PCM vs Sensible Heat Storage: When to Use Latent Storage in Process Plants

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PCM and SHS Overview

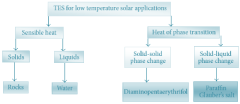

Phase Change Materials (PCMs) and Sensible Heat Storage (SHS) are two fundamental approaches to thermal energy storage in process plants. PCMs utilize the latent heat of phase transitions, typically between solid and liquid states, to store and release energy at a nearly constant temperature. This characteristic makes PCMs particularly effective for applications requiring precise temperature control or those with limited temperature ranges.

SHS, on the other hand, relies on the temperature change of a material to store and release thermal energy. This method is based on the specific heat capacity of the storage medium, which is typically a liquid or solid. SHS systems are generally simpler in design and can operate over a wider temperature range compared to PCM systems.

The choice between PCM and SHS depends on various factors, including the specific requirements of the process, temperature range, energy density needs, and economic considerations. PCMs offer higher energy storage density within a narrow temperature range, making them suitable for applications where space is limited or where maintaining a constant temperature is crucial. They are particularly effective in processes that involve frequent thermal cycling or require rapid heat transfer.

SHS systems, while generally having lower energy density, offer advantages in terms of simplicity, cost-effectiveness, and reliability. They are well-suited for applications with broader temperature ranges or where large volumes of storage material can be accommodated. SHS is often preferred in high-temperature industrial processes or in applications where the temperature change of the storage medium can be effectively utilized.

In process plants, the decision to use latent storage (PCM) over sensible heat storage often hinges on the specific thermal requirements of the process. PCMs are particularly advantageous in processes that require precise temperature control, such as in the food industry or in certain chemical reactions. They can also be beneficial in waste heat recovery systems, where the heat source and demand may not align temporally.

However, the implementation of PCM systems in industrial settings can be challenging due to issues such as thermal cycling stability, containment, and heat transfer efficiency. These challenges have led to ongoing research and development in PCM technologies, including the exploration of new materials and encapsulation techniques to enhance their performance and applicability in industrial processes.

The selection between PCM and SHS also involves considerations of system integration, operational flexibility, and long-term performance. While PCMs offer high energy density and isothermal operation, SHS systems may provide greater flexibility in terms of scalability and adaptability to varying process conditions. The decision ultimately requires a comprehensive analysis of the specific process requirements, technical feasibility, and economic viability.

SHS, on the other hand, relies on the temperature change of a material to store and release thermal energy. This method is based on the specific heat capacity of the storage medium, which is typically a liquid or solid. SHS systems are generally simpler in design and can operate over a wider temperature range compared to PCM systems.

The choice between PCM and SHS depends on various factors, including the specific requirements of the process, temperature range, energy density needs, and economic considerations. PCMs offer higher energy storage density within a narrow temperature range, making them suitable for applications where space is limited or where maintaining a constant temperature is crucial. They are particularly effective in processes that involve frequent thermal cycling or require rapid heat transfer.

SHS systems, while generally having lower energy density, offer advantages in terms of simplicity, cost-effectiveness, and reliability. They are well-suited for applications with broader temperature ranges or where large volumes of storage material can be accommodated. SHS is often preferred in high-temperature industrial processes or in applications where the temperature change of the storage medium can be effectively utilized.

In process plants, the decision to use latent storage (PCM) over sensible heat storage often hinges on the specific thermal requirements of the process. PCMs are particularly advantageous in processes that require precise temperature control, such as in the food industry or in certain chemical reactions. They can also be beneficial in waste heat recovery systems, where the heat source and demand may not align temporally.

However, the implementation of PCM systems in industrial settings can be challenging due to issues such as thermal cycling stability, containment, and heat transfer efficiency. These challenges have led to ongoing research and development in PCM technologies, including the exploration of new materials and encapsulation techniques to enhance their performance and applicability in industrial processes.

The selection between PCM and SHS also involves considerations of system integration, operational flexibility, and long-term performance. While PCMs offer high energy density and isothermal operation, SHS systems may provide greater flexibility in terms of scalability and adaptability to varying process conditions. The decision ultimately requires a comprehensive analysis of the specific process requirements, technical feasibility, and economic viability.

Market Demand Analysis

The market demand for energy storage solutions in process plants has been steadily increasing, driven by the growing need for efficient and sustainable energy management. Both Phase Change Materials (PCM) and Sensible Heat Storage systems play crucial roles in this landscape, with each offering unique advantages for specific applications.

The global thermal energy storage market, which encompasses both PCM and sensible heat storage technologies, is experiencing significant growth. This expansion is fueled by the rising adoption of renewable energy sources, increasing focus on energy efficiency, and the need for grid stability in industrial processes. Process plants, in particular, are showing a keen interest in these technologies due to their potential to optimize energy consumption and reduce operational costs.

PCM-based latent heat storage systems are gaining traction in process industries where temperature stability is critical. These materials can absorb or release large amounts of energy at a constant temperature, making them ideal for applications requiring precise temperature control. Industries such as food processing, pharmaceuticals, and chemical manufacturing are increasingly exploring PCM solutions to maintain product quality and process efficiency.

On the other hand, sensible heat storage systems continue to dominate in applications where large-scale energy storage is required. These systems are particularly favored in process plants dealing with high-temperature operations, such as steel manufacturing, cement production, and power generation. The simplicity and cost-effectiveness of sensible heat storage make it an attractive option for many industrial processes.

The market demand for PCM solutions is expected to grow at a faster rate compared to traditional sensible heat storage systems. This is primarily due to the increasing need for compact and efficient energy storage solutions in space-constrained industrial environments. Additionally, advancements in PCM technology, including the development of new materials with enhanced thermal properties, are driving their adoption in various process plant applications.

However, the choice between PCM and sensible heat storage is highly dependent on specific process requirements. Factors such as operating temperature range, storage capacity, charge/discharge rates, and integration complexity play crucial roles in determining the most suitable technology for a given application. As a result, the market is seeing a trend towards hybrid systems that combine both PCM and sensible heat storage technologies to leverage the benefits of each.

The growing emphasis on sustainability and energy efficiency in industrial processes is expected to further boost the demand for both PCM and sensible heat storage solutions. Government regulations and incentives promoting clean energy technologies are also contributing to market growth. As process plants continue to seek ways to optimize their energy consumption and reduce carbon footprint, the adoption of these thermal energy storage technologies is likely to accelerate in the coming years.

The global thermal energy storage market, which encompasses both PCM and sensible heat storage technologies, is experiencing significant growth. This expansion is fueled by the rising adoption of renewable energy sources, increasing focus on energy efficiency, and the need for grid stability in industrial processes. Process plants, in particular, are showing a keen interest in these technologies due to their potential to optimize energy consumption and reduce operational costs.

PCM-based latent heat storage systems are gaining traction in process industries where temperature stability is critical. These materials can absorb or release large amounts of energy at a constant temperature, making them ideal for applications requiring precise temperature control. Industries such as food processing, pharmaceuticals, and chemical manufacturing are increasingly exploring PCM solutions to maintain product quality and process efficiency.

On the other hand, sensible heat storage systems continue to dominate in applications where large-scale energy storage is required. These systems are particularly favored in process plants dealing with high-temperature operations, such as steel manufacturing, cement production, and power generation. The simplicity and cost-effectiveness of sensible heat storage make it an attractive option for many industrial processes.

The market demand for PCM solutions is expected to grow at a faster rate compared to traditional sensible heat storage systems. This is primarily due to the increasing need for compact and efficient energy storage solutions in space-constrained industrial environments. Additionally, advancements in PCM technology, including the development of new materials with enhanced thermal properties, are driving their adoption in various process plant applications.

However, the choice between PCM and sensible heat storage is highly dependent on specific process requirements. Factors such as operating temperature range, storage capacity, charge/discharge rates, and integration complexity play crucial roles in determining the most suitable technology for a given application. As a result, the market is seeing a trend towards hybrid systems that combine both PCM and sensible heat storage technologies to leverage the benefits of each.

The growing emphasis on sustainability and energy efficiency in industrial processes is expected to further boost the demand for both PCM and sensible heat storage solutions. Government regulations and incentives promoting clean energy technologies are also contributing to market growth. As process plants continue to seek ways to optimize their energy consumption and reduce carbon footprint, the adoption of these thermal energy storage technologies is likely to accelerate in the coming years.

Technical Challenges

The implementation of Phase Change Materials (PCMs) for latent heat storage in process plants faces several significant technical challenges. These obstacles must be addressed to fully harness the potential of PCM technology in industrial applications.

One of the primary challenges is the low thermal conductivity inherent to most PCMs. This characteristic limits the rate of heat transfer during charging and discharging cycles, potentially reducing the overall efficiency of the thermal energy storage system. To overcome this limitation, researchers are exploring various heat transfer enhancement techniques, such as the use of extended surfaces, metal foams, and nanoparticle additives.

Another critical issue is the phenomenon of phase segregation, which can occur in some PCM systems over multiple thermal cycles. This segregation can lead to a reduction in the effective heat storage capacity and compromise the long-term stability of the storage system. Developing PCM formulations that maintain homogeneity throughout numerous phase transitions remains an active area of research.

The containment of PCMs presents additional technical hurdles. Many PCMs undergo significant volume changes during phase transitions, which can lead to mechanical stress on the containment vessels. Designing robust and cost-effective encapsulation methods that can withstand these volume changes while maintaining thermal performance is crucial for widespread adoption in process plants.

Corrosion and material compatibility issues also pose challenges in PCM implementation. Some PCMs may react with or degrade common containment materials over time, potentially leading to system failures or reduced performance. Selecting appropriate materials for both the PCM and the containment system that ensure long-term stability and reliability is essential.

The integration of PCM-based latent heat storage systems into existing process plant infrastructure presents its own set of challenges. Retrofitting existing plants with PCM systems often requires careful consideration of space constraints, process flow modifications, and potential impacts on overall plant operations. Developing modular and flexible PCM storage solutions that can be easily integrated into diverse industrial settings is an ongoing area of development.

Lastly, the optimization of PCM melting and solidification temperatures for specific process applications remains a complex task. Matching the phase transition temperature of the PCM to the operational temperature range of the industrial process while maintaining high energy density and cycling stability is critical for maximizing the benefits of latent heat storage.

One of the primary challenges is the low thermal conductivity inherent to most PCMs. This characteristic limits the rate of heat transfer during charging and discharging cycles, potentially reducing the overall efficiency of the thermal energy storage system. To overcome this limitation, researchers are exploring various heat transfer enhancement techniques, such as the use of extended surfaces, metal foams, and nanoparticle additives.

Another critical issue is the phenomenon of phase segregation, which can occur in some PCM systems over multiple thermal cycles. This segregation can lead to a reduction in the effective heat storage capacity and compromise the long-term stability of the storage system. Developing PCM formulations that maintain homogeneity throughout numerous phase transitions remains an active area of research.

The containment of PCMs presents additional technical hurdles. Many PCMs undergo significant volume changes during phase transitions, which can lead to mechanical stress on the containment vessels. Designing robust and cost-effective encapsulation methods that can withstand these volume changes while maintaining thermal performance is crucial for widespread adoption in process plants.

Corrosion and material compatibility issues also pose challenges in PCM implementation. Some PCMs may react with or degrade common containment materials over time, potentially leading to system failures or reduced performance. Selecting appropriate materials for both the PCM and the containment system that ensure long-term stability and reliability is essential.

The integration of PCM-based latent heat storage systems into existing process plant infrastructure presents its own set of challenges. Retrofitting existing plants with PCM systems often requires careful consideration of space constraints, process flow modifications, and potential impacts on overall plant operations. Developing modular and flexible PCM storage solutions that can be easily integrated into diverse industrial settings is an ongoing area of development.

Lastly, the optimization of PCM melting and solidification temperatures for specific process applications remains a complex task. Matching the phase transition temperature of the PCM to the operational temperature range of the industrial process while maintaining high energy density and cycling stability is critical for maximizing the benefits of latent heat storage.

Current Storage Solutions

01 Phase Change Materials (PCM) for Latent Heat Storage

PCMs are used for efficient latent heat storage due to their ability to absorb and release large amounts of energy during phase transitions. These materials can store and release heat at a nearly constant temperature, making them ideal for thermal energy storage applications. PCMs can be incorporated into various systems to improve heat storage efficiency and temperature regulation.- Phase Change Materials (PCM) for Latent Heat Storage: PCMs are used for efficient latent heat storage due to their ability to absorb and release large amounts of energy during phase transitions. These materials can store and release heat at a nearly constant temperature, making them ideal for thermal energy storage applications. PCMs can be incorporated into various systems to improve heat storage efficiency and temperature regulation.

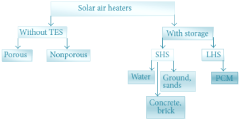

- Sensible Heat Storage Systems: Sensible heat storage systems rely on the temperature change of a storage medium to store and release thermal energy. These systems often use materials with high specific heat capacities, such as water, rocks, or concrete. While they may have lower energy density compared to latent heat storage, sensible heat systems are often simpler and more cost-effective for certain applications.

- Hybrid Latent-Sensible Heat Storage: Combining latent and sensible heat storage technologies can lead to improved overall heat storage efficiency. These hybrid systems leverage the advantages of both methods, utilizing PCMs for their high energy density and constant temperature characteristics, while also incorporating sensible heat storage materials for extended temperature ranges and cost-effectiveness.

- Encapsulation and Containment of PCMs: Encapsulation techniques are used to improve the performance and practicality of PCMs in latent heat storage systems. By encapsulating PCMs in various forms such as microcapsules or macrocapsules, issues like leakage and phase separation can be mitigated. This approach also enhances heat transfer rates and allows for easier integration of PCMs into different applications.

- Heat Transfer Enhancement in Thermal Energy Storage: Various methods are employed to enhance heat transfer in both latent and sensible heat storage systems, improving overall efficiency. These can include the use of extended surfaces (fins), heat pipes, or the incorporation of high thermal conductivity materials. Enhanced heat transfer allows for faster charging and discharging of thermal energy storage systems, leading to improved performance and responsiveness.

02 Sensible Heat Storage Systems

Sensible heat storage systems utilize the temperature change of a material to store thermal energy. These systems often employ materials with high specific heat capacities, such as water or rocks. While they may have lower energy density compared to latent heat storage, sensible heat systems are often simpler and more cost-effective for certain applications.Expand Specific Solutions03 Hybrid Latent and Sensible Heat Storage

Combining latent and sensible heat storage technologies can lead to improved overall heat storage efficiency. These hybrid systems leverage the advantages of both methods, utilizing PCMs for their high energy density and sensible heat materials for their simplicity and cost-effectiveness. This approach can result in more versatile and efficient thermal energy storage solutions.Expand Specific Solutions04 Encapsulation and Containment of PCMs

Encapsulation techniques are used to improve the performance and practicality of PCMs in latent heat storage systems. By encapsulating PCMs in various materials or structures, issues such as leakage and phase separation can be mitigated. This approach also enhances heat transfer and allows for easier integration of PCMs into different applications, ultimately improving heat storage efficiency.Expand Specific Solutions05 Heat Transfer Enhancement in Thermal Storage Systems

Various methods are employed to enhance heat transfer in both latent and sensible heat storage systems. These can include the use of fins, heat pipes, or other heat transfer structures to improve thermal conductivity. Additionally, novel designs and materials are explored to optimize heat exchange between the storage medium and the heat transfer fluid, leading to increased overall heat storage efficiency.Expand Specific Solutions

Key Industry Players

The competition landscape for PCM vs Sensible Heat Storage in process plants is evolving as the industry progresses through early adoption stages. The market size is expanding, driven by increasing demand for energy-efficient thermal management solutions. Technologically, latent heat storage using PCMs is maturing, with companies like Phase Change Solutions, Sunamp, and Axiotherm leading innovation. Universities such as King Fahd University of Petroleum & Minerals and research institutions like CNRS are advancing the fundamental understanding of PCM applications. Established industrial players like Honeywell and Bosch are also entering the field, indicating growing market potential and technological readiness for wider implementation in process plants.

Phase Change Solutions, Inc.

Technical Solution: Phase Change Solutions (PCS) has developed innovative PCM technologies for thermal energy management in various industries. Their proprietary ENRG Blanket system utilizes PCMs to provide passive thermal regulation in process plants and other industrial settings. PCS's technology can maintain temperatures within a narrow range for extended periods, reducing energy consumption and improving process stability [7]. They have also developed PCM-based heat exchangers that can be integrated into existing HVAC and process cooling systems to enhance efficiency. PCS's solutions have been shown to reduce peak cooling loads by up to 50% in some applications [8], making them particularly valuable for process plants with fluctuating thermal demands.

Strengths: Passive thermal regulation, easy integration into existing systems, and significant energy savings potential. Weaknesses: May require careful system design and potential limitations in processes with rapid temperature changes.

Sunamp Ltd.

Technical Solution: Sunamp has developed advanced thermal storage technology using phase change materials (PCMs) for both heating and cooling applications. Their patented Plentigrade technology utilizes salt-based PCMs that can store and release large amounts of thermal energy at specific temperatures [3]. Sunamp's heat batteries are compact, efficient, and can be easily integrated into existing heating and cooling systems. They have demonstrated up to 4 times higher energy density compared to water-based systems [4]. In process plants, Sunamp's technology can be applied for waste heat recovery, temperature stabilization, and peak load shifting, potentially reducing energy costs and improving overall system efficiency.

Strengths: High energy density, compact design, and versatility in integration. Weaknesses: May require careful system design to maximize benefits and potential limitations in very high-temperature industrial processes.

PCM Innovations

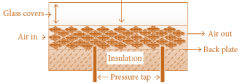

PCM based thermal energy storage system using solar air heater

PatentPendingIN202221051465A

Innovation

- A solar water heater design utilizing wax-type Phase Change Materials (PCMs) in small aluminum cylinders as the heat storage medium, where paraffin wax absorbs and releases latent heat to maintain water temperature, enhancing thermal performance and efficiency by storing energy during the day for nighttime use.

Latent heat storage materials

PatentInactiveEP2488463A1

Innovation

- A latent heat storage material composition incorporating a binder, phase change material, and water with a higher water-to-binder ratio, utilizing magnesia cement or pozzolan cement, and a magnesium chloride solution to achieve higher enthalpy values and improved fire retardant properties, allowing for increased phase change material incorporation and enhanced thermal energy storage.

Economic Feasibility

The economic feasibility of implementing latent heat storage using Phase Change Materials (PCMs) versus sensible heat storage in process plants is a critical consideration for decision-makers. The choice between these two technologies hinges on various factors, including initial investment costs, operational expenses, energy efficiency, and long-term financial benefits.

PCM-based latent heat storage systems generally require a higher upfront investment compared to traditional sensible heat storage solutions. This is primarily due to the cost of specialized PCM materials and the more complex system design needed to accommodate phase change processes. However, the higher initial costs can potentially be offset by the superior energy storage density of PCMs, which allows for more compact storage systems and reduced space requirements in process plants.

Operational costs for PCM systems can vary depending on the specific application and chosen materials. While some PCMs may require periodic replacement or maintenance, their ability to store and release heat at near-constant temperatures can lead to improved energy efficiency in certain processes. This enhanced efficiency can translate into lower energy consumption and reduced operational expenses over time.

The economic viability of PCM systems is particularly pronounced in applications with frequent thermal cycling or where maintaining precise temperature control is crucial. In such scenarios, the ability of PCMs to absorb and release large amounts of latent heat during phase transitions can result in significant energy savings and improved process stability, potentially justifying the higher initial investment.

Sensible heat storage systems, on the other hand, typically have lower upfront costs and are simpler to implement. They rely on the temperature change of a storage medium, such as water or thermal oils, to store and release heat. While these systems may be less efficient in terms of energy storage density, they can be more cost-effective for applications with less stringent temperature control requirements or where large temperature differentials are acceptable.

The economic feasibility of PCM systems also depends on factors such as the availability and cost of suitable PCM materials, the scale of the storage system required, and the specific thermal management needs of the process plant. In some cases, hybrid systems combining both PCM and sensible heat storage may offer the most economically viable solution, leveraging the strengths of both technologies.

Long-term economic benefits of PCM systems can include reduced energy consumption, improved process efficiency, and potential space savings. However, these benefits must be carefully weighed against the higher initial costs and any additional maintenance requirements. A thorough life-cycle cost analysis, considering factors such as energy prices, operational lifetimes, and potential future regulations, is essential for accurately assessing the economic feasibility of PCM versus sensible heat storage in process plants.

PCM-based latent heat storage systems generally require a higher upfront investment compared to traditional sensible heat storage solutions. This is primarily due to the cost of specialized PCM materials and the more complex system design needed to accommodate phase change processes. However, the higher initial costs can potentially be offset by the superior energy storage density of PCMs, which allows for more compact storage systems and reduced space requirements in process plants.

Operational costs for PCM systems can vary depending on the specific application and chosen materials. While some PCMs may require periodic replacement or maintenance, their ability to store and release heat at near-constant temperatures can lead to improved energy efficiency in certain processes. This enhanced efficiency can translate into lower energy consumption and reduced operational expenses over time.

The economic viability of PCM systems is particularly pronounced in applications with frequent thermal cycling or where maintaining precise temperature control is crucial. In such scenarios, the ability of PCMs to absorb and release large amounts of latent heat during phase transitions can result in significant energy savings and improved process stability, potentially justifying the higher initial investment.

Sensible heat storage systems, on the other hand, typically have lower upfront costs and are simpler to implement. They rely on the temperature change of a storage medium, such as water or thermal oils, to store and release heat. While these systems may be less efficient in terms of energy storage density, they can be more cost-effective for applications with less stringent temperature control requirements or where large temperature differentials are acceptable.

The economic feasibility of PCM systems also depends on factors such as the availability and cost of suitable PCM materials, the scale of the storage system required, and the specific thermal management needs of the process plant. In some cases, hybrid systems combining both PCM and sensible heat storage may offer the most economically viable solution, leveraging the strengths of both technologies.

Long-term economic benefits of PCM systems can include reduced energy consumption, improved process efficiency, and potential space savings. However, these benefits must be carefully weighed against the higher initial costs and any additional maintenance requirements. A thorough life-cycle cost analysis, considering factors such as energy prices, operational lifetimes, and potential future regulations, is essential for accurately assessing the economic feasibility of PCM versus sensible heat storage in process plants.

Environmental Impact

The environmental impact of thermal energy storage systems is a critical consideration in the selection between Phase Change Materials (PCM) and Sensible Heat Storage for process plants. PCM-based latent heat storage systems generally offer a more compact and efficient solution, potentially reducing the overall environmental footprint of the storage facility. This is primarily due to their higher energy density, which allows for smaller storage volumes and less material usage in construction.

PCM systems can contribute to energy conservation and greenhouse gas reduction by enabling more efficient use of intermittent renewable energy sources. They can store excess energy during peak production periods and release it when demand is high, thus reducing reliance on fossil fuel-based backup systems. This capability is particularly valuable in industrial processes that require consistent heat supply, as it can help smooth out energy demand curves and reduce the need for constant energy production.

However, the environmental impact of PCM systems is not without concerns. The production of certain phase change materials may involve energy-intensive processes or the use of chemicals with potential environmental risks. Additionally, some PCMs may have limited lifespans or degrade over time, necessitating replacement and potentially creating waste management issues.

In contrast, sensible heat storage systems often utilize more common and naturally occurring materials such as water, rocks, or concrete. These materials generally have lower environmental impacts in terms of production and disposal. However, sensible heat storage typically requires larger volumes to store equivalent amounts of energy, potentially leading to greater land use and more extensive construction activities.

The choice between PCM and sensible heat storage also affects the operational environmental impact of process plants. PCM systems can operate at near-constant temperatures during phase changes, potentially reducing temperature fluctuations in industrial processes. This can lead to more stable operations, fewer thermal cycles, and potentially lower energy consumption in maintaining process conditions.

When considering the full life cycle, the environmental impact of both systems must be evaluated in terms of material sourcing, manufacturing, operational efficiency, and end-of-life disposal or recycling. PCM systems may offer advantages in operational efficiency and space utilization, but their overall environmental benefit depends on factors such as the specific PCM used, system design, and integration with the process plant's energy systems.

PCM systems can contribute to energy conservation and greenhouse gas reduction by enabling more efficient use of intermittent renewable energy sources. They can store excess energy during peak production periods and release it when demand is high, thus reducing reliance on fossil fuel-based backup systems. This capability is particularly valuable in industrial processes that require consistent heat supply, as it can help smooth out energy demand curves and reduce the need for constant energy production.

However, the environmental impact of PCM systems is not without concerns. The production of certain phase change materials may involve energy-intensive processes or the use of chemicals with potential environmental risks. Additionally, some PCMs may have limited lifespans or degrade over time, necessitating replacement and potentially creating waste management issues.

In contrast, sensible heat storage systems often utilize more common and naturally occurring materials such as water, rocks, or concrete. These materials generally have lower environmental impacts in terms of production and disposal. However, sensible heat storage typically requires larger volumes to store equivalent amounts of energy, potentially leading to greater land use and more extensive construction activities.

The choice between PCM and sensible heat storage also affects the operational environmental impact of process plants. PCM systems can operate at near-constant temperatures during phase changes, potentially reducing temperature fluctuations in industrial processes. This can lead to more stable operations, fewer thermal cycles, and potentially lower energy consumption in maintaining process conditions.

When considering the full life cycle, the environmental impact of both systems must be evaluated in terms of material sourcing, manufacturing, operational efficiency, and end-of-life disposal or recycling. PCM systems may offer advantages in operational efficiency and space utilization, but their overall environmental benefit depends on factors such as the specific PCM used, system design, and integration with the process plant's energy systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!