How to Model PCM Charging/Discharging in CFD — Best Practices and Typical Pitfalls

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PCM Modeling Background and Objectives

Phase Change Materials (PCMs) have gained significant attention in recent years due to their unique ability to store and release large amounts of thermal energy during phase transitions. This characteristic makes them particularly valuable in various applications, including thermal management systems, energy storage, and building materials. The modeling of PCM charging and discharging processes in Computational Fluid Dynamics (CFD) has become a crucial area of research and development, aiming to optimize the design and performance of PCM-based systems.

The evolution of PCM modeling techniques has been closely tied to advancements in computational power and numerical methods. Early attempts to simulate PCM behavior were limited by computational constraints and often relied on simplified models that failed to capture the complex physics involved in phase change processes. As computing capabilities improved, more sophisticated models emerged, incorporating detailed heat transfer mechanisms, material properties, and phase change dynamics.

Current trends in PCM modeling focus on developing more accurate and efficient simulation techniques that can handle the multiphysics nature of PCM systems. This includes improved methods for tracking the moving solid-liquid interface, accounting for natural convection in the liquid phase, and incorporating the effects of material property variations during phase change. Additionally, there is a growing emphasis on multi-scale modeling approaches that can bridge the gap between microscopic phase change phenomena and macroscopic system behavior.

The primary objectives of PCM modeling in CFD are to accurately predict the thermal behavior of PCM systems, optimize their design for specific applications, and improve overall system efficiency. This involves developing robust numerical methods that can handle the non-linear nature of phase change processes, validating simulation results against experimental data, and creating user-friendly tools that can be integrated into broader engineering design workflows.

Key challenges in PCM modeling include accurately representing the sharp temperature gradients and property discontinuities at the phase change interface, accounting for hysteresis effects in certain PCMs, and efficiently handling the computational demands of large-scale simulations. Overcoming these challenges is essential for advancing the field and enabling more widespread adoption of PCM technologies across various industries.

As the field continues to evolve, researchers and engineers are exploring novel approaches to PCM modeling, including the use of machine learning techniques to enhance simulation accuracy and speed, the development of multi-functional PCMs with tailored properties, and the integration of PCM models with other energy system simulations for holistic design optimization. These advancements are expected to drive innovation in thermal energy management and storage solutions, contributing to broader efforts in energy efficiency and sustainability.

The evolution of PCM modeling techniques has been closely tied to advancements in computational power and numerical methods. Early attempts to simulate PCM behavior were limited by computational constraints and often relied on simplified models that failed to capture the complex physics involved in phase change processes. As computing capabilities improved, more sophisticated models emerged, incorporating detailed heat transfer mechanisms, material properties, and phase change dynamics.

Current trends in PCM modeling focus on developing more accurate and efficient simulation techniques that can handle the multiphysics nature of PCM systems. This includes improved methods for tracking the moving solid-liquid interface, accounting for natural convection in the liquid phase, and incorporating the effects of material property variations during phase change. Additionally, there is a growing emphasis on multi-scale modeling approaches that can bridge the gap between microscopic phase change phenomena and macroscopic system behavior.

The primary objectives of PCM modeling in CFD are to accurately predict the thermal behavior of PCM systems, optimize their design for specific applications, and improve overall system efficiency. This involves developing robust numerical methods that can handle the non-linear nature of phase change processes, validating simulation results against experimental data, and creating user-friendly tools that can be integrated into broader engineering design workflows.

Key challenges in PCM modeling include accurately representing the sharp temperature gradients and property discontinuities at the phase change interface, accounting for hysteresis effects in certain PCMs, and efficiently handling the computational demands of large-scale simulations. Overcoming these challenges is essential for advancing the field and enabling more widespread adoption of PCM technologies across various industries.

As the field continues to evolve, researchers and engineers are exploring novel approaches to PCM modeling, including the use of machine learning techniques to enhance simulation accuracy and speed, the development of multi-functional PCMs with tailored properties, and the integration of PCM models with other energy system simulations for holistic design optimization. These advancements are expected to drive innovation in thermal energy management and storage solutions, contributing to broader efforts in energy efficiency and sustainability.

Market Demand for PCM Simulation

The market demand for Phase Change Material (PCM) simulation in Computational Fluid Dynamics (CFD) has been steadily growing, driven by the increasing need for efficient thermal management solutions across various industries. PCMs offer unique advantages in thermal energy storage and temperature regulation, making them attractive for applications ranging from building materials to electronic cooling systems.

In the construction sector, there is a rising demand for PCM simulation to optimize the design of energy-efficient buildings. Architects and engineers are leveraging CFD tools to model PCM-integrated building components, such as walls and ceilings, to enhance thermal comfort and reduce energy consumption. This trend is particularly pronounced in regions with extreme climates, where PCMs can significantly contribute to passive heating and cooling strategies.

The renewable energy sector presents another significant market for PCM simulation. As solar thermal and concentrated solar power technologies advance, the need for accurate modeling of PCM-based thermal energy storage systems has intensified. CFD simulations enable engineers to optimize the design of these storage systems, improving their efficiency and cost-effectiveness.

In the automotive industry, the shift towards electric vehicles has created a new demand for PCM simulation. Battery thermal management is crucial for the performance and longevity of electric vehicles, and PCMs offer promising solutions for maintaining optimal battery temperatures. CFD modeling of PCM-based cooling systems allows automotive engineers to develop more efficient and reliable thermal management solutions for electric vehicle batteries.

The electronics industry is another key driver of PCM simulation demand. As electronic devices become more powerful and compact, thermal management challenges intensify. PCMs provide an effective means of absorbing and dissipating heat in electronic components. CFD simulations help engineers design and optimize PCM-based cooling solutions for everything from smartphones to data center servers.

The aerospace sector also contributes to the growing market for PCM simulation. In spacecraft and satellite design, precise thermal control is critical. PCMs offer lightweight and passive thermal management solutions, and CFD simulations are essential for predicting their performance in the extreme conditions of space.

As sustainability becomes a global priority, the demand for PCM simulation in green technology applications is expanding. From developing more efficient refrigeration systems to creating innovative thermal energy storage solutions for industrial processes, CFD modeling of PCMs plays a crucial role in advancing sustainable technologies.

The increasing complexity of PCM applications and the need for more accurate predictions are driving the development of advanced CFD tools and methodologies specifically tailored for PCM simulation. This trend is creating opportunities for software developers and research institutions to develop and commercialize specialized PCM simulation capabilities, further fueling market growth in this area.

In the construction sector, there is a rising demand for PCM simulation to optimize the design of energy-efficient buildings. Architects and engineers are leveraging CFD tools to model PCM-integrated building components, such as walls and ceilings, to enhance thermal comfort and reduce energy consumption. This trend is particularly pronounced in regions with extreme climates, where PCMs can significantly contribute to passive heating and cooling strategies.

The renewable energy sector presents another significant market for PCM simulation. As solar thermal and concentrated solar power technologies advance, the need for accurate modeling of PCM-based thermal energy storage systems has intensified. CFD simulations enable engineers to optimize the design of these storage systems, improving their efficiency and cost-effectiveness.

In the automotive industry, the shift towards electric vehicles has created a new demand for PCM simulation. Battery thermal management is crucial for the performance and longevity of electric vehicles, and PCMs offer promising solutions for maintaining optimal battery temperatures. CFD modeling of PCM-based cooling systems allows automotive engineers to develop more efficient and reliable thermal management solutions for electric vehicle batteries.

The electronics industry is another key driver of PCM simulation demand. As electronic devices become more powerful and compact, thermal management challenges intensify. PCMs provide an effective means of absorbing and dissipating heat in electronic components. CFD simulations help engineers design and optimize PCM-based cooling solutions for everything from smartphones to data center servers.

The aerospace sector also contributes to the growing market for PCM simulation. In spacecraft and satellite design, precise thermal control is critical. PCMs offer lightweight and passive thermal management solutions, and CFD simulations are essential for predicting their performance in the extreme conditions of space.

As sustainability becomes a global priority, the demand for PCM simulation in green technology applications is expanding. From developing more efficient refrigeration systems to creating innovative thermal energy storage solutions for industrial processes, CFD modeling of PCMs plays a crucial role in advancing sustainable technologies.

The increasing complexity of PCM applications and the need for more accurate predictions are driving the development of advanced CFD tools and methodologies specifically tailored for PCM simulation. This trend is creating opportunities for software developers and research institutions to develop and commercialize specialized PCM simulation capabilities, further fueling market growth in this area.

Current Challenges in PCM CFD Modeling

Computational Fluid Dynamics (CFD) modeling of Phase Change Materials (PCMs) presents several significant challenges that researchers and engineers must address to achieve accurate and reliable simulations. One of the primary difficulties lies in capturing the complex phase transition process, which involves latent heat absorption or release. This phenomenon occurs over a temperature range rather than at a single point, making it challenging to model accurately.

The non-linear nature of the phase change process introduces additional complexities in the numerical solution. As the material transitions between solid and liquid states, its thermophysical properties change dramatically, leading to highly non-linear equations that require sophisticated numerical methods to solve effectively. This non-linearity can result in convergence issues and increased computational time.

Another major challenge is the accurate representation of the moving solid-liquid interface, known as the Stefan problem. Tracking this interface as it evolves during the charging or discharging process is crucial for predicting heat transfer rates and overall system performance. Various numerical techniques, such as the enthalpy method or the effective heat capacity method, have been developed to address this issue, but each comes with its own set of limitations and potential inaccuracies.

The multiscale nature of PCM systems further complicates CFD modeling efforts. Heat transfer processes occur at different scales, from the molecular level to the macroscopic system level. Bridging these scales in a computationally efficient manner while maintaining accuracy remains a significant challenge. This is particularly evident in applications involving encapsulated PCMs or PCM composites, where the interaction between the PCM and the encapsulating material or matrix must be accurately modeled.

Modeling natural convection within the liquid phase of the PCM is another area of difficulty. As the PCM melts, buoyancy-driven flows can significantly impact heat transfer rates. Accurately capturing these flows, especially in complex geometries, requires careful consideration of mesh resolution and turbulence modeling approaches. The coupling between fluid flow and heat transfer adds another layer of complexity to the simulation.

Lastly, the long time scales often associated with PCM charging and discharging processes pose computational challenges. Simulating these processes over extended periods can be computationally expensive, requiring efficient time-stepping schemes and potentially the use of adaptive mesh refinement techniques to balance accuracy and computational resources.

Addressing these challenges requires a multifaceted approach, combining advanced numerical methods, careful model validation, and a deep understanding of the underlying physics. As research in this field progresses, new techniques and best practices continue to emerge, pushing the boundaries of what is possible in PCM CFD modeling.

The non-linear nature of the phase change process introduces additional complexities in the numerical solution. As the material transitions between solid and liquid states, its thermophysical properties change dramatically, leading to highly non-linear equations that require sophisticated numerical methods to solve effectively. This non-linearity can result in convergence issues and increased computational time.

Another major challenge is the accurate representation of the moving solid-liquid interface, known as the Stefan problem. Tracking this interface as it evolves during the charging or discharging process is crucial for predicting heat transfer rates and overall system performance. Various numerical techniques, such as the enthalpy method or the effective heat capacity method, have been developed to address this issue, but each comes with its own set of limitations and potential inaccuracies.

The multiscale nature of PCM systems further complicates CFD modeling efforts. Heat transfer processes occur at different scales, from the molecular level to the macroscopic system level. Bridging these scales in a computationally efficient manner while maintaining accuracy remains a significant challenge. This is particularly evident in applications involving encapsulated PCMs or PCM composites, where the interaction between the PCM and the encapsulating material or matrix must be accurately modeled.

Modeling natural convection within the liquid phase of the PCM is another area of difficulty. As the PCM melts, buoyancy-driven flows can significantly impact heat transfer rates. Accurately capturing these flows, especially in complex geometries, requires careful consideration of mesh resolution and turbulence modeling approaches. The coupling between fluid flow and heat transfer adds another layer of complexity to the simulation.

Lastly, the long time scales often associated with PCM charging and discharging processes pose computational challenges. Simulating these processes over extended periods can be computationally expensive, requiring efficient time-stepping schemes and potentially the use of adaptive mesh refinement techniques to balance accuracy and computational resources.

Addressing these challenges requires a multifaceted approach, combining advanced numerical methods, careful model validation, and a deep understanding of the underlying physics. As research in this field progresses, new techniques and best practices continue to emerge, pushing the boundaries of what is possible in PCM CFD modeling.

Best Practices for PCM CFD Modeling

01 PCM thermal energy storage systems

Phase Change Materials (PCMs) are used in thermal energy storage systems to absorb, store, and release large amounts of latent heat during phase transitions. These systems are designed to efficiently charge and discharge thermal energy, improving energy management in various applications such as building climate control, solar energy storage, and industrial processes.- PCM thermal energy storage systems: Phase Change Materials (PCMs) are used in thermal energy storage systems to absorb, store, and release large amounts of latent heat during phase transitions. These systems are designed to efficiently charge and discharge thermal energy, improving energy management in various applications such as building climate control, solar energy storage, and industrial processes.

- PCM integration in battery technologies: PCMs are incorporated into battery designs to enhance thermal management and improve overall performance. By regulating temperature during charging and discharging cycles, PCM integration helps extend battery life, increase efficiency, and enhance safety in various energy storage applications, including electric vehicles and portable electronics.

- PCM-based cooling systems for electronics: PCMs are utilized in cooling systems for electronic devices to manage heat generation during operation. These systems exploit the latent heat absorption properties of PCMs to maintain optimal operating temperatures, enhance performance, and prevent thermal damage in high-power electronics and data centers.

- PCM encapsulation and composite materials: Advanced techniques for PCM encapsulation and the development of PCM composite materials are employed to improve the charging and discharging efficiency of thermal energy storage systems. These innovations enhance heat transfer rates, prevent leakage, and increase the overall stability and longevity of PCM-based systems.

- Smart PCM systems with integrated sensors and controls: Intelligent PCM systems incorporate sensors and control mechanisms to optimize charging and discharging processes. These systems can adapt to changing environmental conditions and energy demands, improving overall efficiency and performance in applications such as smart buildings, renewable energy integration, and thermal management of industrial processes.

02 PCM integration in battery systems

PCMs are incorporated into battery systems to enhance thermal management and improve overall performance. During charging and discharging cycles, PCMs help regulate battery temperature, prevent overheating, and extend battery life. This integration is particularly beneficial for electric vehicles and renewable energy storage applications.Expand Specific Solutions03 PCM-based cooling systems for electronics

PCMs are utilized in cooling systems for electronic devices to manage heat generation during operation. These materials absorb excess heat during peak usage and release it during low-power periods, maintaining optimal operating temperatures. This approach is particularly useful in compact electronic devices and high-performance computing systems.Expand Specific Solutions04 PCM encapsulation and composite materials

Encapsulation techniques and composite materials are developed to improve the performance and stability of PCMs during charging and discharging cycles. These methods enhance heat transfer, prevent leakage, and maintain the structural integrity of the PCM. Advanced composites also allow for better integration of PCMs into various applications.Expand Specific Solutions05 Control systems for PCM charging/discharging

Sophisticated control systems are designed to optimize the charging and discharging processes of PCM-based thermal energy storage. These systems monitor temperature, manage heat flow, and coordinate with other energy systems to maximize efficiency. Advanced algorithms and sensors are employed to predict and respond to changing thermal loads and energy availability.Expand Specific Solutions

Key Players in PCM Modeling Software

The competitive landscape for modeling PCM charging/discharging in CFD is characterized by a mature market with established players and ongoing technological advancements. The market size is substantial, driven by the increasing demand for thermal management solutions in various industries. Key players like IBM, Intel, and Samsung Electronics are leveraging their extensive R&D capabilities to develop advanced CFD modeling techniques. Universities such as UC Berkeley and the University of South Carolina are contributing to the field through academic research. The technology's maturity is evident in the involvement of specialized companies like Xilinx and Renesas Electronics, which are developing tailored solutions for PCM modeling. However, there's still room for innovation, particularly in addressing challenges related to accuracy and computational efficiency in complex PCM systems.

Iontra, Inc.

Technical Solution: Iontra has developed an advanced PCM (Phase Change Material) charging/discharging model for CFD simulations. Their approach incorporates a multi-scale modeling technique that captures both microscopic and macroscopic phenomena during phase transitions. The model accounts for temperature-dependent material properties, latent heat effects, and non-linear heat transfer characteristics[1]. Iontra's CFD model integrates a custom-built enthalpy-porosity method to simulate the melting and solidification processes accurately. They have also implemented adaptive mesh refinement techniques to enhance resolution in critical areas of phase change, improving computational efficiency while maintaining accuracy[3].

Strengths: High accuracy in capturing complex phase change dynamics, efficient computational performance. Weaknesses: May require extensive experimental validation for specific PCM compositions, potentially complex implementation in standard CFD software.

TotalEnergies OneTech SAS

Technical Solution: TotalEnergies OneTech has developed a comprehensive CFD model for PCM charging/discharging, focusing on energy storage applications. Their approach combines a modified enthalpy method with a variable viscosity model to accurately simulate the phase change process[2]. The model incorporates temperature-dependent thermophysical properties and accounts for natural convection in the liquid phase. TotalEnergies' CFD solution employs a hybrid finite volume-finite element method, allowing for complex geometries and multi-dimensional heat transfer analysis. They have also integrated a novel nucleation and growth model to capture the kinetics of crystallization during the discharging process[4].

Strengths: Versatile model applicable to various PCM types and container geometries, robust handling of natural convection effects. Weaknesses: May be computationally intensive for large-scale simulations, potential challenges in modeling PCMs with significant subcooling.

Core Innovations in PCM Simulation

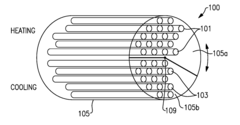

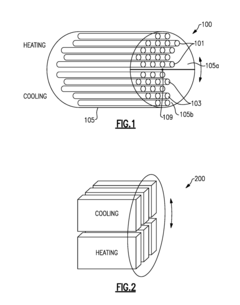

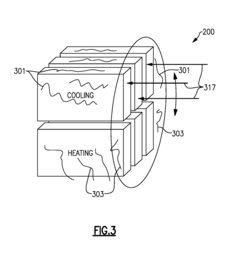

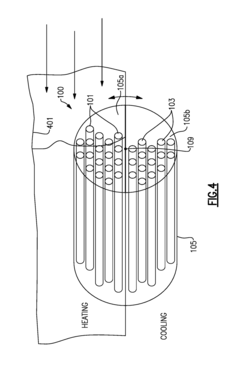

PCM module heat exchanger assembly with concurrent charging and discharging of different PCM sections

PatentInactiveUS20180283726A1

Innovation

- A multi-section PCM module heat exchanger assembly with rotating or sliding sections, incorporating both heating and cooling PCM sections with different melting temperatures, allows for concurrent charging and discharging based on outside air temperatures to optimize thermal energy harvesting and usage, enabling efficient HVAC operation.

Validation Methods for PCM Models

Validation of PCM (Phase Change Material) models in CFD (Computational Fluid Dynamics) simulations is crucial for ensuring the accuracy and reliability of charging and discharging predictions. A comprehensive validation approach typically involves multiple methods, each addressing different aspects of the model's performance.

Experimental validation forms the cornerstone of PCM model validation. This process involves comparing simulation results with data obtained from carefully controlled laboratory experiments. Key parameters for comparison include temperature distributions, phase change front progression, and overall heat transfer rates. Researchers often employ specialized setups, such as transparent enclosures with high-resolution imaging, to capture the dynamic behavior of PCMs during phase transitions.

Analytical solutions, where available, provide another valuable validation tool. While limited to simplified geometries and boundary conditions, these solutions offer exact benchmarks against which numerical models can be tested. Common analytical solutions for PCM problems include the Stefan problem and its variations, which describe one-dimensional phase change processes.

Inter-model comparison is increasingly used to validate PCM models. This method involves comparing results from different numerical approaches or software packages. For instance, results from a CFD model might be compared with those from a finite element analysis (FEA) model or a specialized phase change simulation tool. This approach helps identify potential discrepancies and biases inherent in different modeling techniques.

Sensitivity analysis plays a crucial role in validation by assessing the model's response to variations in input parameters. This includes examining the effects of mesh resolution, time step size, and material property uncertainties on simulation outcomes. A robust PCM model should demonstrate consistent behavior across a range of reasonable input variations.

Long-term performance validation is particularly important for PCM applications in thermal energy storage systems. This involves comparing simulated and experimental data over multiple charging and discharging cycles to ensure the model accurately captures degradation effects and maintains predictive accuracy over time.

Uncertainty quantification methods are increasingly being applied to PCM model validation. These techniques provide a statistical framework for assessing the confidence levels in model predictions, considering uncertainties in both experimental measurements and model inputs. This approach yields more nuanced insights into model performance than simple point-by-point comparisons.

Experimental validation forms the cornerstone of PCM model validation. This process involves comparing simulation results with data obtained from carefully controlled laboratory experiments. Key parameters for comparison include temperature distributions, phase change front progression, and overall heat transfer rates. Researchers often employ specialized setups, such as transparent enclosures with high-resolution imaging, to capture the dynamic behavior of PCMs during phase transitions.

Analytical solutions, where available, provide another valuable validation tool. While limited to simplified geometries and boundary conditions, these solutions offer exact benchmarks against which numerical models can be tested. Common analytical solutions for PCM problems include the Stefan problem and its variations, which describe one-dimensional phase change processes.

Inter-model comparison is increasingly used to validate PCM models. This method involves comparing results from different numerical approaches or software packages. For instance, results from a CFD model might be compared with those from a finite element analysis (FEA) model or a specialized phase change simulation tool. This approach helps identify potential discrepancies and biases inherent in different modeling techniques.

Sensitivity analysis plays a crucial role in validation by assessing the model's response to variations in input parameters. This includes examining the effects of mesh resolution, time step size, and material property uncertainties on simulation outcomes. A robust PCM model should demonstrate consistent behavior across a range of reasonable input variations.

Long-term performance validation is particularly important for PCM applications in thermal energy storage systems. This involves comparing simulated and experimental data over multiple charging and discharging cycles to ensure the model accurately captures degradation effects and maintains predictive accuracy over time.

Uncertainty quantification methods are increasingly being applied to PCM model validation. These techniques provide a statistical framework for assessing the confidence levels in model predictions, considering uncertainties in both experimental measurements and model inputs. This approach yields more nuanced insights into model performance than simple point-by-point comparisons.

Energy Efficiency Impact of PCM

The integration of Phase Change Materials (PCMs) into building systems and energy storage applications has shown significant potential for improving energy efficiency. PCMs can absorb, store, and release large amounts of latent heat during phase transitions, effectively reducing peak energy demands and improving thermal comfort in buildings. In the context of building envelopes, PCM-enhanced walls and roofs can reduce heating and cooling loads by up to 30%, depending on climate conditions and building characteristics.

PCMs also play a crucial role in enhancing the performance of renewable energy systems. When incorporated into solar thermal collectors, PCMs can extend the operational hours of the system by storing excess heat during peak sunlight periods and releasing it during off-peak hours. This application has demonstrated improvements in overall system efficiency by 15-25%, particularly in regions with variable solar radiation.

In HVAC systems, PCM-based thermal energy storage can shift cooling loads to off-peak hours, reducing electricity costs and improving the overall energy efficiency of the building. Studies have shown that PCM-integrated air conditioning systems can achieve energy savings of 10-20% compared to conventional systems, with the added benefit of peak load reduction.

The use of PCMs in data centers for thermal management has gained attention due to the increasing energy demands of these facilities. By implementing PCM-based cooling solutions, data centers can reduce their cooling energy consumption by up to 40%, significantly impacting their overall energy efficiency and operational costs.

In the automotive sector, PCMs are being explored for thermal management of electric vehicle batteries. By maintaining optimal operating temperatures, PCM-based systems can extend battery life, improve charging efficiency, and increase the driving range of electric vehicles by 5-10%.

However, the energy efficiency impact of PCMs is not without challenges. The effectiveness of PCM applications depends heavily on proper material selection, system design, and integration. Factors such as subcooling, hysteresis, and thermal conductivity of PCMs can affect their performance and, consequently, the overall energy efficiency gains. Additionally, the long-term stability and cycling behavior of PCMs need to be carefully considered to ensure sustained energy efficiency improvements over the lifespan of the application.

PCMs also play a crucial role in enhancing the performance of renewable energy systems. When incorporated into solar thermal collectors, PCMs can extend the operational hours of the system by storing excess heat during peak sunlight periods and releasing it during off-peak hours. This application has demonstrated improvements in overall system efficiency by 15-25%, particularly in regions with variable solar radiation.

In HVAC systems, PCM-based thermal energy storage can shift cooling loads to off-peak hours, reducing electricity costs and improving the overall energy efficiency of the building. Studies have shown that PCM-integrated air conditioning systems can achieve energy savings of 10-20% compared to conventional systems, with the added benefit of peak load reduction.

The use of PCMs in data centers for thermal management has gained attention due to the increasing energy demands of these facilities. By implementing PCM-based cooling solutions, data centers can reduce their cooling energy consumption by up to 40%, significantly impacting their overall energy efficiency and operational costs.

In the automotive sector, PCMs are being explored for thermal management of electric vehicle batteries. By maintaining optimal operating temperatures, PCM-based systems can extend battery life, improve charging efficiency, and increase the driving range of electric vehicles by 5-10%.

However, the energy efficiency impact of PCMs is not without challenges. The effectiveness of PCM applications depends heavily on proper material selection, system design, and integration. Factors such as subcooling, hysteresis, and thermal conductivity of PCMs can affect their performance and, consequently, the overall energy efficiency gains. Additionally, the long-term stability and cycling behavior of PCMs need to be carefully considered to ensure sustained energy efficiency improvements over the lifespan of the application.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!