PCM Safety and Fire Performance: Standards, Testing and Selection Criteria

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PCM Safety Background and Objectives

Phase Change Materials (PCMs) have gained significant attention in recent years due to their potential for energy storage and thermal management applications. The safety and fire performance of PCMs are critical aspects that require thorough investigation to ensure their widespread adoption and implementation. This research aims to comprehensively examine the current standards, testing methodologies, and selection criteria for PCM safety and fire performance.

The development of PCMs has a rich history, dating back to the 1940s when their potential for thermal energy storage was first recognized. Since then, the technology has evolved considerably, with advancements in material science and engineering leading to the creation of various types of PCMs, including organic, inorganic, and eutectic compounds. As the applications for PCMs have expanded across industries such as building construction, textiles, and electronics, the need for robust safety standards and fire performance criteria has become increasingly apparent.

The primary objective of this research is to establish a comprehensive understanding of the safety considerations and fire performance characteristics of PCMs. This includes an in-depth analysis of existing safety standards and regulations, as well as an evaluation of current testing methodologies used to assess PCM fire performance. By examining these aspects, we aim to identify potential gaps in current practices and propose improvements to enhance the overall safety of PCM applications.

Another crucial goal of this study is to develop a set of selection criteria that can guide manufacturers, engineers, and end-users in choosing appropriate PCMs for specific applications while prioritizing safety and fire performance. This involves considering factors such as the chemical composition of PCMs, their thermal properties, and their behavior under various environmental conditions.

Furthermore, this research seeks to explore the latest advancements in PCM technology that address safety concerns and improve fire resistance. This includes investigating novel encapsulation techniques, fire-retardant additives, and innovative material combinations that can enhance the overall safety profile of PCMs without compromising their thermal energy storage capabilities.

By conducting this comprehensive analysis, we aim to contribute to the development of more stringent safety standards and testing protocols for PCMs. This will not only help mitigate potential risks associated with their use but also foster greater confidence in PCM technology among stakeholders, ultimately facilitating wider adoption across various industries.

The development of PCMs has a rich history, dating back to the 1940s when their potential for thermal energy storage was first recognized. Since then, the technology has evolved considerably, with advancements in material science and engineering leading to the creation of various types of PCMs, including organic, inorganic, and eutectic compounds. As the applications for PCMs have expanded across industries such as building construction, textiles, and electronics, the need for robust safety standards and fire performance criteria has become increasingly apparent.

The primary objective of this research is to establish a comprehensive understanding of the safety considerations and fire performance characteristics of PCMs. This includes an in-depth analysis of existing safety standards and regulations, as well as an evaluation of current testing methodologies used to assess PCM fire performance. By examining these aspects, we aim to identify potential gaps in current practices and propose improvements to enhance the overall safety of PCM applications.

Another crucial goal of this study is to develop a set of selection criteria that can guide manufacturers, engineers, and end-users in choosing appropriate PCMs for specific applications while prioritizing safety and fire performance. This involves considering factors such as the chemical composition of PCMs, their thermal properties, and their behavior under various environmental conditions.

Furthermore, this research seeks to explore the latest advancements in PCM technology that address safety concerns and improve fire resistance. This includes investigating novel encapsulation techniques, fire-retardant additives, and innovative material combinations that can enhance the overall safety profile of PCMs without compromising their thermal energy storage capabilities.

By conducting this comprehensive analysis, we aim to contribute to the development of more stringent safety standards and testing protocols for PCMs. This will not only help mitigate potential risks associated with their use but also foster greater confidence in PCM technology among stakeholders, ultimately facilitating wider adoption across various industries.

Market Demand Analysis for Safe PCMs

The market demand for safe Phase Change Materials (PCMs) has been steadily increasing due to their potential applications in various sectors, particularly in energy storage and thermal management systems. As energy efficiency and sustainability become paramount concerns across industries, the need for reliable and safe PCM solutions has grown significantly.

In the construction industry, there is a rising demand for PCMs in building materials to enhance energy efficiency and thermal comfort. Safe PCMs are being incorporated into walls, ceilings, and flooring to regulate indoor temperatures and reduce heating and cooling costs. This trend is driven by stringent building energy codes and a growing emphasis on green construction practices.

The automotive sector presents another substantial market for safe PCMs. With the rapid growth of electric vehicles, thermal management of batteries has become crucial. PCMs offer an effective solution for maintaining optimal battery temperatures, thereby extending battery life and improving overall vehicle performance. As electric vehicle adoption continues to accelerate, the demand for safe PCMs in this sector is expected to surge.

In the textile industry, there is an emerging market for smart fabrics and clothing that incorporate PCMs for temperature regulation. These materials are particularly sought after in sportswear, outdoor gear, and protective clothing for extreme environments. The ability of PCMs to maintain a comfortable temperature range makes them invaluable in these applications, driving market growth.

The renewable energy sector, especially solar power, is another key driver of demand for safe PCMs. In concentrated solar power plants, PCMs are used for thermal energy storage, allowing for continuous power generation even when sunlight is not available. As the world transitions towards cleaner energy sources, the demand for efficient and safe energy storage solutions, including PCMs, is projected to increase substantially.

In the healthcare and pharmaceutical industries, safe PCMs are gaining traction for temperature-sensitive applications such as vaccine storage and transport, as well as in medical devices for maintaining precise temperatures. The COVID-19 pandemic has further highlighted the importance of reliable cold chain solutions, potentially boosting the demand for PCM-based storage systems.

However, the market demand for safe PCMs is not without challenges. Concerns about fire safety and long-term stability of PCMs have led to increased scrutiny and the need for rigorous safety standards. This has created a parallel demand for improved testing methodologies and certification processes to ensure the safety and reliability of PCM products across various applications.

In the construction industry, there is a rising demand for PCMs in building materials to enhance energy efficiency and thermal comfort. Safe PCMs are being incorporated into walls, ceilings, and flooring to regulate indoor temperatures and reduce heating and cooling costs. This trend is driven by stringent building energy codes and a growing emphasis on green construction practices.

The automotive sector presents another substantial market for safe PCMs. With the rapid growth of electric vehicles, thermal management of batteries has become crucial. PCMs offer an effective solution for maintaining optimal battery temperatures, thereby extending battery life and improving overall vehicle performance. As electric vehicle adoption continues to accelerate, the demand for safe PCMs in this sector is expected to surge.

In the textile industry, there is an emerging market for smart fabrics and clothing that incorporate PCMs for temperature regulation. These materials are particularly sought after in sportswear, outdoor gear, and protective clothing for extreme environments. The ability of PCMs to maintain a comfortable temperature range makes them invaluable in these applications, driving market growth.

The renewable energy sector, especially solar power, is another key driver of demand for safe PCMs. In concentrated solar power plants, PCMs are used for thermal energy storage, allowing for continuous power generation even when sunlight is not available. As the world transitions towards cleaner energy sources, the demand for efficient and safe energy storage solutions, including PCMs, is projected to increase substantially.

In the healthcare and pharmaceutical industries, safe PCMs are gaining traction for temperature-sensitive applications such as vaccine storage and transport, as well as in medical devices for maintaining precise temperatures. The COVID-19 pandemic has further highlighted the importance of reliable cold chain solutions, potentially boosting the demand for PCM-based storage systems.

However, the market demand for safe PCMs is not without challenges. Concerns about fire safety and long-term stability of PCMs have led to increased scrutiny and the need for rigorous safety standards. This has created a parallel demand for improved testing methodologies and certification processes to ensure the safety and reliability of PCM products across various applications.

Current PCM Safety Challenges

Phase Change Materials (PCMs) have gained significant attention in various applications due to their ability to store and release thermal energy. However, as their usage expands, safety concerns have become increasingly prominent. One of the primary challenges facing PCM implementation is their flammability and potential fire hazards.

Many organic PCMs, particularly those derived from paraffin waxes, are inherently combustible. When exposed to high temperatures or ignition sources, these materials can melt, vaporize, and potentially ignite, contributing to fire spread and intensity. This poses significant risks in building applications, where PCMs are often integrated into construction materials for thermal management.

Another critical safety challenge is the potential for PCMs to release toxic fumes when heated or burned. Some PCMs, especially those containing halogenated compounds or other synthetic additives, may emit harmful gases during thermal decomposition. This not only presents immediate health risks to occupants but also complicates fire-fighting efforts and post-fire cleanup operations.

The encapsulation of PCMs, while often used to improve handling and prevent leakage, can introduce additional safety concerns. Failure of the encapsulation material under extreme conditions may lead to the sudden release of molten PCM, potentially causing burns or accelerating fire spread. Moreover, the interaction between PCMs and their containment systems during fire scenarios is not always well understood, leading to uncertainties in predicting overall fire behavior.

The lack of standardized testing protocols specifically designed for PCM-integrated materials presents another significant challenge. Current fire safety standards and building codes may not adequately address the unique properties and behaviors of PCMs under fire conditions. This gap in regulation and testing methodologies makes it difficult for manufacturers to demonstrate compliance and for building authorities to ensure safety.

Furthermore, the long-term stability and performance of PCMs in terms of fire safety remain areas of concern. Degradation of PCMs or their containment systems over time could potentially alter their fire performance characteristics, necessitating ongoing monitoring and maintenance strategies that are not yet well-established.

Addressing these safety challenges requires a multifaceted approach. This includes the development of more fire-resistant PCM formulations, improved encapsulation technologies, and the establishment of comprehensive testing standards that accurately reflect real-world fire scenarios involving PCMs. Additionally, there is a pressing need for enhanced risk assessment methodologies that can effectively evaluate the fire safety implications of PCM integration in various applications.

Many organic PCMs, particularly those derived from paraffin waxes, are inherently combustible. When exposed to high temperatures or ignition sources, these materials can melt, vaporize, and potentially ignite, contributing to fire spread and intensity. This poses significant risks in building applications, where PCMs are often integrated into construction materials for thermal management.

Another critical safety challenge is the potential for PCMs to release toxic fumes when heated or burned. Some PCMs, especially those containing halogenated compounds or other synthetic additives, may emit harmful gases during thermal decomposition. This not only presents immediate health risks to occupants but also complicates fire-fighting efforts and post-fire cleanup operations.

The encapsulation of PCMs, while often used to improve handling and prevent leakage, can introduce additional safety concerns. Failure of the encapsulation material under extreme conditions may lead to the sudden release of molten PCM, potentially causing burns or accelerating fire spread. Moreover, the interaction between PCMs and their containment systems during fire scenarios is not always well understood, leading to uncertainties in predicting overall fire behavior.

The lack of standardized testing protocols specifically designed for PCM-integrated materials presents another significant challenge. Current fire safety standards and building codes may not adequately address the unique properties and behaviors of PCMs under fire conditions. This gap in regulation and testing methodologies makes it difficult for manufacturers to demonstrate compliance and for building authorities to ensure safety.

Furthermore, the long-term stability and performance of PCMs in terms of fire safety remain areas of concern. Degradation of PCMs or their containment systems over time could potentially alter their fire performance characteristics, necessitating ongoing monitoring and maintenance strategies that are not yet well-established.

Addressing these safety challenges requires a multifaceted approach. This includes the development of more fire-resistant PCM formulations, improved encapsulation technologies, and the establishment of comprehensive testing standards that accurately reflect real-world fire scenarios involving PCMs. Additionally, there is a pressing need for enhanced risk assessment methodologies that can effectively evaluate the fire safety implications of PCM integration in various applications.

Existing PCM Safety Solutions

01 Fire retardant additives for PCMs

Incorporating fire retardant additives into Phase Change Materials (PCMs) can significantly improve their fire performance and safety. These additives can include halogenated compounds, phosphorus-based materials, or inorganic fillers that reduce flammability and smoke production. The integration of these additives helps to meet fire safety standards while maintaining the thermal energy storage properties of PCMs.- Fire retardant additives for PCMs: Incorporating fire retardant additives into Phase Change Materials (PCMs) can significantly improve their fire performance and safety. These additives can include halogenated compounds, phosphorus-based materials, or inorganic fillers that reduce flammability and smoke production. The integration of these additives helps to meet fire safety standards while maintaining the thermal energy storage properties of PCMs.

- Encapsulation techniques for PCM safety: Encapsulation of PCMs in fire-resistant shells or matrices enhances their safety and fire performance. This technique involves coating or embedding PCM particles within materials that have higher melting points and better fire resistance. Encapsulation not only improves fire safety but also prevents leakage and increases the overall stability of PCM-based systems.

- PCM composite materials with enhanced fire resistance: Developing composite materials that combine PCMs with inherently fire-resistant substances can improve overall fire performance. These composites may include PCMs mixed with ceramics, high-temperature polymers, or other materials that exhibit excellent fire resistance. The resulting materials maintain thermal energy storage capabilities while significantly reducing fire hazards.

- Testing and standardization of PCM fire safety: Establishing comprehensive testing protocols and standardization methods for evaluating the fire performance of PCMs is crucial for ensuring their safe implementation. This includes developing specific fire tests tailored to PCM applications, as well as creating industry-wide safety standards. Such measures help in assessing and comparing the fire safety of different PCM formulations and applications.

- Smart PCM systems with integrated safety features: Incorporating smart technologies and sensors into PCM systems can enhance their safety performance. These advanced systems can include temperature monitoring, automatic shut-off mechanisms, or phase change indicators that alert users to potential safety issues. By integrating these features, the overall safety and reliability of PCM applications can be significantly improved.

02 Encapsulation techniques for PCM safety

Encapsulation of PCMs in fire-resistant shells or matrices enhances their safety and fire performance. This technique involves coating or embedding PCM particles within materials that have higher melting points or inherent flame-retardant properties. Encapsulation prevents PCM leakage during phase change and provides an additional barrier against fire propagation.Expand Specific Solutions03 Testing and certification of PCM fire performance

Standardized testing methods and certification processes are crucial for evaluating the fire performance of PCMs. These tests assess factors such as ignitability, flame spread, heat release rate, and smoke production. Compliance with international fire safety standards and obtaining relevant certifications are essential for the safe application of PCMs in various industries.Expand Specific Solutions04 PCM composite materials for improved safety

Developing composite materials that combine PCMs with other fire-resistant substances can enhance overall safety and fire performance. These composites may include gypsum, cement, or other inorganic materials that provide thermal stability and fire resistance. The synergistic effect of these combinations results in materials with both effective thermal energy storage and improved fire safety characteristics.Expand Specific Solutions05 Smart PCM systems with integrated safety features

Incorporating smart technologies and sensors into PCM systems can enhance their safety performance. These advanced systems can include temperature monitoring, automatic shut-off mechanisms, or integration with building management systems. Such features allow for real-time monitoring of PCM performance and rapid response to potential fire hazards, improving overall safety in PCM applications.Expand Specific Solutions

Key Players in PCM Industry

The research on PCM safety and fire performance is in a developing stage, with the market showing significant growth potential. The industry is transitioning from early-stage research to more practical applications, driven by increasing demand for fire-safe materials in construction and energy storage. The market size is expanding, fueled by stricter safety regulations and growing awareness of fire risks. Technologically, while progress has been made, there's still room for advancement. Key players like State Grid Corp. of China, China Electric Power Research Institute, and universities such as Nanjing Tech University and Huazhong University of Science & Technology are actively contributing to the field, indicating a collaborative effort between industry and academia to enhance PCM safety standards and testing methodologies.

State Grid Corp. of China

Technical Solution: State Grid Corp. of China has developed a comprehensive approach to PCM safety and fire performance research. Their method involves advanced testing protocols for phase change materials used in energy storage systems. They utilize thermal runaway simulations and real-time monitoring systems to assess PCM behavior under various thermal conditions[1]. The company has also implemented stringent selection criteria based on thermal stability, fire retardancy, and environmental impact[3]. Their research includes the development of novel fire-resistant PCM composites, incorporating flame retardants and encapsulation techniques to enhance overall safety[5]. State Grid's testing facilities are equipped with state-of-the-art calorimetry and gas analysis tools to evaluate the emission of toxic gases during PCM combustion, ensuring compliance with international safety standards[7].

Strengths: Extensive research infrastructure, access to large-scale testing facilities, and integration with power grid systems for real-world data. Weaknesses: Potential bias towards grid-scale applications, possibly overlooking smaller-scale or consumer-oriented PCM solutions.

China Electric Power Research Institute Ltd.

Technical Solution: China Electric Power Research Institute Ltd. has pioneered a multi-faceted approach to PCM safety and fire performance research. Their methodology encompasses the development of standardized testing procedures specifically tailored for PCMs used in electrical power systems[2]. The institute has created a comprehensive database of PCM thermal properties and fire behavior, which informs their selection criteria for different applications[4]. They have also developed advanced computational models to predict PCM performance under extreme conditions, including electrical faults and external fire exposure[6]. The institute's research extends to the formulation of novel PCM blends with inherent fire-retardant properties, aiming to improve safety without compromising thermal efficiency[8]. Additionally, they have established guidelines for the safe integration of PCMs in power infrastructure, addressing installation, maintenance, and emergency response protocols[10].

Strengths: Strong focus on power system applications, extensive data collection and analysis capabilities. Weaknesses: May have limited experience with non-power related PCM applications, potentially narrowing the scope of their research.

Core PCM Safety Innovations

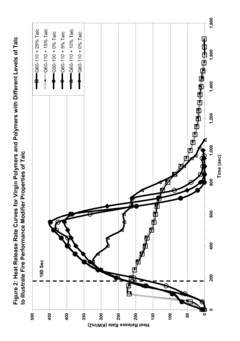

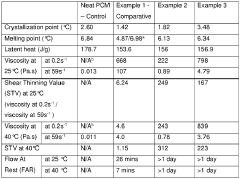

Talc as a fire performance modifier in polymer compositions

PatentInactiveUS20120094049A1

Innovation

- Talc, when added at low concentrations (≤30 wt %), functions as a fire performance modifier by decreasing the Peak Heat Release and shortening the time to reach Peak Heat Release, while also acting as a char agent to increase the overall ignition time, thus modifying the Heat Release Rate curve and enhancing fire safety without compromising the polymer's properties.

Gel composition comprising a phase change material

PatentWO2019068458A1

Innovation

- A gel composition is created using a combination of a silica gelling additive and a styrene co-polymer gelling additive, with a weight ratio of 0.6 to 5:1, to enhance the gel's flow at rest and shear thinning properties, forming a stable gel that prevents leakage.

Regulatory Framework for PCMs

The regulatory framework for Phase Change Materials (PCMs) is a complex and evolving landscape that encompasses various standards, guidelines, and regulations across different jurisdictions. At the international level, organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) have developed standards that address aspects of PCM safety and performance. These standards provide a foundation for testing methodologies, classification systems, and performance criteria.

In the United States, the regulatory oversight of PCMs falls under multiple agencies, including the Consumer Product Safety Commission (CPSC) and the Occupational Safety and Health Administration (OSHA). The National Fire Protection Association (NFPA) has also developed codes and standards that are relevant to the use of PCMs in building materials and systems. These regulations focus on fire safety, toxicity, and overall material performance.

The European Union has established a comprehensive framework for PCMs through the Construction Products Regulation (CPR) and the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. These regulations set requirements for the safety assessment, labeling, and market authorization of PCMs used in construction and other applications. Additionally, the European Committee for Standardization (CEN) has developed specific standards for PCMs in building applications.

In Asia, countries like Japan and South Korea have implemented their own regulatory frameworks for PCMs. The Japanese Industrial Standards (JIS) and the Korean Agency for Technology and Standards (KATS) have developed guidelines that address the safety and performance of PCMs in various applications, including building materials and energy storage systems.

The regulatory landscape also includes industry-specific standards and guidelines. For instance, the automotive industry has developed its own set of standards for PCMs used in vehicle thermal management systems. Similarly, the aerospace industry has specific requirements for PCMs used in aircraft components and systems.

As the adoption of PCMs continues to grow across various sectors, there is an increasing need for harmonization of regulatory frameworks at the global level. Efforts are underway to develop more comprehensive and consistent standards that address the unique properties and applications of PCMs. This includes the development of standardized testing protocols for fire performance, thermal stability, and long-term durability of PCMs.

In the United States, the regulatory oversight of PCMs falls under multiple agencies, including the Consumer Product Safety Commission (CPSC) and the Occupational Safety and Health Administration (OSHA). The National Fire Protection Association (NFPA) has also developed codes and standards that are relevant to the use of PCMs in building materials and systems. These regulations focus on fire safety, toxicity, and overall material performance.

The European Union has established a comprehensive framework for PCMs through the Construction Products Regulation (CPR) and the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. These regulations set requirements for the safety assessment, labeling, and market authorization of PCMs used in construction and other applications. Additionally, the European Committee for Standardization (CEN) has developed specific standards for PCMs in building applications.

In Asia, countries like Japan and South Korea have implemented their own regulatory frameworks for PCMs. The Japanese Industrial Standards (JIS) and the Korean Agency for Technology and Standards (KATS) have developed guidelines that address the safety and performance of PCMs in various applications, including building materials and energy storage systems.

The regulatory landscape also includes industry-specific standards and guidelines. For instance, the automotive industry has developed its own set of standards for PCMs used in vehicle thermal management systems. Similarly, the aerospace industry has specific requirements for PCMs used in aircraft components and systems.

As the adoption of PCMs continues to grow across various sectors, there is an increasing need for harmonization of regulatory frameworks at the global level. Efforts are underway to develop more comprehensive and consistent standards that address the unique properties and applications of PCMs. This includes the development of standardized testing protocols for fire performance, thermal stability, and long-term durability of PCMs.

Environmental Impact of PCMs

The environmental impact of Phase Change Materials (PCMs) is a critical consideration in their development, application, and disposal. PCMs, while offering significant benefits in thermal energy storage and management, can potentially pose environmental risks if not properly handled throughout their lifecycle.

One of the primary environmental concerns associated with PCMs is their potential for leakage or release into the environment. Many PCMs, particularly those based on paraffins or salt hydrates, can be harmful to aquatic ecosystems if they enter water bodies. This risk is especially pertinent during the manufacturing, transportation, and disposal phases of PCM-containing products.

The production of PCMs also carries environmental implications. Depending on the type of PCM, the manufacturing process may involve energy-intensive steps or the use of chemicals that could contribute to air or water pollution if not properly managed. Additionally, the sourcing of raw materials for PCM production may have associated environmental impacts, such as resource depletion or habitat disruption.

In terms of their use phase, PCMs generally contribute positively to environmental sustainability by improving energy efficiency in buildings and other applications. By reducing the need for active heating and cooling systems, PCMs can help lower overall energy consumption and associated greenhouse gas emissions. However, the long-term durability and stability of PCMs in various applications need to be considered to ensure that their environmental benefits are not outweighed by frequent replacement or maintenance requirements.

End-of-life considerations for PCMs are another crucial aspect of their environmental impact. The recyclability or biodegradability of PCMs varies widely depending on their composition. Some organic PCMs may be biodegradable, while others, particularly those containing synthetic materials or additives, may require special disposal procedures to prevent environmental contamination.

Research into more environmentally friendly PCMs is ongoing, with a focus on developing bio-based and non-toxic alternatives. These efforts aim to mitigate the potential negative environmental impacts while maintaining or improving the thermal performance of PCMs. Additionally, the development of encapsulation techniques and containment systems is crucial in preventing PCM leakage and enhancing their overall environmental safety profile.

Regulatory frameworks and standards regarding the environmental aspects of PCMs are evolving. These include guidelines for safe handling, disposal, and lifecycle assessment of PCM-containing products. Compliance with these standards is essential for minimizing the environmental footprint of PCMs and ensuring their sustainable use in various applications.

One of the primary environmental concerns associated with PCMs is their potential for leakage or release into the environment. Many PCMs, particularly those based on paraffins or salt hydrates, can be harmful to aquatic ecosystems if they enter water bodies. This risk is especially pertinent during the manufacturing, transportation, and disposal phases of PCM-containing products.

The production of PCMs also carries environmental implications. Depending on the type of PCM, the manufacturing process may involve energy-intensive steps or the use of chemicals that could contribute to air or water pollution if not properly managed. Additionally, the sourcing of raw materials for PCM production may have associated environmental impacts, such as resource depletion or habitat disruption.

In terms of their use phase, PCMs generally contribute positively to environmental sustainability by improving energy efficiency in buildings and other applications. By reducing the need for active heating and cooling systems, PCMs can help lower overall energy consumption and associated greenhouse gas emissions. However, the long-term durability and stability of PCMs in various applications need to be considered to ensure that their environmental benefits are not outweighed by frequent replacement or maintenance requirements.

End-of-life considerations for PCMs are another crucial aspect of their environmental impact. The recyclability or biodegradability of PCMs varies widely depending on their composition. Some organic PCMs may be biodegradable, while others, particularly those containing synthetic materials or additives, may require special disposal procedures to prevent environmental contamination.

Research into more environmentally friendly PCMs is ongoing, with a focus on developing bio-based and non-toxic alternatives. These efforts aim to mitigate the potential negative environmental impacts while maintaining or improving the thermal performance of PCMs. Additionally, the development of encapsulation techniques and containment systems is crucial in preventing PCM leakage and enhancing their overall environmental safety profile.

Regulatory frameworks and standards regarding the environmental aspects of PCMs are evolving. These include guidelines for safe handling, disposal, and lifecycle assessment of PCM-containing products. Compliance with these standards is essential for minimizing the environmental footprint of PCMs and ensuring their sustainable use in various applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!