grow further. Industries are increasingly looking for solutions that not only offer immediate benefits but also demonstrate long-term reliability and effectiveness. This trend underscores the critical need for advanced testing methodologies that can keep pace with market demands and technological advancements in PCM development.

Current Challenges in PCM Cycling Test Acceleration

Accelerating PCM (Phase Change Material) cycling tests to predict long-term performance presents several significant challenges. The primary issue lies in the complexity of simulating real-world conditions that PCMs would experience over a decade within a compressed timeframe. Environmental factors such as temperature fluctuations, humidity, and mechanical stress can significantly impact PCM performance, making it difficult to accurately replicate these conditions in accelerated tests.

One of the key challenges is maintaining the integrity of the PCM during accelerated cycling. Rapid temperature changes and frequent phase transitions can lead to material degradation, which may not accurately represent the gradual wear that occurs over years of normal use. This accelerated degradation can potentially lead to overestimation of performance decline, resulting in inaccurate long-term predictions.

Another critical challenge is the development of standardized protocols for accelerated testing. Currently, there is a lack of universally accepted methods for accelerating PCM cycling tests, making it difficult to compare results across different studies or laboratories. This absence of standardization hinders the ability to draw reliable conclusions about long-term performance from accelerated tests.

The correlation between accelerated test results and real-world performance also poses a significant challenge. Establishing a reliable relationship between the outcomes of accelerated tests and actual long-term performance requires extensive validation studies, which are time-consuming and resource-intensive. Without this correlation, the predictive value of accelerated tests remains limited.

Furthermore, the diverse range of PCM compositions and applications complicates the development of universally applicable acceleration protocols. Different types of PCMs may respond differently to accelerated cycling, necessitating tailored approaches for each material category. This diversity makes it challenging to create a one-size-fits-all solution for accelerated testing.

Lastly, the challenge of accurately simulating the thermal cycling patterns that PCMs would experience over a decade is substantial. Real-world applications often involve irregular cycling patterns influenced by seasonal changes, daily temperature fluctuations, and varying usage conditions. Replicating these complex patterns in an accelerated test environment while maintaining relevance to long-term performance prediction is a formidable task that requires sophisticated testing equipment and methodologies.

One of the key challenges is maintaining the integrity of the PCM during accelerated cycling. Rapid temperature changes and frequent phase transitions can lead to material degradation, which may not accurately represent the gradual wear that occurs over years of normal use. This accelerated degradation can potentially lead to overestimation of performance decline, resulting in inaccurate long-term predictions.

Another critical challenge is the development of standardized protocols for accelerated testing. Currently, there is a lack of universally accepted methods for accelerating PCM cycling tests, making it difficult to compare results across different studies or laboratories. This absence of standardization hinders the ability to draw reliable conclusions about long-term performance from accelerated tests.

The correlation between accelerated test results and real-world performance also poses a significant challenge. Establishing a reliable relationship between the outcomes of accelerated tests and actual long-term performance requires extensive validation studies, which are time-consuming and resource-intensive. Without this correlation, the predictive value of accelerated tests remains limited.

Furthermore, the diverse range of PCM compositions and applications complicates the development of universally applicable acceleration protocols. Different types of PCMs may respond differently to accelerated cycling, necessitating tailored approaches for each material category. This diversity makes it challenging to create a one-size-fits-all solution for accelerated testing.

Lastly, the challenge of accurately simulating the thermal cycling patterns that PCMs would experience over a decade is substantial. Real-world applications often involve irregular cycling patterns influenced by seasonal changes, daily temperature fluctuations, and varying usage conditions. Replicating these complex patterns in an accelerated test environment while maintaining relevance to long-term performance prediction is a formidable task that requires sophisticated testing equipment and methodologies.

Existing Accelerated PCM Cycling Test Protocols

01 Improving PCM cycling stability

Various methods are employed to enhance the cycling stability of phase change materials. These include encapsulation techniques, addition of stabilizing agents, and optimization of material composition. Improved cycling stability ensures consistent performance over multiple phase change cycles, extending the lifespan and efficiency of PCM-based systems.- Improving PCM cycling stability: Various methods are employed to enhance the cycling stability of phase change materials. These include encapsulation techniques, the use of composite materials, and the addition of stabilizing agents. Such approaches aim to maintain the PCM's thermal properties and prevent degradation over multiple phase change cycles.

- PCM integration in energy storage systems: Phase change materials are incorporated into energy storage systems to improve their efficiency and capacity. This integration involves designing specialized containers, developing heat transfer mechanisms, and optimizing the overall system architecture to maximize the benefits of PCM's latent heat storage capabilities.

- PCM performance in battery applications: PCMs are utilized in battery systems to regulate temperature and enhance performance. This application focuses on integrating PCMs into battery packs, developing thermal management strategies, and improving the overall efficiency and lifespan of batteries through effective heat absorption and release during charge-discharge cycles.

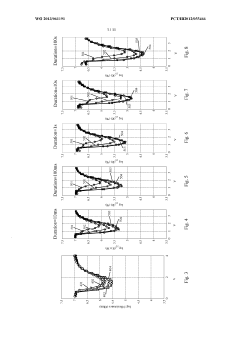

- Characterization and testing of PCM cycling performance: Advanced techniques and methodologies are developed to accurately characterize and test the cycling performance of PCMs. These include thermal cycling tests, accelerated aging studies, and the use of specialized equipment to measure thermal properties and structural changes over multiple phase change cycles.

- Novel PCM compositions for improved cycling: Research focuses on developing new PCM compositions with enhanced cycling performance. This involves exploring various material combinations, nanostructured PCMs, and hybrid systems to achieve better thermal stability, increased heat storage capacity, and improved long-term reliability over numerous phase change cycles.

02 PCM thermal management in electronic devices

Phase change materials are utilized for thermal management in electronic devices. PCMs absorb excess heat during operation and release it during cooling, helping to maintain optimal operating temperatures. This application improves device performance, extends battery life, and enhances overall reliability of electronic components.Expand Specific Solutions03 PCM integration in energy storage systems

Phase change materials are incorporated into energy storage systems to improve efficiency and capacity. PCMs can store and release thermal energy during phase transitions, complementing traditional energy storage methods. This integration enhances the overall performance of renewable energy systems and grid-scale storage solutions.Expand Specific Solutions04 PCM performance in building materials

Phase change materials are integrated into building materials to enhance thermal regulation and energy efficiency. PCMs in construction elements like walls, floors, and ceilings help maintain comfortable indoor temperatures by absorbing excess heat during the day and releasing it at night, reducing the need for artificial heating and cooling.Expand Specific Solutions05 Characterization and testing of PCM cycling performance

Advanced methods and equipment are developed for characterizing and testing the cycling performance of phase change materials. These techniques involve thermal cycling, calorimetry, and microscopy to assess material stability, phase transition behavior, and long-term performance under repeated cycling conditions. Accurate characterization ensures optimal selection and application of PCMs in various systems.Expand Specific Solutions

Key Players in PCM Testing and Prediction Technologies

The accelerated PCM cycling test market is in a growth phase, driven by increasing demand for reliable long-term performance predictions in energy storage applications. The market size is expanding as more industries adopt phase change materials for thermal management. Technologically, the field is advancing rapidly, with companies like Toyobo, Seiko Epson, and Robert Bosch leading innovations in test protocols and equipment. Academic institutions such as East China University of Science & Technology and Yale University are contributing fundamental research. While established players dominate, emerging companies like Feipeng Biotechnology are entering the space, indicating a dynamic competitive landscape. The technology is maturing but still evolving, with ongoing efforts to improve accuracy and reduce testing time.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has engineered an accelerated PCM cycling test protocol specifically designed for automotive-grade PCM devices, which require extreme reliability and longevity. Their approach combines thermal, mechanical, and electrical stress factors to simulate the harsh conditions experienced in automotive environments. The protocol involves rapid thermal cycling between -40°C and 150°C, coupled with vibration stress to mimic real-world vehicle conditions. Electrical cycling is performed at various temperatures to assess the impact of thermal conditions on switching behavior. Bosch's method also incorporates a unique "power cycling" test, where the PCM device is subjected to rapid power on/off cycles to simulate frequent vehicle starts and stops[9]. To predict 10-year performance, they use a combination of Weibull reliability analysis and physics-of-failure models. This hybrid approach allows for both statistical prediction of failure rates and mechanistic understanding of degradation processes[10].

Strengths: Comprehensive simulation of automotive environmental stresses, combination of statistical and physics-based prediction models. Weaknesses: May be overly specific to automotive applications, potentially overlooking failure modes relevant to other PCM use cases.

California Institute of Technology

Technical Solution: California Institute of Technology has developed an accelerated PCM cycling test protocol that utilizes elevated temperatures and increased cycling rates to predict 10-year performance in a shorter timeframe. Their approach involves conducting tests at temperatures ranging from 60°C to 80°C, which is significantly higher than typical operating conditions. By applying Arrhenius acceleration factors, they can extrapolate long-term performance from these accelerated tests[1]. Additionally, they have implemented a high-frequency cycling regime, increasing the number of cycles per day to further compress the testing timeline. This method is complemented by advanced data analysis techniques, including machine learning algorithms, to improve the accuracy of long-term predictions based on short-term accelerated test results[3].

Strengths: Significantly reduced testing time, ability to simulate long-term degradation mechanisms, and improved prediction accuracy through advanced data analysis. Weaknesses: Potential for introducing new failure modes not present in normal operating conditions, and the need for careful validation of acceleration factors.

Innovative Approaches to PCM Performance Prediction

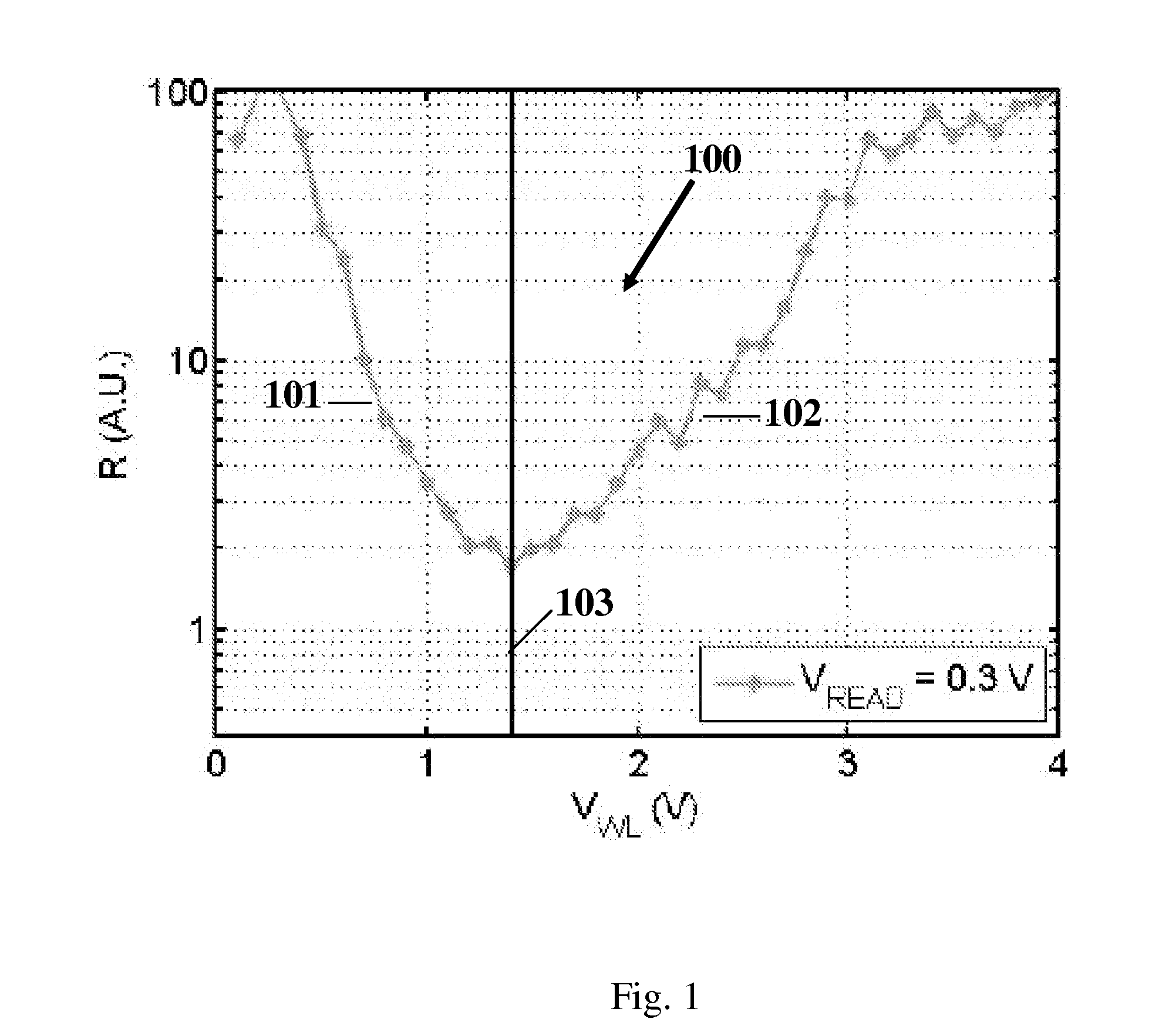

Conditioning phase change memory cells

PatentWO2013061191A1

Innovation

- A method for conditioning PCM cells by applying specific conditioning pulses to tailor their characteristics, such as resistance margin, programming speed, and power, to suit various applications, enabling simultaneous enhancement of performance and reduction of programming power, and increasing multi-level cell capability.

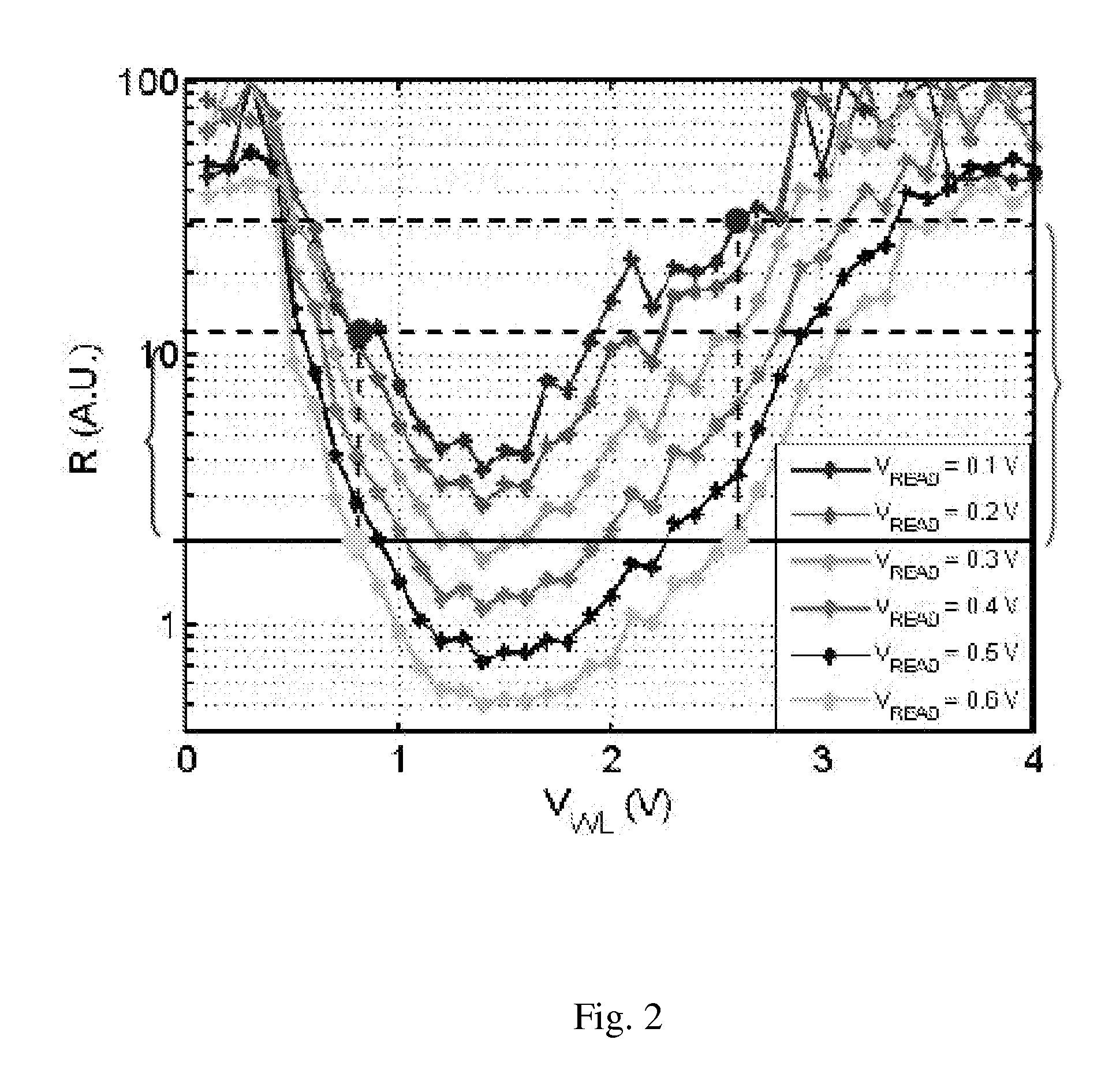

Programming at Least One Multi-Level Phase Change Memory Cell

PatentInactiveUS20110242884A1

Innovation

- A two-dimensional programming scheme is introduced, where the cell state is defined not only by the resistance value but also by the type of programming pulse (annealing or melting pulse), allowing for increased storage capacity by distinguishing between left and right slopes of the programming curve.

Standardization Efforts for PCM Testing Protocols

Efforts to standardize PCM testing protocols have gained significant momentum in recent years, driven by the need for consistent and reliable performance data across the industry. The International Energy Agency's Technology Collaboration Programme on Energy Storage (IEA-ES TCP) has been at the forefront of these initiatives, working to develop comprehensive guidelines for PCM characterization and testing.

One of the key focus areas has been the establishment of uniform cycling test procedures that can accurately predict long-term PCM performance. The IEA-ES TCP has proposed a set of standardized protocols that include specific temperature ranges, cycling rates, and measurement techniques. These protocols aim to simulate real-world conditions while accelerating the aging process to provide meaningful data in a shorter timeframe.

The American Society for Testing and Materials (ASTM) has also contributed to the standardization efforts through its Committee E44 on Solar, Geothermal, and Other Alternative Energy Sources. ASTM has developed several standards related to PCM testing, including ASTM E2586 for measuring latent heat of fusion and ASTM E2954 for thermal cycling stability.

In Europe, the European Committee for Standardization (CEN) has been working on a series of standards under the umbrella of EN 17140, which covers the testing and evaluation of PCM products for building applications. These standards address various aspects of PCM performance, including thermal cycling stability and accelerated aging tests.

The International Organization for Standardization (ISO) has also recognized the importance of PCM standardization. ISO/TC 163 on Thermal Performance and Energy Use in the Built Environment has been developing standards that include PCM testing methodologies, with a focus on ensuring compatibility with existing building energy simulation tools.

Despite these advancements, challenges remain in achieving full consensus on accelerated testing protocols. Researchers and industry stakeholders continue to debate the most effective methods for correlating short-term test results with long-term performance predictions. Ongoing collaborative efforts between academic institutions, national laboratories, and industry partners are crucial for refining and validating these standardized protocols.

As the field of PCM technology evolves, these standardization efforts will play a vital role in fostering innovation, improving product quality, and enhancing market confidence. The development of universally accepted testing protocols will enable more accurate comparisons between different PCM formulations and facilitate the integration of these materials into a wide range of energy storage applications.

One of the key focus areas has been the establishment of uniform cycling test procedures that can accurately predict long-term PCM performance. The IEA-ES TCP has proposed a set of standardized protocols that include specific temperature ranges, cycling rates, and measurement techniques. These protocols aim to simulate real-world conditions while accelerating the aging process to provide meaningful data in a shorter timeframe.

The American Society for Testing and Materials (ASTM) has also contributed to the standardization efforts through its Committee E44 on Solar, Geothermal, and Other Alternative Energy Sources. ASTM has developed several standards related to PCM testing, including ASTM E2586 for measuring latent heat of fusion and ASTM E2954 for thermal cycling stability.

In Europe, the European Committee for Standardization (CEN) has been working on a series of standards under the umbrella of EN 17140, which covers the testing and evaluation of PCM products for building applications. These standards address various aspects of PCM performance, including thermal cycling stability and accelerated aging tests.

The International Organization for Standardization (ISO) has also recognized the importance of PCM standardization. ISO/TC 163 on Thermal Performance and Energy Use in the Built Environment has been developing standards that include PCM testing methodologies, with a focus on ensuring compatibility with existing building energy simulation tools.

Despite these advancements, challenges remain in achieving full consensus on accelerated testing protocols. Researchers and industry stakeholders continue to debate the most effective methods for correlating short-term test results with long-term performance predictions. Ongoing collaborative efforts between academic institutions, national laboratories, and industry partners are crucial for refining and validating these standardized protocols.

As the field of PCM technology evolves, these standardization efforts will play a vital role in fostering innovation, improving product quality, and enhancing market confidence. The development of universally accepted testing protocols will enable more accurate comparisons between different PCM formulations and facilitate the integration of these materials into a wide range of energy storage applications.

Environmental Impact of PCM Lifecycle Testing

The environmental impact of PCM lifecycle testing is a critical consideration in the development and implementation of accelerated protocols for predicting long-term performance. As the demand for phase change materials (PCMs) in various applications continues to grow, it is essential to assess the ecological footprint of the testing processes used to evaluate their durability and efficiency.

Accelerated cycling tests, while crucial for predicting 10-year performance, can potentially contribute to increased energy consumption and waste generation. The repetitive heating and cooling cycles required to simulate long-term use may result in significant electricity consumption, particularly when conducted on a large scale or for extended periods. This energy usage not only impacts operational costs but also contributes to greenhouse gas emissions if the power source is not renewable.

Furthermore, the materials used in PCM samples during testing may pose environmental challenges. Depending on the composition of the PCM, there could be concerns regarding the disposal or recycling of tested samples. Some PCMs may contain chemicals that require special handling or treatment to prevent environmental contamination. The frequent replacement of samples during accelerated testing could lead to an accumulation of waste materials that need proper management.

Water usage is another environmental factor to consider in PCM lifecycle testing. Certain test protocols may require substantial amounts of water for temperature control or as a heat transfer medium. In regions facing water scarcity, this could strain local resources and potentially impact ecosystems.

The production of specialized testing equipment and infrastructure also contributes to the overall environmental footprint. Manufacturing, transporting, and maintaining these facilities and devices involve resource consumption and potential emissions throughout their lifecycle.

However, it is important to note that accelerated testing protocols, when properly designed and implemented, can actually lead to positive environmental outcomes. By accurately predicting long-term performance, these tests can help optimize PCM formulations and applications, potentially reducing material waste and improving energy efficiency in end-use scenarios. This optimization could result in more sustainable products with extended lifespans, ultimately decreasing the environmental impact of PCM production and disposal.

To mitigate the environmental impact of PCM lifecycle testing, researchers and industry professionals should focus on developing more sustainable testing methodologies. This could include the use of renewable energy sources to power testing facilities, implementing closed-loop systems for water and material recycling, and exploring virtual simulation techniques to complement physical testing. Additionally, standardizing test protocols across the industry could lead to more efficient resource utilization and reduced redundancy in testing efforts.

Accelerated cycling tests, while crucial for predicting 10-year performance, can potentially contribute to increased energy consumption and waste generation. The repetitive heating and cooling cycles required to simulate long-term use may result in significant electricity consumption, particularly when conducted on a large scale or for extended periods. This energy usage not only impacts operational costs but also contributes to greenhouse gas emissions if the power source is not renewable.

Furthermore, the materials used in PCM samples during testing may pose environmental challenges. Depending on the composition of the PCM, there could be concerns regarding the disposal or recycling of tested samples. Some PCMs may contain chemicals that require special handling or treatment to prevent environmental contamination. The frequent replacement of samples during accelerated testing could lead to an accumulation of waste materials that need proper management.

Water usage is another environmental factor to consider in PCM lifecycle testing. Certain test protocols may require substantial amounts of water for temperature control or as a heat transfer medium. In regions facing water scarcity, this could strain local resources and potentially impact ecosystems.

The production of specialized testing equipment and infrastructure also contributes to the overall environmental footprint. Manufacturing, transporting, and maintaining these facilities and devices involve resource consumption and potential emissions throughout their lifecycle.

However, it is important to note that accelerated testing protocols, when properly designed and implemented, can actually lead to positive environmental outcomes. By accurately predicting long-term performance, these tests can help optimize PCM formulations and applications, potentially reducing material waste and improving energy efficiency in end-use scenarios. This optimization could result in more sustainable products with extended lifespans, ultimately decreasing the environmental impact of PCM production and disposal.

To mitigate the environmental impact of PCM lifecycle testing, researchers and industry professionals should focus on developing more sustainable testing methodologies. This could include the use of renewable energy sources to power testing facilities, implementing closed-loop systems for water and material recycling, and exploring virtual simulation techniques to complement physical testing. Additionally, standardizing test protocols across the industry could lead to more efficient resource utilization and reduced redundancy in testing efforts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!